Stepper Motor Power

Posted by lordcat

|

Stepper Motor Power November 03, 2007 08:23PM |

Registered: 16 years ago Posts: 20 |

So I've been running my new boards with my NEMA 17 motors for a while today, and I've noticed that the motors have been getting really hot...

Then I got to thinking about the voltage going to them... these motors are apparently rated for 5.1V... but am I correct in guessing that the stepper driver board is putting out closer to 9-12V?

What voltage are these boards made for? and is there an easy way to bring that voltage down to the range of 3.3-5.1V?

lordcat

Then I got to thinking about the voltage going to them... these motors are apparently rated for 5.1V... but am I correct in guessing that the stepper driver board is putting out closer to 9-12V?

What voltage are these boards made for? and is there an easy way to bring that voltage down to the range of 3.3-5.1V?

lordcat

|

Re: Stepper Motor Power November 03, 2007 09:12PM |

Registered: 16 years ago Posts: 447 |

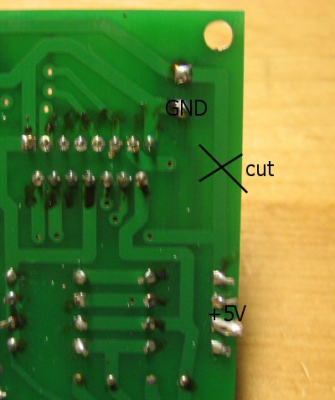

OK, this is based on looking at the board for maybe 2 minutes. I could be completely wrong and this could completely fry the board but, based on what I can see, you can mod the board for a 5V stepper like this:

1. cut the trace between the +12V line and the L298N

2. solder an alternate +5V supply where marked

3. use the - supply as a common ground

That should send 5V to the stepper motor without affecting the rest of the board.

Another possibility is to drive the whole board off of 5V. To do that, you'd remove U1, jumper the +12V bus to the +5V bus and hook up a regulated 5V supply to the power terminals. P4, P6 and P7 won't work but you probably don't need them.

Again, just a wild guess based on a cursory look at the board.

1. cut the trace between the +12V line and the L298N

2. solder an alternate +5V supply where marked

3. use the - supply as a common ground

That should send 5V to the stepper motor without affecting the rest of the board.

Another possibility is to drive the whole board off of 5V. To do that, you'd remove U1, jumper the +12V bus to the +5V bus and hook up a regulated 5V supply to the power terminals. P4, P6 and P7 won't work but you probably don't need them.

Again, just a wild guess based on a cursory look at the board.

|

Anonymous User

Re: Stepper Motor Power November 04, 2007 01:43AM |

You're right that the stepper board will be feeding your motor 9 volts or so. The easy way to bring the voltage down is to lower the Torque setting in the preferences. That causes the PIC to toggle the power to the motor on and off rapidly, which will limit the amount of current going through the motor's coils (which is what you really care about).

I've read that a good approximation of the correct setting is the percentage of the actual voltage you want your motor to get. A 5 volt motor on a 9ish volt supply would need a setting of around 55%. If you can turn the torque down even further without skipping steps, that's even better -- you'll use less power and generate less heat.

If you don't want to mess with the torque setting, you could put some resistors inline with the motor (one on each winding) to drop the voltage to whatever you want.

I've read that a good approximation of the correct setting is the percentage of the actual voltage you want your motor to get. A 5 volt motor on a 9ish volt supply would need a setting of around 55%. If you can turn the torque down even further without skipping steps, that's even better -- you'll use less power and generate less heat.

If you don't want to mess with the torque setting, you could put some resistors inline with the motor (one on each winding) to drop the voltage to whatever you want.

|

Re: Stepper Motor Power November 04, 2007 08:32AM |

Registered: 16 years ago Posts: 20 |

|

Re: Stepper Motor Power November 06, 2007 11:16AM |

Registered: 16 years ago Posts: 447 |

Sorry, only registered users may post in this forum.