McWire Print Speed too Slow

Posted by jeffpark_

|

McWire Print Speed too Slow May 06, 2008 10:40AM |

Registered: 16 years ago Posts: 106 |

I finally got my McWire up and running (mostly) but I am having some speed control issues.

While printing the machine slows to a crawl and instead of producing nice neat extruded lines I get large piles of goo in the shape of my object. During the exercises the speed is fine. Although, when printing the first "nozzle clearing" strip the speed is acceptable.

I have tried setting my ExtruderXYSpeed everywhere from 100 to 250, adjusting the Outline speed and Infill speed up to 1 and back down to defaults, all with no success. The steppers still slow to a crawl. Though these settings do seem to speed it up very slightly (my goo pile shrinks from ~10mm to ~7mm in width) it is not enough to make a sizable difference.

I came across a similar post where someone was using 400steps/rev motors (mine are 200steps/rev) and was thinking of a belt drive. I would prefer not to do this as I plan to convert my McWire to a CNC mill once I have my Darwin parts produced.

I have the PIC electronics with the latest firmware and host version 0.8.3 I have tried 0.8.1 with exactly the same results. Most everything seems to work normally until it actually starts printing.

One other issue, completely unrelated, is my nozzle temp tends to stay around 125 C no matter what I set it at in extruder properties. Perhaps this a calibration issue?

Thanks for any help.

Jeff

While printing the machine slows to a crawl and instead of producing nice neat extruded lines I get large piles of goo in the shape of my object. During the exercises the speed is fine. Although, when printing the first "nozzle clearing" strip the speed is acceptable.

I have tried setting my ExtruderXYSpeed everywhere from 100 to 250, adjusting the Outline speed and Infill speed up to 1 and back down to defaults, all with no success. The steppers still slow to a crawl. Though these settings do seem to speed it up very slightly (my goo pile shrinks from ~10mm to ~7mm in width) it is not enough to make a sizable difference.

I came across a similar post where someone was using 400steps/rev motors (mine are 200steps/rev) and was thinking of a belt drive. I would prefer not to do this as I plan to convert my McWire to a CNC mill once I have my Darwin parts produced.

I have the PIC electronics with the latest firmware and host version 0.8.3 I have tried 0.8.1 with exactly the same results. Most everything seems to work normally until it actually starts printing.

One other issue, completely unrelated, is my nozzle temp tends to stay around 125 C no matter what I set it at in extruder properties. Perhaps this a calibration issue?

Thanks for any help.

Jeff

|

Re: McWire Print Speed too Slow May 06, 2008 03:27PM |

Admin Registered: 17 years ago Posts: 1,487 |

what are you trying to print? my guess is that this is an object with lots of round corners?

if so, the problem is that there is no segment queue or anything, and its pausing between all the tiny little segments that make up the circle. there are some options to fix this, but i'm not sure of them off the top of my head.

if so, the problem is that there is no segment queue or anything, and its pausing between all the tiny little segments that make up the circle. there are some options to fix this, but i'm not sure of them off the top of my head.

|

Re: McWire Print Speed too Slow May 06, 2008 03:49PM |

Registered: 16 years ago Posts: 106 |

That sounds about like what is happening. I'll give some square models a try tonight.

If this is the problem, what do I do about round holes? Square ones don't fit threaded rod very well.

Thanks Zach

btw Is this something to do with the pic chips that the Arduino alleviates?

Edited 1 time(s). Last edit at 05/06/2008 04:03PM by jeffpark_.

If this is the problem, what do I do about round holes? Square ones don't fit threaded rod very well.

Thanks Zach

btw Is this something to do with the pic chips that the Arduino alleviates?

Edited 1 time(s). Last edit at 05/06/2008 04:03PM by jeffpark_.

|

Re: McWire Print Speed too Slow May 06, 2008 06:34PM |

Registered: 16 years ago Posts: 370 |

Yes, the Arduino electronics make the problem much less prominent.

This is a known bug, and it is doubtful, now that the project is officially switching to being run via Arduino, that it will be fixed on the PIC platform. My impression is that your best solution is just to bite the bullet and switch to Arduino electronics.

This is a known bug, and it is doubtful, now that the project is officially switching to being run via Arduino, that it will be fixed on the PIC platform. My impression is that your best solution is just to bite the bullet and switch to Arduino electronics.

|

Anonymous User

Re: McWire Print Speed too Slow May 08, 2008 08:22AM |

|

Re: McWire Print Speed too Slow May 08, 2008 08:54AM |

Registered: 16 years ago Posts: 370 |

|

Re: McWire Print Speed too Slow May 08, 2008 12:57PM |

Registered: 16 years ago Posts: 106 |

I have been able to mitigate the effects of the slowdown slightly by reducing AngleSpeedLength=0.01mm in the extruder preferences. This seems to increase the speed during corners. I also tried a few models with more straight lines and the results are promising. With a little more tweaking I think the prints will start to look better.

On a side note, I am upgrading my electronics to the Arduino, and will post how much of a difference it makes.

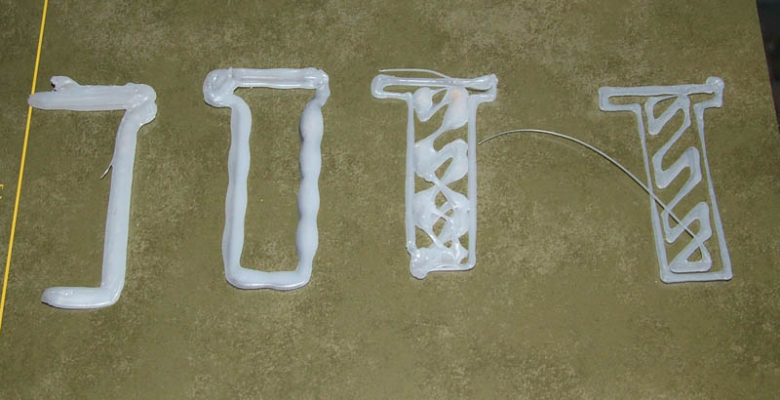

Attached is a picture of some early builds. You can see as they progressed the outlines are a little more precise, and I believe with a little tweaking I'll have some working objects...minus the round corners and holes.

edit note. spelling, grammar and fast typing do not go hand in hand.

Edited 3 time(s). Last edit at 05/08/2008 01:00PM by jeffpark_.

On a side note, I am upgrading my electronics to the Arduino, and will post how much of a difference it makes.

Attached is a picture of some early builds. You can see as they progressed the outlines are a little more precise, and I believe with a little tweaking I'll have some working objects...minus the round corners and holes.

edit note. spelling, grammar and fast typing do not go hand in hand.

Edited 3 time(s). Last edit at 05/08/2008 01:00PM by jeffpark_.

|

Re: McWire Print Speed too Slow May 08, 2008 01:10PM |

Registered: 16 years ago Posts: 106 |

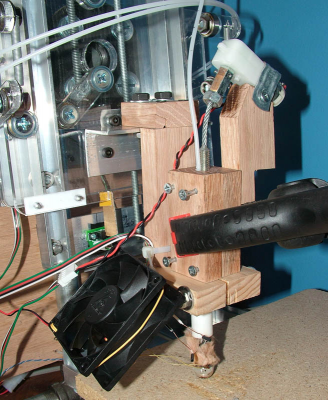

Another issue could be my extruder

It isn't the most precise creature in the world and requires a high setting (about 190 to 200) for the motor to overcome static friction.

note: the screws are what I use to control the pressure between the drive and the medium. Then channel was smoothed using a high-speed diamond bit to the point of almost burning the wood. On oak, this makes a very slick surface.

Edited 1 time(s). Last edit at 05/08/2008 01:14PM by jeffpark_.

It isn't the most precise creature in the world and requires a high setting (about 190 to 200) for the motor to overcome static friction.

note: the screws are what I use to control the pressure between the drive and the medium. Then channel was smoothed using a high-speed diamond bit to the point of almost burning the wood. On oak, this makes a very slick surface.

Edited 1 time(s). Last edit at 05/08/2008 01:14PM by jeffpark_.

|

Re: McWire Print Speed too Slow May 08, 2008 02:38PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Anonymous User

Re: McWire Print Speed too Slow May 08, 2008 03:54PM |

|

Re: McWire Print Speed too Slow May 08, 2008 05:20PM |

Admin Registered: 17 years ago Posts: 7,879 |

I noticed the other day that we have a Teflon non-stick cooking mat in the kitchen. It is only 0.07mm thick so you could use it to line an extruder easily.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: McWire Print Speed too Slow May 28, 2008 09:07AM |

Registered: 16 years ago Posts: 293 |

I'm having these same problems with PIC based electronics. This makes the segments that should be a hole (round, so many short curve instructions) completely filled with plastic. This considerable slowdown that even when mitigated will limit the build quality. Correct me if I'm wrong, but I don't think that anyone could get print quality like nophead with the current PIC electronics.

I'm having more problems with them. An Analog to Digital trick (voltage referencing the charge on a capacitor) is needed because a PIC16F6x8A doesn't have a hardware Analog 2 digital. In my setup, something seems to break every time with the measurement system. E.g. last time, the leads of the thermistor get very hot and have melted together through the wire coating. This zero resistance probably fries the part of the PIC chip that is used for the measurement. I've been thinking about adding a PTC (self resetting fuse) to prevent these problems, but I guess things will fry before the PTC gets hot enough to start limiting the current. I've been replacing chips each time I had problems, but now I've run out.

There are PIC chips in the same package that have on board A2D and I've been able to use this reliably. This would free-up a pin on the chip and simplifies the code (which currently fills all the memory). I don't think that using PIC electronics was a poor choice, and I like the way the controller boards for steppers and extruders are mostly the same (cheaper, higher quantities of PCBs) and the ability to convert them and use them for other own projects... It's also more scalable than an Arduino setup, which uses all its I/O pins. I also really like the good documentation of the PIC setup. Please don't get me wrong on how it was developed, just the underspec'd PIC was poorly chosen.

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

I'm having more problems with them. An Analog to Digital trick (voltage referencing the charge on a capacitor) is needed because a PIC16F6x8A doesn't have a hardware Analog 2 digital. In my setup, something seems to break every time with the measurement system. E.g. last time, the leads of the thermistor get very hot and have melted together through the wire coating. This zero resistance probably fries the part of the PIC chip that is used for the measurement. I've been thinking about adding a PTC (self resetting fuse) to prevent these problems, but I guess things will fry before the PTC gets hot enough to start limiting the current. I've been replacing chips each time I had problems, but now I've run out.

There are PIC chips in the same package that have on board A2D and I've been able to use this reliably. This would free-up a pin on the chip and simplifies the code (which currently fills all the memory). I don't think that using PIC electronics was a poor choice, and I like the way the controller boards for steppers and extruders are mostly the same (cheaper, higher quantities of PCBs) and the ability to convert them and use them for other own projects... It's also more scalable than an Arduino setup, which uses all its I/O pins. I also really like the good documentation of the PIC setup. Please don't get me wrong on how it was developed, just the underspec'd PIC was poorly chosen.

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

|

Re: McWire Print Speed too Slow May 28, 2008 09:27AM |

Admin Registered: 17 years ago Posts: 7,879 |

I am not sure line segment pausing is actualy down to the PIC being slow. When I asked Adrian about it, a long time ago, he indicated it was a problem with the serial comms at the PC end.

I am surprised a shorted thermistor would take out the PIC. Are you sure it didn't short to the heater?

BTW, I use PTFE sleaving to insulate the thermistor and heater wires. I have not had a short since.

[www.hydraraptor.blogspot.com]

I am surprised a shorted thermistor would take out the PIC. Are you sure it didn't short to the heater?

BTW, I use PTFE sleaving to insulate the thermistor and heater wires. I have not had a short since.

[www.hydraraptor.blogspot.com]

|

Re: McWire Print Speed too Slow May 28, 2008 10:09AM |

Registered: 16 years ago Posts: 293 |

Hi Nophead,

If that's simply it, that would save me the switch to Arduino for this RepRap. I intend to build more with friends based on Arduino.

I have had a lot of comms errors. One reason seems to be because the extruder controller stops responding (well) if the thermistor is not connected or has a too low resistance (at least I think those are the two conditions). Very often I've had problem even when measuring the resistance @ 50-100K of thermistor connector that goes to the PCB. I've replaced and re-soldering tx/rx lines, but this may have prevented more errors, they never went away. I also switched to a different laptop that had a hardware serial port so I took the USB2Serial out of the equation. This resulted in less problems, but communication errors stayed. I got all PCBs together on an acrylic pane (to prevent shorts). Could it be electromagnetic interference?

I really want to crack this problem, I WAS able to print for a while.

It could also be this: My RepRap has traveled a lot. I've showed it to family across the country. Maybe car-trips aren't good for the electronics after all? The frame has no trouble with it. The vibrations from the steppers are much worse (loosening bots all the time).

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

If that's simply it, that would save me the switch to Arduino for this RepRap. I intend to build more with friends based on Arduino.

I have had a lot of comms errors. One reason seems to be because the extruder controller stops responding (well) if the thermistor is not connected or has a too low resistance (at least I think those are the two conditions). Very often I've had problem even when measuring the resistance @ 50-100K of thermistor connector that goes to the PCB. I've replaced and re-soldering tx/rx lines, but this may have prevented more errors, they never went away. I also switched to a different laptop that had a hardware serial port so I took the USB2Serial out of the equation. This resulted in less problems, but communication errors stayed. I got all PCBs together on an acrylic pane (to prevent shorts). Could it be electromagnetic interference?

I really want to crack this problem, I WAS able to print for a while.

It could also be this: My RepRap has traveled a lot. I've showed it to family across the country. Maybe car-trips aren't good for the electronics after all? The frame has no trouble with it. The vibrations from the steppers are much worse (loosening bots all the time).

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

|

Re: McWire Print Speed too Slow May 28, 2008 10:22AM |

Admin Registered: 17 years ago Posts: 7,879 |

Hi Erik,

As you probably know I am using my own electronics, but I had terrible problems with my extruder controller until I fitted a suppressor to the motor :-

[hydraraptor.blogspot.com]

One way to check if that is your problem would be to disconnect the GM3 and see if your comms problems go away.

[www.hydraraptor.blogspot.com]

As you probably know I am using my own electronics, but I had terrible problems with my extruder controller until I fitted a suppressor to the motor :-

[hydraraptor.blogspot.com]

One way to check if that is your problem would be to disconnect the GM3 and see if your comms problems go away.

[www.hydraraptor.blogspot.com]

|

Re: McWire Print Speed too Slow May 28, 2008 11:15AM |

Admin Registered: 17 years ago Posts: 7,879 |

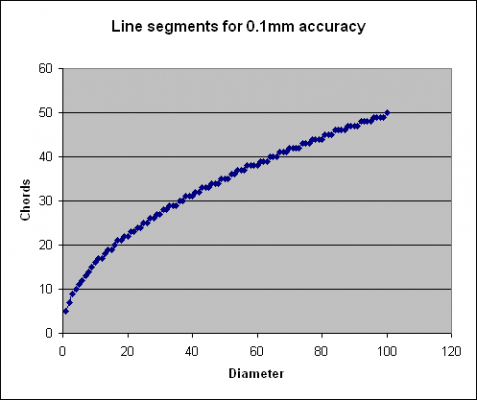

You might be able to alleviate the line segment problem by using the Solid Editor plug in to AOI. If you repeatedly do "Optimise" and "Simplify" with 0.1mm accuracy until it wont reduce the number of triangles anymore you get less line segments. It is surprising how few segments you need to remain within 0.1mm.

pi / acos((r - 0.05) / (r + 0.05)) I think which 9 for a 3mm circle and looks like this: -

[www.hydraraptor.blogspot.com]

pi / acos((r - 0.05) / (r + 0.05)) I think which 9 for a 3mm circle and looks like this: -

[www.hydraraptor.blogspot.com]

|

Re: McWire Print Speed too Slow May 28, 2008 12:19PM |

Registered: 16 years ago Posts: 293 |

Hi, I read it a while ago, forgot about it afterwards. This may be what's haunting me. I remember always fixing the problem and then putting everything back together and seeing that it didn't work for an actual print... (how annoying) of course for each actual print the GM3 motor is used. I'll see if this helps!

1nF capacitors are on order (10 times a 100pF in parallel (that I do have some of) is a bit of a waste).

The Universal Controller Board has diodes on it, but it's 5 cm away from the motor. Still, I imagine I won't need this like you used it? I also want to be able to reverse the direction of the motor, so I can't apply this diode like you did.

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

1nF capacitors are on order (10 times a 100pF in parallel (that I do have some of) is a bit of a waste).

The Universal Controller Board has diodes on it, but it's 5 cm away from the motor. Still, I imagine I won't need this like you used it? I also want to be able to reverse the direction of the motor, so I can't apply this diode like you did.

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

|

Re: McWire Print Speed too Slow May 28, 2008 12:22PM |

Admin Registered: 17 years ago Posts: 7,879 |

Don't reverse it if you are still using the flexible drive. It just unwinds the wire, destroying it.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: McWire Print Speed too Slow May 28, 2008 12:25PM |

Registered: 16 years ago Posts: 293 |

Thanks for the warning. I got rid of the flex drive for now. Not that it's much improved in general but the flex drive broke loose from the screw more and more often.

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

Sorry, only registered users may post in this forum.