Low cost 32-bit controller board

Posted by dc42

|

Low cost 32-bit controller board February 20, 2015 07:12AM |

Registered: 10 years ago Posts: 14,672 |

I have done some preliminary design work for a low-cost 32-bit 3D printer controller board. The idea is to make a board that would cost less than Arduino Mega/RAMPS clones to build in quantity, but have much more processor power and so capable of running more advanced software. My provisional specification is:

* ATSAM3S4B processor (which costs less than half the price of ATMEGA2560), 64MHz clock speed, 256K flash, 48K RAM, native USB port.

* 5 stepper driver sockets (XYZ plus 2 extruders). Each would accept either a standard stepstick-type driver, or a modified stepstick with an additional pin for digital current control.

* Two Z motor connectors to make it easy to connect two motors in series.

* One heated bed output, rated at 20A.

* Two hot end heater outputs rated at 10A.

* Two outputs for 12V fans etc., one with PWM, the other without.

* Three endstop inputs

* Three thermistor inputs

* A 4-pin connector for supporting several different kinds of Z probe.

* Digital control of stepper motor current (when modified stepsticks are used) split into 2 channels. One channel would control the XYZ currents, the other would control the extruder motor currents.

* 12 to 24V (max 30V) input voltage range.

* On-board 5V 1A regulator, probably a linear one for simplicity and low cost, with provision for attaching a heatsink.

* On-board SDHC card socket.

* Expansion connector with about 8 or 10 I/O lines, for connecting control panels, servos, etc.

Before I put any more work into this, I would like to know whether others think there is a market for such a board. There is already one low-cost 32-bit board - the AZSMZ Mini, which has many of the same features (but not the digital stepper motor current control) and costs $60 plus shipping from China and import tax. Another factor is that many people who are looking for something better than Arduino/RAMPS may rather pay extra and buy a board with Ethernet support, of which there are already several (Duet, Smoothie, and the recently-announced Alligator).

Comments please?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

* ATSAM3S4B processor (which costs less than half the price of ATMEGA2560), 64MHz clock speed, 256K flash, 48K RAM, native USB port.

* 5 stepper driver sockets (XYZ plus 2 extruders). Each would accept either a standard stepstick-type driver, or a modified stepstick with an additional pin for digital current control.

* Two Z motor connectors to make it easy to connect two motors in series.

* One heated bed output, rated at 20A.

* Two hot end heater outputs rated at 10A.

* Two outputs for 12V fans etc., one with PWM, the other without.

* Three endstop inputs

* Three thermistor inputs

* A 4-pin connector for supporting several different kinds of Z probe.

* Digital control of stepper motor current (when modified stepsticks are used) split into 2 channels. One channel would control the XYZ currents, the other would control the extruder motor currents.

* 12 to 24V (max 30V) input voltage range.

* On-board 5V 1A regulator, probably a linear one for simplicity and low cost, with provision for attaching a heatsink.

* On-board SDHC card socket.

* Expansion connector with about 8 or 10 I/O lines, for connecting control panels, servos, etc.

Before I put any more work into this, I would like to know whether others think there is a market for such a board. There is already one low-cost 32-bit board - the AZSMZ Mini, which has many of the same features (but not the digital stepper motor current control) and costs $60 plus shipping from China and import tax. Another factor is that many people who are looking for something better than Arduino/RAMPS may rather pay extra and buy a board with Ethernet support, of which there are already several (Duet, Smoothie, and the recently-announced Alligator).

Comments please?

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 20, 2015 11:02AM |

Registered: 9 years ago Posts: 1,159 |

|

Re: Low cost 32-bit controller board February 20, 2015 11:15AM |

Registered: 9 years ago Posts: 55 |

Should be feasible, I'm in the design, please look forward to, thank you!

New 32 bit ARM based Motion controller for 3D printers, CNC Machines and Laser cutters. Like Azteeg x5 mini or smoothieboard(no network).

AZSMZ Mini [www.ebay.com] [bancuit.aliexpress.com]

AZSMZ 12864 LCD [www.ebay.com] [bancuit.aliexpress.com] [azsmz.aliexpress.com]

SMART RAMPS [www.ebay.com] [bancuit.aliexpress.com] [azsmz.aliexpress.com]

[www.facebook.com]

New 32 bit ARM based Motion controller for 3D printers, CNC Machines and Laser cutters. Like Azteeg x5 mini or smoothieboard(no network).

AZSMZ Mini [www.ebay.com] [bancuit.aliexpress.com]

AZSMZ 12864 LCD [www.ebay.com] [bancuit.aliexpress.com] [azsmz.aliexpress.com]

SMART RAMPS [www.ebay.com] [bancuit.aliexpress.com] [azsmz.aliexpress.com]

[www.facebook.com]

|

Re: Low cost 32-bit controller board February 20, 2015 11:47AM |

Registered: 10 years ago Posts: 903 |

My £0.013 (two cents USD) is that to keep the cost down for use as a 32-bit board for the masses, it needs on-board, ribbon cable header-compatible support for the two common LCD drivers from the RAMPS platform, namely the LCD-2004 and the RRD GLCD-12864. No piggyback boards for this feature. This is purely because these boards are so common that the pricing is low, not because they are the best options.

With that said, I would not be a customer for such a pedestrian, under-powered board, but do think that it would be something that could drag the RepRap community into the 32-bit generation with minimal kicking and screaming. If you brand the firmware "DC42's Marlin" instead of what it is currently branded, everyone will buy it.....

board, but do think that it would be something that could drag the RepRap community into the 32-bit generation with minimal kicking and screaming. If you brand the firmware "DC42's Marlin" instead of what it is currently branded, everyone will buy it.....

With that said, I would not be a customer for such a pedestrian, under-powered

board, but do think that it would be something that could drag the RepRap community into the 32-bit generation with minimal kicking and screaming. If you brand the firmware "DC42's Marlin" instead of what it is currently branded, everyone will buy it.....

board, but do think that it would be something that could drag the RepRap community into the 32-bit generation with minimal kicking and screaming. If you brand the firmware "DC42's Marlin" instead of what it is currently branded, everyone will buy it.....

|

Re: Low cost 32-bit controller board February 20, 2015 11:51AM |

Registered: 10 years ago Posts: 903 |

Another suggestion to make an improvement on the current status quo. I don't know how much a couple thermocouple interface chips cost, but having them on-board might drive the adoption of that superior technology over time. The reason why I bought my Megatronics 2.0 board when I started was because it had two thermocouple inputs and no other board had the option.....

|

Re: Low cost 32-bit controller board February 20, 2015 01:09PM |

Registered: 10 years ago Posts: 869 |

With knowing zero about if such suggestions are reasonable or possible with the number of IO pins and such...

Perhaps go both ways. Two are series wired and two that are parallel wired (or share a common header between the two different ways)

Reduce different part count and increase flexibility. Make all 3 20A. Just because they are all 20A rated doesn't mean they have to be ran at that current or be capable of providing 60A total.

I'd like to see more low-current options. Even with my printer now I have a hot end cooling fan, bed fan, and LED lighting. Other people have a larger whole bed fan to help with cooling a part after the job is finished. With multiple hot ends you might have a need for independently controlling more fans.

Probably enough. But I can't help but think someone, somewhere is going to think of a need for just one more endstop|thermistor|probe...but you'll probably have that no matter how many you have. Not sure if the 4-pin connector is just for the z-probe switch or also a servo, but if not at least 1 servo port would be nice. You have that mentioned further done with the expansion connector, but it'd be nice if all the necessary pins were together for power and control of the servo.

A couple of other things that I've thought about or I've seen asked is:

* ATX power supply connector in addition to dedicated screw terminals. Makes hookup super easy. Maybe just an optional connector or empty headers if cost is a concern?

* Headers for any indicator LEDs for remote locating somewhere else on the device. Could just be a header pin hole and the end user adds the header or wire if needed.

* Screw terminals in addition to headers for any connection including steppers and fans. Or option for screw terminals again to keep cost down

* A few headers for Vin, 12v, and 5v for powering "other things" that comes up down the road.

* PS_ON pin for turning on/off power supply...would also require being able to minimally power the microcontroller via 5VSB

Quote

dc42

* Two Z motor connectors to make it easy to connect two motors in series.

Perhaps go both ways. Two are series wired and two that are parallel wired (or share a common header between the two different ways)

Quote

* One heated bed output, rated at 20A.

* Two hot end heater outputs rated at 10A.

Reduce different part count and increase flexibility. Make all 3 20A. Just because they are all 20A rated doesn't mean they have to be ran at that current or be capable of providing 60A total.

Quote

Two outputs for 12V fans etc., one with PWM, the other without.

I'd like to see more low-current options. Even with my printer now I have a hot end cooling fan, bed fan, and LED lighting. Other people have a larger whole bed fan to help with cooling a part after the job is finished. With multiple hot ends you might have a need for independently controlling more fans.

Quote

* Three endstop inputs

* Three thermistor inputs

* A 4-pin connector for supporting several different kinds of Z probe.

Probably enough. But I can't help but think someone, somewhere is going to think of a need for just one more endstop|thermistor|probe...but you'll probably have that no matter how many you have. Not sure if the 4-pin connector is just for the z-probe switch or also a servo, but if not at least 1 servo port would be nice. You have that mentioned further done with the expansion connector, but it'd be nice if all the necessary pins were together for power and control of the servo.

A couple of other things that I've thought about or I've seen asked is:

* ATX power supply connector in addition to dedicated screw terminals. Makes hookup super easy. Maybe just an optional connector or empty headers if cost is a concern?

* Headers for any indicator LEDs for remote locating somewhere else on the device. Could just be a header pin hole and the end user adds the header or wire if needed.

* Screw terminals in addition to headers for any connection including steppers and fans. Or option for screw terminals again to keep cost down

* A few headers for Vin, 12v, and 5v for powering "other things" that comes up down the road.

* PS_ON pin for turning on/off power supply...would also require being able to minimally power the microcontroller via 5VSB

|

Re: Low cost 32-bit controller board February 20, 2015 01:41PM |

Registered: 10 years ago Posts: 14,672 |

Thanks to all for your comments.

The parts cost is less than £15 including PCB. Assembling it in the UK would be uneconomic because of the large number of through-hole parts (i.e. the connectors), so it would have to be assembled in China. I'll get some quotations when the Chinese New Year is over. The initial selling price I had in mind was about £35, but if the production volume became high enough then sub-£30 + shipping + tax (where applicable) should be achievable.

Regarding LCD displays, my intention was to be able to drive a 12864 display and rotary encoder directly from pins on the expansion connector, with 5V signal levels for the 12864. I have a driver for the 12864 that supports proportionally-spaced text and uses a 1K image buffer. The mcu could DMA from the image buffer to the 12864 on a regular basis, to keep the load on the mcu low.

I chose series wiring for Z motors instead of parallel wiring for a few reasons:

* It is more appropriate in most cases, assuming the Z steppers are the same sort as the X and Y steppers (and therefore need about the same current) and are reasonably-well matched to the drivers.

* Novices can generally manage to wire stepper motors in parallel, but don't know how to wire them in series

* If the option of software-controlled stepper motor current is used, then the XYZ steppers will all get the same current; so if they are the same types of motor, series wiring is again more appropriate.

I've chosen screw terminals for the power and heater connections, but not for the others. A lot of controller boards are sold in kits, and the wiring of a kit is simpler if the looms just plug into the board.

I don't plan to support an ATX power connector, because IMO this is better done on a separate board that also provides resistors to give the minimum load needed on the 5V and 12V rails (as RepRapPro did on the Ormerod 1). Such a board could also include a diode for implementing the PS_ON facility, using one of the expansion header pins. However, I would provide a dedicated PS_ON output if the demand is there.

Regarding thermocouple inputs, I don't think they belong on a budget board like this. It would be easy enough to connect a thermocouple amplifier board to the expansion connector. On-board thermocouple amplifiers might be a good addition to higher-end boards, such as the Duet and Smoothie.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Quote

dougal1957

I think you could be on to a winner with this idea especially if you can get the price break to be similar to that of a Mega + Ramps combo and that seems to be around the £25-30 mark (suspect this may be the stumbling block).

The parts cost is less than £15 including PCB. Assembling it in the UK would be uneconomic because of the large number of through-hole parts (i.e. the connectors), so it would have to be assembled in China. I'll get some quotations when the Chinese New Year is over. The initial selling price I had in mind was about £35, but if the production volume became high enough then sub-£30 + shipping + tax (where applicable) should be achievable.

Regarding LCD displays, my intention was to be able to drive a 12864 display and rotary encoder directly from pins on the expansion connector, with 5V signal levels for the 12864. I have a driver for the 12864 that supports proportionally-spaced text and uses a 1K image buffer. The mcu could DMA from the image buffer to the 12864 on a regular basis, to keep the load on the mcu low.

I chose series wiring for Z motors instead of parallel wiring for a few reasons:

* It is more appropriate in most cases, assuming the Z steppers are the same sort as the X and Y steppers (and therefore need about the same current) and are reasonably-well matched to the drivers.

* Novices can generally manage to wire stepper motors in parallel, but don't know how to wire them in series

* If the option of software-controlled stepper motor current is used, then the XYZ steppers will all get the same current; so if they are the same types of motor, series wiring is again more appropriate.

I've chosen screw terminals for the power and heater connections, but not for the others. A lot of controller boards are sold in kits, and the wiring of a kit is simpler if the looms just plug into the board.

I don't plan to support an ATX power connector, because IMO this is better done on a separate board that also provides resistors to give the minimum load needed on the 5V and 12V rails (as RepRapPro did on the Ormerod 1). Such a board could also include a diode for implementing the PS_ON facility, using one of the expansion header pins. However, I would provide a dedicated PS_ON output if the demand is there.

Regarding thermocouple inputs, I don't think they belong on a budget board like this. It would be easy enough to connect a thermocouple amplifier board to the expansion connector. On-board thermocouple amplifiers might be a good addition to higher-end boards, such as the Duet and Smoothie.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 20, 2015 03:03PM |

Registered: 9 years ago Posts: 569 |

What would be the price difference between two hotends vs a single hotend? If the idea is to keep the costs low, I am not sure that a lot of individuals looking to be "cheap" are planning to use more than one hotend. I would assume a decent price point would also encourage kit makers to transition from 8-bit to 32-bit, most of whom could care less about dual extrusion.

Also, I only skimmed the list, but don't forget pins for fans, servos, and LEDs. Probably my biggest gripe with my current RAMPs board.

Also, I only skimmed the list, but don't forget pins for fans, servos, and LEDs. Probably my biggest gripe with my current RAMPs board.

|

Re: Low cost 32-bit controller board February 20, 2015 04:53PM |

Registered: 10 years ago Posts: 14,672 |

Quote

Kurzaa

What would be the price difference between two hotends vs a single hotend?

Very little, given that the stepper motor drive is a plug-in board. Dual-extruder printing is becoming very popular these days, so I think it's worth supporting. RAMPS supports dual extruders if you don't also want a controllable fan. E3D are selling two different dual extruder nozzles (Chimera and Cyclops), and it's also quite easy to convert some other hot end designs to dual nozzle (e.g. see my blog entry on converting the Ormerod to dual nozzle).

Quote

Kurzaa

Also, I only skimmed the list, but don't forget pins for fans, servos, and LEDs. Probably my biggest gripe with my current RAMPs board.

The expansion connector would have about 10 uncommitted I/O pins + 5V and 3.3V power for those sorts of thing, although up to 5 of the I/O pins would commonly be used for attaching an LCD control panel and encoder.

Edited 1 time(s). Last edit at 02/20/2015 04:54PM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 21, 2015 10:06AM |

Registered: 13 years ago Posts: 7,616 |

Nice!

Like @Kurzaa I think you're already pretty high on the feature list for a low end board. Not much more and you can simply copy the Duet.

A few words about what I observed about people's recognition over the years:

If you also offer a StepStick derivate with digital current control, people will likely recognize these derivates are required. The fact that Gen7 Opto Endstops exist makes most people thinking Gen7 requires Opto Endstops. Of course it doesn't, mechanical endstops work just as fine as on any other controller. With this in mind I'd stick to the pure Pololu form factor for the stepper drivers which is pretty much an industry standard now.

Interestingly, years back many many people considered a $150 RAMPS & Arduino to be a better value than a $90 Sanguinololu or Gen7. "If I burn out my ATmega I can simply replace the Arduino". Totally ignoring the fact you can replace just the chip easily for $8 on the other controllers. This (odd) recognition made much of the success of RAMPS.

Visual appearance is more important than technical facts. These large silkscreen logos on the back or similar. 4pi is recognized as "the controller with an entirely flat back". RepRapDiscount makes all its boards white (second silkscreen covering the whole board), for a more friendly appearance. Asking a friend with an artistic mind to put something nice, unique onto the board is likely a good idea.

From the Open Source perspective: doing the design in gEDA or KiCAD would be awesome. Both are entirely sufficient for such tasks and KiCAD is currently on a steep rise: [reprap.org]

Like @Kurzaa I think you're already pretty high on the feature list for a low end board. Not much more and you can simply copy the Duet.

A few words about what I observed about people's recognition over the years:

If you also offer a StepStick derivate with digital current control, people will likely recognize these derivates are required. The fact that Gen7 Opto Endstops exist makes most people thinking Gen7 requires Opto Endstops. Of course it doesn't, mechanical endstops work just as fine as on any other controller. With this in mind I'd stick to the pure Pololu form factor for the stepper drivers which is pretty much an industry standard now.

Interestingly, years back many many people considered a $150 RAMPS & Arduino to be a better value than a $90 Sanguinololu or Gen7. "If I burn out my ATmega I can simply replace the Arduino". Totally ignoring the fact you can replace just the chip easily for $8 on the other controllers. This (odd) recognition made much of the success of RAMPS.

Visual appearance is more important than technical facts. These large silkscreen logos on the back or similar. 4pi is recognized as "the controller with an entirely flat back". RepRapDiscount makes all its boards white (second silkscreen covering the whole board), for a more friendly appearance. Asking a friend with an artistic mind to put something nice, unique onto the board is likely a good idea.

From the Open Source perspective: doing the design in gEDA or KiCAD would be awesome. Both are entirely sufficient for such tasks and KiCAD is currently on a steep rise: [reprap.org]

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Low cost 32-bit controller board February 21, 2015 11:07AM |

Registered: 10 years ago Posts: 14,672 |

Quote

Traumflug

Like @Kurzaa I think you're already pretty high on the feature list for a low end board. Not much more and you can simply copy the Duet.

Tramflug, thanks for your comments.

The only features I think I could remove and still have a useful board are the support for a 2nd extruder, and the support for optional digital stepper current control (restricted to just 2 channels, one to set XYZ current and one to set extruder currents). Support for a second extruder is something that RAMPS already provides. if you can live without a controllable cooling fan, and I think it would be a mistake to produce a board that does less than RAMPS. The only costs are for the connectors for the extra stepstick and extruder motor, a low-cost mosfet for controlling the heater, and 2 extra connectors on the terminal block. Total cost less than £0.50. Well worth it I think, especially given the rise of dual-nozzle printing.

The optional digital stepper motor current control is essentially free, because the microcontroller has a built-in 2-channel DAC, and the extra cost of 1 extra socket pin per stepper driver is tiny.

The main feature missing is Ethernet, because that does add a significant amount of cost.

Quote

Traumflug

A few words about what I observed about people's recognition over the years:

If you also offer a StepStick derivate with digital current control, people will likely recognize these derivates are required. The fact that Gen7 Opto Endstops exist makes most people thinking Gen7 requires Opto Endstops. Of course it doesn't, mechanical endstops work just as fine as on any other controller. With this in mind I'd stick to the pure Pololu form factor for the stepper drivers which is pretty much an industry standard now.

Thanks, however IME digital; stepper motor current is very valuable, and it's even more valuable for novices, who may not even have a multimeter. But I take the point: it needs to be made very clear that standard stepsticks work with the board. My hope is that the modified stepstick with an extra pin for current control would be adopted by other boards and eventually become a standard too.

Quote

Traumflug

Visual appearance is more important than technical facts. These large silkscreen logos on the back or similar. 4pi is recognized as "the controller with an entirely flat back". RepRapDiscount makes all its boards white (second silkscreen covering the whole board), for a more friendly appearance. Asking a friend with an artistic mind to put something nice, unique onto the board is likely a good idea.

Interesting, thanks.

Quote

Traumflug

From the Open Source perspective: doing the design in gEDA or KiCAD would be awesome. Both are entirely sufficient for such tasks and KiCAD is currently on a steep rise: [reprap.org]

I'm in favour of using open source tools as long as they are up to the job, so I started doing a board layout for this in KiCad. But I quickly found that none of the major SMD components or even most of the connectors I need are in the KiCad library, or any other libraries for Kicad that I could find. I don't have time to design them all. So unless someone can point me to KiCad libraries for these parts that I failed to find myself, or an Eagle to KiCad library converter, I will carry on using Eagle. But I'm keeping the size to within the 100x80mm size limit of the version that is free for individuals to use. It's a great pity that there is no universal XML format to describe components to PCB layout programs, if there were then the component manufacturers might produce these files themselves.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 21, 2015 12:35PM |

Registered: 9 years ago Posts: 1,159 |

Quote

dc42

I'm in favour of using open source tools as long as they are up to the job, so I started doing a board layout for this in KiCad. But I quickly found that none of the major SMD components or even most of the connectors I need are in the KiCad library, or any other libraries for Kicad that I could find. I don't have time to design them all. So unless someone can point me to KiCad libraries for these parts that I failed to find myself, or an Eagle to KiCad library converter, I will carry on using Eagle. But I'm keeping the size to within the 100x80mm size limit of the version that is free for individuals to use. It's a great pity that there is no universal XML format to describe components to PCB layout programs, if there were then the component manufacturers might produce these files themselves.

Dave might this help at all (But I am sure you have already seen this) Eagle to Kicad libray conversion

Doug

|

Re: Low cost 32-bit controller board February 21, 2015 04:46PM |

Registered: 10 years ago Posts: 14,672 |

Thanks Doug, it hadn't occurred to me to look for an Eagle to KiCad convertor before I wrote that post.

Seriously, lack of component libraries is the bane of my life whenever I do electronic circuit design. Eagle is just less bad than most other PCB layout programs, in part because of open source libraries contributed by Sparkfun, Adafruit and others.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Seriously, lack of component libraries is the bane of my life whenever I do electronic circuit design. Eagle is just less bad than most other PCB layout programs, in part because of open source libraries contributed by Sparkfun, Adafruit and others.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 21, 2015 06:57PM |

Registered: 9 years ago Posts: 6 |

|

Re: Low cost 32-bit controller board February 21, 2015 07:07PM |

Registered: 9 years ago Posts: 6 |

|

Re: Low cost 32-bit controller board February 21, 2015 08:08PM |

Registered: 13 years ago Posts: 7,616 |

Quote

JamesP166

I am an electronics engineer and do my own board layouts with Altium - - - a bit more than an open source or free tools. but the cost is worth it for the power and performance and the libraries

The cost in dollars perhaps, but also the cost in lack of freedom? When doing Open Source / community work I answer the latter question differently than when being employee.

Anyways, here's another mailing list post, explaining this RAMPS replacement mystery: [reprap.org] It looks like in practice, people don't burn their Arduino, but rarther their RAMPS, and replacing just the RAMPS does not require uploading new firmware and such stuff.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Low cost 32-bit controller board February 21, 2015 10:29PM |

Registered: 9 years ago Posts: 977 |

Hi,

This is a great project for the RepRap community and I hope it reaches the "working" status in 2015 while at the same time achieving all its objectives, in particular the low-cost aspect which I see as the pitfall for many previous projects of this kind.

As for the "Ethernet support" option, which would increase the price of the board considerably, I would suggest it is not needed.

Personally I use a small Linux ARM box with WiFi, running OctoPrint, as a front end for all my 3D printers (see OctoGoatBox or RepRapBox in the wiki if you are curious). There is no way a 68MHz ARM MCU can provide the same Web interface as a dedicated dual or quad core Cortex A7 Linux box. Also, Ethernet in a soho is simply not used anymore, most everybody has switched to WiFi nowadays. And finally, having a TCP/IP stack running eats CPU cycles, takes ROM and RAM space and costs hours to develop and maintain, for zero benefit the way I see it.

I also support the suggestion by vreihen above that the already existing and mass produced (hence low cost) LCD controllers supported by the RAMPS board should also be compatible out-of-the-box with this new board, namely the LCD2004 Smart Controller and the 12864 Full Graphics controller.

Finally, I have a question about the firmware development environment for such a board. I imagine one would be forced to stray away from the Arduino IDE, so what is the recommended alternative in this case? Something a lot more complex to use will unfortunately turn away many developers and potential users of this board.

Good luck and thanks for your excellent work so far,

Andrew

This is a great project for the RepRap community and I hope it reaches the "working" status in 2015 while at the same time achieving all its objectives, in particular the low-cost aspect which I see as the pitfall for many previous projects of this kind.

As for the "Ethernet support" option, which would increase the price of the board considerably, I would suggest it is not needed.

Personally I use a small Linux ARM box with WiFi, running OctoPrint, as a front end for all my 3D printers (see OctoGoatBox or RepRapBox in the wiki if you are curious). There is no way a 68MHz ARM MCU can provide the same Web interface as a dedicated dual or quad core Cortex A7 Linux box. Also, Ethernet in a soho is simply not used anymore, most everybody has switched to WiFi nowadays. And finally, having a TCP/IP stack running eats CPU cycles, takes ROM and RAM space and costs hours to develop and maintain, for zero benefit the way I see it.

I also support the suggestion by vreihen above that the already existing and mass produced (hence low cost) LCD controllers supported by the RAMPS board should also be compatible out-of-the-box with this new board, namely the LCD2004 Smart Controller and the 12864 Full Graphics controller.

Finally, I have a question about the firmware development environment for such a board. I imagine one would be forced to stray away from the Arduino IDE, so what is the recommended alternative in this case? Something a lot more complex to use will unfortunately turn away many developers and potential users of this board.

Good luck and thanks for your excellent work so far,

Andrew

|

Re: Low cost 32-bit controller board February 22, 2015 12:50AM |

Registered: 11 years ago Posts: 173 |

Can you add another stepper stepper driver socket to make it 6 in total for tri-colour printing and an extra thermistor input for heated chamber measurement? How much will the extras add to the cost?

You only learn when you change your mind.

[www.deltaprinter.co.za]

You only learn when you change your mind.

[www.deltaprinter.co.za]

|

Re: Low cost 32-bit controller board February 22, 2015 04:59AM |

Registered: 10 years ago Posts: 14,672 |

Thanks for the additional comments.

Regarding Ethernet support and a web interface, the Duet electronics and firmware provides an excellent web interface at the same time as running the printer, all on a 84MHz Cortex M3 processor with 96K RAM. The benefit is huge IMO. Once you have used the web interface, you never want to go back to Pronterface. You definitely do not need to add a RPi or similar to get this functionality. Having the web interface built in means that it can provide information that is not available via gcodes, and continue to provide real time information when the printer is executing commands that take a long time to complete. I can see that having a single web interface served by an RPi or similar may be a good solution for controlling several printers, but most people have only one printer.

I agree that many users would find wifi more useful than an Ethernet socket. However, it is a simple matter to connect an inexpensive wifi to Ethernet bridge to the Ethernet port. The worst part is having to provide power for the bridge. Maybe a USB-A socket should be included on the board for this purpose. A wifi piggyback board could be another option.

Regarding the development environment, Arduino is great for novices, but both the IDE and the core libraries are in my experience woefully inadequate for serious firmware projects such as 3D printer firmware. As long as most users never need to build the firmware, the development environment required is not important as long as it is freely available. Eclipse is the obvious choice for open source firmware.

Regarding a 6th stepper driver socket, the constraint is board space. Another hot end mosfet would also be needed, requiring yet more space. A thermistor to measure enclosure temperature could be connected to the expansion connector.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Regarding Ethernet support and a web interface, the Duet electronics and firmware provides an excellent web interface at the same time as running the printer, all on a 84MHz Cortex M3 processor with 96K RAM. The benefit is huge IMO. Once you have used the web interface, you never want to go back to Pronterface. You definitely do not need to add a RPi or similar to get this functionality. Having the web interface built in means that it can provide information that is not available via gcodes, and continue to provide real time information when the printer is executing commands that take a long time to complete. I can see that having a single web interface served by an RPi or similar may be a good solution for controlling several printers, but most people have only one printer.

I agree that many users would find wifi more useful than an Ethernet socket. However, it is a simple matter to connect an inexpensive wifi to Ethernet bridge to the Ethernet port. The worst part is having to provide power for the bridge. Maybe a USB-A socket should be included on the board for this purpose. A wifi piggyback board could be another option.

Regarding the development environment, Arduino is great for novices, but both the IDE and the core libraries are in my experience woefully inadequate for serious firmware projects such as 3D printer firmware. As long as most users never need to build the firmware, the development environment required is not important as long as it is freely available. Eclipse is the obvious choice for open source firmware.

Regarding a 6th stepper driver socket, the constraint is board space. Another hot end mosfet would also be needed, requiring yet more space. A thermistor to measure enclosure temperature could be connected to the expansion connector.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 22, 2015 06:53AM |

Registered: 13 years ago Posts: 7,616 |

Quote

dc42

Having the web interface built in means that it can provide information that is not available via gcodes, and continue to provide real time information when the printer is executing commands that take a long time to complete.

I see no reason why this couldn't be implemented over USB. The limitation to G-code is a self-choosen one, not one enforced by the USB technology.

Quote

dc42

Eclipse is the obvious choice for open source firmware.

Eeek! Eclipse is way to complex. :-) That said, the good thing about Eclipse is, one can continue with any text editor as well as long as a makefile is maintained. In Teacup we maintain an empty .ino file and a makefile which builds by compiling *.c in the toplevel directory. This way you can use Arduino IDE as well; Arduino library gets compiled then, but isn't used.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Low cost 32-bit controller board February 22, 2015 02:16PM |

Registered: 9 years ago Posts: 977 |

I confess I never actually used Pronterface, as I had an OctoPrint RPi box up and running before my first 3D printer was even fully operational.Quote

dc42

Thanks for the additional comments.

Regarding Ethernet support and a web interface, the Duet electronics and firmware provides an excellent web interface at the same time as running the printer, all on a 84MHz Cortex M3 processor with 96K RAM. The benefit is huge IMO. Once you have used the web interface, you never want to go back to Pronterface.

...

The big hurdle I see for this new project is that basically it offers almost the same feature set as a Duet board (except for the fact that the Duet includes 4 Allegro A4982 steppers drivers soldered in), and yet one of its objectives is to reach a manufacturing cost similar to that of an Arduino Mega 2560 + RAMPS combo, something I would deem is very difficult if not impossible.

Also, since the Duet project is completely open source and has already achieved the "working" status, wouldn't it be simpler to just edit the Duet schematics and PCB design to remove the Allegro chips and include headers for Pololu-style carrier boards?

Back to cost considerations: a Duet board goes for around $120 + shipping whereas I can source a Mega 2560 + RAMPS + 5 x DRV8825 Pololu carriers + 12864LCD for approx. $35 (including shipping), and an extra dual core Cortex A7 1GHz Debian Linux box with WiFi for approximately $50 (again including shipping).

So for a grand total of $85 I get a lot more functionality than a basic Duet board and I still save $35.

Given these facts, I have a hard time convincing myself that I should use a Duet board or something similar and similarly expensive.

Wouldn't it be a lot faster to develop, simpler, cheaper and more effective to just move the heavy duty processing to the Linux box and leave only the nitty-gritty realtime pulse generation and sensor reading to the Mega 2560?

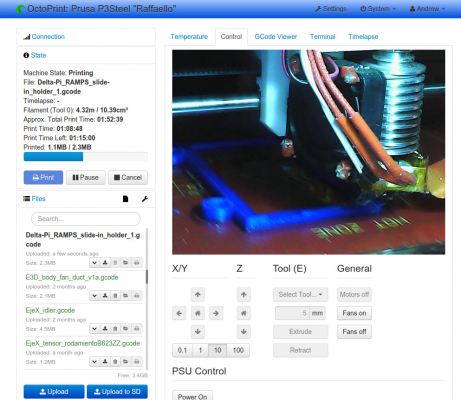

Since some people may not be aware of how practical OctoPrint can be to use, I am including a screenshot of OctoPrint just as I am using it right now, as I write these lines:

Edited 1 time(s). Last edit at 02/22/2015 02:29PM by AndrewBCN.

|

Re: Low cost 32-bit controller board February 22, 2015 02:42PM |

Registered: 10 years ago Posts: 14,672 |

Quote

AndrewBCN

The big hurdle I see for this new project is that basically it offers almost the same feature set as a Duet board (except for the fact that the Duet includes 4 Allegro A4982 steppers drivers soldered in), and yet one of its objectives is to reach a manufacturing cost similar to that of an Arduino Mega 2560 + RAMPS combo, something I would deem is very difficult if not impossible.

The parts cost for the board I propose is significantly less than the parts cost for an Arduino and a RAMPS, if purchased in the same quantities. For example, the ATSAM3S4B is less than half the price of the ATMEGA2560, and it does not need the USB-to-serial converter. So if it were taken up by the same Chinese manufacturers, then it should eventually cost less than the $35 you quote, including the accessories. Of course, if the Chinese clone manufacturers started making the Duet, then its price would come down too.

The board I propose will also cost less to manufacture than a Duet, mostly by using a microcontroller with fewer pins and without on-chip Ethernet, leaving off the other Ethernet bits, leaving off the digipot chip that provides individual control of stepper motor currents, and using a 2-layer PCB instead of 4 layer (which is only possible because the stepper drivers are off the board). My planned selling price for the first batch would be about £35 + shipping + tax, which equates to about $54 - so less than half the price of the Duet (but you would still need to add your choice of stepper drivers).

Quote

AndrewBCN

Wouldn't it be a lot faster to develop, simpler, cheaper and more effective to just move the heavy duty processing to the Linux box and leave only the nitty-gritty realtime pulse generation and sensor reading to the Mega 2560?

The mega2560 is not a serious contender for new designs on account of its costing more than twice as much as a more capable 32-bit chip. I'd be reluctant to move anything to a Linux box, because I like the fact that both my Duet-powered printers are ready to be controlled within a second of being powered up. But it would be nice to have a multicore chip so that the hard real-time functions could be separated from the TCP/IP stack etc.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 22, 2015 06:03PM |

Registered: 9 years ago Posts: 977 |

Quote

dc42

...

The board I propose will also cost less to manufacture than a Duet, mostly by using a microcontroller with fewer pins and without on-chip Ethernet, leaving off the other Ethernet bits...

Just two posts above you argued in favor of including an Ethernet interface and now you are arguing that to save costs this same Ethernet interface should not be included in your new design?

Quote

dc42

...

I'd be reluctant to move anything to a Linux box, because I like the fact that both my Duet-powered printers are ready to be controlled within a second of being powered up.

The small ARM boxes I use as Linux Debian / OctoPrint servers stay on 24/7, their power consumption being approximately the same as the standby power consumption of the ATX PSUs I use for my 3D printers (i.e 2.5W), so as far as "readyness to print after power on" is concerned, they are a non-issue.

So far it seems to me that you are planning your new design basically by making small changes to the Duet design, what I am proposing is to think outside the box and do something different.

Edited 1 time(s). Last edit at 02/22/2015 06:04PM by AndrewBCN.

|

Re: Low cost 32-bit controller board February 22, 2015 07:07PM |

Registered: 10 years ago Posts: 14,672 |

Andrew, thanks for your thoughts.

Read the whole thread. I have always said that this board will not have Ethernet. But I posed the question, will that limit sales of the board too much, because I suspect that Ethernet will in time become a must-have feature.

To me that's a horrible workaround. I don't want to leave any part of the printer on when I have turned it off. I don't use an ATX power supply. Besides, having to set up and manage a Linux box is unnecessary complexity for novice users.

I am proposing a board that has significantly less functionally than the Duet (in particular, no Ethernet) and would cost around half the price. For computer geeks who would like to use a Linux server to provide the web interface anyway, I would have thought it was a near-ideal solution.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Quote

AndrewBCN

Just two posts above you argued in favor of including an Ethernet interface and now you are arguing that to save costs this same Ethernet interface should not be included in your new design?

Read the whole thread. I have always said that this board will not have Ethernet. But I posed the question, will that limit sales of the board too much, because I suspect that Ethernet will in time become a must-have feature.

Quote

The small ARM boxes I use as Linux Debian / OctoPrint servers stay on 24/7, their power consumption being approximately the same as the standby power consumption of the ATX PSUs I use for my 3D printers (i.e 2.5W), so as far as "readyness to print after power on" is concerned, they are a non-issue

To me that's a horrible workaround. I don't want to leave any part of the printer on when I have turned it off. I don't use an ATX power supply. Besides, having to set up and manage a Linux box is unnecessary complexity for novice users.

Quote

So far it seems to me that you are planning your new design basically by making small changes to the Duet design, what I am proposing is to think outside the box and do something different.

I am proposing a board that has significantly less functionally than the Duet (in particular, no Ethernet) and would cost around half the price. For computer geeks who would like to use a Linux server to provide the web interface anyway, I would have thought it was a near-ideal solution.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 22, 2015 07:55PM |

Registered: 9 years ago Posts: 977 |

Quote

dc42

Andrew, thanks for your thoughts.

Quote

AndrewBCN

Just two posts above you argued in favor of including an Ethernet interface and now you are arguing that to save costs this same Ethernet interface should not be included in your new design?

Read the whole thread. I have always said that this board will not have Ethernet. But I posed the question, will that limit sales of the board too much, because I suspect that Ethernet will in time become a must-have feature.

And I wrote above that just the contrary has already happened: wireless is the norm nowadays for interfacing devices and has been for a few years now. Perhaps you don't recognize this because of the way you are using Duet controllers and still thinking that this is the paradigm, but it's not. Ethernet is a "must-lose" feature in 2015 and if anything will become even more so in time.

There is a discussion in another thread here in this subforum about possible alternatives to the Smoothieboard, and another thread about an Alligator board, and what I am observing is that this project, like the others, continues to rehash the very same controller/electronics design that we have had since 2007. The basic "formula" has not changed one bit, some components are upgraded and some are deleted to differentiate one design from the other and that's it. The consequence of this is that the vast majority of RepRap builders choose to use 8-bit designs, and most just go for the most affordable solution i.e. Arduino + RAMPS 1.4.

You are trying to differentiate your design from the Duet and other 32-bit controller boards by removing some functionality from the Duet board and hoping that these changes plus possible economies of scale will allow your costs to reach levels comparable to that of existing 8-bit solutions. I have expressed some doubts about the feasibility of this and I still believe that a better alternative exists by thinking outside the box.

Edited 1 time(s). Last edit at 02/22/2015 08:02PM by AndrewBCN.

|

Re: Low cost 32-bit controller board February 23, 2015 03:41AM |

Admin Registered: 16 years ago Posts: 13,884 |

... I'm receiving great problems with wireless communication for high-speed data transfer, as needed for high resolution printing, milling or laser-engraving

So for data transfer rates above 500kBit/s and realtime communication it's better to use "wire-based" com's

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

So for data transfer rates above 500kBit/s and realtime communication it's better to use "wire-based" com's

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Low cost 32-bit controller board February 23, 2015 05:14AM |

Registered: 9 years ago Posts: 100 |

I think we can probably all agree that some form of network connectivity is a desirable feature, however if it will add significantly to the projected cost then that will defeat the intended purpose of this board (and Oco-Print is certainly a good solution for anyone that needs a Web interface).

@AndrewBCN

You make a good point that the software toolchain could be redesigned to remove more of the heavy lifting from the printer electronics (as has been discussed before on this forum), and that in turn could allow a rethink of the printer electronics, however that is a much bigger project than "just" producing a 32 bit RAMPS/Mega replacement.

@dc42

Good luck with this, a low cost viable alternative to RAMPS/Mega is long overdue (before anyone says anything, I know there are lots of alternatives already out there, but none have yet had the right combination of price and features to wean the majority of users away from RAMPS - which this project sounds like it could), my only request on the hardware would be to use screw terminals or friction fit (not ordinary pcb headers) for the main connections like stepper motors, endstops, and thermistors (as well as power, heatbed, and extruder(s)). If that is not possible then consider leaving room for people to solder whatever type of connector they want.

+1 for a pin for ATX power standby.

You might want to take note of the lesson from RAMPS-FD, don't publish the full schematic until the worst bugs have been worked out (RAMPS-FD was picked up by the clone makers, but they cloned the early beta version of the board).

The biggest stumbling block I see to take up will be firmware, unless this can run a straight port of firmware from another board then you will not get large scale take up until people see it can match the features and performance of the likes of Marlin. Also the clone makers probably won't pick it up until they see viable firmware. Is your plan to develop new FW from scratch, or will this be based on an existing FW?

Tim

@AndrewBCN

You make a good point that the software toolchain could be redesigned to remove more of the heavy lifting from the printer electronics (as has been discussed before on this forum), and that in turn could allow a rethink of the printer electronics, however that is a much bigger project than "just" producing a 32 bit RAMPS/Mega replacement.

@dc42

Good luck with this, a low cost viable alternative to RAMPS/Mega is long overdue (before anyone says anything, I know there are lots of alternatives already out there, but none have yet had the right combination of price and features to wean the majority of users away from RAMPS - which this project sounds like it could), my only request on the hardware would be to use screw terminals or friction fit (not ordinary pcb headers) for the main connections like stepper motors, endstops, and thermistors (as well as power, heatbed, and extruder(s)). If that is not possible then consider leaving room for people to solder whatever type of connector they want.

+1 for a pin for ATX power standby.

You might want to take note of the lesson from RAMPS-FD, don't publish the full schematic until the worst bugs have been worked out (RAMPS-FD was picked up by the clone makers, but they cloned the early beta version of the board).

The biggest stumbling block I see to take up will be firmware, unless this can run a straight port of firmware from another board then you will not get large scale take up until people see it can match the features and performance of the likes of Marlin. Also the clone makers probably won't pick it up until they see viable firmware. Is your plan to develop new FW from scratch, or will this be based on an existing FW?

Tim

|

Re: Low cost 32-bit controller board February 23, 2015 05:33AM |

Registered: 10 years ago Posts: 14,672 |

Plankton, thanks for your comments.

Screw terminals are nice for anyone who designs and builds a printer from scratch and doesn't want to pay £20 or so for for a crimp tool. For kit makers and anyone with a crimp tool, plug-in connectors are better. The kit manufacturers benefit by reducing the possibility of miswiring, and.users benefit from being able to disconnect the wiring from the electronics quickly and easily (and again reducing the possibility of miswiring when they reconnect). I removed most of the screw terminal blocks from a Duet board I received and replaced them with header pin strips, to make the wiring of my Mini Kossel easier. I'm not sure whether to go for pin headers to keep the cost down, or locking/polarised Molex connectors that cost a little more. For anyone who really wants to use screw terminals, I guess I could offer a board with the connectors not fitted. I do plan to use screw terminals for the heated bed, hot end heaters and power connections.

I would port RepRapFirmware to it, because I am familiar with it and it is one of the best 32-bit firmwares available, with features such as segmentation-free Delta printer support, near-instant print pausing, macros files to run when pausing/resuming prints, and Bowden extruder elasticity compensation in testing. I would leave out the Ethernet bits, and add direct read/write of the SD card via the USB port.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Quote

plankton

@dc42

Good luck with this, a low cost viable alternative to RAMPS/Mega is long overdue (before anyone says anything, I know there are lots of alternatives already out there, but none have yet had the right combination of price and features to wean the majority of users away from RAMPS - which this project sounds like it could), my only request on the hardware would be to use screw terminals or friction fit (not ordinary pcb headers) for the main connections like stepper motors, endstops, and thermistors (as well as power, heatbed, and extruder(s)). If that is not possible then consider leaving room for people to solder whatever type of connector they want.

+1 for a pin for ATX power standby

Screw terminals are nice for anyone who designs and builds a printer from scratch and doesn't want to pay £20 or so for for a crimp tool. For kit makers and anyone with a crimp tool, plug-in connectors are better. The kit manufacturers benefit by reducing the possibility of miswiring, and.users benefit from being able to disconnect the wiring from the electronics quickly and easily (and again reducing the possibility of miswiring when they reconnect). I removed most of the screw terminal blocks from a Duet board I received and replaced them with header pin strips, to make the wiring of my Mini Kossel easier. I'm not sure whether to go for pin headers to keep the cost down, or locking/polarised Molex connectors that cost a little more. For anyone who really wants to use screw terminals, I guess I could offer a board with the connectors not fitted. I do plan to use screw terminals for the heated bed, hot end heaters and power connections.

Quote

plankton

The biggest stumbling block I see to take up will be firmware, unless this can run a straight port of firmware from another board then you will not get large scale take up until people see it can match the features and performance of the likes of Marlin. Also the clone makers probably won't pick it up until they see viable firmware. Is your plan to develop new FW from scratch, or will this be based on an existing FW?

I would port RepRapFirmware to it, because I am familiar with it and it is one of the best 32-bit firmwares available, with features such as segmentation-free Delta printer support, near-instant print pausing, macros files to run when pausing/resuming prints, and Bowden extruder elasticity compensation in testing. I would leave out the Ethernet bits, and add direct read/write of the SD card via the USB port.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Low cost 32-bit controller board February 23, 2015 07:48AM |

Registered: 9 years ago Posts: 100 |

Quote

dc42

Screw terminals are nice for anyone who designs and builds a printer from scratch and doesn't want to pay £20 or so for for a crimp tool.

Yes, for a scratch builder the cost of a crimp tool, plus the crimp housings and the pins, can be in excess of £30 (not insignificant for someone building on a budget). However that's a somewhat hidden cost that many people won't consider when comparing the cost of controllers.

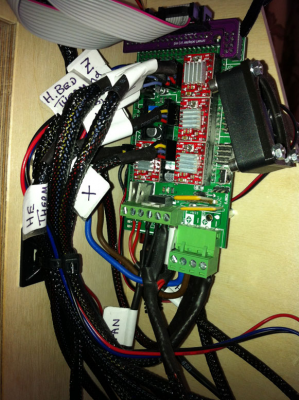

A picture is worth a thousand words, this is the RAMPS on my first build, the weight of those cables tends to pull them off the connectors unless the weight is supported with tie wraps, and it's easy to knock them loose when working around there.

Of course different printers lend themselves to different wiring solutions, and I wouldn't use heavy sheathing like that again if I had to wire to another RAMPS, but the experience has put me off PCB pins for these connectors. In the end every build (and builder) will have slightly different requirements, I think the best solution would allow a degree of flexibility for the builder to choose his preferred connections (if that can be done within the PCB size constraints).

Tim

Printers:

Prusa i3 (plywood box frame)

RAMPS 1.4 and Arduino Mega

Mendel 90 (sturdy)

Smoothieware

My RepRap Blog

|

Re: Low cost 32-bit controller board February 23, 2015 07:48AM |

Registered: 9 years ago Posts: 977 |

Quote

plankton

I think we can probably all agree that some form of network connectivity is a desirable feature, however if it will add significantly to the projected cost then that will defeat the intended purpose of this board (and Octo-Print is certainly a good solution for anyone that needs a Web interface).

@AndrewBCN

You make a good point that the software toolchain could be redesigned to remove more of the heavy lifting from the printer electronics (as has been discussed before on this forum), and that in turn could allow a rethink of the printer electronics, however that is a much bigger project than "just" producing a 32 bit RAMPS/Mega replacement.

...

Tim

Tim,

The issue here is that there are already quite a few 32-bit controller designs available, basically all of them from the very same mold: take any one of the "old" 8-bit controller boards, replace the AVR with an inexpensive 32-bit ARM MCU, and voila: shiny "new" controller that will magically both accelerate and improve the quality of your prints and of course costs 3 x as much as the "inadequate" 8-bit electronics it replaces. The magic part here (repeated ad nauseam in this forum and elsewhere) being the claim that using the same mechanics, steppers, nozzle, cooling, etc, one gets both better quality and faster prints.

And note that a more user-friendly interface, WiFi connectivity, better protocol standards, etc usually get swept under the rug as though these are "secondary" issues that can be dealt with later, after we upgrade the MCU from 8 to 32-bit. I guess I am starting to sound just like Markus, now! :-)

So, this project follows exactly the same paradigm as all the others that preceded it, and right now I don't see how dc42 can bring down the costs of a Duet board ($120 + shipping) to the same level as that of a RAMPS + Arduino combo (around $20, shipping included), by just changing the ARM processor, removing four Allegro chips that costs around $1 each, and using a double-sided PCB, since these small changes certainly won't decrease costs by more than $20 or so.

Economies of scale can bring down the costs of a 3D printer controller significantly but why hasn't this applied to the Duet controller yet? Imo that is a question that would need to be answered first and foremost, before the community moves on to this or any of the other very similar designs (which btw will all run exactly the same software).

Edited 1 time(s). Last edit at 02/23/2015 07:53AM by AndrewBCN.

Sorry, only registered users may post in this forum.