Skeinforge Milling

Posted by Rick

|

Skeinforge Milling December 15, 2008 11:43AM |

Registered: 15 years ago Posts: 36 |

Once I finish getting the bugs out of my McWire (fingers crossed...nearly there)I'm considering strapping my trusty Dremel to the Z Axis and milling the fabricated Extruder parts.

Has anyone tried this, how successful was it and do you have any tips on proceeding setup-wise (trying to avoid reinventing the wheel)? Thanks in advance.

- Rick

A chicken has a head the size of a walnut. Yet, even it has the sense to come in out of the rain.

Has anyone tried this, how successful was it and do you have any tips on proceeding setup-wise (trying to avoid reinventing the wheel)? Thanks in advance.

- Rick

A chicken has a head the size of a walnut. Yet, even it has the sense to come in out of the rain.

|

Re: Skeinforge Milling December 15, 2008 12:23PM |

Admin Registered: 17 years ago Posts: 1,915 |

Rick Wrote:

-------------------------------------------------------

>

> Has anyone tried this,

>

Yeah.

>

> how successful was it

>

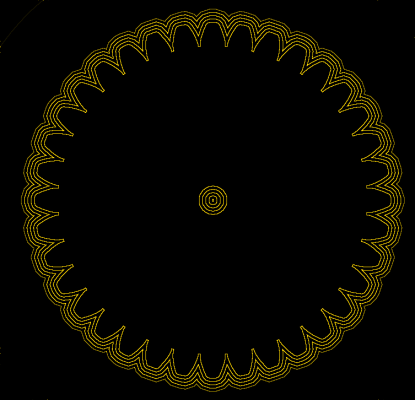

I milled enough things, including a 10 mm six-toothed involute profile gear in HDPE, to convince myself that it was a workable situation and then went on to other tasks.

>

> do you have any tips on proceeding setup-wise

> (trying to avoid reinventing the wheel)?

>

I didn't use Skeinforge because I didn't want to get involved with yet another language (Python). Modified my own software written in Visual Basic to do the job.

That's not to say that Skeinforge couldn't be made to do that task. I don't know of anyone who has tried yet, though.

Edited 1 time(s). Last edit at 12/15/2008 12:24PM by Forrest Higgs.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

>

> Has anyone tried this,

>

Yeah.

>

> how successful was it

>

I milled enough things, including a 10 mm six-toothed involute profile gear in HDPE, to convince myself that it was a workable situation and then went on to other tasks.

>

> do you have any tips on proceeding setup-wise

> (trying to avoid reinventing the wheel)?

>

I didn't use Skeinforge because I didn't want to get involved with yet another language (Python). Modified my own software written in Visual Basic to do the job.

That's not to say that Skeinforge couldn't be made to do that task. I don't know of anyone who has tried yet, though.

Edited 1 time(s). Last edit at 12/15/2008 12:24PM by Forrest Higgs.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Skeinforge Milling December 15, 2008 12:53PM |

Registered: 17 years ago Posts: 550 |

|

Re: Skeinforge Milling December 15, 2008 01:43PM |

Registered: 15 years ago Posts: 36 |

Looks like it would be relatively simple...Reversing the GCode so the commands would build (or rather subtract) from top to bottom...the real trick is the offset for the subtractive bit (oversized for the outer lines, undersized for interior holes, etc). Haven't dug too deeply into Skeinforge yet to see if it was possible...and Skeinforge may not be the best tool for this, just curious if anyone else had tried it yet and what would be the best way to proceed. Wade looks to be up to his elbows with requests for Darwin parts and I was hoping to not have to whittle the extruder by hand...

- Rick

A chicken has a head the size of a walnut. Yet, even it has the sense to come in out of the rain.

- Rick

A chicken has a head the size of a walnut. Yet, even it has the sense to come in out of the rain.

|

Re: Skeinforge Milling December 15, 2008 05:07PM |

Admin Registered: 17 years ago Posts: 1,915 |

sid Wrote:

-------------------------------------------------------

> Forrest, do not forget to tell, that your

> tommelise is certainly not a mcwire setup

>

LOL! It's a lot closer to a McWire setup than Darwin is.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

> Forrest, do not forget to tell, that your

> tommelise is certainly not a mcwire setup

>

LOL! It's a lot closer to a McWire setup than Darwin is.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Skeinforge Milling December 15, 2008 07:36PM |

Registered: 17 years ago Posts: 550 |

|

Re: Skeinforge Milling December 15, 2008 09:33PM |

Admin Registered: 17 years ago Posts: 1,915 |

sid Wrote:

-------------------------------------------------------

> Forrest, I wasn't talking about type of z-axis,

> but of rigidity

>

Whatever...

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

> Forrest, I wasn't talking about type of z-axis,

> but of rigidity

>

Whatever...

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Skeinforge Milling December 16, 2008 12:20AM |

Registered: 15 years ago Posts: 300 |

Rick Wrote:

-------------------------------------------------------

> Once I finish getting the bugs out of my McWire

> (fingers crossed...nearly there)I'm considering

> strapping my trusty Dremel to the Z Axis and

> milling the fabricated Extruder parts.

>

> Has anyone tried this, how successful was it and

> do you have any tips on proceeding setup-wise

> (trying to avoid reinventing the wheel)? Thanks in

> advance.

I will be in the same boat shortly, so I would love to know how you do it.

-------------------------------------------------------

> Once I finish getting the bugs out of my McWire

> (fingers crossed...nearly there)I'm considering

> strapping my trusty Dremel to the Z Axis and

> milling the fabricated Extruder parts.

>

> Has anyone tried this, how successful was it and

> do you have any tips on proceeding setup-wise

> (trying to avoid reinventing the wheel)? Thanks in

> advance.

I will be in the same boat shortly, so I would love to know how you do it.

|

Re: Skeinforge Milling December 16, 2008 01:33AM |

Registered: 16 years ago Posts: 213 |

Skeinforge only handles additive fabrication. It won't handle milling for many moons because the todo list seems to grow as fast as I develop Indeed it should be possible to subtract the shape from a box, reverse the z slices and play with offsets, but skeinforge doesn't do this now and probably won't be the best tool for a milling job for a long time if ever.

Indeed it should be possible to subtract the shape from a box, reverse the z slices and play with offsets, but skeinforge doesn't do this now and probably won't be the best tool for a milling job for a long time if ever.

I haven't tried it, but Ralith mentioned the GNU Computer Aided Manufacturing (GCAM) package, whose home page is at:

[gcam.js.cx]

Some posts from Forrest's site about adapting additive software for milling are at:

[3dreplicators.com]

[www.3dreplicators.com]

September was mostly about milling:

[www.3dreplicators.com]

and there was a milling post in October:

[www.3dreplicators.com]

Enrique

Indeed it should be possible to subtract the shape from a box, reverse the z slices and play with offsets, but skeinforge doesn't do this now and probably won't be the best tool for a milling job for a long time if ever.

Indeed it should be possible to subtract the shape from a box, reverse the z slices and play with offsets, but skeinforge doesn't do this now and probably won't be the best tool for a milling job for a long time if ever.I haven't tried it, but Ralith mentioned the GNU Computer Aided Manufacturing (GCAM) package, whose home page is at:

[gcam.js.cx]

Some posts from Forrest's site about adapting additive software for milling are at:

[3dreplicators.com]

[www.3dreplicators.com]

September was mostly about milling:

[www.3dreplicators.com]

and there was a milling post in October:

[www.3dreplicators.com]

Enrique

|

Re: Skeinforge Milling December 16, 2008 08:09AM |

Admin Registered: 17 years ago Posts: 1,915 |

Enrique Wrote:

-------------------------------------------------------

>

> I haven't tried it, but Ralith mentioned the GNU

> Computer Aided Manufacturing (GCAM) package, whose

> home page is at:

> [gcam.js.cx]

>

You need to check that link.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

>

> I haven't tried it, but Ralith mentioned the GNU

> Computer Aided Manufacturing (GCAM) package, whose

> home page is at:

> [gcam.js.cx]

>

You need to check that link.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Skeinforge Milling December 17, 2008 05:03PM |

Registered: 16 years ago Posts: 213 |

Hi Forrest,

The GNU Computer Aided Manufacturing link:

[gcam.js.cx]

works for me. If it doesn't work for anyone else, try googling:

GNU Computer Aided Manufacturing open source package

or try the cached link at:

[209.85.173.132]

The GNU Computer Aided Manufacturing link:

[gcam.js.cx]

works for me. If it doesn't work for anyone else, try googling:

GNU Computer Aided Manufacturing open source package

or try the cached link at:

[209.85.173.132]

|

Re: Skeinforge Milling December 17, 2008 05:25PM |

Admin Registered: 17 years ago Posts: 1,915 |

[www.3dreplicators.com]

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

Sorry, only registered users may post in this forum.