Build thread, 100 pin STM Arm Cortex board with driver chips.

Posted by grael

|

Build thread, 100 pin STM Arm Cortex board with driver chips. January 31, 2009 01:01AM |

Registered: 15 years ago Posts: 242 |

I've been over in the "beyond the Sanguino" thread, but what I'm working on is gelling, and so, to avoid distractions to those of you still looking at other directions to develop in, I'm putting my progress under this thread heading.

Basically, I have researched the current public reprap motherboards, and decided I want for my first machine, something with more memory, more highly integrated motor control, and more capacity for add on features.

STM do an ARM Cortex-M3 microcontroller in various packages, and I happened to get 20 from my distributor, for what I suspect was quite a good, introductory price.

It's 32/16 bit, and has plenty of grunt. If you run "difficult" code in RAM, it's about twice as fast as in Flash, but even so, it's going to storm past the 8 bit Atmels, it has memory management, and a much faster clock rate, as well as the extra bits for maths ops. From memory, it has a barrel shifter too, so you can do bit shifts of arbitary length.

Where I'm up to, at the start of this thread, is making best use of the available 100 pins.

These are the features I'm incorporating, some of which don't actually have to be populated, if someone has minimal requirements and wants to scrimp on cost:

----------------Essentials:--------------------------

>JTAG programming interface. (I'm not using the trace connections, those are for WIMPS) > <

<

>USB

>X,Y,Z limits (the ends of an axis are not differentiated)

4'th axis input, it's an analogue input, so it could be connected to a potentiometer.

>Extrusion Heater, PWM. I know it's a luxury to use PWM for such a slow changing device, but it could also be used, for alternate power control where the resolution is more of benefit (i.e. milling motor speed contro etc)

>Extruder head temperature monitoring

>3 x Servo drive, PWM, to reduce the main controller workload.

>8 x stepper motor coil drive enables. (all dedicated PWM)

>16 x Stepper motor wire polarity controls (we get rid of the L297 s this way)

>8 x Coil current monitoring Analogue inputs. (hopefully, this allows us to shut down misbehaving motors before a serious problem develops)

>status piezo, wired to a PWM, so it can play tunes, basically, give a range of audible messages.

>2 x status LEDs. These are also really useful when you want to debug something, pop the LED control into your problem subroutine, and check for action- or not.

----------------Luxuries, need not be populated:--------------------------

+ Extruder cold zone temperature.

+ 3 x LCD control pins + 8 x LCD data pins. Yes, I know about 4 wire data bus mode, and I've written drivers for it before, but some graphics LCDs need 8 data lines, and considering that CNC machines work in at least 2 dimensions, I figure we may want a larger dot matrix display, to preview part "recipes"

+ One analogue pin reserved for push button controls, i.e. , each button pused gives a different feedback voltage. Wait for a stable reading, and take the action.

+ I2C, 2 pins. This is purely for I2C off chip expansion, I'm not intending on board I2C memory. (shudders) We have a PC for that, or an SD card for stand alone mode, or to allow the PC to be switched off while the machine is not being attended, but is left running.

+ 6 x general purpose darlington transistor pull-down outputs (6/7 of ULN2003 package)

+ SD card socket and connections via SPI on 4 dedicated pins.

I'm working on fitting all these in the freeware version of Eagle, so space is limited. The main processor is a fine pitch SMD chip, and it's beyond the capability of non experts to solder by hand. You need considerable experience in hand soldering fine pitch packages to be able to reliably solder one of these by hand, but if there is a lot of interest in this type of board, the practical way to do it, is to order the board with all the difficult chips pre-soldered.

I welcome ideas, and hope to keep this open, but I don't know how feasible it will be to parcel out parts of the project to any other interested people. I can do the whole project by myself, but for a simple implementation, and working only in my spare time, I expect to be busy for at least 3 months before I have interesting results. I may get a bit bogged down in the software initially, because I haven't programmed in C, or on the ARM in assembler before.

These are the steps:

*Selection of chipset.

Microcontroller is the most influential here, I've chosen the one above. For the driver chips, I'm using L298 for 4 x channels of dual full bridge driving. I may put extra pins on the connectors though, so that each plug carries axis limit and motor drive connections. Standardisation is the thing here, use the common large size, and stick with it. The footprint is good, the sustained current is a couple of amps. I'm using the vertical SIL full wave bridge rectifier package for capturing transients, and only in the 1.5 amp size. It's running a low duty cycle.

I will see if it's fast enough... If I "Scope" problems, then I may have to put a transorb across each coil in addition, to clip any nasties that the FWB aren't fast enough to contain.

*Pin assignments.

Done, unless I need to amend anything.

*Draw the schematic. (partially done.)

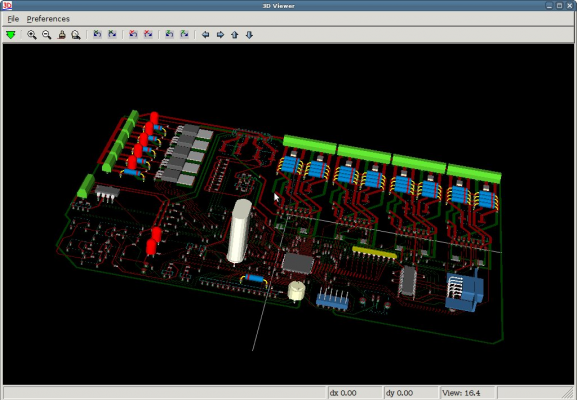

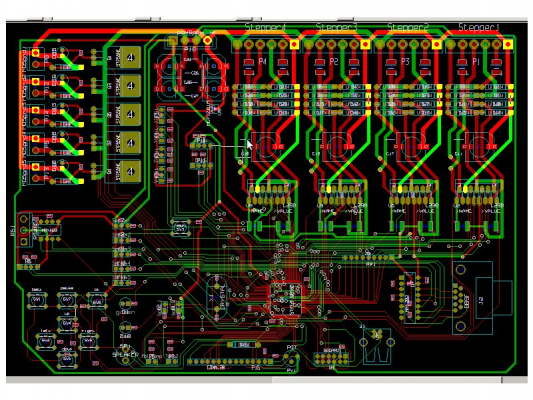

*Draw the PCB (auto routing in Eagle with SMD packages seems more "problematic" than I've experienced in Protel)

*Check all connections against chip manuals and intended connection paths.

*Order a batch of prototype board to these plans

*Inspect prototype boards for trace, via integrity, check no traces are joined where they shouldn't be

*Assemble and check.

*blink the LEDs.

*write an LCD driver

*get really stuck in, to writing the main software, testing stepper motors, Gcode interpreter, stepper motor control layers, etc, etc.

Graham Daniel.

Basically, I have researched the current public reprap motherboards, and decided I want for my first machine, something with more memory, more highly integrated motor control, and more capacity for add on features.

STM do an ARM Cortex-M3 microcontroller in various packages, and I happened to get 20 from my distributor, for what I suspect was quite a good, introductory price.

It's 32/16 bit, and has plenty of grunt. If you run "difficult" code in RAM, it's about twice as fast as in Flash, but even so, it's going to storm past the 8 bit Atmels, it has memory management, and a much faster clock rate, as well as the extra bits for maths ops. From memory, it has a barrel shifter too, so you can do bit shifts of arbitary length.

Where I'm up to, at the start of this thread, is making best use of the available 100 pins.

These are the features I'm incorporating, some of which don't actually have to be populated, if someone has minimal requirements and wants to scrimp on cost:

----------------Essentials:--------------------------

>JTAG programming interface. (I'm not using the trace connections, those are for WIMPS) >

<

<>USB

>X,Y,Z limits (the ends of an axis are not differentiated)

4'th axis input, it's an analogue input, so it could be connected to a potentiometer.

>Extrusion Heater, PWM. I know it's a luxury to use PWM for such a slow changing device, but it could also be used, for alternate power control where the resolution is more of benefit (i.e. milling motor speed contro etc)

>Extruder head temperature monitoring

>3 x Servo drive, PWM, to reduce the main controller workload.

>8 x stepper motor coil drive enables. (all dedicated PWM)

>16 x Stepper motor wire polarity controls (we get rid of the L297 s this way)

>8 x Coil current monitoring Analogue inputs. (hopefully, this allows us to shut down misbehaving motors before a serious problem develops)

>status piezo, wired to a PWM, so it can play tunes, basically, give a range of audible messages.

>2 x status LEDs. These are also really useful when you want to debug something, pop the LED control into your problem subroutine, and check for action- or not.

----------------Luxuries, need not be populated:--------------------------

+ Extruder cold zone temperature.

+ 3 x LCD control pins + 8 x LCD data pins. Yes, I know about 4 wire data bus mode, and I've written drivers for it before, but some graphics LCDs need 8 data lines, and considering that CNC machines work in at least 2 dimensions, I figure we may want a larger dot matrix display, to preview part "recipes"

+ One analogue pin reserved for push button controls, i.e. , each button pused gives a different feedback voltage. Wait for a stable reading, and take the action.

+ I2C, 2 pins. This is purely for I2C off chip expansion, I'm not intending on board I2C memory. (shudders) We have a PC for that, or an SD card for stand alone mode, or to allow the PC to be switched off while the machine is not being attended, but is left running.

+ 6 x general purpose darlington transistor pull-down outputs (6/7 of ULN2003 package)

+ SD card socket and connections via SPI on 4 dedicated pins.

I'm working on fitting all these in the freeware version of Eagle, so space is limited. The main processor is a fine pitch SMD chip, and it's beyond the capability of non experts to solder by hand. You need considerable experience in hand soldering fine pitch packages to be able to reliably solder one of these by hand, but if there is a lot of interest in this type of board, the practical way to do it, is to order the board with all the difficult chips pre-soldered.

I welcome ideas, and hope to keep this open, but I don't know how feasible it will be to parcel out parts of the project to any other interested people. I can do the whole project by myself, but for a simple implementation, and working only in my spare time, I expect to be busy for at least 3 months before I have interesting results. I may get a bit bogged down in the software initially, because I haven't programmed in C, or on the ARM in assembler before.

These are the steps:

*Selection of chipset.

Microcontroller is the most influential here, I've chosen the one above. For the driver chips, I'm using L298 for 4 x channels of dual full bridge driving. I may put extra pins on the connectors though, so that each plug carries axis limit and motor drive connections. Standardisation is the thing here, use the common large size, and stick with it. The footprint is good, the sustained current is a couple of amps. I'm using the vertical SIL full wave bridge rectifier package for capturing transients, and only in the 1.5 amp size. It's running a low duty cycle.

I will see if it's fast enough... If I "Scope" problems, then I may have to put a transorb across each coil in addition, to clip any nasties that the FWB aren't fast enough to contain.

*Pin assignments.

Done, unless I need to amend anything.

*Draw the schematic. (partially done.)

*Draw the PCB (auto routing in Eagle with SMD packages seems more "problematic" than I've experienced in Protel)

*Check all connections against chip manuals and intended connection paths.

*Order a batch of prototype board to these plans

*Inspect prototype boards for trace, via integrity, check no traces are joined where they shouldn't be

*Assemble and check.

*blink the LEDs.

*write an LCD driver

*get really stuck in, to writing the main software, testing stepper motors, Gcode interpreter, stepper motor control layers, etc, etc.

Graham Daniel.

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. January 31, 2009 07:36PM |

Registered: 15 years ago Posts: 45 |

Hi there grael.

I've thought for a while that instead of grudgingly moving up a single processor size whenever we hit a limit is not the best idea - the non-recoverable expenses aren't too hot. Moving to a nice big ARM will give plenty of elbow room for future development.

I also suggest an RS232 port for debugging work - they have been very very very helpful for me in the past.

Motor drivers:

As you're doing the work, the actual development is up to you, but might I suggest that if you're having space problems you consider moving the motor drive boards onto a sub-board? This will let you keep the high current stuff away from the micro and not risk the expensive main board if you tinker with the motors.

Additionally, you mention suppressing transients coming back from the motors using diode bridges. If you're using PWM at frequencies above a few hundred Hz (and who wouldn't), you need to use fast diodes with low reverse recovery charge or they will get hot and bothered!

Finally, keep the tracks around the motor drivers nice and short - they carry high frequency current from the PWM switching and will act like inductors if they're too long! Decouple power supplies carefully: a 100nF capacitor should be placed across each chip's power rails, plus a 10uF or so next to each L298 to help with the low frequency currents.

Hope this helps.

jbb

I've thought for a while that instead of grudgingly moving up a single processor size whenever we hit a limit is not the best idea - the non-recoverable expenses aren't too hot. Moving to a nice big ARM will give plenty of elbow room for future development.

I also suggest an RS232 port for debugging work - they have been very very very helpful for me in the past.

Motor drivers:

As you're doing the work, the actual development is up to you, but might I suggest that if you're having space problems you consider moving the motor drive boards onto a sub-board? This will let you keep the high current stuff away from the micro and not risk the expensive main board if you tinker with the motors.

Additionally, you mention suppressing transients coming back from the motors using diode bridges. If you're using PWM at frequencies above a few hundred Hz (and who wouldn't), you need to use fast diodes with low reverse recovery charge or they will get hot and bothered!

Finally, keep the tracks around the motor drivers nice and short - they carry high frequency current from the PWM switching and will act like inductors if they're too long! Decouple power supplies carefully: a 100nF capacitor should be placed across each chip's power rails, plus a 10uF or so next to each L298 to help with the low frequency currents.

Hope this helps.

jbb

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. January 31, 2009 09:18PM |

Registered: 15 years ago Posts: 242 |

Thanks for the advice JBB,

I admit I've only done stepper motor control once before, and that was for an EFTPOS receipt printer I did. I ended up having to place some parallel jumpers on the board, because I'd not allowed enough copper width on some critical lines. The problems were very intermittant glitches, and the jumpers fixed it.

I may have to do some testing, and check suppliers for a faster FWB package in DIL. I suspect it's a big ask. I really like the footprint I have at the moment though, as it's very compact. Regarding putting them on another board... I may have to, but I'm somewhat shocked at the piecemeal approach of the current versions, and I'm trying hard to make it work on one board. Electrically, it's possible, it's more the constraints of working with the free version of Eagle. Else, I may use the very old free version of Protel.

The cost of the driver chips is higher than that of the microcontroller, so I'm not convinced that adding the cost of more connectors and a second board, with mounts is worth it. Once the power outputs are created for a stepper motor, it only needs 4 cores per connector, so it's one of my goals, to reduce overall complexity of the machine.

Graham.

I admit I've only done stepper motor control once before, and that was for an EFTPOS receipt printer I did. I ended up having to place some parallel jumpers on the board, because I'd not allowed enough copper width on some critical lines. The problems were very intermittant glitches, and the jumpers fixed it.

I may have to do some testing, and check suppliers for a faster FWB package in DIL. I suspect it's a big ask. I really like the footprint I have at the moment though, as it's very compact. Regarding putting them on another board... I may have to, but I'm somewhat shocked at the piecemeal approach of the current versions, and I'm trying hard to make it work on one board. Electrically, it's possible, it's more the constraints of working with the free version of Eagle. Else, I may use the very old free version of Protel.

The cost of the driver chips is higher than that of the microcontroller, so I'm not convinced that adding the cost of more connectors and a second board, with mounts is worth it. Once the power outputs are created for a stepper motor, it only needs 4 cores per connector, so it's one of my goals, to reduce overall complexity of the machine.

Graham.

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 02, 2009 01:43PM |

Registered: 15 years ago Posts: 401 |

Graham,

I have a few comments for you which I hope will be useful.

1) Instead of eagle, if you have a linux box available, try gEDA. I haven't had much chance to play with it yet, but it seems to be a very full featured, completely free electronics CAD package. It has import capability from a lot of other tools, so you might even be able to pull in the work you've done.

2) Stepper control. I'm finalizing a stepper/BLDC motor controller which has some techniques in it that might work for you. It uses an L293 to drive N+P MOSFET H-Bridge. The only inputs to it are direction control and PWM setpoint current. The cost on it is pretty good. I'm anticipating that it should be cheaper than Zach's stepper controller, but it will allow for microstepping, and up to 5A/phase motors. The down side is it will take a little more space because it is not an integrated solution.

3) Please provide a modular expansion port. I think that most everyone has now agreed that RS-485 is the thing to use. I'd make it full-duplex, with a transmitter enable. I still think that SATA cables are an excellent choice because they come pre-made in lengths up to about one meter, they are very cheap, small, flexible and they have the option of locking connectors. I could also see an argument for using CAT5 cable. Both are designed with twisted pairs. SATA is also shielded.

If you do decide to put an RS-485 modular expansion port (or two) onto your board, your development and mine will be interoperable.

While we do disagree on whether the base build should be capable of doing everything on one board, I think we do agree that interoperability and expansion are nice features. If the cost for that is an optional RS485 driver and a connector, it would seem a shame to lose those possibilities.

4) I think it's a good idea to try to keep the body of your code platform independent. I do this by separating all architecture and chip specific operations into functions which I define in an arch.h/arch.c module. This means that when someone comes to port your code to another microcontroller, all they have to do is rewrite those two files. Everything else should work as planned.

Brendan

Edited 1 time(s). Last edit at 02/02/2009 01:47PM by Annirak.

I have a few comments for you which I hope will be useful.

1) Instead of eagle, if you have a linux box available, try gEDA. I haven't had much chance to play with it yet, but it seems to be a very full featured, completely free electronics CAD package. It has import capability from a lot of other tools, so you might even be able to pull in the work you've done.

2) Stepper control. I'm finalizing a stepper/BLDC motor controller which has some techniques in it that might work for you. It uses an L293 to drive N+P MOSFET H-Bridge. The only inputs to it are direction control and PWM setpoint current. The cost on it is pretty good. I'm anticipating that it should be cheaper than Zach's stepper controller, but it will allow for microstepping, and up to 5A/phase motors. The down side is it will take a little more space because it is not an integrated solution.

3) Please provide a modular expansion port. I think that most everyone has now agreed that RS-485 is the thing to use. I'd make it full-duplex, with a transmitter enable. I still think that SATA cables are an excellent choice because they come pre-made in lengths up to about one meter, they are very cheap, small, flexible and they have the option of locking connectors. I could also see an argument for using CAT5 cable. Both are designed with twisted pairs. SATA is also shielded.

If you do decide to put an RS-485 modular expansion port (or two) onto your board, your development and mine will be interoperable.

While we do disagree on whether the base build should be capable of doing everything on one board, I think we do agree that interoperability and expansion are nice features. If the cost for that is an optional RS485 driver and a connector, it would seem a shame to lose those possibilities.

4) I think it's a good idea to try to keep the body of your code platform independent. I do this by separating all architecture and chip specific operations into functions which I define in an arch.h/arch.c module. This means that when someone comes to port your code to another microcontroller, all they have to do is rewrite those two files. Everything else should work as planned.

Brendan

Edited 1 time(s). Last edit at 02/02/2009 01:47PM by Annirak.

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 02, 2009 11:28PM |

Registered: 15 years ago Posts: 242 |

Hi Annirak/Brendan,

in reply to your items:

1. I also have "PCB", which is free, and runs on Linux. Just checking, it's also known as the gEda that you mention. I had a bit of a play on it about 2 years back, but haven't actually built a board with it. Worth another look at though, as I may need the extra footprint space to properly incorporate the high speed freewheeling motor diodes.

2. I've used the L293D before on the printer I designed.(inbuilt diode version) I don't think the L298 are much more expensive, but they are double the current, and it's nice to have more, rather than less, than you actually need. I was thinking that for serious power, to have an add-on board that has the NPN high, PNP low configuration with load sharing resistor from the tied bases to the tied emitters. It's an easy circuit, and would need the diodes too. I have some limited stock of the L293D, but I think my machine will need a bit more current than they can supply. Not a bad choice though if they are just there to give current boost and prevent driving a high and low at the same time, on the same side of a winding (smoke rising...)

3.I agree about the modular expansion port, but I'm doing RS485, which is 2 wire, not RS422, which is 4. The practicalities of using RS422 to best advantage, involve making your software take advantage of duplex coms via interrupt, and dual buffers. Generally, you don't need a lot of traffic both ways at any given time, it's more like:

TX:"Z axis: coordinates over next 10 mS",RX:"yes" TX:"extruder: profile for next 10 mS",RX:"yes", TX:"Fan set speed to n",RX:"yes",TX:"all channels: synch"...(repeat)

Mostly, the traffic is one way, and once you make an expansion module with local intelligence, you have the power to set remote abstract tasks, rather than just having a bigger address bus.

Where that might differ, is if you have a sensing head, which is reading a lot of high resolution data. I believe though, that it's easy to buffer moves ahead, and use global synchronisation.

The other good thing about RS485, is that it can run in your proposed SATA leads, AND share with power, just like a SATA drive.

4. I think without working for the same company, under one dictator overseer, it's hard to get everyone following the same rules. I did find though, in my 4'th year of business, I was starting to make my code much more modular, and so I didn't have the same need to debug sections that had previously worked, when writing new code. I'll keep what you said in mind, but I have some catchup to do in C yet anyway, if I don't code it in ASM !

I do tend to seperate my code out into a lot of different function modules already.

Graham.

Edited 1 time(s). Last edit at 02/02/2009 11:40PM by grael.

in reply to your items:

1. I also have "PCB", which is free, and runs on Linux. Just checking, it's also known as the gEda that you mention. I had a bit of a play on it about 2 years back, but haven't actually built a board with it. Worth another look at though, as I may need the extra footprint space to properly incorporate the high speed freewheeling motor diodes.

2. I've used the L293D before on the printer I designed.(inbuilt diode version) I don't think the L298 are much more expensive, but they are double the current, and it's nice to have more, rather than less, than you actually need. I was thinking that for serious power, to have an add-on board that has the NPN high, PNP low configuration with load sharing resistor from the tied bases to the tied emitters. It's an easy circuit, and would need the diodes too. I have some limited stock of the L293D, but I think my machine will need a bit more current than they can supply. Not a bad choice though if they are just there to give current boost and prevent driving a high and low at the same time, on the same side of a winding (smoke rising...)

3.I agree about the modular expansion port, but I'm doing RS485, which is 2 wire, not RS422, which is 4. The practicalities of using RS422 to best advantage, involve making your software take advantage of duplex coms via interrupt, and dual buffers. Generally, you don't need a lot of traffic both ways at any given time, it's more like:

TX:"Z axis: coordinates over next 10 mS",RX:"yes" TX:"extruder: profile for next 10 mS",RX:"yes", TX:"Fan set speed to n",RX:"yes",TX:"all channels: synch"...(repeat)

Mostly, the traffic is one way, and once you make an expansion module with local intelligence, you have the power to set remote abstract tasks, rather than just having a bigger address bus.

Where that might differ, is if you have a sensing head, which is reading a lot of high resolution data. I believe though, that it's easy to buffer moves ahead, and use global synchronisation.

The other good thing about RS485, is that it can run in your proposed SATA leads, AND share with power, just like a SATA drive.

4. I think without working for the same company, under one dictator overseer, it's hard to get everyone following the same rules. I did find though, in my 4'th year of business, I was starting to make my code much more modular, and so I didn't have the same need to debug sections that had previously worked, when writing new code. I'll keep what you said in mind, but I have some catchup to do in C yet anyway, if I don't code it in ASM !

I do tend to seperate my code out into a lot of different function modules already.

Graham.

Edited 1 time(s). Last edit at 02/02/2009 11:40PM by grael.

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 03, 2009 09:48AM |

Registered: 15 years ago Posts: 401 |

grael Wrote:

-------------------------------------------------------

> 2. I've used the L293D before on the printer I

> designed.(inbuilt diode version) I don't think the

> L298 are much more expensive, but they are double

> the current, and it's nice to have more, rather

> than less, than you actually need. I was thinking

> that for serious power, to have an add-on board

> that has the NPN high, PNP low configuration with

> load sharing resistor from the tied bases to the

> tied emitters. It's an easy circuit, and would

> need the diodes too. I have some limited stock of

> the L293D, but I think my machine will need a bit

> more current than they can supply. Not a bad

> choice though if they are just there to give

> current boost and prevent driving a high and low

> at the same time, on the same side of a winding

> (smoke rising...)

The L298 is over double the price of the L293. My plan is to use the L293 as a MOSFET driver.

>

> 3.I agree about the modular expansion port, but

> I'm doing RS485, which is 2 wire, not RS422, which

> is 4.

It's not that simple. RS-485 specifies a bus in which both sides use transmitter enables, and can therefore be more than a point-to-point connection. RS-422 specifies a bus with always-on transceivers. This difference makes it possible for RS-485 to be run in half-duplex mode, but it doesn't guarantee that it must be.

There is a full duplex version of RS-485. But this is not the point. The point is that using half-duplex is limiting for no good reason. There's very limited benefit to insisting on a half-duplex physical layer. The protocol can still be half-duplex even if the physical layer is full duplex. In fact, this is the case with SATA.

> The other good thing about RS485, is that it can

> run in your proposed SATA leads, AND share with

> power, just like a SATA drive.

SATA drives DO NOT run power and data on the same cable, and the cables are not built to handle enough current to make that practical, so let's drop that idea before it even gets started.

> 4. I think without working for the same company,

> under one dictator overseer, it's hard to get

> everyone following the same rules. I did find

> though, in my 4'th year of business, I was

> starting to make my code much more modular, and so

> I didn't have the same need to debug sections that

> had previously worked, when writing new code. I'll

> keep what you said in mind, but I have some

> catchup to do in C yet anyway, if I don't code it

> in ASM !

> I do tend to seperate my code out into a lot of

> different function modules already.

That is absolutely not true. Why do you think that PC's took over the market? It's because a standards body said "if you want to play nice with all the other hardware, you have to adhere to this specification" and everyone did. More than that, you have the Linux kernel, where thousands of people all around the world have written code that works together without much of a specification at all.

Brendan

-------------------------------------------------------

> 2. I've used the L293D before on the printer I

> designed.(inbuilt diode version) I don't think the

> L298 are much more expensive, but they are double

> the current, and it's nice to have more, rather

> than less, than you actually need. I was thinking

> that for serious power, to have an add-on board

> that has the NPN high, PNP low configuration with

> load sharing resistor from the tied bases to the

> tied emitters. It's an easy circuit, and would

> need the diodes too. I have some limited stock of

> the L293D, but I think my machine will need a bit

> more current than they can supply. Not a bad

> choice though if they are just there to give

> current boost and prevent driving a high and low

> at the same time, on the same side of a winding

> (smoke rising...)

The L298 is over double the price of the L293. My plan is to use the L293 as a MOSFET driver.

>

> 3.I agree about the modular expansion port, but

> I'm doing RS485, which is 2 wire, not RS422, which

> is 4.

It's not that simple. RS-485 specifies a bus in which both sides use transmitter enables, and can therefore be more than a point-to-point connection. RS-422 specifies a bus with always-on transceivers. This difference makes it possible for RS-485 to be run in half-duplex mode, but it doesn't guarantee that it must be.

There is a full duplex version of RS-485. But this is not the point. The point is that using half-duplex is limiting for no good reason. There's very limited benefit to insisting on a half-duplex physical layer. The protocol can still be half-duplex even if the physical layer is full duplex. In fact, this is the case with SATA.

> The other good thing about RS485, is that it can

> run in your proposed SATA leads, AND share with

> power, just like a SATA drive.

SATA drives DO NOT run power and data on the same cable, and the cables are not built to handle enough current to make that practical, so let's drop that idea before it even gets started.

> 4. I think without working for the same company,

> under one dictator overseer, it's hard to get

> everyone following the same rules. I did find

> though, in my 4'th year of business, I was

> starting to make my code much more modular, and so

> I didn't have the same need to debug sections that

> had previously worked, when writing new code. I'll

> keep what you said in mind, but I have some

> catchup to do in C yet anyway, if I don't code it

> in ASM !

> I do tend to seperate my code out into a lot of

> different function modules already.

That is absolutely not true. Why do you think that PC's took over the market? It's because a standards body said "if you want to play nice with all the other hardware, you have to adhere to this specification" and everyone did. More than that, you have the Linux kernel, where thousands of people all around the world have written code that works together without much of a specification at all.

Brendan

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 04, 2009 06:52AM |

Registered: 15 years ago Posts: 242 |

Annirak Wrote:

> The L298 is over double the price of the L293. My

> plan is to use the L293 as a MOSFET driver.

[parts.digikey.com]

[search.digikey.com]

Surprisingly, the higher current chip, is actually cheaper, even in the multiwatt package ! (I'm keeping the L298)

> It's not that simple. RS-485 specifies a bus in

> which both sides use transmitter enables, and can

> therefore be more than a point-to-point

> connection. RS-422 specifies a bus with always-on

> transceivers. This difference makes it possible

> for RS-485 to be run in half-duplex mode, but it

> doesn't guarantee that it must be.

OK, I've read up on it after you wrote that, and I see now that you're right.

> There is a full duplex version of RS-485. But

> this is not the point. The point is that using

> half-duplex is limiting for no good reason.

> There's very limited benefit to insisting on a

> half-duplex physical layer. The protocol can

> still be half-duplex even if the physical layer is

> full duplex. In fact, this is the case with

> SATA.

The "good reason", as stated, is simplicity. I haven't checked out cost comparisons, but RS485 2-wire is also far more common in my experience. I think when first introduced, a lot of the system designers shared your views. However, there was still a shift to half duplex comms. Why ? I think the reasons I expressed previously explain, but I'll try to sum it up again, a little differently:

*Typical* RS485 communications are of an unbalanced volumetric nature: Usually, there is only one master, and the master either spends most of it's time listening, or most of it's time talking. Also, as I wrote earlier, it's perfectly possible to buffer serial data, and synch globally. It's more likely that we would run into a bottle neck that required a baud rate increase to solve, than that we would run into a problem that full duplex comms alone was able to solve.

If speed is that much of an issue, then the other ways of dealing to it would be:

1) go parallel (use enable signals per tool head, but share control/data signals)

2) electrical rotary or linear contact set, mechanical tool swapping, with general purpose contacts that align with currently rotated tool head.

3) More I/O:

I'm hoping to make my LCD port available as a CPLD expansion route too.

I can use an enable signal, low for the LCD, high for the CPLD. Once the CPLD enable is active, all the LCD signals would become available to the CPLD, allowing 8 bit wide bidirectional transfers, and CPLD register select, read/write of CPLD pins, and operation of custom CPLD functions. I'm having another crack at PCB/GEDA, so space won't be a problem.

> SATA drives DO NOT run power and data on the same

> cable, and the cables are not built to handle

> enough current to make that practical, so let's

> drop that idea before it even gets started.

OK, I have SATA all wrong.

It appears to contain 2 x signal pairs well suited to full duplex RS485, as you say, and with 3 spare cores. Certainly, I agree, they wouldn't handle an "extra low voltage" element for extruder heating, but there are other options in which two of the cores might well be rated to carry the current.

> That is absolutely not true. Why do you think

> that PC's took over the market? It's because a

> standards body said "if you want to play nice with

> all the other hardware, you have to adhere to this

> specification" and everyone did. More than that,

> you have the Linux kernel, where thousands of

> people all around the world have written code that

> works together without much of a specification at

> all.

> Brendan

It's about the success of a modular approach, be that DOS/Windows(Microsoft) for an OS, 8088 backwards compatible successors(Intel) for computer microprocessors, or modularity of software, such that major functions, of different types, can be used according to general rule sets.

The case in point:

You want full duplex RS485 so you have the option of full speed transmissions in the other direction, simultaneously.

My argument, transmission in either one direction or the other, is typically underused anyway, and that full duplex is not a cost effective method of increasing communications speed.

Given that each of us believes ourself to be right, a joint project would now stall, or further split direction, and development efforts. Alternatively, provision is made for both, to satisfy both our egos, and the project wears the financial cost of that ego soothing, in the form of additional hardware/jumpers/connectors.

Graham

> The L298 is over double the price of the L293. My

> plan is to use the L293 as a MOSFET driver.

[parts.digikey.com]

[search.digikey.com]

Surprisingly, the higher current chip, is actually cheaper, even in the multiwatt package ! (I'm keeping the L298)

> It's not that simple. RS-485 specifies a bus in

> which both sides use transmitter enables, and can

> therefore be more than a point-to-point

> connection. RS-422 specifies a bus with always-on

> transceivers. This difference makes it possible

> for RS-485 to be run in half-duplex mode, but it

> doesn't guarantee that it must be.

OK, I've read up on it after you wrote that, and I see now that you're right.

> There is a full duplex version of RS-485. But

> this is not the point. The point is that using

> half-duplex is limiting for no good reason.

> There's very limited benefit to insisting on a

> half-duplex physical layer. The protocol can

> still be half-duplex even if the physical layer is

> full duplex. In fact, this is the case with

> SATA.

The "good reason", as stated, is simplicity. I haven't checked out cost comparisons, but RS485 2-wire is also far more common in my experience. I think when first introduced, a lot of the system designers shared your views. However, there was still a shift to half duplex comms. Why ? I think the reasons I expressed previously explain, but I'll try to sum it up again, a little differently:

*Typical* RS485 communications are of an unbalanced volumetric nature: Usually, there is only one master, and the master either spends most of it's time listening, or most of it's time talking. Also, as I wrote earlier, it's perfectly possible to buffer serial data, and synch globally. It's more likely that we would run into a bottle neck that required a baud rate increase to solve, than that we would run into a problem that full duplex comms alone was able to solve.

If speed is that much of an issue, then the other ways of dealing to it would be:

1) go parallel (use enable signals per tool head, but share control/data signals)

2) electrical rotary or linear contact set, mechanical tool swapping, with general purpose contacts that align with currently rotated tool head.

3) More I/O:

I'm hoping to make my LCD port available as a CPLD expansion route too.

I can use an enable signal, low for the LCD, high for the CPLD. Once the CPLD enable is active, all the LCD signals would become available to the CPLD, allowing 8 bit wide bidirectional transfers, and CPLD register select, read/write of CPLD pins, and operation of custom CPLD functions. I'm having another crack at PCB/GEDA, so space won't be a problem.

> SATA drives DO NOT run power and data on the same

> cable, and the cables are not built to handle

> enough current to make that practical, so let's

> drop that idea before it even gets started.

OK, I have SATA all wrong.

It appears to contain 2 x signal pairs well suited to full duplex RS485, as you say, and with 3 spare cores. Certainly, I agree, they wouldn't handle an "extra low voltage" element for extruder heating, but there are other options in which two of the cores might well be rated to carry the current.

> That is absolutely not true. Why do you think

> that PC's took over the market? It's because a

> standards body said "if you want to play nice with

> all the other hardware, you have to adhere to this

> specification" and everyone did. More than that,

> you have the Linux kernel, where thousands of

> people all around the world have written code that

> works together without much of a specification at

> all.

> Brendan

It's about the success of a modular approach, be that DOS/Windows(Microsoft) for an OS, 8088 backwards compatible successors(Intel) for computer microprocessors, or modularity of software, such that major functions, of different types, can be used according to general rule sets.

The case in point:

You want full duplex RS485 so you have the option of full speed transmissions in the other direction, simultaneously.

My argument, transmission in either one direction or the other, is typically underused anyway, and that full duplex is not a cost effective method of increasing communications speed.

Given that each of us believes ourself to be right, a joint project would now stall, or further split direction, and development efforts. Alternatively, provision is made for both, to satisfy both our egos, and the project wears the financial cost of that ego soothing, in the form of additional hardware/jumpers/connectors.

Graham

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 04, 2009 10:46AM |

Registered: 15 years ago Posts: 401 |

grael Wrote:

-------------------------------------------------------

> Annirak Wrote:

> > The L298 is over double the price of the L293.

> My

> > plan is to use the L293 as a MOSFET driver.

>

> [parts.digikey.com]-

> p-4ch-w-diodes-16-dip-l293d.html

> [search.digikey.com]

> ll?Detail&name=497-1395-5-ND

> Surprisingly, the higher current chip, is actually

> cheaper, even in the multiwatt package ! (I'm

> keeping the L298)

You missed the other one: [www.digikey.com]

> > There's very limited benefit to insisting on a

> > half-duplex physical layer. The protocol can

> > still be half-duplex even if the physical layer

> is

> > full duplex. In fact, this is the case with

> > SATA.

>

> The "good reason", as stated, is simplicity. I

> haven't checked out cost comparisons, but RS485

> 2-wire is also far more common in my experience. I

> think when first introduced, a lot of the system

> designers shared your views. However, there was

> still a shift to half duplex comms. Why ? I think

> the reasons I expressed previously explain, but

> I'll try to sum it up again, a little

> differently:

Let me put it to you another way, there are three points you need to consider:

1) Half-duplex protocols are more complex. All the nodes on the bus must implement collision detection and arbitration. In a half duplex bus, the protocol is much simpler.

2) If you have a full duplex comms bus where the master has one side dedicated to it, no slave can ever take over the bus. The master can always transmit when it needs to. This is important for timing, as the master can send a sync packet while a slave is transmitting. This is not the case in a half-duplex bus. There, the master must wait until the bus is free before it can sync.

3) If we use SATA cables, we have a free pair. I fail to see the difference in cost.

> > SATA drives DO NOT run power and data on the

> same

> > cable, and the cables are not built to handle

> > enough current to make that practical, so let's

> > drop that idea before it even gets started.

>

> OK, I have SATA all wrong.

> It appears to contain 2 x signal pairs well suited

> to full duplex RS485, as you say, and with 3 spare

> cores. Certainly, I agree, they wouldn't handle an

> "extra low voltage" element for extruder heating,

> but there are other options in which two of the

> cores might well be rated to carry the current.

I still wouldn't try to run more than about 100mA on those pairs.

> Given that each of us believes ourself to be

> right, a joint project would now stall, or further

> split direction, and development efforts.

> Alternatively, provision is made for both, to

> satisfy both our egos, and the project wears the

> financial cost of that ego soothing, in the form

> of additional hardware/jumpers/connectors.

Don't try to talk to me about my ego. That just weakens your argument by implying that you need to resort to name calling.

Lets talk about our two design perspectives from the point of view of relative merit, not ego.

-------------------------------------------------------

> Annirak Wrote:

> > The L298 is over double the price of the L293.

> My

> > plan is to use the L293 as a MOSFET driver.

>

> [parts.digikey.com]-

> p-4ch-w-diodes-16-dip-l293d.html

> [search.digikey.com]

> ll?Detail&name=497-1395-5-ND

> Surprisingly, the higher current chip, is actually

> cheaper, even in the multiwatt package ! (I'm

> keeping the L298)

You missed the other one: [www.digikey.com]

> > There's very limited benefit to insisting on a

> > half-duplex physical layer. The protocol can

> > still be half-duplex even if the physical layer

> is

> > full duplex. In fact, this is the case with

> > SATA.

>

> The "good reason", as stated, is simplicity. I

> haven't checked out cost comparisons, but RS485

> 2-wire is also far more common in my experience. I

> think when first introduced, a lot of the system

> designers shared your views. However, there was

> still a shift to half duplex comms. Why ? I think

> the reasons I expressed previously explain, but

> I'll try to sum it up again, a little

> differently:

Let me put it to you another way, there are three points you need to consider:

1) Half-duplex protocols are more complex. All the nodes on the bus must implement collision detection and arbitration. In a half duplex bus, the protocol is much simpler.

2) If you have a full duplex comms bus where the master has one side dedicated to it, no slave can ever take over the bus. The master can always transmit when it needs to. This is important for timing, as the master can send a sync packet while a slave is transmitting. This is not the case in a half-duplex bus. There, the master must wait until the bus is free before it can sync.

3) If we use SATA cables, we have a free pair. I fail to see the difference in cost.

> > SATA drives DO NOT run power and data on the

> same

> > cable, and the cables are not built to handle

> > enough current to make that practical, so let's

> > drop that idea before it even gets started.

>

> OK, I have SATA all wrong.

> It appears to contain 2 x signal pairs well suited

> to full duplex RS485, as you say, and with 3 spare

> cores. Certainly, I agree, they wouldn't handle an

> "extra low voltage" element for extruder heating,

> but there are other options in which two of the

> cores might well be rated to carry the current.

I still wouldn't try to run more than about 100mA on those pairs.

> Given that each of us believes ourself to be

> right, a joint project would now stall, or further

> split direction, and development efforts.

> Alternatively, provision is made for both, to

> satisfy both our egos, and the project wears the

> financial cost of that ego soothing, in the form

> of additional hardware/jumpers/connectors.

Don't try to talk to me about my ego. That just weakens your argument by implying that you need to resort to name calling.

Lets talk about our two design perspectives from the point of view of relative merit, not ego.

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 04, 2009 02:47PM |

Registered: 15 years ago Posts: 45 |

Woah there... lets not get personal.

On the RS485: Annirak has a good point - you need tight timing on some of the master -> slave communications. Remember the RepRap gen 1 electronics had a synch line?

This isn't about bandwidth, it's about predictable timing, which is essential if we want to keep the build quality up. Going to a two lane connection will indeed increase the cost a little bit but it gives you deterministic master->slave timing. You can still bus up 31 slaves if you want, you'll just have to carry 5 wires instead of 3 (including earth).

To keep the signal quality up we'll need termination resistors at both ends of the RS485 bus. I suggest that each board should have two headers / sockets on it which are straight through connections and that these resistors should be mounted on a dummy plug like the old coax computer networks were.

On the SATA cable: they do come prebuilt and all and should have nice AC characteristics, but I'm not sure they'll thank you for subjecting them to repeated mechanical cycling. Only one thing to do: build it, test it, keep a spare cable by the RepRap. Good old stranded Cat 5 network cable is also great for this kind of thing and probably cheaper.

jbb

On the RS485: Annirak has a good point - you need tight timing on some of the master -> slave communications. Remember the RepRap gen 1 electronics had a synch line?

This isn't about bandwidth, it's about predictable timing, which is essential if we want to keep the build quality up. Going to a two lane connection will indeed increase the cost a little bit but it gives you deterministic master->slave timing. You can still bus up 31 slaves if you want, you'll just have to carry 5 wires instead of 3 (including earth).

To keep the signal quality up we'll need termination resistors at both ends of the RS485 bus. I suggest that each board should have two headers / sockets on it which are straight through connections and that these resistors should be mounted on a dummy plug like the old coax computer networks were.

On the SATA cable: they do come prebuilt and all and should have nice AC characteristics, but I'm not sure they'll thank you for subjecting them to repeated mechanical cycling. Only one thing to do: build it, test it, keep a spare cable by the RepRap. Good old stranded Cat 5 network cable is also great for this kind of thing and probably cheaper.

jbb

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 04, 2009 03:27PM |

Registered: 15 years ago Posts: 401 |

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 05, 2009 06:26AM |

Registered: 15 years ago Posts: 242 |

Annirak Wrote:

> Don't try to talk to me about my ego. That just

> weakens your argument by implying that you need to

> resort to name calling.

I have to call you out on this one Brendan:

Your words: "Don't try to talk to me about"...

Please avoid the "don't try to" phrase in this context, it's a personal attack, rather than on topic argument.

In case it's not perfectly clear, "try to" (in this context) implies that the person is trying something that they are not competent to do.

We are both human, we both have egos. I suspect, by now, that other visitors to this thread have found it rather hard not to observe them.

> Lets talk about our two design perspectives from

> the point of view of relative merit, not ego.

My parents used to live on a lighthouse station. Communications, were by letter, fortnightly. They were surprised at the amount of useful revision that could be done, on subjects initially warranting great passion.

It's correct to say that you and I are both passionate about our own views on development.

I'm not persuaded to your view yet.

*I still think that half duplex allows synchronisation just fine,

*I recognise the advantages of full duplex, but I think they are inconsequential in this application, as there are far more effective ways to ensure fast, synchronised response times. My idea of a CPLD expansion port as an alternate function of the LCD interface, for example, allows for a much better degree of synchronisation and rapid response, than either full duplex, or baud rate increase on RS485.

There are many many ways to implement a CPLD expansion, a simple one such as that I outlined in my above post, or, for example, one in which the CPLD is directly attached to the LCD, and to the uC, but where the LCD has no direct connection to the uC.

In such an implementation, the uC reads or writes registers in the CPLD, and can make state changes to switch which external device is being controlled. I've done this before, with a 68HC11, using the CPLD to respond to certain addresses on the micro, to perform bank select functions

*The L293D package incorporates protection diodes, but is only rated to 0.6 amps constant.

The issue here, is that I'm trying to build a machine that can potentially serve something like 95% of reprapper's typical needs.

I can see you have good ideas for alternative output stages, but I'm concerned that the L298N package, rated at 1 amp continous, (with heatsinking), is not going to meet the vast majority's needs. I know your mosfet expansion is meant to overcome this, but I'm trying to standardise at a higher unamplified power rating to make something that's less likely to need a boost board in the first place. That, to me, is worth the cost difference between an L298 versus an L293N.

I've glanced at your schematic for a toolhead controller, and I can see you have a time investment in doing things the way you've already decided on. There are going to be standisation issues if the main board only does full, or only does half duplex, and people want to design slave boards to the other standard. I don't have that particular investment in time, butt you have a conservative bias (conservation of your current design work's hours of effort, and/or personal investment of PCB costs)

On the other hand, I have these 20 x STM32FVBT103 chips sitting in my stock, and otherwise, I might be looking more seriously at other variants. We all have biases, and admitting, disclosing our biases to others, allows better understanding of other's motives, and more agreeable co-development effort.

------------------------------------------------------------------------------

JBB:

Synchronisation on half duplex should still be a global process, i.e. "Calling all devices, sync NOW", in which case the remaining issue is whether each device knows what it's tasks are, until it's next update moment. I suspect the operation of multiple toolheads concurrently is not going to complicate matters much, as the x, y & z axis are bound to a single working platform, and so the data transmitted is going to be of minimal complexity. I did have a lot of extra features from the standard reprap already assigned to the uC in this project... for example PWM outputs that could be utilised for servo motor valve control.

There comes a point, where trying to do everything with one machine, becomes counter productive, and it's better to have another machine, more specialised, for the additional tasks. I'm not trying to make something here that does CNC, extrusion, EDM, AND makes coffee !

Graham

Edited 1 time(s). Last edit at 02/05/2009 06:28AM by grael.

> Don't try to talk to me about my ego. That just

> weakens your argument by implying that you need to

> resort to name calling.

I have to call you out on this one Brendan:

Your words: "Don't try to talk to me about"...

Please avoid the "don't try to" phrase in this context, it's a personal attack, rather than on topic argument.

In case it's not perfectly clear, "try to" (in this context) implies that the person is trying something that they are not competent to do.

We are both human, we both have egos. I suspect, by now, that other visitors to this thread have found it rather hard not to observe them.

> Lets talk about our two design perspectives from

> the point of view of relative merit, not ego.

My parents used to live on a lighthouse station. Communications, were by letter, fortnightly. They were surprised at the amount of useful revision that could be done, on subjects initially warranting great passion.

It's correct to say that you and I are both passionate about our own views on development.

I'm not persuaded to your view yet.

*I still think that half duplex allows synchronisation just fine,

*I recognise the advantages of full duplex, but I think they are inconsequential in this application, as there are far more effective ways to ensure fast, synchronised response times. My idea of a CPLD expansion port as an alternate function of the LCD interface, for example, allows for a much better degree of synchronisation and rapid response, than either full duplex, or baud rate increase on RS485.

There are many many ways to implement a CPLD expansion, a simple one such as that I outlined in my above post, or, for example, one in which the CPLD is directly attached to the LCD, and to the uC, but where the LCD has no direct connection to the uC.

In such an implementation, the uC reads or writes registers in the CPLD, and can make state changes to switch which external device is being controlled. I've done this before, with a 68HC11, using the CPLD to respond to certain addresses on the micro, to perform bank select functions

*The L293D package incorporates protection diodes, but is only rated to 0.6 amps constant.

The issue here, is that I'm trying to build a machine that can potentially serve something like 95% of reprapper's typical needs.

I can see you have good ideas for alternative output stages, but I'm concerned that the L298N package, rated at 1 amp continous, (with heatsinking), is not going to meet the vast majority's needs. I know your mosfet expansion is meant to overcome this, but I'm trying to standardise at a higher unamplified power rating to make something that's less likely to need a boost board in the first place. That, to me, is worth the cost difference between an L298 versus an L293N.

I've glanced at your schematic for a toolhead controller, and I can see you have a time investment in doing things the way you've already decided on. There are going to be standisation issues if the main board only does full, or only does half duplex, and people want to design slave boards to the other standard. I don't have that particular investment in time, butt you have a conservative bias (conservation of your current design work's hours of effort, and/or personal investment of PCB costs)

On the other hand, I have these 20 x STM32FVBT103 chips sitting in my stock, and otherwise, I might be looking more seriously at other variants. We all have biases, and admitting, disclosing our biases to others, allows better understanding of other's motives, and more agreeable co-development effort.

------------------------------------------------------------------------------

JBB:

Synchronisation on half duplex should still be a global process, i.e. "Calling all devices, sync NOW", in which case the remaining issue is whether each device knows what it's tasks are, until it's next update moment. I suspect the operation of multiple toolheads concurrently is not going to complicate matters much, as the x, y & z axis are bound to a single working platform, and so the data transmitted is going to be of minimal complexity. I did have a lot of extra features from the standard reprap already assigned to the uC in this project... for example PWM outputs that could be utilised for servo motor valve control.

There comes a point, where trying to do everything with one machine, becomes counter productive, and it's better to have another machine, more specialised, for the additional tasks. I'm not trying to make something here that does CNC, extrusion, EDM, AND makes coffee !

Graham

Edited 1 time(s). Last edit at 02/05/2009 06:28AM by grael.

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 05, 2009 06:40AM |

Registered: 15 years ago Posts: 242 |

Re: CPLD extension of the base circuit board:

As a sample of what you can do with a CPLD, have a look at this AHDL code I wrote about 6 years back, it interfaced a 68HC11 to a battery backed SRAM and a realtime clock, with an arrangement that allowed for a big chunk of main memory, and two page registers to give access to the rest of a chip would otherwise have been out of the 68HC11's address space:

--------------------------------------------

Title "GDsample";

subdesign GDsample--Address map:

--0000-3f7f=unchanged

--0480-04ff=FPGA control window:

--0480-04BF=Window#1, applies: 2000-3fff, last 6 bits select 8 K page within 512k byte range

--04C0-04DF=Window#2, applies: C000-CFFF, last 5 bits select 4 K page within 128k byte range (low)

--04F8-output pin 1 =GND

--04F9-output pin 1 =VCC

--04FA-output pin 2 =GND

--04FB-output pin 2 =VCC

--3FFC --> write protect top 32k

--04FD --> allow writes to top 32k

--04FE --> write protect top 32k

--2000-3fff=Window#1, 16 K page within 512k byte range

--8000-bfff=unchanged

--C000-CFFF=Window#2, last 5 bits select 4 K page within 128k byte range (low)

--d000-ffff=unchanged

--last locations of external SRAM (7FFFFh-7FFF0h) are automatically diverted to access the SRAM /

--RTC controller chip, which also temporarily disables SRAM I/O.

(

AddrIn[15..0] : input; -- microprocessor address port

Eclk : input; -- sync address latching.

Read : input; -- Rd/Write HC11 output.

Rst : input; -- clr registers

AddrOut[18..12] : output; -- synthesised extra 3 address lines + remapped 4 to RAM

_Oe : output; -- Read inverted, drives /OE - output enable signal.

_We : output; -- /WE - /Write enable, masked areas.

Out1 : output; -- spare

Out2 : output; -- spare

)

variable

LoBank[5..0] : DFF; --8 k chunks

HiBank[4..0] : DFF; --4 k chunks

RamNRom : node; --upper area write lockout option.

OutN1 : node;

OutN2 : node;

begin

---RamNRom.CLRN=Rst; -- default lockout

LoBank[5..0].CLRN=Rst; --reset at all zeros

HiBank[4..0].CLRN=Rst; --reset at all zeros

LoBank[5..0].D=AddrIn[5..0]; --connection path, addr to #1 window latch

HiBank[4..0].D=AddrIn[4..0]; --connection path, addr to #2 window latch

Out1=OutN1;

Out2=OutN2;

if Rst==GND then

RamNRom=GND;

end if;

_Oe=!(Read and Eclk);

If (AddrIn[15] == B"1") & (RamNRom==gnd) then

_We=Vcc; --lock mode

ELSE

_We=!(!Read & Eclk); --unlocked mode

END IF;

IF (AddrIn[15..7] == (H"04",B"1")) & !Read then -- FPGA register address, low order 7 bits set action.

CASE AddrIn[6..0] IS

--RAM lockout control above $7FFF on HC11 bus:

WHEN B"1111110" => -- lock

RamNRom=gnd;

WHEN B"1111101" => -- unlock

RamNRom=vcc;

WHEN B"1111100" => -- lock

RamNRom=gnd;

--Spare outputs:

WHEN B"111100x" => -- Output pin #1

OutN1=AddrIn[0];

WHEN B"111101x" => -- Output pin #2

OutN2=AddrIn[0];

--Low bank select write:

WHEN B"0xxxxxx" => -- Window#1, 4000-7fff

LoBank[].CLK=Eclk;

--High bank select write:

WHEN B"10xxxxx" => -- Window#2, C000-CFFF

HiBank[].CLK=Eclk;

END CASE;

END IF;

CASE AddrIn[15..12] IS

WHEN B"001x" => --Substitute bank @ window#1 2000-3FFF

AddrOut[18..12] = (LoBank[5..0],AddrIn[12]);

WHEN B"1000" => --Substitute bank @ window#2 C000-CFFF

AddrOut[18..12] = (B"00",HiBank[4..0]);

WHEN OTHERS => -- feed through AddrIn[15..12]

AddrOut[18..12] = (B"000",AddrIn[15..12]); -- first block of 64k bytes

END CASE;

end;

--------------------------------------------

Now if I were to do a design for a CNC machine add on, there could be options like Servo PWM outputs, shaft encoders, with readable registers, stepper motor position registers, they are really very flexible devices.

As a sample of what you can do with a CPLD, have a look at this AHDL code I wrote about 6 years back, it interfaced a 68HC11 to a battery backed SRAM and a realtime clock, with an arrangement that allowed for a big chunk of main memory, and two page registers to give access to the rest of a chip would otherwise have been out of the 68HC11's address space:

--------------------------------------------

Title "GDsample";

subdesign GDsample--Address map:

--0000-3f7f=unchanged

--0480-04ff=FPGA control window:

--0480-04BF=Window#1, applies: 2000-3fff, last 6 bits select 8 K page within 512k byte range

--04C0-04DF=Window#2, applies: C000-CFFF, last 5 bits select 4 K page within 128k byte range (low)

--04F8-output pin 1 =GND

--04F9-output pin 1 =VCC

--04FA-output pin 2 =GND

--04FB-output pin 2 =VCC

--3FFC --> write protect top 32k

--04FD --> allow writes to top 32k

--04FE --> write protect top 32k

--2000-3fff=Window#1, 16 K page within 512k byte range

--8000-bfff=unchanged

--C000-CFFF=Window#2, last 5 bits select 4 K page within 128k byte range (low)

--d000-ffff=unchanged

--last locations of external SRAM (7FFFFh-7FFF0h) are automatically diverted to access the SRAM /

--RTC controller chip, which also temporarily disables SRAM I/O.

(

AddrIn[15..0] : input; -- microprocessor address port

Eclk : input; -- sync address latching.

Read : input; -- Rd/Write HC11 output.

Rst : input; -- clr registers

AddrOut[18..12] : output; -- synthesised extra 3 address lines + remapped 4 to RAM

_Oe : output; -- Read inverted, drives /OE - output enable signal.

_We : output; -- /WE - /Write enable, masked areas.

Out1 : output; -- spare

Out2 : output; -- spare

)

variable

LoBank[5..0] : DFF; --8 k chunks

HiBank[4..0] : DFF; --4 k chunks

RamNRom : node; --upper area write lockout option.

OutN1 : node;

OutN2 : node;

begin

---RamNRom.CLRN=Rst; -- default lockout

LoBank[5..0].CLRN=Rst; --reset at all zeros

HiBank[4..0].CLRN=Rst; --reset at all zeros

LoBank[5..0].D=AddrIn[5..0]; --connection path, addr to #1 window latch

HiBank[4..0].D=AddrIn[4..0]; --connection path, addr to #2 window latch

Out1=OutN1;

Out2=OutN2;

if Rst==GND then

RamNRom=GND;

end if;

_Oe=!(Read and Eclk);

If (AddrIn[15] == B"1") & (RamNRom==gnd) then

_We=Vcc; --lock mode

ELSE

_We=!(!Read & Eclk); --unlocked mode

END IF;

IF (AddrIn[15..7] == (H"04",B"1")) & !Read then -- FPGA register address, low order 7 bits set action.

CASE AddrIn[6..0] IS

--RAM lockout control above $7FFF on HC11 bus:

WHEN B"1111110" => -- lock

RamNRom=gnd;

WHEN B"1111101" => -- unlock

RamNRom=vcc;

WHEN B"1111100" => -- lock

RamNRom=gnd;

--Spare outputs:

WHEN B"111100x" => -- Output pin #1

OutN1=AddrIn[0];

WHEN B"111101x" => -- Output pin #2

OutN2=AddrIn[0];

--Low bank select write:

WHEN B"0xxxxxx" => -- Window#1, 4000-7fff

LoBank[].CLK=Eclk;

--High bank select write:

WHEN B"10xxxxx" => -- Window#2, C000-CFFF

HiBank[].CLK=Eclk;

END CASE;

END IF;

CASE AddrIn[15..12] IS

WHEN B"001x" => --Substitute bank @ window#1 2000-3FFF

AddrOut[18..12] = (LoBank[5..0],AddrIn[12]);

WHEN B"1000" => --Substitute bank @ window#2 C000-CFFF

AddrOut[18..12] = (B"00",HiBank[4..0]);

WHEN OTHERS => -- feed through AddrIn[15..12]

AddrOut[18..12] = (B"000",AddrIn[15..12]); -- first block of 64k bytes

END CASE;

end;

--------------------------------------------

Now if I were to do a design for a CNC machine add on, there could be options like Servo PWM outputs, shaft encoders, with readable registers, stepper motor position registers, they are really very flexible devices.

|

Re: Build thread, 100 pin STM Arm Cortex board with driver chips. February 05, 2009 11:27AM |

Registered: 15 years ago Posts: 401 |

> I'm not persuaded to your view yet.

> *I still think that half duplex allows

> synchronisation just fine,

> *I recognise the advantages of full duplex, but I

> think they are inconsequential in this

> application, as there are far more effective ways

> to ensure fast, synchronised response times. My

> idea of a CPLD expansion port as an alternate

> function of the LCD interface, for example, allows

> for a much better degree of synchronisation and

> rapid response, than either full duplex, or baud

> rate increase on RS485.

I appreciate that you said "yet." You still haven't addressed two issues with half-duplex communication.

1) Collision detection/arbitration. How do you propose to address these issues with deterministic timing?

2) The master wants to transmit a sync packet, but there is a slave transmitting a data packet (for example, a mouse sensor has the option of transmitting a pixel-by-pixel image of what the sensor currently sees. This is 484 1-byte pixels, for ~512 byte packet. That's quite a big wait time for a sync packet. So do we interrupt the data packet? If so, what does that look like? If not, how do we guarantee a sync packet with guaranteed timing?

> There are many many ways to implement a CPLD

> expansion, a simple one such as that I outlined in

> my above post, or, for example, one in which the

> CPLD is directly attached to the LCD, and to the

> uC, but where the LCD has no direct connection to

> the uC.

> In such an implementation, the uC reads or writes

> registers in the CPLD, and can make state changes

> to switch which external device is being

> controlled. I've done this before, with a 68HC11,

> using the CPLD to respond to certain addresses on

> the micro, to perform bank select functions

These are really easy to implement, I agree. I have made quite a few CPLD interfaces for the ISA bus (It's still used a lot in the embedded computing industry. See PC/104).

I agree that CPLD's allow easy building of extra peripherals. The concern which has been brought up before is that not many people can either a) write HDL code, or b) debug HDL code.

> *The L293D package incorporates protection diodes,

> but is only rated to 0.6 amps constant.

Use whatever works for you. I would suggest, though, that you consider driving FETs instead of buying an expensive integrated FET driver. Check out my stepper driver thread for more information on how that works.

> The issue here, is that I'm trying to build a

> machine that can potentially serve something like

> 95% of reprapper's typical needs.

>

> I can see you have good ideas for alternative

> output stages, but I'm concerned that the L298N

> package, rated at 1 amp continous, (with

> heatsinking), is not going to meet the vast

> majority's needs. I know your mosfet expansion is

> meant to overcome this, but I'm trying to

> standardise at a higher unamplified power rating

> to make something that's less likely to need a

> boost board in the first place. That, to me, is

> worth the cost difference between an L298 versus

> an L293N.

The point was that it doesn't take much to drive a FET instead of a whole package. For the same price as the L298, you can drive four H-bridges at 5 A each.

> I've glanced at your schematic for a toolhead

> controller, and I can see you have a time

> investment in doing things the way you've already

> decided on. There are going to be standisation

> issues if the main board only does full, or only

> does half duplex, and people want to design slave

> boards to the other standard. I don't have that

> particular investment in time, butt you have a

> conservative bias (conservation of your current

> design work's hours of effort, and/or personal

> investment of PCB costs)

Frankly, I don't care about my time investment. I'm planning to make some changes to it already. I simply care that we make the right design decisions.

> On the other hand, I have these 20 x STM32FVBT103

> chips sitting in my stock, and otherwise, I might

> be looking more seriously at other variants. We

> all have biases, and admitting, disclosing our

> biases to others, allows better understanding of

> other's motives, and more agreeable co-development

> effort.

I understand your decision. I might even make the same one in your situation. It probably won't make a big difference in the long run. Maybe your next gen will be different.

I think the important point is that we decide on an interface standard. Once we've got this full duplex vs. half duplex argument settled, we can move on to the messaging protocol.

> *I still think that half duplex allows

> synchronisation just fine,

> *I recognise the advantages of full duplex, but I

> think they are inconsequential in this

> application, as there are far more effective ways

> to ensure fast, synchronised response times. My

> idea of a CPLD expansion port as an alternate

> function of the LCD interface, for example, allows

> for a much better degree of synchronisation and

> rapid response, than either full duplex, or baud

> rate increase on RS485.

I appreciate that you said "yet." You still haven't addressed two issues with half-duplex communication.

1) Collision detection/arbitration. How do you propose to address these issues with deterministic timing?

2) The master wants to transmit a sync packet, but there is a slave transmitting a data packet (for example, a mouse sensor has the option of transmitting a pixel-by-pixel image of what the sensor currently sees. This is 484 1-byte pixels, for ~512 byte packet. That's quite a big wait time for a sync packet. So do we interrupt the data packet? If so, what does that look like? If not, how do we guarantee a sync packet with guaranteed timing?

> There are many many ways to implement a CPLD

> expansion, a simple one such as that I outlined in

> my above post, or, for example, one in which the

> CPLD is directly attached to the LCD, and to the

> uC, but where the LCD has no direct connection to

> the uC.

> In such an implementation, the uC reads or writes

> registers in the CPLD, and can make state changes

> to switch which external device is being

> controlled. I've done this before, with a 68HC11,

> using the CPLD to respond to certain addresses on

> the micro, to perform bank select functions

These are really easy to implement, I agree. I have made quite a few CPLD interfaces for the ISA bus (It's still used a lot in the embedded computing industry. See PC/104).

I agree that CPLD's allow easy building of extra peripherals. The concern which has been brought up before is that not many people can either a) write HDL code, or b) debug HDL code.

> *The L293D package incorporates protection diodes,

> but is only rated to 0.6 amps constant.

Use whatever works for you. I would suggest, though, that you consider driving FETs instead of buying an expensive integrated FET driver. Check out my stepper driver thread for more information on how that works.

> The issue here, is that I'm trying to build a

> machine that can potentially serve something like

> 95% of reprapper's typical needs.

>

> I can see you have good ideas for alternative

> output stages, but I'm concerned that the L298N

> package, rated at 1 amp continous, (with

> heatsinking), is not going to meet the vast