T-Bone: A radically new Reprap Board

Posted by InteractiveMatter

|

T-Bone: A radically new Reprap Board April 01, 2014 12:06PM |

Registered: 11 years ago Posts: 14 |

Hi,

we are currently developing new Reprap Board: The T-Bone.

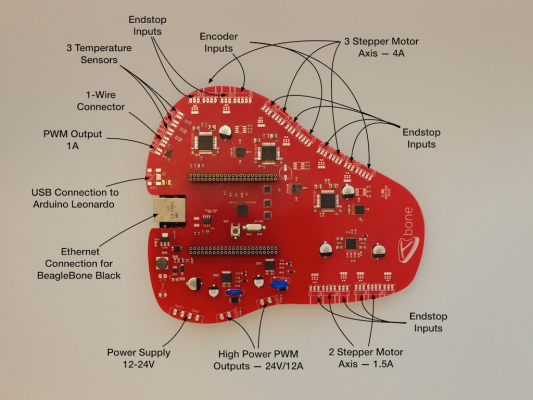

The T-Bone first of all is a board aimed at driving a complete Mendel printer. It got:

12-24V operating voltage

5 stepper motor driver

10 inputs for end switches

3 inputs for incremental encoders (3 axis supporting closed loop control)

3 inputs for thermistors

1-wire interface for digital tempsensors

2 high power outputs (for extruder and heatbed)

2 mid power output (for fans, LEDs, …)

But the hidden features is where it really shines:

It uses motion controllers from Trinamic which enable us to:

This enables us to implement the whole 3D Printer -like axis coordination and path planning in python. So we can realize features like the most advanced firmwares but with much more potential for adaptions dn optimization since the code is easy to understand and change. Timing and performance is much more relaxed since more buffers are used to cache recalculated values.

Furthermore we can give the printer a nice web interface and make it a complete stand alone appliance.

Currently we are trying to get funding for manufacturing at Indiegogo. So we are happy if you can support us with funding or intelligent questions and suggestions …

What do you think?

Is it something you consider useful?

Is the t-bone interesting for you?

What is missing?

Thanks

Marcus

we are currently developing new Reprap Board: The T-Bone.

The T-Bone first of all is a board aimed at driving a complete Mendel printer. It got:

12-24V operating voltage

5 stepper motor driver

10 inputs for end switches

3 inputs for incremental encoders (3 axis supporting closed loop control)

3 inputs for thermistors

1-wire interface for digital tempsensors

2 high power outputs (for extruder and heatbed)

2 mid power output (for fans, LEDs, …)

But the hidden features is where it really shines:

It uses motion controllers from Trinamic which enable us to:

- Leave the positiong of the stepper motors to the motion controller ICs

- Drive the motors with constant jerk in a nice S-Motion ramp. The force on the mechanic is slowly increased during acceleration - reducing the stress and enabling driving at much higher speed.

- Reduce the real-time control requirements

This enables us to implement the whole 3D Printer -like axis coordination and path planning in python. So we can realize features like the most advanced firmwares but with much more potential for adaptions dn optimization since the code is easy to understand and change. Timing and performance is much more relaxed since more buffers are used to cache recalculated values.

Furthermore we can give the printer a nice web interface and make it a complete stand alone appliance.

Currently we are trying to get funding for manufacturing at Indiegogo. So we are happy if you can support us with funding or intelligent questions and suggestions …

What do you think?

Is it something you consider useful?

Is the t-bone interesting for you?

What is missing?

Thanks

Marcus

|

Re: T-Bone: A radically new Reprap Board April 02, 2014 03:09AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: T-Bone: A radically new Reprap Board April 02, 2014 03:59AM |

Registered: 11 years ago Posts: 14 |

Hehe,

yes - the form factor of the PCB is something like a indiiegogo campaign special. We are currently discussing to release a square version. I think it will come in the long run. BTW if you are interested how the chips are used in the software I have created a short writeup:

[www.tbone.cc]

Thanks for your feedback

Marcus

yes - the form factor of the PCB is something like a indiiegogo campaign special. We are currently discussing to release a square version. I think it will come in the long run. BTW if you are interested how the chips are used in the software I have created a short writeup:

[www.tbone.cc]

Thanks for your feedback

Marcus

|

Re: T-Bone: A radically new Reprap Board April 02, 2014 08:08PM |

Registered: 10 years ago Posts: 903 |

|

Re: T-Bone: A radically new Reprap Board April 03, 2014 03:08AM |

Registered: 11 years ago Posts: 14 |

Quote

vreihen

While you're shooting people, don't forget to throw some lead into the person who forgot to put mounting holes in the PCB.....

No problem - we just drill the hole after fabrication …

Honestly the board you are seeing is a proof of concept how it will look in the end. The final version has more holes in it (6 to be really specific) and the square one will most probably have even more holes

|

Re: T-Bone: A radically new Reprap Board April 03, 2014 03:13AM |

Registered: 11 years ago Posts: 14 |

|

Re: T-Bone: A radically new Reprap Board April 03, 2014 06:43AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: T-Bone: A radically new Reprap Board April 03, 2014 11:00AM |

Registered: 11 years ago Posts: 14 |

|

Re: T-Bone: A radically new Reprap Board April 03, 2014 01:38PM |

Registered: 13 years ago Posts: 1,352 |

|

Re: T-Bone: A radically new Reprap Board April 04, 2014 03:26AM |

Registered: 11 years ago Posts: 14 |

Yes and no (but yes).

Yes there will be firmware for this board. It consist of several parts:

- The 3d Printing is done in Python and the motion controller control in C on an Arduino.

A bit more details on the software architecture are revealed on the T-Bone blog.

Currently there is no way in the software to upload your own current tables for the motors.But there is no reason to not do so. In development there are just some other priorities until now. But I would be happy to help and provide information to integrate this into the firmware.

For others who may not know this feature:

The trinamic motion controllers allow to configure a lot of details of the motor chopper providing the motor current and the current per winding depending on the current micro step for precise and smooth motor operation. This is all done in software so that it is pretty easy to provide external configuration for this to configure you motor for best performance.

Edited 1 time(s). Last edit at 04/04/2014 03:27AM by InteractiveMatter.

Yes there will be firmware for this board. It consist of several parts:

- The 3d Printing is done in Python and the motion controller control in C on an Arduino.

A bit more details on the software architecture are revealed on the T-Bone blog.

Currently there is no way in the software to upload your own current tables for the motors.But there is no reason to not do so. In development there are just some other priorities until now. But I would be happy to help and provide information to integrate this into the firmware.

For others who may not know this feature:

The trinamic motion controllers allow to configure a lot of details of the motor chopper providing the motor current and the current per winding depending on the current micro step for precise and smooth motor operation. This is all done in software so that it is pretty easy to provide external configuration for this to configure you motor for best performance.

Edited 1 time(s). Last edit at 04/04/2014 03:27AM by InteractiveMatter.

|

Re: T-Bone: A radically new Reprap Board April 04, 2014 08:59AM |

Registered: 11 years ago Posts: 14 |

I have explained the configuration possibilities a bit more in the blog [www.tbone.cc]

|

Re: T-Bone: A radically new Reprap Board April 04, 2014 11:04AM |

Registered: 13 years ago Posts: 1,352 |

|

Re: T-Bone: A radically new Reprap Board April 04, 2014 11:04AM |

Registered: 10 years ago Posts: 869 |

+1. The size is ridiculous. Production costs could be decreased and/or yield increased with a more compact design unless there's some unseen design limitation that requires such a big board. I'm not ashamed of my electronics and don't mind showing them off, but I don't want them to be the focal point. Plus wiring is going to be all over the place with that layout.Quote

Dust

I think your marketing division needs to be shot!

The shape makes it dumb and unusable.

Other weird things is 10 end stop connections, but only 3 PWM outputs. Go hog wild (or should that be beef wild) with the stops most people at least in the RepRap community will never use or need but have just a single fan (or some other lower power device) seems backwards. I much rather have 5 or 6 end stops and 5 or 6 PWM outputs to control extra fans, maybe some LEDs for lighting, etc.

The naming of the different funding goal levels of the indigogo campaign is also off: 22.5k€ Filet Mignon, 25k€ Rib-Eye, 30k€ Porterhouse, 40k€ Sirloin, 50k€ Tenderloin. Have you guys ever been to a steak house? A serloin at nearly twice the level of of a filet? Why not have a 75k€ level of ground chuck and 100k€ of gristle just in case. I'll take the 22.5 filet, you can keep the 40 sirloin.

|

Re: T-Bone: A radically new Reprap Board April 04, 2014 11:22AM |

Registered: 11 years ago Posts: 14 |

Quote

cdru

+1. The size is ridiculous. Production costs could be decreased and/or yield increased with a more compact design unless there's some unseen design limitation that requires such a big board. I'm not ashamed of my electronics and don't mind showing them off, but I don't want them to be the focal point. Plus wiring is going to be all over the place with that layout.Quote

Dust

I think your marketing division needs to be shot!

The shape makes it dumb and unusable.

Stay tuned - we are working on that issue!

Quote

Dust

Other weird things is 10 end stop connections, but only 3 PWM outputs. Go hog wild (or should that be beef wild) with the stops most people at least in the RepRap community will never use or need but have just a single fan (or some other lower power device) seems backwards. I much rather have 5 or 6 end stops and 5 or 6 PWM outputs to control extra fans, maybe some LEDs for lighting, etc.

The endstops and encoders are directly handled by the motion drivers - so it is merely just breaking out some pins to connectors. On the other hand we are discussing to add another mid power PWM channel …

Thanks for the feedback

Marcus

PS: Thanks for the kind words

|

Re: T-Bone: A radically new Reprap Board April 04, 2014 11:27PM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: T-Bone: A radically new Reprap Board April 05, 2014 09:06AM |

Registered: 10 years ago Posts: 903 |

|

Re: T-Bone: A radically new Reprap Board April 06, 2014 03:37AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: T-Bone: A radically new Reprap Board April 07, 2014 07:30PM |

Registered: 11 years ago Posts: 142 |

Hmm, interesting project. I'm inspired to play with the TMC2660 drivers now. However, I was looking around your site and couldn't find what motion controller IC is used. It's labeled as 4361 on the block diagram, but I can't find any motion controller chips with that number.

Also, I'd like to see how your motion control is done with these chips, but can't find any code anywhere. You say open source a lot in your video, but I can't actually find any sources.

Also, I'd like to see how your motion control is done with these chips, but can't find any code anywhere. You say open source a lot in your video, but I can't actually find any sources.

|

Re: T-Bone: A radically new Reprap Board April 08, 2014 02:34AM |

Registered: 11 years ago Posts: 14 |

Quote

TopherMan

Hmm, interesting project. I'm inspired to play with the TMC2660 drivers now. However, I was looking around your site and couldn't find what motion controller IC is used. It's labeled as 4361 on the block diagram, but I can't find any motion controller chips with that number.

Also, I'd like to see how your motion control is done with these chips, but can't find any code anywhere. You say open source a lot in your video, but I can't actually find any sources.

Hi,

you are right … the motion controller is yet to be released by Trinamic - we have the privilege to work with a prerelease version. And you cannot find the software right now. It will be released as Open Source (due to other sources we used we are bound to GPL v3). We will release it together with the product release.

Marcus

|

Re: T-Bone: A radically new Reprap Board April 11, 2014 02:29PM |

Registered: 13 years ago Posts: 19 |

Quote

vreihen

I'm surprised that nobody pointed out the obvious global marketing problem caused because some major cultures around the world don't eat beef, and at least one big player worships cows as gods which could actually make your product name offensive to them.....

I'm surprised how many people hook onto the design aspect, which is imho absolutly unimportant in an open source project where everybody is free to use the building plans to give it a design of his own choice.

What counts more is the whole bunch of new features, which are to my knowledge uniqe, at least i dont know about other controllers which offers the same.

So i would love to see a discussion which is more focused on the technical details and the benefits and possibilities of this features, especially since the indiegogo-campaign is still running and more supporters are still welcome. I am one of the supporters and i really would appreciate to see this project coming into life.

|

Re: T-Bone: A radically new Reprap Board April 11, 2014 03:05PM |

Registered: 11 years ago Posts: 14 |

Quote

case

…

What counts more is the whole bunch of new features, which are to my knowledge uniqe, at least i dont know about other controllers which offers the same.

So i would love to see a discussion which is more focused on the technical details and the benefits and possibilities of this features, especially since the indiegogo-campaign is still running and more supporters are still welcome. I am one of the supporters and i really would appreciate to see this project coming into life.

Yea that is the interesting question for me: What do you like and what don't you like about the features?

|

Re: T-Bone: A radically new Reprap Board April 11, 2014 03:41PM |

Registered: 13 years ago Posts: 1,352 |

I am thinking about

I like very much the closed loops, that would be awesome. I said it before but again, the trinamic chips are awesome too, and the level of configuration would be as far as i know unprecedented for reprap. I think this project did not received all the praise it should. Its a big leap forward. Now either i am too excited about these features because i think are long overdue for reprap, or others ppls are overlooking them - to be fair, but probably both.

Edited 1 time(s). Last edit at 04/11/2014 04:03PM by NoobMan.

3 inputs for incremental encoders (3 axis supporting closed loop control)Reprap is by all means 4 axes, where the extruder is the 4th dimension - and the most important one. So i think it makes sense to have 4 closed loops. Only 3 closed loops would be limited to applications like a milling head. Using closed loops means what i believe is named hybrid stepper, sort of speaking a stepper which is able to keep its current low and otherwise increase its own current only when its actually needed, sort of like a servo. This would be an awesome thing. The commercial drivers that do stuff like this are prohibitively expensive. So i think the feature is totally worth it - but at least 4th is required. But well, since the board has 5 steppers, me for one i would give loops to all of them.

I like very much the closed loops, that would be awesome. I said it before but again, the trinamic chips are awesome too, and the level of configuration would be as far as i know unprecedented for reprap. I think this project did not received all the praise it should. Its a big leap forward. Now either i am too excited about these features because i think are long overdue for reprap, or others ppls are overlooking them - to be fair, but probably both.

Edited 1 time(s). Last edit at 04/11/2014 04:03PM by NoobMan.

|

Re: T-Bone: A radically new Reprap Board April 11, 2014 04:09PM |

Registered: 11 years ago Posts: 14 |

Quote

NoobMan

I am thinking about

3 inputs for incremental encoders (3 axis supporting closed loop control)Reprap is by all means 4 axes, where the extruder is the 4th dimension - and the most important one. So i think it makes sense to have 4 closed loops. Only 3 closed loops would be limited to applications like a milling head. Using closed loops means what i believe is named hybrid stepper, sort of speaking a stepper which is able to keep its current low and otherwise increase its own current only when its actually needed, sort of like a servo. This would be an awesome thing. The commercial drivers that do stuff like this are prohibitively expensive. So i think the feature is totally worth it - but at least 4th is required. But well, since the board has 5 steppers ...

Thanks for the hint. But don't forget that you have 5 Axis available. 2 Axis are a bit less powerful and have constant acceleration.

But your view of the closed loop drive is a bit different than it is implemented: Of course the motion drivers can increase or decrease the current in stand still, acceleration, run and high speed run (yes!). Driving them closed loop with encoders transform the stepper motors into servos. So the driver itself maintains the position of the motor no matter if it looses steps or not - those are detected with the encoder and it is automatically corrected.

|

Re: T-Bone: A radically new Reprap Board April 11, 2014 04:51PM |

Registered: 13 years ago Posts: 1,352 |

Yes on second thought i think could use it like 3 closed loop for x, y and e, while leaving z open loop, this way could stick with 3 closed loops in sort of a 3.5D movement, where z only counts for 0.5 of an axis as it is used only between slices.

And i believe we are both thinking at the same thing with the closed loop. Just an wording difference of "hybrid". I thought these kinds of steppers are named "hybrid drives" as in they get commands by a step and are basically stepper drivers and motors, except they can push the "current" pedal when needed because the encoder lets them know when they need to do that to keep up position. I avoid label of pure servo, because the width of the pulse is not related to velocity or position, and they still use steppers instead of dc or ac motors. Not sure if the term "hybrid" is actually correct, but seems suitable. Anyway again, just a wording difference.

About practical use, i would rather set the start current low, and have low consumption when the motor stays still, and then it will detect itself losses and supply more current only when necessary. This means they will run much more efficient and much more cooler. In relation to the long print time, could feel some energy savings.

And i believe we are both thinking at the same thing with the closed loop. Just an wording difference of "hybrid". I thought these kinds of steppers are named "hybrid drives" as in they get commands by a step and are basically stepper drivers and motors, except they can push the "current" pedal when needed because the encoder lets them know when they need to do that to keep up position. I avoid label of pure servo, because the width of the pulse is not related to velocity or position, and they still use steppers instead of dc or ac motors. Not sure if the term "hybrid" is actually correct, but seems suitable. Anyway again, just a wording difference.

About practical use, i would rather set the start current low, and have low consumption when the motor stays still, and then it will detect itself losses and supply more current only when necessary. This means they will run much more efficient and much more cooler. In relation to the long print time, could feel some energy savings.

|

Re: T-Bone: A radically new Reprap Board April 11, 2014 04:51PM |

Registered: 13 years ago Posts: 19 |

Quote

InteractiveMatter

What do you like and what don't you like about the features?

First at all, i'm not a big electronics-nerd, so i see this merely from a normal consumers point of view.

I have no really dislikes at any of the features, the worst thing i may say is, that its not a small number of them what makes it harder for me to understand it

.

.Because i own a Beagleboneblack i am interested in 3d-printer capes for it and so i was watching Replicape and ReplicapePlus and now T-Bone has my attention

as a promising project by a competent team and hopefully an interested user-community in the near future.

I also like the fact, that with higher amperage for the stepper motors, one can use stronger motors. So it can be used in small cnc-applications as well and fills perfectly the gap between pololu and powerlolu and may have also some benefits in printer-applications.

1/256-Microstepping sounds interesting to me. I have no experience with such a resolution so far and therefore it surely would be fun to test it - in the best case we can achieve even a signifikant higher resolution in 3D-printing-quality

The stallguard is also new to me and if it really works well, it may offer an occasion to save some costs for other stoppers and even better to reduce the cabling-tree.

There may be other things which i cannot really survey from here, but of course i will be happy if i can discover later further nice things the board can do.

So i continue with pressing my thumbs for that project.

|

Re: T-Bone: A radically new Reprap Board April 11, 2014 06:17PM |

Registered: 13 years ago Posts: 1,352 |

|

Re: T-Bone: A radically new Reprap Board April 11, 2014 08:00PM |

Registered: 10 years ago Posts: 903 |

Quote

NoobMan

Yes on second thought i think could use it like 3 closed loop for x, y and e, while leaving z open loop, this way could stick with 3 closed loops in sort of a 3.5D movement, where z only counts for 0.5 of an axis as it is used only between slices.

So, you essentially are saying that you want to make the thing a paperweight in a Delta application, where X, Y, and Z all need to move at the same resolution.....

|

Re: T-Bone: A radically new Reprap Board April 12, 2014 12:02AM |

Registered: 13 years ago Posts: 1,352 |

What i meant was something else, for a cartesian bot which completes a layer / slice, by moving X and Y together. Then the Z is used, but in separate movements, distinct from x and y, because Z is just sort of a layer change. I believe this is commonly called 2.5D in a generic machine. We use an extruder for toolhead, that adds up as a full dimension because it is used together with x and y. But in our case, for printers, we still use Z separate. We print a slice, then move to the next one, this is how it works. We do not print with movements which include Z. So this is x+y+e counting as 1 each, and with Z like that we have somewhat of a 3.5D space. To have full 4D, we would have to deposit plastic in Z direction, that is in a diagonal move across multiple layers, but we do not do that.

In a delta you could use the 3 closed loops for the 3 motors and then you will have to use z and also extruder in open loop. It still would work a bit better if there were 4 closed loops to include extruder. Also on a separate note, the resolution and closed loop are different concepts and not related. Also you would not have to use the closed loop, its not something mandatory but optional. Or better yet, this is rather a sort of a wishlist feature, since no reprap has that now. Currently reprap drivers are open loop.

In a delta you could use the 3 closed loops for the 3 motors and then you will have to use z and also extruder in open loop. It still would work a bit better if there were 4 closed loops to include extruder. Also on a separate note, the resolution and closed loop are different concepts and not related. Also you would not have to use the closed loop, its not something mandatory but optional. Or better yet, this is rather a sort of a wishlist feature, since no reprap has that now. Currently reprap drivers are open loop.

|

Re: T-Bone: A radically new Reprap Board April 17, 2014 02:46AM |

Registered: 11 years ago Posts: 14 |

Quote

NoobMan

What i meant was something else, for a cartesian bot which completes a layer / slice, by moving X and Y together. Then the Z is used, but in separate movements, distinct from x and y, because Z is just sort of a layer change. I believe this is commonly called 2.5D in a generic machine. We use an extruder for toolhead, that adds up as a full dimension because it is used together with x and y. But in our case, for printers, we still use Z separate. We print a slice, then move to the next one, this is how it works. We do not print with movements which include Z. So this is x+y+e counting as 1 each, and with Z like that we have somewhat of a 3.5D space. To have full 4D, we would have to deposit plastic in Z direction, that is in a diagonal move across multiple layers, but we do not do that.

Yes, we just have included the stack ability of the T-Bones. With 1 T-Bone you have 3 coordinated and 2 controlled Axis - excellent for cartesian bots, since you can coordinate X,Y and the extruder together. The two controlled axis are used for the two Z motors. With two T-Bone Boards stacked over each other you have 6 coordinated axis - this should be enough for X,Y, some extruders and some Z motors …

Quote

NoobMan

In a delta you could use the 3 closed loops for the 3 motors and then you will have to use z and also extruder in open loop. It still would work a bit better if there were 4 closed loops to include extruder. Also on a separate note, the resolution and closed loop are different concepts and not related. Also you would not have to use the closed loop, its not something mandatory but optional. Or better yet, this is rather a sort of a wishlist feature, since no reprap has that now. Currently reprap drivers are open loop.

Thanks - but the coordinated motors can go closed loop - so we got you covered here

|

Re: T-Bone: A radically new Reprap Board April 17, 2014 11:36AM |

Admin Registered: 11 years ago Posts: 3,096 |

All sounds nice, the only thing that I would demand is more Mid-power outputs:

2 mid power output (for fans, LEDs, …)

Only 2 is not enough for me. I already use 5 with a breakout board from Gadgets3D, however, it would ofcourse have it's quality if the board could run around 5 different fans/LED's.

And finally, the size, but I think this has been covered in this topic before, so please, keep in mind. Keep things square, and small. Put the traces tighter together and more efficient, and maybe make it a 2-layer PCB?

Your options are very interesting, I hope it's serious

Edited 1 time(s). Last edit at 04/17/2014 11:39AM by Ohmarinus.

2 mid power output (for fans, LEDs, …)

Only 2 is not enough for me. I already use 5 with a breakout board from Gadgets3D, however, it would ofcourse have it's quality if the board could run around 5 different fans/LED's.

And finally, the size, but I think this has been covered in this topic before, so please, keep in mind. Keep things square, and small. Put the traces tighter together and more efficient, and maybe make it a 2-layer PCB?

Your options are very interesting, I hope it's serious

Edited 1 time(s). Last edit at 04/17/2014 11:39AM by Ohmarinus.

Sorry, only registered users may post in this forum.