Cheap Rotory Encoder

Posted by Ant

|

Cheap Rotory Encoder October 20, 2008 08:37AM |

Registered: 15 years ago Posts: 73 |

This is kind of obsolete, but just for the sake of argument, or if anyone wants to experiment with it... There may still be some use for it.

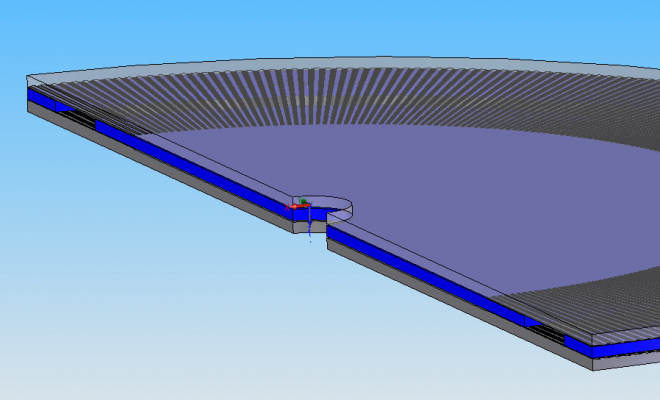

Here's a picture which shows the basic idea of a rotary encoder made out of film. Film can make pretty high resolution. There are two discs with lines on them, one of them turns, the other is stationary. The blue areas are spacers to prevent the two pieces of film from rubbing against each other in the working area.

As it turn, when the lines on the stationary disc are lined with with the lines on the rotary disc they let light pass. When the lines on the stationary disc are opposite the lines on the rotary disc, they block light.

There needs to be two discs with lines, because otherwise you'd need lenses or something to get the fine detail.

Tony

Creating the society of the future

[conceivia.com]

Here's a picture which shows the basic idea of a rotary encoder made out of film. Film can make pretty high resolution. There are two discs with lines on them, one of them turns, the other is stationary. The blue areas are spacers to prevent the two pieces of film from rubbing against each other in the working area.

As it turn, when the lines on the stationary disc are lined with with the lines on the rotary disc they let light pass. When the lines on the stationary disc are opposite the lines on the rotary disc, they block light.

There needs to be two discs with lines, because otherwise you'd need lenses or something to get the fine detail.

Tony

Creating the society of the future

[conceivia.com]

|

Re: Cheap Rotory Encoder October 20, 2008 09:41AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Tony,

similar disks are used in high-precision rotary encoders - i have some made from glass with the lines printed or etched in a silver-coating and some etched metallic-discs with some houndred to some thousand lines per rev.

You need a very precise mask or your angular precision wouldn't be very exact ...

I think it's 'normal evolution' from milled or fabbed tooth-disks with only 40 teeth to higher density; and from simple light-barriers to quadrature-encoders ...

Viktor

similar disks are used in high-precision rotary encoders - i have some made from glass with the lines printed or etched in a silver-coating and some etched metallic-discs with some houndred to some thousand lines per rev.

You need a very precise mask or your angular precision wouldn't be very exact ...

I think it's 'normal evolution' from milled or fabbed tooth-disks with only 40 teeth to higher density; and from simple light-barriers to quadrature-encoders ...

Viktor

|

Re: Cheap Rotory Encoder October 20, 2008 12:46PM |

Registered: 15 years ago Posts: 73 |

Quadrature would just have two sets of lines for the stationary disc, which would be offset from each other to give the phase info. One set of lines for each opto-interuptor.

As for angular precision, you can fix that with calibrate that in the computer. You'd need 3 opto-interuptors for that, one for zero. Calibration would be easy for rotary, just spin it at a constant speed.

It would be extremely easy to get very accurate mask if you could print onto film from a computer. Even taking a picture of a computer monitor would likely be quite accurate. Also you could print out a transparency and then take it to a developer and have them transfer it to film. Lots of ways to get accurate printing on photo film.

Etching on glass sounds pretty difficult for do it yourselfers. How do you do it? Do you have special equipment to deposit the silver coating on and stuff?

Tony

As for angular precision, you can fix that with calibrate that in the computer. You'd need 3 opto-interuptors for that, one for zero. Calibration would be easy for rotary, just spin it at a constant speed.

It would be extremely easy to get very accurate mask if you could print onto film from a computer. Even taking a picture of a computer monitor would likely be quite accurate. Also you could print out a transparency and then take it to a developer and have them transfer it to film. Lots of ways to get accurate printing on photo film.

Etching on glass sounds pretty difficult for do it yourselfers. How do you do it? Do you have special equipment to deposit the silver coating on and stuff?

Tony

|

Re: Cheap Rotory Encoder October 20, 2008 03:03PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Tony,

some years ago i had to develop a tool-center for aligning the sensor, a window with 4 areas with displaced lines and the rotary disk of 1024- to 4096-step-encoders with an accuracy of 2 microns - from this time i have some prototypes and salvage of the disks and encoders

The glass-disks and windows were made by sputtering the disks with different metals (not only silver) and then etching the lines, some text and brands.

The full-metall-disks were from Nickel or Nickel-coated steel and etched too ...

Viktor

some years ago i had to develop a tool-center for aligning the sensor, a window with 4 areas with displaced lines and the rotary disk of 1024- to 4096-step-encoders with an accuracy of 2 microns - from this time i have some prototypes and salvage of the disks and encoders

The glass-disks and windows were made by sputtering the disks with different metals (not only silver) and then etching the lines, some text and brands.

The full-metall-disks were from Nickel or Nickel-coated steel and etched too ...

Viktor

|

Re: Cheap Rotory Encoder October 21, 2008 09:30AM |

Registered: 15 years ago Posts: 78 |

|

Re: Cheap Rotory Encoder October 21, 2008 02:44PM |

Registered: 15 years ago Posts: 73 |

Actually, offsetting the sensor wouldn't work when you use two sensors. It only works for one sensor. Anyway, it'd be much easier and more accurate to make a second grating on the stationary side. No need to line up the sensor that way.

Interestingly, I opened up my printer (Cannon i250) and noticed that there is a strip of clear film about 1/8 inch wide, on which a stripped pattern is printed. A very fine stripped pattern, difficult for me to see, it looks gray to me, but when I look close I can see it is striped. I'd say .005 inch stripes with .005 inches between them.

Anyway, that stripped film is just clear plastic of some sort. I suspect it may have been printed on a laser printer with transparency "paper".

Another interesting thing I noticed, is when I put my cell phone flashlight up to it, right next to it, it projects larger stripes.

This suggests to me that we could get really nice resolution if we could get some sort of printed film like that. I want a linear encoder to eliminate mechanical slope and stuff, so that gives me a problem of getting long strips of this stuff. Small strips would be extremely easy, on a laser printer or whatever. Long strips are more difficult.

My plan is to use a mouse chip for a encoder. Basically an 18 x 18 pixel video camera (very fast). Without the projection idea it'd make resolution around .0025 inches. Twist it slightly, and we can get resolution around 0.00016 inches. For reference, paper is 0.005 inches thick. Accuracy not that good, but better than the accuracy of the printing, 'cause it'd average the results. Anyway, accuracy can be fixed by calibration with software.

With projection, we should be easily able to get resolution better than 0.0001 inches.

One way I think could be done is to use photo film. I'm not sure, but I suspect that it is continuous, not frame by frame. Even so, we'd need a device to print the lines on the film. It'd be a simple device to make of course.

I believe resolution should be at least 4 times higher than accuracy. Also I believe resolution should be at least 4 times higher than pixel size. If you are going to make dots of plastic 0.01 inches in diameter you should have resolution of .0025 inches or better. If you are going to make dots 0.001 inches in diameter you should have resolution of 0.00025 inches or better. For commercial quality I'd want resolution of at least 0.0005 inches or better.

Actual accuracy is not as important. If our accuracy is only 0.010 we'll hardly ever have a problem with it. Resolution is what makes the parts look nice, as long as the repeatability is also high. If we miss the mark by 0.010 inches, the parts will look pretty bad. Anyway, repeatability and accuracy can be fixed to a pretty good extent in the software.

Tony

Interestingly, I opened up my printer (Cannon i250) and noticed that there is a strip of clear film about 1/8 inch wide, on which a stripped pattern is printed. A very fine stripped pattern, difficult for me to see, it looks gray to me, but when I look close I can see it is striped. I'd say .005 inch stripes with .005 inches between them.

Anyway, that stripped film is just clear plastic of some sort. I suspect it may have been printed on a laser printer with transparency "paper".

Another interesting thing I noticed, is when I put my cell phone flashlight up to it, right next to it, it projects larger stripes.

This suggests to me that we could get really nice resolution if we could get some sort of printed film like that. I want a linear encoder to eliminate mechanical slope and stuff, so that gives me a problem of getting long strips of this stuff. Small strips would be extremely easy, on a laser printer or whatever. Long strips are more difficult.

My plan is to use a mouse chip for a encoder. Basically an 18 x 18 pixel video camera (very fast). Without the projection idea it'd make resolution around .0025 inches. Twist it slightly, and we can get resolution around 0.00016 inches. For reference, paper is 0.005 inches thick. Accuracy not that good, but better than the accuracy of the printing, 'cause it'd average the results. Anyway, accuracy can be fixed by calibration with software.

With projection, we should be easily able to get resolution better than 0.0001 inches.

One way I think could be done is to use photo film. I'm not sure, but I suspect that it is continuous, not frame by frame. Even so, we'd need a device to print the lines on the film. It'd be a simple device to make of course.

I believe resolution should be at least 4 times higher than accuracy. Also I believe resolution should be at least 4 times higher than pixel size. If you are going to make dots of plastic 0.01 inches in diameter you should have resolution of .0025 inches or better. If you are going to make dots 0.001 inches in diameter you should have resolution of 0.00025 inches or better. For commercial quality I'd want resolution of at least 0.0005 inches or better.

Actual accuracy is not as important. If our accuracy is only 0.010 we'll hardly ever have a problem with it. Resolution is what makes the parts look nice, as long as the repeatability is also high. If we miss the mark by 0.010 inches, the parts will look pretty bad. Anyway, repeatability and accuracy can be fixed to a pretty good extent in the software.

Tony

|

Re: Cheap Rotory Encoder October 22, 2008 05:04PM |

Registered: 15 years ago Posts: 78 |

Im not clear - how do you offset one sesnor ? what is it offset from?

Quadrature requires two sensing channels anyway, at 90 degrees phase shift - how you get the 90 degrees is either from two rings of markings with one shifted and both sensors at 0 degree shift OR one ring with one of the sensors shifted.

If you require a zero position then a third sesnor/marking may be required.

or you could get loads of sensors and rings and set up an absolute position grey code.

Quadrature requires two sensing channels anyway, at 90 degrees phase shift - how you get the 90 degrees is either from two rings of markings with one shifted and both sensors at 0 degree shift OR one ring with one of the sensors shifted.

If you require a zero position then a third sesnor/marking may be required.

or you could get loads of sensors and rings and set up an absolute position grey code.

|

Re: Cheap Rotory Encoder October 23, 2008 02:39AM |

Registered: 15 years ago Posts: 73 |

You don't need two rings to have a 90 degree phase shift. On the stationary ring you simply put two portions of a ring of strips, you don't need a whole ring, just enough to be in front of each sensor. You put the 90 degree phase shift in one of those two portions on the stationary ring.

When the lines on the stationary sensor are lined up with the lines on the moving ring, light passes. When they are out of alignment,light that gets past the moving ring hits the black lines on the stationary ring and is blocked, so all light is blocked.

Those lines on the stationary sensor are simply in one place on one sensor, and on the other sensor are at a 90 degree phase shift from the other. So when light is passing through to one sensor, only half as much light is passing through to the other sensor.

Tony

When the lines on the stationary sensor are lined up with the lines on the moving ring, light passes. When they are out of alignment,light that gets past the moving ring hits the black lines on the stationary ring and is blocked, so all light is blocked.

Those lines on the stationary sensor are simply in one place on one sensor, and on the other sensor are at a 90 degree phase shift from the other. So when light is passing through to one sensor, only half as much light is passing through to the other sensor.

Tony

|

Re: Cheap Rotory Encoder October 23, 2008 09:33AM |

Registered: 16 years ago Posts: 438 |

And a grey code absolute positioning sensor only needs one ring - but does need one sensor per bit of accuracy.

As someone else pointed out in a post I'm not going to try to find, it's possible to design a ring such that each position is a unique set of sensor values and only one sensor changes between any two adjacent positions. So you only need one ring, but 8 or 10 pins. Bad idea unless you're going to do SPI or something.

--

I'm building it with Baling Wire

As someone else pointed out in a post I'm not going to try to find, it's possible to design a ring such that each position is a unique set of sensor values and only one sensor changes between any two adjacent positions. So you only need one ring, but 8 or 10 pins. Bad idea unless you're going to do SPI or something.

--

I'm building it with Baling Wire

|

Re: Cheap Rotory Encoder October 24, 2008 05:55PM |

Registered: 15 years ago Posts: 78 |

Ok, I re-read this and now realise the layout. My coments were based on 'conventinal' stuff.

This system certainly appeals - no need for a precision optical path between light source and sensor. The larger area available for light transmision would allow cheaper sensors and/or less signal conditioning too i suppose.

This system certainly appeals - no need for a precision optical path between light source and sensor. The larger area available for light transmision would allow cheaper sensors and/or less signal conditioning too i suppose.

Sorry, only registered users may post in this forum.