Alligator Board Q & A

Posted by geotete

|

Re: Alligator Board Q & A May 14, 2015 05:09AM |

Registered: 11 years ago Posts: 95 |

|

Re: Alligator Board Q & A May 14, 2015 06:01AM |

Registered: 11 years ago Posts: 95 |

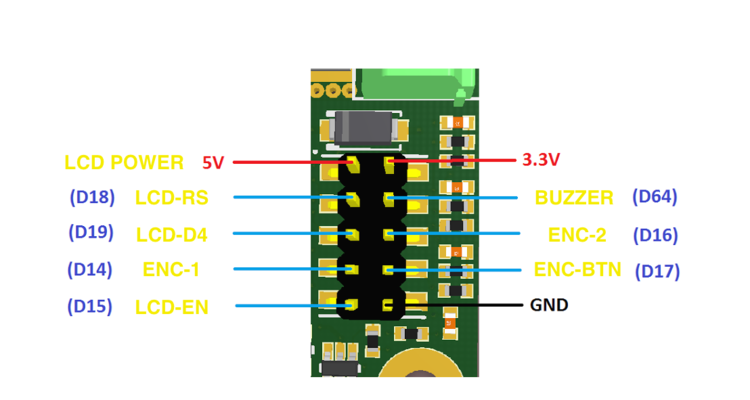

For the 128x64 display will need to create an adapter.

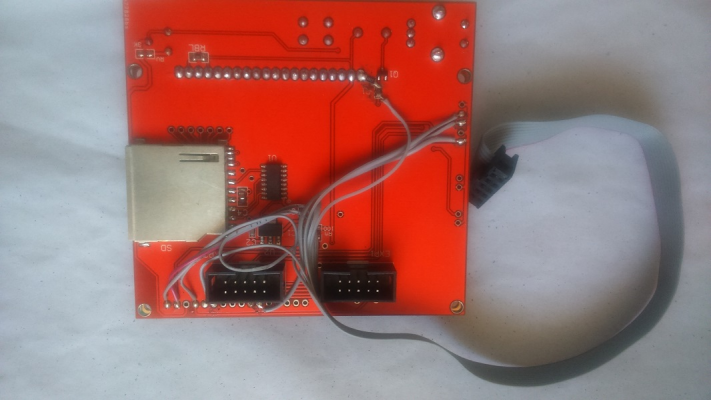

I soldered directly behind the display a 10-pin flat cable.

These are my wiring, I used the Alligator expansion connector next to the sd card :

I soldered directly behind the display a 10-pin flat cable.

These are my wiring, I used the Alligator expansion connector next to the sd card :

|

Re: Alligator Board Q & A May 14, 2015 07:40PM |

Registered: 8 years ago Posts: 13 |

|

Re: Alligator Board Q & A May 14, 2015 07:59PM |

Registered: 8 years ago Posts: 52 |

Quote

dc42

It's a shame the Alligator team didn't learn from the Duet (which is also based around the Arduino Due but came out a year earlier) and design the board to use the native USB port as standard. Using the native USB port instead of the USB-over-serial port solves two problems:

- it means that it doesn't matter what you set the baud rate to, because there is no async comms involved;

- it provides higher speed with flow control, which means you can get much better data rates.

But I understand there are issues with the 5V supply on the Alligator native USB port. Maybe they will fix that in a future revision of the board.

I don't want this to turn into a flame war, but as a customer and a backer, I am actually quite glad and very pleased they enabled the Alligator board like they did compared to other ARM based boards out there. the fact 3D artists designed it closer to the original Arduino Due design bodes well for repurposing this board for future scenarios. Nobody said you could not program it through the native port, because you can, and I have, and haven't had a problem.... but given that Arduino.cc themselves, and just about anybody who has had to deal with a crashed or half-flashed ARM can tell you, you really need a separate programming port

just sayin... like it says out on arduino.cc:

just sayin... like it says out on arduino.cc: "Either of the USB ports can be used for programming the board, though it is recommended to use the Programming port due to the way the erasing of the chip is handled"

On the alligator, they honored this with a DIP switch that makes erasing and flashing pretty easy. flip, reset, flip, flash using the programming port. reduces the risk of sending resetting baud rates, hitting reset buttons, etc. It is simpler, no argument, to flash through the native port, but to do so, Duet changed the Arduino due model design; to enable native programming and control, they blocked the otg power output for the native MCU, which limits any ability to use it for USB OTG. That was the one of the original scenarios with the Arduino due, (and 32-bit proc) but the point is it was there for a reason...and for me the Duet didn't honor that principle. That is hard for me to accept if I'm looking for a board that is nearing "industry standard" quality, especially if I'm in support of arduino.cc

Also, I love the potential for USB OTG control of another downstream device; that just simply shows foresight and adherence to the standard. In my opinion, that is what I think Arduino.cc intended; expand the platform, Enhance the platform, but don't cripple it... On that point, looking further at the design, having native Raspberry pi integration is a positive example of that kind of expandability. to add; the fact that it POWERS the pi from that same connection...well, you get the idea.

(hint: it frees up the USB ports! )

(hint: it frees up the USB ports! ) Just to make this even more awesomer, They added a native JTAG. that makes me very happy. (Makers program by USB; real hackers program by JTAG

)

)next, on the point of issue with 5V, I haven't run into those issues on the USB, because most experienced ARM programmers know to not plug into the native port with power on the board, so I'm unsure what you are referring to, but I *CAN* tell you about the issues and limitations of having to step down to 3.3v stuff when you have all 5v parts on EVERYTHING ELSE I use, so this is a welcome addition to the ecosystem in my opinion. I no longer have to worry about plugging in a 3.3v wall wart *anywhere* anymore. ever again. plus, the alligator board has options to shift down with dip switches already on board, in case I have need to (which I hope I never do) so, it's all good

Now, if you are really truly worried about baud rate and control flow at 115200, if my firmware coded proper transport and flow control, why is this still a problem?

Now, on expandability. Bottom line: I imagine I can expand my Alligator much easier than what I would have with a Duet. You see, with the Duet to expand it to 3 new extruders, I need a 2nd board, a 50-pin ribbon cable, another pin to pin cable for a ground because of some thermistor ground issue, more real estate for the 2nd board, which means a new mount, etc. Shoving that into the underside of my Kossel, I would not be looking forward to that shoehorn project. With the alligator, I imagine I simply plug in my expansion board onto the top, run some wires for my new extrusion motors and sensors, re-flash. I'm done.

Lastly, the decision point that ultimately led me to an Alligator and not the Duet: it just looks so much more prettier Italians know how to make quality.

Edited 1 time(s). Last edit at 05/14/2015 08:00PM by EljefedsecurIT.

|

Re: Alligator Board Q & A May 15, 2015 04:18AM |

Registered: 10 years ago Posts: 14,672 |

EljefedsecurIT, I don't want to get into a flame war either. From what I have seen of the Alligator, it looks to me like a well-built board, with some nice features such as the easy RPi connection and 1/32 microstepping. However:

1. The USB-over-serial port on the Arduino Due is a hangover from older Arduino designs. I think the only reason for it is so that you can program the Due from the Arduino IDE without having to press any buttons on the board, just like the other Arduinos. So on a 3D printer controller, there is really no reason to have it at all, assuming that the board makes the Erase button accessible.

Using the USB-over-serial interface to pass large amounts of data is just stupid. You need a port with built-in flow control. I remember the dramatic improvement we had with throughput to the Duet when I patched Pronterface over a year ago to not require each command to be acknowledged, which is something you can only do if the channel has flow control. Repetier host already had a similar option.

2. The other thing that makes the Alligator a poor choice at present IMO is that it runs ancient firmware designed for 8-bit processors. However, it should be very easy to port RepRapFirmware to it, then it would have modern features such as easy configuration, a good web interface, segmentation-free delta movement, and 30-second delta auto-calibration. It might also be possible to port Smoothieware to it.

Regarding your comments on the Duet:

- It has pads for a JTAG connector, you just need to add the connector.

- It has a separate chip for controlling 5V power to the USB port.

- You can add 2 extra extruders and heaters to the Duet using the Duet shield, which is a piggyback board rather like the one the Alligator has. You only need the DueX4 board if you want more than 3 extruders or 4 heaters in total.

The Duet isn't perfect - the Erase and Reset buttons are not well placed on boards prior to revision 0.8, and the change from a switching to a linear 5V regulator on the 0.8 board is IMO a backward step. But it does everything I need, at an affordable price.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

1. The USB-over-serial port on the Arduino Due is a hangover from older Arduino designs. I think the only reason for it is so that you can program the Due from the Arduino IDE without having to press any buttons on the board, just like the other Arduinos. So on a 3D printer controller, there is really no reason to have it at all, assuming that the board makes the Erase button accessible.

Using the USB-over-serial interface to pass large amounts of data is just stupid. You need a port with built-in flow control. I remember the dramatic improvement we had with throughput to the Duet when I patched Pronterface over a year ago to not require each command to be acknowledged, which is something you can only do if the channel has flow control. Repetier host already had a similar option.

2. The other thing that makes the Alligator a poor choice at present IMO is that it runs ancient firmware designed for 8-bit processors. However, it should be very easy to port RepRapFirmware to it, then it would have modern features such as easy configuration, a good web interface, segmentation-free delta movement, and 30-second delta auto-calibration. It might also be possible to port Smoothieware to it.

Regarding your comments on the Duet:

- It has pads for a JTAG connector, you just need to add the connector.

- It has a separate chip for controlling 5V power to the USB port.

- You can add 2 extra extruders and heaters to the Duet using the Duet shield, which is a piggyback board rather like the one the Alligator has. You only need the DueX4 board if you want more than 3 extruders or 4 heaters in total.

The Duet isn't perfect - the Erase and Reset buttons are not well placed on boards prior to revision 0.8, and the change from a switching to a linear 5V regulator on the 0.8 board is IMO a backward step. But it does everything I need, at an affordable price.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Alligator Board Q & A May 15, 2015 04:35PM |

Registered: 8 years ago Posts: 52 |

I don't know if I agree entirely on your first point, but I can concede there is a performance improvement wrt serial vs a native interface. I saw duet added the one chip to manage the 5v power - I figured that was to mitigate the 5v power problem.

I can agree on your 2nd one, I would love to see a reprapfirmware port, I know Repetier firmware works, Marlin Kimbra appears to work (as I compare/contrast it this weekend). I wonder what would it take to build the reprap firmware for this board. nonetheless, at least we can agree we each like our respective boards

I can agree on your 2nd one, I would love to see a reprapfirmware port, I know Repetier firmware works, Marlin Kimbra appears to work (as I compare/contrast it this weekend). I wonder what would it take to build the reprap firmware for this board. nonetheless, at least we can agree we each like our respective boards

|

Re: Alligator Board Q & A May 15, 2015 04:42PM |

Registered: 8 years ago Posts: 52 |

|

Re: Alligator Board Q & A May 16, 2015 04:40AM |

Registered: 10 years ago Posts: 14,672 |

It should be easy to port RepRapFirmware to the Alligator, because it and the Duet use the same mcu and are both similar to Arduino Due. All the hardware dependencies such as pin numbers and port IDs are in just 2 modules.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Alligator Board Q & A May 16, 2015 07:58AM |

Registered: 11 years ago Posts: 95 |

Repetier Firmware work very well on my delta machine , I love it

I've got high quality prints with Repetier + Alligator + delta machine.

Porting Alligator on RepRapFirmware requires :

- some fix to SPI communication

- add SPI EEPROM support

- add SPI DAC support for motor current

- add SPI FLASH support (useful for storing webserver files)

- add motor selectable microstep size support

I've got high quality prints with Repetier + Alligator + delta machine.

Porting Alligator on RepRapFirmware requires :

- some fix to SPI communication

- add SPI EEPROM support

- add SPI DAC support for motor current

- add SPI FLASH support (useful for storing webserver files)

- add motor selectable microstep size support

|

Re: Alligator Board Q & A May 16, 2015 01:16PM |

Registered: 8 years ago Posts: 52 |

I managed to get a PLA print off my alligator delta. aside from some mild distortion tuning and flow rate, it was a print!

it can only get better at this point. (see attached hint: the print is the heart )

I'm having some troubles with heat mgmt., I am curious, are you using 12v power or 24v power? if 24, I might have need to upgrade, or get creative with my heatbed & extruder setup, because 12v just does not seem able to sustain ABS level heat...If I plan to upgrade to the diamond nozzle, I'll need the piggy board and more extruders, and replace my hot end, so I have plans.. Of course, that would put me one step closer from starting the build on the 2nd printer.. I might have need of another board if I were to get into dev and test for reprap fw too

I might have need of another board if I were to get into dev and test for reprap fw too

i'm not smart enough to follow what needs to be added (right away), but I could take a stab at testing and proving capabilities if this port takes off.

Edited 1 time(s). Last edit at 05/16/2015 01:17PM by EljefedsecurIT.

it can only get better at this point. (see attached hint: the print is the heart )

I'm having some troubles with heat mgmt., I am curious, are you using 12v power or 24v power? if 24, I might have need to upgrade, or get creative with my heatbed & extruder setup, because 12v just does not seem able to sustain ABS level heat...If I plan to upgrade to the diamond nozzle, I'll need the piggy board and more extruders, and replace my hot end, so I have plans.. Of course, that would put me one step closer from starting the build on the 2nd printer..

I might have need of another board if I were to get into dev and test for reprap fw too

I might have need of another board if I were to get into dev and test for reprap fw too

i'm not smart enough to follow what needs to be added (right away), but I could take a stab at testing and proving capabilities if this port takes off.

Edited 1 time(s). Last edit at 05/16/2015 01:17PM by EljefedsecurIT.

|

Re: Alligator Board Q & A May 17, 2015 10:28AM |

Registered: 9 years ago Posts: 24 |

|

Re: Alligator Board Q & A May 17, 2015 09:52PM |

Registered: 8 years ago Posts: 52 |

tomxwagner, I imagine you would want to run ES6 along with the power and ground from the sensor bridge for ES5/ES6 pair. from there you would map out what your connector would do. my preference is for simple mechanical roller switches, as they are easily configurable in firmware... a search on the forums highlight some examples. if you plan on a heated bed, you might want to reconsider anything inductive/capacitive as they are sensitive to heat. opto/ir designs might also be useful options.

hope this helps.

hope this helps.

|

Re: Alligator Board Q & A May 18, 2015 12:17AM |

Registered: 9 years ago Posts: 24 |

|

Re: Alligator Board Q & A May 19, 2015 03:56AM |

Registered: 8 years ago Posts: 18 |

Hello Marco,

ist a nice Picture you take from the Display Board, but can you specify the Pins on the Display Board ? Witch Cable with ID, on witch Solderpin ? For Example: Pin 1 on Alligator Board to Solderpin ... on the Displayboard, that would be much easier for me to identify the correct Wiring !

I don t have any idea where on the Diplay is +3,3v or +5,0v and so on.

In Repetier Firmware Configurator i use the REPRAP SMART DISPLAY WITH SD-SLOT ? Or do i have to Change to something other ?

Greetings from Germany !

Prusa MK3s

Anycubic Photon Mono 4k

Isel Portalfräse, gesteuert mit TripleBeast und Eding CNC

ist a nice Picture you take from the Display Board, but can you specify the Pins on the Display Board ? Witch Cable with ID, on witch Solderpin ? For Example: Pin 1 on Alligator Board to Solderpin ... on the Displayboard, that would be much easier for me to identify the correct Wiring !

I don t have any idea where on the Diplay is +3,3v or +5,0v and so on.

In Repetier Firmware Configurator i use the REPRAP SMART DISPLAY WITH SD-SLOT ? Or do i have to Change to something other ?

Greetings from Germany !

Prusa MK3s

Anycubic Photon Mono 4k

Isel Portalfräse, gesteuert mit TripleBeast und Eding CNC

|

Re: Alligator Board Q & A May 20, 2015 01:49AM |

Registered: 8 years ago Posts: 52 |

I don't know if it helps, but I've been staring at this schema for a while, and thinking what it might take to have an adapter made to take in the 2 connectors and output them in the proper order...

I wrote a blog post to start mapping that out...

[eljefeproofs.azurewebsites.net]

now, unless there's a need for 3.3v on the 12864, i'm assuming that pin2 isn't really necessary.

Edited 2 time(s). Last edit at 05/20/2015 03:32AM by EljefedsecurIT.

I wrote a blog post to start mapping that out...

[eljefeproofs.azurewebsites.net]

now, unless there's a need for 3.3v on the 12864, i'm assuming that pin2 isn't really necessary.

Edited 2 time(s). Last edit at 05/20/2015 03:32AM by EljefedsecurIT.

|

Re: Alligator Board Q & A May 20, 2015 04:57AM |

Registered: 8 years ago Posts: 18 |

|

Re: Alligator Board Q & A May 21, 2015 12:33PM |

Registered: 9 years ago Posts: 24 |

|

Re: Alligator Board Q & A May 23, 2015 12:33PM |

Registered: 8 years ago Posts: 52 |

I have an old microsoft camera that worked good enough with ffmpeg before. i'll be giving that a try.

Marco, following up on an earlier piece of the thread, i'll try repetier server, i'm unsure of whether I will prefer it as I've worked with octoprint briefly before, is there anything special with it if I decide to go octoprint vs. repetier server??

EDIT: managed to answer my own questions wrt to octoprint. In the settings, you will need to manually add the serial port /dev/ttyAMA0. you may also need to double-check that your usb is actually disconnected from your pc, or anything else serial/communications related. I managed to spend a couple of hours trying to figure out why I could not talk to my printer from the very pi that it was powering... once I disconnected that, it was able to discover the printer on ttyAMA0.

I managed to spend a couple of hours trying to figure out why I could not talk to my printer from the very pi that it was powering... once I disconnected that, it was able to discover the printer on ttyAMA0.

also, be double-sure that in raspi-config, that you have set serial connection to , and have rebooted your Pi. and disconnected the usb cable.

Edited 1 time(s). Last edit at 05/23/2015 06:17PM by EljefedsecurIT.

Marco, following up on an earlier piece of the thread, i'll try repetier server, i'm unsure of whether I will prefer it as I've worked with octoprint briefly before, is there anything special with it if I decide to go octoprint vs. repetier server??

EDIT: managed to answer my own questions wrt to octoprint. In the settings, you will need to manually add the serial port /dev/ttyAMA0. you may also need to double-check that your usb is actually disconnected from your pc, or anything else serial/communications related.

I managed to spend a couple of hours trying to figure out why I could not talk to my printer from the very pi that it was powering... once I disconnected that, it was able to discover the printer on ttyAMA0.

I managed to spend a couple of hours trying to figure out why I could not talk to my printer from the very pi that it was powering... once I disconnected that, it was able to discover the printer on ttyAMA0. also, be double-sure that in raspi-config, that you have set serial connection to , and have rebooted your Pi. and disconnected the usb cable.

Edited 1 time(s). Last edit at 05/23/2015 06:17PM by EljefedsecurIT.

|

Re: Alligator Board Q & A May 23, 2015 01:14PM |

Registered: 9 years ago Posts: 24 |

Hi,

maybe I will try the raspberry cam. Could not make my cloud IP cam (Dlink DCS-942L)working on eiter repetier nor octoprint.

Octoprint is also a pretty piece of software and is quite an option in the case repetier makes its software to pay for.

At the moment I prefer repetier server, and I also use their firmware - without problems, so far. Lets see what comes next?

deltaTower - Alligator Board - modified E3D hotend - Repetier 0.92 FW - RepetierServer

maybe I will try the raspberry cam. Could not make my cloud IP cam (Dlink DCS-942L)working on eiter repetier nor octoprint.

Octoprint is also a pretty piece of software and is quite an option in the case repetier makes its software to pay for.

At the moment I prefer repetier server, and I also use their firmware - without problems, so far. Lets see what comes next?

deltaTower - Alligator Board - modified E3D hotend - Repetier 0.92 FW - RepetierServer

|

Re: Alligator Board Q & A May 23, 2015 06:06PM |

Registered: 8 years ago Posts: 52 |

you might want to try cams from this wiki page:

cams known to work with ffmpeg and raspberry pi

cams known to work with ffmpeg and raspberry pi

|

Re: Alligator Board Q & A May 27, 2015 10:15PM |

Registered: 8 years ago Posts: 52 |

|

Re: Alligator Board Q & A May 28, 2015 01:40PM |

Registered: 11 years ago Posts: 95 |

Quote

Hello,

which camera works well?

I use the rapsberrypi camera with mjpg-streamer, it works well with high quality stream .

Quote

is there a way to tune the motors in repetier? I have need of turning down my motors...they are well...hot..

Reduce motor current in Configuration.h, search MOTOR_CURRENT variable.

In Alligator MOTOR_CURRENT max value is 255 , corresponds to 2.5A .

|

Re: Alligator Board Q & A June 01, 2015 11:59AM |

Registered: 8 years ago Posts: 1 |

Hello,

I was wondering if it was normal to put heatsink on the Alligator DR8825 driver? I had to do that because of thermal shutdown if the current is more than 2amps.

Do you also had this issue?

I also have a lot of problem using the Repetier firmware with my custom cartesian printer. But with MarlinKimbra4Due, I don't have any problem so far!

Motor's are loud and vibrate a lot, microstepping doesn't seem to work properly, etc... Any idea?

Thank you!

Mike

I was wondering if it was normal to put heatsink on the Alligator DR8825 driver? I had to do that because of thermal shutdown if the current is more than 2amps.

Do you also had this issue?

I also have a lot of problem using the Repetier firmware with my custom cartesian printer. But with MarlinKimbra4Due, I don't have any problem so far!

Motor's are loud and vibrate a lot, microstepping doesn't seem to work properly, etc... Any idea?

Thank you!

Mike

|

Re: Alligator Board Q & A June 01, 2015 02:04PM |

Registered: 11 years ago Posts: 739 |

|

Re: Alligator Board Q & A June 01, 2015 02:49PM |

Registered: 8 years ago Posts: 18 |

Hello,

on Sunday i tried to instal Repetier for Alligator to my naked Board using only the Native USB and Arduino 1.6.3 without 12v Power with no effort ... i tought the native USB Port is only for Progamming, but not even Windows 7 didnt showed up the Alligator ???

I wrote a Mail to Marco and he told me to connect the Board with 12v and program with the UART USB Port. Ok i did what he told me and Windows took the Board as a HS-232 . With Arduino i compiled the Repetier and want to upload ( and yes i cleared the Flash) but Arduino says after compiling , no Device on COM6 ...

What do i wrong ? Is there a Special Windows Driver for Alligator ? I tried Arduino 1.5.8 also ... no effort ...

Ive no Idea how to get the Firmware on the Board

I am very pleased for some Ideas !

Greetings

Prusa MK3s

Anycubic Photon Mono 4k

Isel Portalfräse, gesteuert mit TripleBeast und Eding CNC

on Sunday i tried to instal Repetier for Alligator to my naked Board using only the Native USB and Arduino 1.6.3 without 12v Power with no effort ... i tought the native USB Port is only for Progamming, but not even Windows 7 didnt showed up the Alligator ???

I wrote a Mail to Marco and he told me to connect the Board with 12v and program with the UART USB Port. Ok i did what he told me and Windows took the Board as a HS-232 . With Arduino i compiled the Repetier and want to upload ( and yes i cleared the Flash) but Arduino says after compiling , no Device on COM6 ...

What do i wrong ? Is there a Special Windows Driver for Alligator ? I tried Arduino 1.5.8 also ... no effort ...

Ive no Idea how to get the Firmware on the Board

I am very pleased for some Ideas !

Greetings

Prusa MK3s

Anycubic Photon Mono 4k

Isel Portalfräse, gesteuert mit TripleBeast und Eding CNC

|

Re: Alligator Board Q & A June 01, 2015 06:12PM |

Registered: 8 years ago Posts: 52 |

Quote

maralb

MOTOR CURRENT Is PERCENT

exaggerated its setting

#define MOTOR_CURRENT_PERCENT { 250,200,170,230,230}

I've been looking into this, I do not believe it is

MOTOR_CURRENT_PERCENT

it is

MOTOR_CURRENT

, now, if you are saying that 0-255 is a percentage of 0-100, then

- 128 = 50%, or 1.25a

-135 = 52.9%, or 1.32a

-170 = 67%, or 1.6a

- 200 = 78%, or 1.95a

- 230 = 90%, or 2.25a

-255 = 100%, or 2.5a

does that seem right?

|

Re: Alligator Board Q & A June 01, 2015 06:23PM |

Registered: 8 years ago Posts: 52 |

Quote

JET-A1

Hello,

on Sunday i tried to instal Repetier for Alligator to my naked Board using only the Native USB and Arduino 1.6.3 without 12v Power with no effort ... i tought the native USB Port is only for Progamming, but not even Windows 7 didnt showed up the Alligator ???

I wrote a Mail to Marco and he told me to connect the Board with 12v and program with the UART USB Port. Ok i did what he told me and Windows took the Board as a HS-232 . With Arduino i compiled the Repetier and want to upload ( and yes i cleared the Flash) but Arduino says after compiling , no Device on COM6 ...

What do i wrong ? Is there a Special Windows Driver for Alligator ? I tried Arduino 1.5.8 also ... no effort ...

Ive no Idea how to get the Firmware on the Board

I am very pleased for some Ideas !

Greetings

there shouldn't be any special drivers. you simply need the Arduino IDE 1.6.3 or .4. in either case, you will need to load the ARM drivers. check out this post [eljefeproofs.azurewebsites.net]

if your IDE is set up, and you have the ARM drivers all configured, the Arduino IDE should show your board on one of the ports. if not, it may have something to do with how you handle the DIP switch dance

When I would flash my firmware, I would put the DIP switch in the center or bottom position, closest the ARM chip. when I want to re-flash it, I would switch it top the setting furthest from the ARM chip, press the reset button. this clears out the flash and you have a clean (bricked) board, ready for you to re-flash.

then I put the switch back into either center, or down, closest to the ARM chip. once doing that, I would flash my firmware. at the end, it would say something like CPU reset, at that point I would hit the reset button, and my firmware would be on my board. take care not to attempt to flash using the MCU drivers on the UART port, or vice-versa. it shouldn't cause you an issue, but it should block you and tell you to pick the right board and port...

hope this helps...

I also use the UART USB exclusively. mine is set to 115200 serial. Windows should not have any problems finding a serial port on one of the COM's once that is configured.

|

Re: Alligator Board Q & A June 01, 2015 06:41PM |

Registered: 8 years ago Posts: 52 |

Quote

theprophet

Hello,

I was wondering if it was normal to put heatsink on the Alligator DR8825 driver? I had to do that because of thermal shutdown if the current is more than 2amps.

Do you also had this issue?

I also have a lot of problem using the Repetier firmware with my custom cartesian printer. But with MarlinKimbra4Due, I don't have any problem so far!

Motor's are loud and vibrate a lot, microstepping doesn't seem to work properly, etc... Any idea?

Thank you!

Mike

I've not had to put a heatsink on the alligator; given the last couple of comments you might want to check your motor current. you might want to make sure thermal shutdown isn't happening because of your heater extruders; that's what was killing my printer...motors were fine.

microstepping is affected by the #steps on your motors and the count that the firmware assumes for your step motor. for example, my 400 step .9 degree motors at 1/32 microstepping at set to 320 steps/mm (I believe?)

I had issues with Marlin in the past, if I could get it to work I might have tried that instead, but I already had a working mega board with repetier, so this was a natural selection for me.

|

Re: Alligator Board Q & A June 02, 2015 01:15AM |

Registered: 8 years ago Posts: 18 |

Hello EljefedsecurIT,

i just set up the Arduino 1.6.3 like you said on your Blog. When i connect my Alligator with the USB MCU Port, nothing happens, Windows is not tking the Alligator , no Looking for Driver , nothing. It seems, that the USB MCU Port is Dead !

When i put 12v and use the UART USB Port on Alligator , Windows is lokking for Driver and tkes the board as a HS 232 in Printer an Devices.

before Firmware instal i put the Dipswitch, who is normaly in the toward Processor Position , in toward Motor engine, press the Reset Button wait for a secound, put dipswitsch in toward Processor Position and press the reset Button again , wait a secound , like ist dicribbled in the Alligator Github Documentation.

Arduino compiles the sketch after it it say no device on com 6, where com 6 is the virtual USB adress.

Is anyone having programming issue with Windows 7 64 and USB 3 ?

can it be possible that the marked IC on the Picture is not really welded ? I see some Copper on the PCB and the Chip is not on the marked Position on the PCB ! Maybe this causing my Problems ?

Greetings

Edited 1 time(s). Last edit at 06/02/2015 01:36AM by JET-A1.

Prusa MK3s

Anycubic Photon Mono 4k

Isel Portalfräse, gesteuert mit TripleBeast und Eding CNC

i just set up the Arduino 1.6.3 like you said on your Blog. When i connect my Alligator with the USB MCU Port, nothing happens, Windows is not tking the Alligator , no Looking for Driver , nothing. It seems, that the USB MCU Port is Dead !

When i put 12v and use the UART USB Port on Alligator , Windows is lokking for Driver and tkes the board as a HS 232 in Printer an Devices.

before Firmware instal i put the Dipswitch, who is normaly in the toward Processor Position , in toward Motor engine, press the Reset Button wait for a secound, put dipswitsch in toward Processor Position and press the reset Button again , wait a secound , like ist dicribbled in the Alligator Github Documentation.

Arduino compiles the sketch after it it say no device on com 6, where com 6 is the virtual USB adress.

Is anyone having programming issue with Windows 7 64 and USB 3 ?

can it be possible that the marked IC on the Picture is not really welded ? I see some Copper on the PCB and the Chip is not on the marked Position on the PCB ! Maybe this causing my Problems ?

Greetings

Edited 1 time(s). Last edit at 06/02/2015 01:36AM by JET-A1.

Prusa MK3s

Anycubic Photon Mono 4k

Isel Portalfräse, gesteuert mit TripleBeast und Eding CNC

|

Re: Alligator Board Q & A June 02, 2015 05:33AM |

Registered: 8 years ago Posts: 5 |

I recently received my alligator board and had it running yesterday. I need to finish the printer itself but i've got the motors running using repetier firmware and software on windows 7 64bit. Software downloaded from repetier and firmware from [github.com] (src > arduinodue > repetier, check configuration.h with the repetier manual, currently its configured for a deltaprinter)

JET-A1, did you follow the steps described on [github.com] in the readme file, copying the files to the described locations?

Also mine did not work without powering it with 12v so that seems 'right'.

Greetings

Mark

Edited 1 time(s). Last edit at 06/02/2015 05:45AM by Mark_O.

JET-A1, did you follow the steps described on [github.com] in the readme file, copying the files to the described locations?

Also mine did not work without powering it with 12v so that seems 'right'.

Greetings

Mark

Edited 1 time(s). Last edit at 06/02/2015 05:45AM by Mark_O.

Sorry, only registered users may post in this forum.