|

Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 12:35AM |

Registered: 9 years ago Posts: 245 |

Firstly:

I don't know wheter this is an Sbase issue or a Smoothieware issue.

Previous builds:

I have build several printers, all of them based on Arduino+ramps + marlin firmware. Been using different drivers like A4988, DRV8825 and Silent Step Stick (TMC2100).

All of them Works fine with my motors, except maybe DRV8825, which tends to make a whining noise. I normally use them as extruder driver though due to the higher current output.

Symptoms on Sbase 1.2 with Smoothieware and onboard drivers:

The motors whine a lot, which forces me to set current according to whine and not performance, which is extremely annoying! This is the minor issue though...

The biggest issue is how the printer sounds and feels like my motors are being ripped apart/punished... feels like every single move is being forced a lot, which makes my machines vibrate and make grinding noises... almost like if I had a bad ball-bearing or something.. just much worse.

The extruder works but makes loud ticking noises every move.. sounds like it is being jump-started and violently pulled forward and then stopped abrutly... with each little step!

Mitigate by using external drivers - almost

When I use DRV8825 on external drivers they behave the same. Remember I could use these drivers ok on Marlin.

A4988 drivers on external driver boards and my printer runs smoothly and silenty again.

I use the 17HS4401N motor for my XYZ

Voltage: 3.4

Amp/current: 1.7

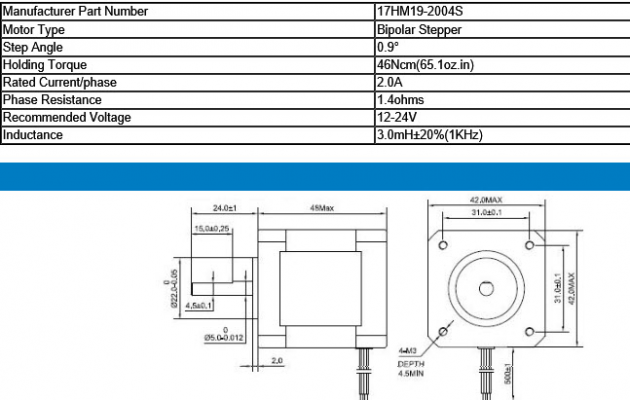

I use 17HM19-2004S as my extruder motor

Voltage: 2.8

Amp: 2

In Smoothieware I have tried setting current to everything from 0.4 to 1 for XYZ and up to 1.2 for extruder.

Only real change regarding noise is how the annoying whine change frequency.

I have not changed any frequency or something like that, but maybe there is a firmware setting to make the moves less aggressive? I hope so, as it doesn't make sense that I have to use external drivers for all axes?

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

I don't know wheter this is an Sbase issue or a Smoothieware issue.

Previous builds:

I have build several printers, all of them based on Arduino+ramps + marlin firmware. Been using different drivers like A4988, DRV8825 and Silent Step Stick (TMC2100).

All of them Works fine with my motors, except maybe DRV8825, which tends to make a whining noise. I normally use them as extruder driver though due to the higher current output.

Symptoms on Sbase 1.2 with Smoothieware and onboard drivers:

The motors whine a lot, which forces me to set current according to whine and not performance, which is extremely annoying! This is the minor issue though...

The biggest issue is how the printer sounds and feels like my motors are being ripped apart/punished... feels like every single move is being forced a lot, which makes my machines vibrate and make grinding noises... almost like if I had a bad ball-bearing or something.. just much worse.

The extruder works but makes loud ticking noises every move.. sounds like it is being jump-started and violently pulled forward and then stopped abrutly... with each little step!

Mitigate by using external drivers - almost

When I use DRV8825 on external drivers they behave the same. Remember I could use these drivers ok on Marlin.

A4988 drivers on external driver boards and my printer runs smoothly and silenty again.

I use the 17HS4401N motor for my XYZ

Voltage: 3.4

Amp/current: 1.7

I use 17HM19-2004S as my extruder motor

Voltage: 2.8

Amp: 2

In Smoothieware I have tried setting current to everything from 0.4 to 1 for XYZ and up to 1.2 for extruder.

Only real change regarding noise is how the annoying whine change frequency.

I have not changed any frequency or something like that, but maybe there is a firmware setting to make the moves less aggressive? I hope so, as it doesn't make sense that I have to use external drivers for all axes?

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 02:48AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 04:24AM |

Registered: 9 years ago Posts: 245 |

Any idea on what to change in firmware, if possible?Quote

o_lampe

IIRC the step-pulse duration on some 32bit boards is pretty short. Don't remember exactly if it was a smoothie- or RRP firmware. ( dc42_delta version )

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 04:54AM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

IIRC the step-pulse duration on some 32bit boards is pretty short. Don't remember exactly if it was a smoothie- or RRP firmware. ( dc42_delta version )

I think you are referring to an issue that someone had with RepRapFirmware on RADDS with DRV8825 drivers. The DRV8825s need a wider step pulse and a longer interval between step pulses than the A4982 drivers used in the Duet, and RRF wasn't providing enough time for the DRV8825 when running at high speeds. The pulse timing isn't yet configurable in the config.g file for RRF, so Dan Newman did a patch to the RADDS port to lengthen the times.

The problem with DRV8825 drivers whining in fast decay mode is well-known. A solution that works for some is to increase the voltage drop of the motors by putting back-to-back diodes in series with them, see [cabristor.blogspot.co.uk].

My advice is to avoid DRV8825 drivers. Either stick to the A4982/A4988 series, or if you want higher microstepping then go for THB6128, TMC2100 or one of the other modern driver chips.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 05:33AM |

Registered: 9 years ago Posts: 245 |

Whining. yea, I know I can increase or decrease current.Quote

dc42

Quote

o_lampe

IIRC the step-pulse duration on some 32bit boards is pretty short. Don't remember exactly if it was a smoothie- or RRP firmware. ( dc42_delta version )

I think you are referring to an issue that someone had with RepRapFirmware on RADDS with DRV8825 drivers. The DRV8825s need a wider step pulse and a longer interval between step pulses than the A4982 drivers used in the Duet, and RRF wasn't providing enough time for the DRV8825 when running at high speeds. The pulse timing isn't yet configurable in the config.g file for RRF, so Dan Newman did a patch to the RADDS port to lengthen the times.

The problem with DRV8825 drivers whining in fast decay mode is well-known. A solution that works for some is to increase the voltage drop of the motors by putting back-to-back diodes in series with them, see [cabristor.blogspot.co.uk].

My advice is to avoid DRV8825 drivers. Either stick to the A4982/A4988 series, or if you want higher microstepping then go for THB6128, TMC2100 or one of the other modern driver chips.

It's hard to drop DRV8825 since they are soldered onto the board.

I have a couple of external driver boards, but I do have 2 printers running this setup, so I'd need a lot of external drivers to drop 8825... there must be some firmware fix for this? Surely!?

I experienced whining in Marlin for sure, but the machine never acted as if a 10hk motor is trying to drive my tiny axes...

I have actually lowered the "jerk" (can't remember the name in smoothieware), as it was even worse to begin.. can only improve up to a certain point though, and nothing close to fixiing this.

That is pure alien-spakeQuote

dc42

The problem with DRV8825 drivers whining in fast decay mode is well-known. A solution that works for some is to increase the voltage drop of the motors by putting back-to-back diodes in series with them, see [cabristor.blogspot.co.uk]

Is it something like this? [www.watterott.com]

Is it something like this? [www.watterott.com]Edit: I actually have read that article several times.. only thing I understood is that DRV8825 is bad when using higher input voltage than the voltage needed to drive the motor... He didn't quantify it though, so is it 12 to 3, 24 to 3 or 200 to 3?.. meaning it was rather useless for me aside from stating that there are tangible problems Associated with the 8825

Edited 3 time(s). Last edit at 05/22/2016 05:38AM by dintid.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 07:53AM |

Registered: 10 years ago Posts: 14,672 |

Quote

dintid

Edit: I actually have read that article several times.. only thing I understood is that DRV8825 is bad when using higher input voltage than the voltage needed to drive the motor... He didn't quantify it though, so is it 12 to 3, 24 to 3 or 200 to 3?.. meaning it was rather useless for me aside from stating that there are tangible problems Associated with the 8825

It's not a fixed ratio, because it depends on the inductance of the motor as well as the supply voltage.

The voltage you need to drive the motors depends on how fast you want to step them, so reducing the supply voltage will in some cases reduce the available movement speed. The voltage quoted on the data sheet is the voltage needed to hold the motor still at maximum rated current.

The main effect of the diodes isn't to reduce the supply voltage, it's to increase the decay rate of the motor current when using mixed decay mode.

Quote

Is it something like this? [www.watterott.com]

They call that device a "protector", so although it appears to have 8 diodes, I suspect that it is actually a set of Schottky flyback diodes to carry the flyback current so that the driver chips don't have to. I have often wondered whether a similar arrangement would be effective in protecting stepper driver chips from motors being connected or disconnected with the power on.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 08:28AM |

Registered: 9 years ago Posts: 245 |

I find it odd how often people say someone need to adjust "decay", but there really isn't any way to do so for the average mortal.. I sure as heck can't do it.. don't even really know what it is.Quote

dc42

Quote

dintid

Edit: I actually have read that article several times.. only thing I understood is that DRV8825 is bad when using higher input voltage than the voltage needed to drive the motor... He didn't quantify it though, so is it 12 to 3, 24 to 3 or 200 to 3?.. meaning it was rather useless for me aside from stating that there are tangible problems Associated with the 8825

It's not a fixed ratio, because it depends on the inductance of the motor as well as the supply voltage.

The voltage you need to drive the motors depends on how fast you want to step them, so reducing the supply voltage will in some cases reduce the available movement speed. The voltage quoted on the data sheet is the voltage needed to hold the motor still at maximum rated current.

The main effect of the diodes isn't to reduce the supply voltage, it's to increase the decay rate of the motor current when using mixed decay mode.

No need to explain it. It's just going to pass way over my head.

Again really didn't grasp the entirety of what you said, but is the gist of it, that you think it might Work to hinder the undesireable noise of the 8825 (not talking about whine)?Quote

dc42

Quote

dintid

Is it something like this? [www.watterott.com]

They call that device a "protector", so although it appears to have 8 diodes, I suspect that it is actually a set of Schottky flyback diodes to carry the flyback current so that the driver chips don't have to. I have often wondered whether a similar arrangement would be effective in protecting stepper driver chips from motors being connected or disconnected with the power on.

Asking as I am going to buy a few TMC2100 at some point, and would buy some of these protectors if they might make smoothieware more edible.

Edited 1 time(s). Last edit at 05/22/2016 08:29AM by dintid.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 08:30AM |

Registered: 9 years ago Posts: 245 |

Regardless of all of the above talk about 8825 decay rate and Things I do not understand really... surely there must be some firmware setting to adjust to mitigate this?

The printers can run soooo nice and silently on marlin.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

The printers can run soooo nice and silently on marlin.

My Instructables - both total newbie instructables and some for intermediate users.

My Designs on Thingiverse

YouTube channel containing a few 3D printing videos - they are videos for my Instructables, and mostly not standalone.

Ultius / Tantillus Thingiverse Group

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 10:20AM |

Registered: 8 years ago Posts: 5,232 |

Quote

dc42

They call that device a "protector", so although it appears to have 8 diodes, I suspect that it is actually a set of Schottky flyback diodes to carry the flyback current so that the driver chips don't have to. I have often wondered whether a similar arrangement would be effective in protecting stepper driver chips from motors being connected or disconnected with the power on

I'm afraid all modern MOSFets already have an inbuilt flyback diode, so do the FET-based H-bridges.

|

Re: Sbase and/or Smoothieware + DRV8825 drivers makes my motors very noisy and vibrating + grinding sounds! May 22, 2016 05:23PM |

Registered: 10 years ago Posts: 14,672 |

Quote

o_lampe

Quote

dc42

They call that device a "protector", so although it appears to have 8 diodes, I suspect that it is actually a set of Schottky flyback diodes to carry the flyback current so that the driver chips don't have to. I have often wondered whether a similar arrangement would be effective in protecting stepper driver chips from motors being connected or disconnected with the power on

I'm afraid all modern MOSFets already have an inbuilt flyback diode, so do the FET-based H-bridges.

Of course I already know that. But the built-in flyback diodes are ordinary mosfet body diodes. The purpose of external Shottky diodes would be to conduct before the mosfet body diodes do, and to turn on and off faster. This may be relevant in the case of disconnecting a motor that is powered up. One day when I feel like blowing up a few stepsticks, I'll try it.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Sorry, only registered users may post in this forum.