Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header?

Posted by SOI Sentinel

|

Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header? September 22, 2007 02:13AM |

Registered: 16 years ago Posts: 113 |

Hi all,

This isn't a critical question right now, but let me explain what I'm looking for some feedback on. I'm mucking around with a design for an SBC for RepRap. Power conditioning will be done offchip and final conditioning on-chip. My current board is using a dsPIC33, but an ARM chip could work for someone else.

I'm planning on four "slots" on this board. Each slot will be capable of taking an adder card. It could be digital or analog IO, I am planning Slot0 to have the wires to run the ICD2 through on mine for dsPIC programming. Primary use will be motor driver boards. This lets me isolate the motor drives from the logic supply, use higher voltage boards if I wish with the same logic, or test or mix and match motor driver boards. I'm currently planning fully integrated H bridges, possibly stepper boards, and half-H's for testing control schemes for brushless DC motors.

I'm currently planning the following pins (might add a few more, I'm using a TQFP package for this). All pins are from the microcontroller's viewpoint

2 analog inputs

Analog power

Analog ground

Digital power (3.3V and 5V)

Digital ground

2 PWM outputs

4 general IO

SPI with chip select

I2C

2 I2C address lines, hardwired to the slot

uC Board Reset

the SPI is there for high speed IO needs (be it an SPI IO expander or if the motor chip needs some configuration before run). The I2C can also be used for slow IO, but its primary purpose is to provide a hardwired addressable EEPROM on the board to allow for auto detection and configuration.

Two PWM signals allow me to either directly drive a high and low side MOSFET or control more advanced systems. I can also get additional general IO that way. I've looked through quite a few motor driver chips, and few use more than 4 IO and 2 PWM. Those that do don't use the additional pins for anything highspeed such as motor direction or fault alerts and can be relegated to an SPI IO expander if needed at all. The two analog signals allow for various schemes of current detection to be used.

This does complicate the designs since I now need additional boards and real estate, but I can keep the XY footprint smaller this way, easily set up a fan to cool my motor driver "fins", test different driver concepts, and replace damaged motor drivers with spares and without a full board refit .

Theres also some fancy buffer and logic interlocks I'm looking at for when voltage shifts are needed, and that'll be a few more pins.

------------------------

Now that I've put the idea of what I'm looking at, I'm curious what everyone's opinion would be. I'm considering older style "card edge" connectors versus a 0.1" dual row pin header.

The Card edge connector has the advantage of being a bit more mechanically sound, capable of high currents if the design needs it (5A/pin, nice but no plans for this right now), and mechanically simpler as I'd only have to etch the card fingers instead of solder on a pin header. Disadvantages are that you have to get the edge spacing right for that connector and the connector probably needs to be plated to keep it from corroding.

The dual row pin header has the advantage of more recognizable parts and more compeition and they can easily be expanded by common hardware (especially if made to match with 40 pin ATA EIDE cabling). Disadvantage is that I'd need to solder a multipin connector on every driver card, I'd probably need to develop some type of card support rail system to keep it even marginally sound, and concern over bent pins. Given the analog and high frequency IO, I'd probably have to make one row all ground connections just to provide lots of guard grounds against coupling noise. Dual row is a requirement then.

Price is actually somewhat cheaper for the first set for the card edge connector, and it drops from there.

This isn't a critical question right now, but let me explain what I'm looking for some feedback on. I'm mucking around with a design for an SBC for RepRap. Power conditioning will be done offchip and final conditioning on-chip. My current board is using a dsPIC33, but an ARM chip could work for someone else.

I'm planning on four "slots" on this board. Each slot will be capable of taking an adder card. It could be digital or analog IO, I am planning Slot0 to have the wires to run the ICD2 through on mine for dsPIC programming. Primary use will be motor driver boards. This lets me isolate the motor drives from the logic supply, use higher voltage boards if I wish with the same logic, or test or mix and match motor driver boards. I'm currently planning fully integrated H bridges, possibly stepper boards, and half-H's for testing control schemes for brushless DC motors.

I'm currently planning the following pins (might add a few more, I'm using a TQFP package for this). All pins are from the microcontroller's viewpoint

2 analog inputs

Analog power

Analog ground

Digital power (3.3V and 5V)

Digital ground

2 PWM outputs

4 general IO

SPI with chip select

I2C

2 I2C address lines, hardwired to the slot

uC Board Reset

the SPI is there for high speed IO needs (be it an SPI IO expander or if the motor chip needs some configuration before run). The I2C can also be used for slow IO, but its primary purpose is to provide a hardwired addressable EEPROM on the board to allow for auto detection and configuration.

Two PWM signals allow me to either directly drive a high and low side MOSFET or control more advanced systems. I can also get additional general IO that way. I've looked through quite a few motor driver chips, and few use more than 4 IO and 2 PWM. Those that do don't use the additional pins for anything highspeed such as motor direction or fault alerts and can be relegated to an SPI IO expander if needed at all. The two analog signals allow for various schemes of current detection to be used.

This does complicate the designs since I now need additional boards and real estate, but I can keep the XY footprint smaller this way, easily set up a fan to cool my motor driver "fins", test different driver concepts, and replace damaged motor drivers with spares and without a full board refit .

Theres also some fancy buffer and logic interlocks I'm looking at for when voltage shifts are needed, and that'll be a few more pins.

------------------------

Now that I've put the idea of what I'm looking at, I'm curious what everyone's opinion would be. I'm considering older style "card edge" connectors versus a 0.1" dual row pin header.

The Card edge connector has the advantage of being a bit more mechanically sound, capable of high currents if the design needs it (5A/pin, nice but no plans for this right now), and mechanically simpler as I'd only have to etch the card fingers instead of solder on a pin header. Disadvantages are that you have to get the edge spacing right for that connector and the connector probably needs to be plated to keep it from corroding.

The dual row pin header has the advantage of more recognizable parts and more compeition and they can easily be expanded by common hardware (especially if made to match with 40 pin ATA EIDE cabling). Disadvantage is that I'd need to solder a multipin connector on every driver card, I'd probably need to develop some type of card support rail system to keep it even marginally sound, and concern over bent pins. Given the analog and high frequency IO, I'd probably have to make one row all ground connections just to provide lots of guard grounds against coupling noise. Dual row is a requirement then.

Price is actually somewhat cheaper for the first set for the card edge connector, and it drops from there.

|

Re: Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header? September 22, 2007 09:58AM |

Admin Registered: 17 years ago Posts: 7,879 |

Card edge fingers need to be gold plated IMHO. Sir Clive Sinclair thought he could get away with solder tinning on the ZX81 expansion connector but it was a nightmare.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header? September 22, 2007 11:46AM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header? September 29, 2007 06:15PM |

Registered: 16 years ago Posts: 113 |

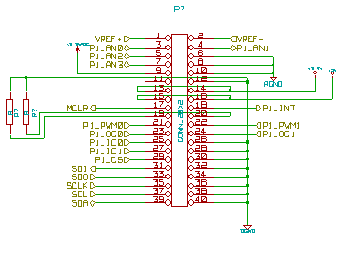

Thanks for the feedback, Here's what I've decided on in the meantime (subject to change upon final routing requirements/headaches).

|

Re: Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header? October 02, 2007 07:24PM |

Hey. This looks quite interesting as an approach.

Obviously in the future the RepRap electronics will get more complicated, so having a more 'generic' module could be good.

My two cents' worth:

1) You might want an IRQ line from the card. These could all be ORed on the SBC, but I think that you want a protective 'trip' functionality.

2) You might also want to have some 'address' pins for the board. These would be set to prearranged codes on the SBC and allow the daughter boards to know which slot they're in. Something I've seen around and about is that many I2C chips have similar addresses, and you need some way to address individual chips or the output will be really strange.

3) Another SPI CS line could be useful - you don't want to limit your chip space too much.

4) The SPI will be either 3.3V or 5V... would the card or the SBC be responsible for level conversion (if necessary). These days everything is moving towards 3.3V operation so it could be easiest to just get rid of the 5V.

Jono

Obviously in the future the RepRap electronics will get more complicated, so having a more 'generic' module could be good.

My two cents' worth:

1) You might want an IRQ line from the card. These could all be ORed on the SBC, but I think that you want a protective 'trip' functionality.

2) You might also want to have some 'address' pins for the board. These would be set to prearranged codes on the SBC and allow the daughter boards to know which slot they're in. Something I've seen around and about is that many I2C chips have similar addresses, and you need some way to address individual chips or the output will be really strange.

3) Another SPI CS line could be useful - you don't want to limit your chip space too much.

4) The SPI will be either 3.3V or 5V... would the card or the SBC be responsible for level conversion (if necessary). These days everything is moving towards 3.3V operation so it could be easiest to just get rid of the 5V.

Jono

|

Re: Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header? October 02, 2007 08:39PM |

Registered: 16 years ago Posts: 113 |

Dissection time!

1) See pin 18? P1_INT. External interrupt pin for my dsPIC.

2) The pair of resistors are there for 2 bit slot addressing of the I2C EEPROM plus whatever else I need it for.

3) Well, I'm considering another chip select, but since this is not hardware defined on my platform, I can use any of the IC/OC/PWM pins that aren't used for motor control as a CS line.

4) The card is responsible for conversion. However, most motor control chips, if they have need of an external power supply, require 5V. Other than the analog lines, all other lines are 5V input tolerant on the dsPIC. If I need 5V output, the shifting has to be done on the card. Hmmm... I forgot something. Looks like I'm sacrificing one of my digital ground pins to provide a card logic power line. This way, say you're running a 2.5V CPU in the future. As long as you can absorb (or the card is designed to shift) 5V inputs, this will let you do 5V outputs still.

(Addendum)

Let's see...

While I could easily set up a stepper motor control with this setup, I'm personally more interested in motor control. My personal plans for these are to standardize on an automotive motor control chip for most 12V DC motor applications ( [www.st.com] ). The separation of the main power bus also lets me mix in 24VDC power if I can find a cheap but high amp power supply ( [www.freescale.com] ).

I'm also interested in brushless DC servo loops, but to get the CPU to close these servo loops are more CPU and interrupt intensive, so I expect these to have their own dedicated DSPs. This may change if I find the right control chip that lets me get torque and not worry about commutation.

All the axes are going to get Austria Microsystems mag encoder chips on them, but I'm using differential driver chips and the SSI absolute readings to close the loops.

Edited 1 time(s). Last edit at 10/02/2007 11:26PM by SOI Sentinel.

1) See pin 18? P1_INT. External interrupt pin for my dsPIC.

2) The pair of resistors are there for 2 bit slot addressing of the I2C EEPROM plus whatever else I need it for.

3) Well, I'm considering another chip select, but since this is not hardware defined on my platform, I can use any of the IC/OC/PWM pins that aren't used for motor control as a CS line.

4) The card is responsible for conversion. However, most motor control chips, if they have need of an external power supply, require 5V. Other than the analog lines, all other lines are 5V input tolerant on the dsPIC. If I need 5V output, the shifting has to be done on the card. Hmmm... I forgot something. Looks like I'm sacrificing one of my digital ground pins to provide a card logic power line. This way, say you're running a 2.5V CPU in the future. As long as you can absorb (or the card is designed to shift) 5V inputs, this will let you do 5V outputs still.

(Addendum)

Let's see...

While I could easily set up a stepper motor control with this setup, I'm personally more interested in motor control. My personal plans for these are to standardize on an automotive motor control chip for most 12V DC motor applications ( [www.st.com] ). The separation of the main power bus also lets me mix in 24VDC power if I can find a cheap but high amp power supply ( [www.freescale.com] ).

I'm also interested in brushless DC servo loops, but to get the CPU to close these servo loops are more CPU and interrupt intensive, so I expect these to have their own dedicated DSPs. This may change if I find the right control chip that lets me get torque and not worry about commutation.

All the axes are going to get Austria Microsystems mag encoder chips on them, but I'm using differential driver chips and the SSI absolute readings to close the loops.

Edited 1 time(s). Last edit at 10/02/2007 11:26PM by SOI Sentinel.

|

mimarob to lazy to login...

Re: Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header? January 05, 2008 04:50PM |

|

Re: Semi-Industrial RepRap Board Design Question: Card Edge or Pin Header? January 16, 2008 04:09PM |

Registered: 16 years ago Posts: 58 |

Maybe it will be better to wait with this project a little. Conductive material extruder should be main step just after Darwin release. As far as I understand, manufacturing of this high-modular system will be perfect goal for next-genration RepRap. And the best design of RepRap-made design depend of RepRap printing capabilities.

After all, maybe best form-factor for RepRap-made electronics will be solid-cube with 3d-wiring inside it...connected in some way like, LEGO for example.

So, as far as this project was described as long-therm one, I propose to concentrate on electronic logic instead of phisical realisation questions.

After all, maybe best form-factor for RepRap-made electronics will be solid-cube with 3d-wiring inside it...connected in some way like, LEGO for example.

So, as far as this project was described as long-therm one, I propose to concentrate on electronic logic instead of phisical realisation questions.

Sorry, only registered users may post in this forum.