2.54mm connector pin crimper review

Posted by mikey

|

2.54mm connector pin crimper review September 01, 2011 12:17PM |

Registered: 12 years ago Posts: 26 |

I don't know if anybody has reviewed any crimpers yet, but since I couldn't find anything about them, I thought this would be a good idea.

The standard header for the Arduino and RAMPS is the 2.54mm (.100") pitch header system. These are readily available as pins, and can be purchased for connectors with a little homework. I recently purchased sets of 4-pin and 3-pin crimpable pin connectors for use on the RAMPS V1.2. While having the proper connectors is good, not having a crimper that works effectively is bad. I have used needle nose pliers in a pinch, but B-style crimpers for these pins are the proper method to ensure an effective crimp that is unlikely to fail.

I have a Sargent crimper I use for Tyco econoseal crimping in automotive connections for cars and motorcycles, as well as in my work doing automation controls, but it was too large for the significantly smaller 2.54mm header pins. It would leave the insulation crimps undone, and would only properly reverse the conductor tabs part of the time. The rest of the time it would bend it in the wrong direction, requiring more work with the needle nose. The worst part about this is that the opening in the header connector body doesn't have enough space to allow for much error in the crimped end dimensions, and I wasted at least 1 for every 5 with it either failing to due dimensional tolerances, or simply breaking off. If more than 1 pin was already in the body and, due to a jammed pin, required removal for a new body, it stood as much chance to come out as be damaged on removal. This would be bad.

The solution? I did some research and found the proper sized crimper. I bought the MultiComp HT-225D from Newark. First off, it was only $26, which had me concerned, but on another electronics forum, the reviewer swore by it, so I figured since I have about $500 in the machine, $26 for a crimper was the least of my worries and worth checking out. It was delivered yesterday, and the difference in the quality by having the correct crimper is ASTOUNDING. I get a nice, clean crimp, all tabs bend correctly, fits right into the connector body easily, and doesn't damage the wire body behind the crimp, which was causing failures.

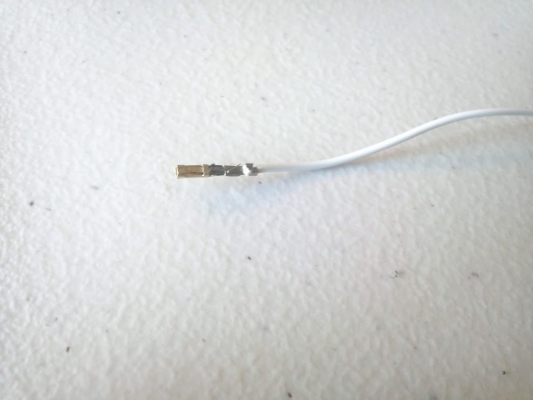

You can see how clean the crimp is, and how the insulation tab crimp is almost exactly the same size as the conductor tab crimp, nice and square, which lends itself to a clean insertion into the connector body. Based on my satisfaction with the quality and affordability of the device,I will also be buying replacement jaws for the unit, because they do suffer from wear over time, and I'd be less then thrilled to find the unit was no longer offered when I needed new jaws.

Bottom line: Well worth the $26 to have a proper crimp on connector pins. Highly recommended.

Edited 4 time(s). Last edit at 09/01/2011 12:48PM by mikey.

The standard header for the Arduino and RAMPS is the 2.54mm (.100") pitch header system. These are readily available as pins, and can be purchased for connectors with a little homework. I recently purchased sets of 4-pin and 3-pin crimpable pin connectors for use on the RAMPS V1.2. While having the proper connectors is good, not having a crimper that works effectively is bad. I have used needle nose pliers in a pinch, but B-style crimpers for these pins are the proper method to ensure an effective crimp that is unlikely to fail.

I have a Sargent crimper I use for Tyco econoseal crimping in automotive connections for cars and motorcycles, as well as in my work doing automation controls, but it was too large for the significantly smaller 2.54mm header pins. It would leave the insulation crimps undone, and would only properly reverse the conductor tabs part of the time. The rest of the time it would bend it in the wrong direction, requiring more work with the needle nose. The worst part about this is that the opening in the header connector body doesn't have enough space to allow for much error in the crimped end dimensions, and I wasted at least 1 for every 5 with it either failing to due dimensional tolerances, or simply breaking off. If more than 1 pin was already in the body and, due to a jammed pin, required removal for a new body, it stood as much chance to come out as be damaged on removal. This would be bad.

The solution? I did some research and found the proper sized crimper. I bought the MultiComp HT-225D from Newark. First off, it was only $26, which had me concerned, but on another electronics forum, the reviewer swore by it, so I figured since I have about $500 in the machine, $26 for a crimper was the least of my worries and worth checking out. It was delivered yesterday, and the difference in the quality by having the correct crimper is ASTOUNDING. I get a nice, clean crimp, all tabs bend correctly, fits right into the connector body easily, and doesn't damage the wire body behind the crimp, which was causing failures.

You can see how clean the crimp is, and how the insulation tab crimp is almost exactly the same size as the conductor tab crimp, nice and square, which lends itself to a clean insertion into the connector body. Based on my satisfaction with the quality and affordability of the device,I will also be buying replacement jaws for the unit, because they do suffer from wear over time, and I'd be less then thrilled to find the unit was no longer offered when I needed new jaws.

Bottom line: Well worth the $26 to have a proper crimp on connector pins. Highly recommended.

Edited 4 time(s). Last edit at 09/01/2011 12:48PM by mikey.

|

Re: 2.54mm connector pin crimper review September 01, 2011 12:49PM |

Registered: 13 years ago Posts: 601 |

|

Re: 2.54mm connector pin crimper review September 01, 2011 01:21PM |

Registered: 12 years ago Posts: 26 |

Only if you can print metal or some high-density material like delrin. Either may, the real work is done in the jaw. You might be able to print a device to HOLD jaws (which are much cheaper), but the tolerances of the jaw, plus the hardness required to bend the pins and compress the barrel are above what we can do with a Mendel and PLA.

|

Re: 2.54mm connector pin crimper review September 02, 2011 03:57AM |

Registered: 13 years ago Posts: 7,616 |

Who says a crimp pin has to be crimped? Soldering the wire in is simpler and more reliable.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: 2.54mm connector pin crimper review September 02, 2011 04:12AM |

Registered: 14 years ago Posts: 3,742 |

First crimp, THEN solder!

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

Bob Morrison

Wörth am Rhein, Germany

"Luke, use the source!"

BLOG - PHOTOS - Thingiverse

|

Re: 2.54mm connector pin crimper review September 02, 2011 10:16AM |

Registered: 12 years ago Posts: 26 |

Traumflug Wrote:

-------------------------------------------------------

> Who says a crimp pin has to be crimped? Soldering

> the wire in is simpler and more reliable.

Crimping is no less simpler or less reliable. Soldering works, but you are still required to bend the pins for almost all insertions to be locked securely. A soldered wire may not be dimensionally capable of insertion due to interference issues, and a tinned wire may not allow enough bend with pliers to allow insertion. Add to that the fact that the insulation crimps intent as a strain relief, and you see why crimping is an industry wide practice.

Edited 1 time(s). Last edit at 09/02/2011 05:40PM by mikey.

-------------------------------------------------------

> Who says a crimp pin has to be crimped? Soldering

> the wire in is simpler and more reliable.

Crimping is no less simpler or less reliable. Soldering works, but you are still required to bend the pins for almost all insertions to be locked securely. A soldered wire may not be dimensionally capable of insertion due to interference issues, and a tinned wire may not allow enough bend with pliers to allow insertion. Add to that the fact that the insulation crimps intent as a strain relief, and you see why crimping is an industry wide practice.

Edited 1 time(s). Last edit at 09/02/2011 05:40PM by mikey.

|

Re: 2.54mm connector pin crimper review September 03, 2011 06:27AM |

Registered: 13 years ago Posts: 7,616 |

Quote

you are still required to bend the pins for almost all insertions to be locked securely.

... or simply cut that crimp latches off. I've done this for a few hundred pins now and they insert just nicely.

The industry prefers crimping because it's faster (given the appropriate tool) and can be automated better, not because it's more reliable.

Sorry for talking up so harsh here.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: 2.54mm connector pin crimper review September 03, 2011 02:56PM |

Registered: 12 years ago Posts: 26 |

Traumflug Wrote:

-------------------------------------------------------

> you are still required to bend the pins for almost

> all insertions to be locked securely.

>

> ... or simply cut that crimp latches off. I've

> done this for a few hundred pins now and they

> insert just nicely.

>

> The industry prefers crimping because it's faster

> (given the appropriate tool) and can be automated

> better, not because it's more reliable.

>

> Sorry for talking up so harsh here.

Not harsh. Everybody has their own opinion on the subject. I've been a working electrical engineer for the last 20 years, and I've seen more than my fair share of solder joints fail right along with crimp joints, numbering into the thousands. One automotive factory I worked in will not allow a soldered joint due to the fact that a cold solder joint is subject to failure at a higher rate than crimped joints under identical circumstances (with associated 6Ʃ data to affirm the decision), and the ability to train a technician to properly solder a joint and be able to correctly ascrertain the resultant quality is much more difficult than training the same technician to operate a crimper correctly and achieve the same quality standards.

In fact, NASA allows crimping of wiring terminals [workmanship.nasa.gov], and has a manual to cover all aspects of it. The DOE nuclear design guideleines do not allow any soldered connections to be used for wiring of DCS systems, which is what controls the entire facility. If NASA can send a man to space in something with crimped connectors, every single manufacturing facility I've worked in can use crimped connectors, the nuclear power industry uses crimped connectors, and the 747 I fly in to go to jobsites can use crimped connectors, I think I can trust it to run a home build plastics printer just fine.

-------------------------------------------------------

> you are still required to bend the pins for almost

> all insertions to be locked securely.

>

> ... or simply cut that crimp latches off. I've

> done this for a few hundred pins now and they

> insert just nicely.

>

> The industry prefers crimping because it's faster

> (given the appropriate tool) and can be automated

> better, not because it's more reliable.

>

> Sorry for talking up so harsh here.

Not harsh. Everybody has their own opinion on the subject. I've been a working electrical engineer for the last 20 years, and I've seen more than my fair share of solder joints fail right along with crimp joints, numbering into the thousands. One automotive factory I worked in will not allow a soldered joint due to the fact that a cold solder joint is subject to failure at a higher rate than crimped joints under identical circumstances (with associated 6Ʃ data to affirm the decision), and the ability to train a technician to properly solder a joint and be able to correctly ascrertain the resultant quality is much more difficult than training the same technician to operate a crimper correctly and achieve the same quality standards.

In fact, NASA allows crimping of wiring terminals [workmanship.nasa.gov], and has a manual to cover all aspects of it. The DOE nuclear design guideleines do not allow any soldered connections to be used for wiring of DCS systems, which is what controls the entire facility. If NASA can send a man to space in something with crimped connectors, every single manufacturing facility I've worked in can use crimped connectors, the nuclear power industry uses crimped connectors, and the 747 I fly in to go to jobsites can use crimped connectors, I think I can trust it to run a home build plastics printer just fine.

|

Re: 2.54mm connector pin crimper review September 08, 2011 05:04AM |

Registered: 15 years ago Posts: 478 |

Its the same in the UK regarding crimped connections... just think back to whole system board pototypes and some final product all being wirewraped connections... The IDC connection is not very diffrent from a criped connection and it was used on every PATA hard disk or disk drive for 10s of years. All cat5 and phone connections are crimped or IDC The majority of car connections washing machine connections are all crimped...connections...

However knowing all this and having been involved in electronics in all of the above areas since 1970 when I started work in the MOD ...

For my persononal use I still prefer and trust a hand solderd connection over a crimp connection maybe because I have seen many failed crimp connections and not very many failed solder connections... This could be because there are many more crimped conections than any other type of connection thou..

Or maybe Im just a lowsy crimper

Edit: The cost of crimpng tools back in the day you were looking at a low cost tool for £70 for a tool like the one shown I've not cheked crimpng tool prices in years.. The IDC tooling was even more expensive so I have always used a vice for making my IDC connections for DIL header pins a soft wood block with a pin socket hammerd into the wood to enable the use of a vice. Nascom computers had lots of DIL pin headers in the late 70s before the use of the grey blue or black header connections became the standard...

I can not imagine that you could print a crimp tool that would be strong enough to make a crimp Crimp tools are made out of heavy steel blocks to take the presure invoved in the crimping process. Usualy 15mm to 20mm thick blocks of hardend steel.

.

Edited 2 time(s). Last edit at 09/08/2011 05:32AM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

However knowing all this and having been involved in electronics in all of the above areas since 1970 when I started work in the MOD ...

For my persononal use I still prefer and trust a hand solderd connection over a crimp connection maybe because I have seen many failed crimp connections and not very many failed solder connections... This could be because there are many more crimped conections than any other type of connection thou..

Or maybe Im just a lowsy crimper

Edit: The cost of crimpng tools back in the day you were looking at a low cost tool for £70 for a tool like the one shown I've not cheked crimpng tool prices in years.. The IDC tooling was even more expensive so I have always used a vice for making my IDC connections for DIL header pins a soft wood block with a pin socket hammerd into the wood to enable the use of a vice. Nascom computers had lots of DIL pin headers in the late 70s before the use of the grey blue or black header connections became the standard...

I can not imagine that you could print a crimp tool that would be strong enough to make a crimp Crimp tools are made out of heavy steel blocks to take the presure invoved in the crimping process. Usualy 15mm to 20mm thick blocks of hardend steel.

.

Edited 2 time(s). Last edit at 09/08/2011 05:32AM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: 2.54mm connector pin crimper review September 08, 2011 06:05AM |

Registered: 12 years ago Posts: 1,611 |

Quick price check in the UK for the crimping tool suggested by OP.

Farnell - £44.45 (inc VAT, plus shipping) [uk.farnell.com]

Kustom PCs - £25.02 (inc VAT, plus shipping) [www.kustompcs.co.uk]

Rapid online - £23.65 (inc VAT, plus shipping) [www.rapidonline.com]

Add about £5 for delivery.

Farnell - £44.45 (inc VAT, plus shipping) [uk.farnell.com]

Kustom PCs - £25.02 (inc VAT, plus shipping) [www.kustompcs.co.uk]

Rapid online - £23.65 (inc VAT, plus shipping) [www.rapidonline.com]

Add about £5 for delivery.

|

Re: 2.54mm connector pin crimper review September 09, 2011 01:04PM |

Registered: 15 years ago Posts: 478 |

Now If we take $26 X 1.6 those prices look better than the price in the USA for a change..

Don't think I will be buying one after nearly 40 years of making them by hand if I've need them..

My usual choice is 3A - 5A chocolate block or the Crimp connectors as used in cars washing machines microwaves etc works for me.. You can usualy get a full set of crimps and tool in for under £5 ..if you shop arround

I do have some crimp tools for connectors like Cat5 and BNC connectors where there was no choice but to buy one.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Don't think I will be buying one after nearly 40 years of making them by hand if I've need them..

My usual choice is 3A - 5A chocolate block or the Crimp connectors as used in cars washing machines microwaves etc works for me.. You can usualy get a full set of crimps and tool in for under £5 ..if you shop arround

I do have some crimp tools for connectors like Cat5 and BNC connectors where there was no choice but to buy one.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Sorry, only registered users may post in this forum.