|

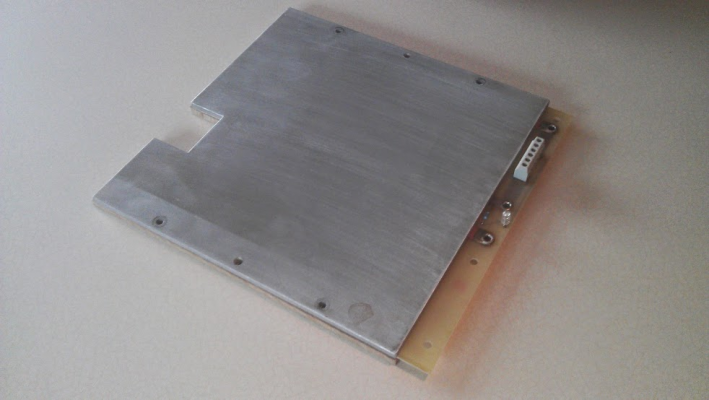

Mendel Heatbed PCB. 12v, 80w. June 17, 2013 06:17PM |

Registered: 10 years ago Posts: 75 |

Attached is the Eagle PCB file for my Mendel Heatbed PCB. its (nearly) the same dimensions as the Aluminium bed on a Mendel.

It requires some knowledge of PCB fabrication / sourcing, as well as basic tools, drill etc. Plus some extra parts, nuts, bolts, washers and a hand full of components.

Its a sandwich design using a 6mm MDF sheet as a bottom insulator and the original aluminium bed on top with my PCB in the middle.

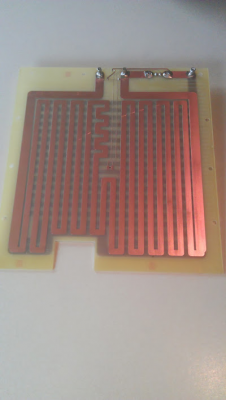

Here is the underside before I insulated it with Kapton tape......

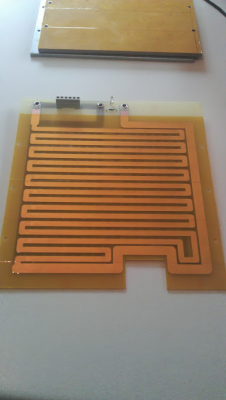

...and the topside after I had finished.

OK, this is what I did....

Firstly make a PCB.

Once you have done that offer it up to the aluminium bed and use it as a drilling template to mark all of your hole centers.

This consists of blind hole in the middle of the bed for a thermocouple / thermister. Mine was 2mm diameter and 4mm deep.

If you look at the top picture you may notice that my bed has 6 holes for nuts and bolts, you will need to drill a hole between the two existing bolts on each side. this allows our sandwich to stay together when secured with nuts and bolts.

A great advantage may be to convert the bed into a three point leveling system and have 3 bolts to secure the layers!

Use your aluminium bed as a drilling / cutting template for you insulator!

You may or may not want to drill a center hole for a thermocouple at this point depending on what your planning.

The PCB does have pads in the middle for a thermistor which are broken out to the main connector at the PCB's edge. I haven't tried this approach yet as Im planning to use an old PID with a K-type thermocuople for the moment.

Grab some Kapton tape and insulate both sides of your PCB, make sure this area is bigger than your aluminium plate.

Stick a layer of tape onto you MDF in the top / inside side, This is optional but I did it to minimize the MDF 'Toasting' smell as it beds in, however it doesn't smell hot at all.

Soldering time.

I'm making the assumption that you or a friend can solder a board up so...

Solder your 1k resistor (assuming your gonna run this thing on 12v) your led and your .2" connector to the PCB connect both layers together. I used budget 4mm pcb sockets, soldered on both sides of the board, if you cant find them, I'm sure M5 nuts and bolts will do the trick.

The next step is to put down the soldering iron and pick up some heat transfer compound and smear it onto the underside of your aluminium bed.

Fill your blind hole up to the top.

Place your hotbed PCB onto the aluminium bed, upside down, with your thermistor pads up. install chosen thermistor, solder it down.

Place the insulating layer on top of the PCB and install your new middle nuts and bolts to secure your sandwich.

Your nearly done at this point, put the other 4 nuts and bolts in the holes and test out your hotbed before installation, do this somewhere safe and have a means of controlling you temperature setpoint. When left connected directly to an 8 amp supply my hotbed levels out at 108.9c.

Once you are happy that you have made a safe, working hotbed fit it to your Mendel as you would but with one slight mod... cut your standard printed bed springs into an S shape, loosing the 7mm you have just gained by installing the hotplate to the aluminium bed.

Use some strain relief on your wires by making use of the provided holes on the back edge of your hotplate PCB and your ready to go.

Enjoy.

Edited 1 time(s). Last edit at 06/18/2013 05:13AM by slymike.

It requires some knowledge of PCB fabrication / sourcing, as well as basic tools, drill etc. Plus some extra parts, nuts, bolts, washers and a hand full of components.

Its a sandwich design using a 6mm MDF sheet as a bottom insulator and the original aluminium bed on top with my PCB in the middle.

Here is the underside before I insulated it with Kapton tape......

...and the topside after I had finished.

OK, this is what I did....

Firstly make a PCB.

Once you have done that offer it up to the aluminium bed and use it as a drilling template to mark all of your hole centers.

This consists of blind hole in the middle of the bed for a thermocouple / thermister. Mine was 2mm diameter and 4mm deep.

If you look at the top picture you may notice that my bed has 6 holes for nuts and bolts, you will need to drill a hole between the two existing bolts on each side. this allows our sandwich to stay together when secured with nuts and bolts.

A great advantage may be to convert the bed into a three point leveling system and have 3 bolts to secure the layers!

Use your aluminium bed as a drilling / cutting template for you insulator!

You may or may not want to drill a center hole for a thermocouple at this point depending on what your planning.

The PCB does have pads in the middle for a thermistor which are broken out to the main connector at the PCB's edge. I haven't tried this approach yet as Im planning to use an old PID with a K-type thermocuople for the moment.

Grab some Kapton tape and insulate both sides of your PCB, make sure this area is bigger than your aluminium plate.

Stick a layer of tape onto you MDF in the top / inside side, This is optional but I did it to minimize the MDF 'Toasting' smell as it beds in, however it doesn't smell hot at all.

Soldering time.

I'm making the assumption that you or a friend can solder a board up so...

Solder your 1k resistor (assuming your gonna run this thing on 12v) your led and your .2" connector to the PCB connect both layers together. I used budget 4mm pcb sockets, soldered on both sides of the board, if you cant find them, I'm sure M5 nuts and bolts will do the trick.

The next step is to put down the soldering iron and pick up some heat transfer compound and smear it onto the underside of your aluminium bed.

Fill your blind hole up to the top.

Place your hotbed PCB onto the aluminium bed, upside down, with your thermistor pads up. install chosen thermistor, solder it down.

Place the insulating layer on top of the PCB and install your new middle nuts and bolts to secure your sandwich.

Your nearly done at this point, put the other 4 nuts and bolts in the holes and test out your hotbed before installation, do this somewhere safe and have a means of controlling you temperature setpoint. When left connected directly to an 8 amp supply my hotbed levels out at 108.9c.

Once you are happy that you have made a safe, working hotbed fit it to your Mendel as you would but with one slight mod... cut your standard printed bed springs into an S shape, loosing the 7mm you have just gained by installing the hotplate to the aluminium bed.

Use some strain relief on your wires by making use of the provided holes on the back edge of your hotplate PCB and your ready to go.

Enjoy.

Edited 1 time(s). Last edit at 06/18/2013 05:13AM by slymike.

|

Re: Mendel Heatbed PCB. 12v, 80w. June 21, 2013 07:56AM |

Registered: 10 years ago Posts: 75 |

|

Re: Mendel Heatbed PCB. 12v, 80w. June 26, 2013 10:04PM |

Registered: 10 years ago Posts: 2 |

|

Re: Mendel Heatbed PCB. 12v, 80w. June 27, 2013 05:13AM |

Registered: 10 years ago Posts: 75 |

Nice, let me know how it goes and thanks for the feedback!!

This heater is good for PLA, although I got mine to settle at 108.9c, in the real world (with a 80mm fan pointing at it) it would take ages to heat up to ABS temps when running on 12v.

I have set mine to 70c for the first layer and 65 for all other layers. It holds heat well once up to temp and stays consistant.

I added a bit of gcode at the end of the print to keep it at 65c so I dont have to wait too long for the next 0.5mm thin wall to print.......and I have been making alot of them!!

This heater is good for PLA, although I got mine to settle at 108.9c, in the real world (with a 80mm fan pointing at it) it would take ages to heat up to ABS temps when running on 12v.

I have set mine to 70c for the first layer and 65 for all other layers. It holds heat well once up to temp and stays consistant.

I added a bit of gcode at the end of the print to keep it at 65c so I dont have to wait too long for the next 0.5mm thin wall to print.......and I have been making alot of them!!

Sorry, only registered users may post in this forum.