|

CNC and RepRap advice? October 13, 2011 11:35PM |

Registered: 12 years ago Posts: 31 |

Well heres what i have to work with... i went out and bought a Zen Toolworks 7x7 3D printer model CNC machine and its accompanying driver/control board

[www.zentoolworks.com]

[www.zentoolworks.com]

I figured i would try and to integrate it like an expanded Sanguinololu, where i would have the connections to the steppers go into the respective pins of the Zen driver/controller..

I have a Wade's Extruder and a spark fun easy driver that i can directly connect to the main Sanguinololu-like controller for when i want to print.

But my real question is, would i really be able to use the same Sanguinololu firmware (With possibly config mods of course) and ReplicatorG to control the actions of the machine both milling and printing?

(I have Sketchup setup so it outputs STL for 3d printing and straight g-code for cutting, need something for subtractive milling later on i guess)

So I'm basically wondering about using the same host and driving software

[www.zentoolworks.com]

[www.zentoolworks.com]

I figured i would try and to integrate it like an expanded Sanguinololu, where i would have the connections to the steppers go into the respective pins of the Zen driver/controller..

I have a Wade's Extruder and a spark fun easy driver that i can directly connect to the main Sanguinololu-like controller for when i want to print.

But my real question is, would i really be able to use the same Sanguinololu firmware (With possibly config mods of course) and ReplicatorG to control the actions of the machine both milling and printing?

(I have Sketchup setup so it outputs STL for 3d printing and straight g-code for cutting, need something for subtractive milling later on i guess)

So I'm basically wondering about using the same host and driving software

|

Re: CNC and RepRap advice? October 30, 2011 12:20PM |

Registered: 12 years ago Posts: 48 |

Hi

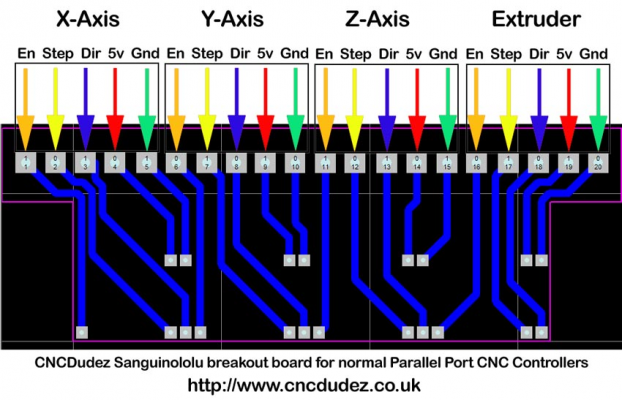

I have just started an area on my forums where I am releasing a Breakout PCB for the Sanguinololu Board.

It allows you to connect an existing CNC Controller instead of the Stepper Driver Boards.

Also handy if people want to use bigger motors and higher current stepper drivers.

[www.cncdudez.co.uk]

The reason I have brought out so many GND and 5V lines is for people wanting to put bigger Stepper Drivers on rather than a whole controller box.

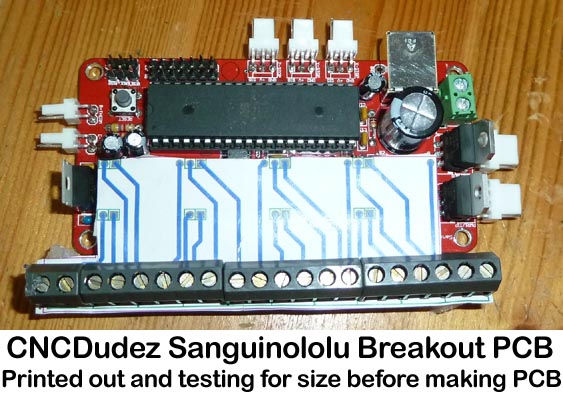

Here is a picture of PCB Printed out and layed on top of the Sanguinololu Controller. Just checking for size before I make the PCB.

Will get the PCB etched next weekend and let you know it goes.

Cheers

Sean.

Edited 2 time(s). Last edit at 10/30/2011 12:26PM by CLaNZeR.

I have just started an area on my forums where I am releasing a Breakout PCB for the Sanguinololu Board.

It allows you to connect an existing CNC Controller instead of the Stepper Driver Boards.

Also handy if people want to use bigger motors and higher current stepper drivers.

[www.cncdudez.co.uk]

The reason I have brought out so many GND and 5V lines is for people wanting to put bigger Stepper Drivers on rather than a whole controller box.

Here is a picture of PCB Printed out and layed on top of the Sanguinololu Controller. Just checking for size before I make the PCB.

Will get the PCB etched next weekend and let you know it goes.

Cheers

Sean.

Edited 2 time(s). Last edit at 10/30/2011 12:26PM by CLaNZeR.

|

Re: CNC and RepRap advice? July 28, 2020 05:25PM |

Registered: 3 years ago Posts: 1 |

Hey,

I think For woodworkers looking to get their first DIY CNC carving machine, Zen Toolworks CNC carving machine 7 x 7 is going to be a really great choice. It doesn't matter where you are in the learning curve of woodworking. This machine has everything you need to create hobby projects and also make your hobby a commercial enterprise.

I am quoting some content from an article on Zen toolworks which i found quiet impressive as they talk in detail about it, Here i am just posting some text from it.

It contains :-

1. A high-density PVC Frame and precision linear bearings.

2. Stainless steel components

3. Includes Anti-backlash lead screw nut

4. F8 Lead Screws with ball bearing end support for all 3 axis (X, Y, Z),

5. NEMA 17 stepper motors included for each axis.

6. Offers a 7”x7”x5” cutting area.

7. Complete assembly guide

Hope this might help others to decide whether to buy it or not.

I think For woodworkers looking to get their first DIY CNC carving machine, Zen Toolworks CNC carving machine 7 x 7 is going to be a really great choice. It doesn't matter where you are in the learning curve of woodworking. This machine has everything you need to create hobby projects and also make your hobby a commercial enterprise.

I am quoting some content from an article on Zen toolworks which i found quiet impressive as they talk in detail about it, Here i am just posting some text from it.

It contains :-

1. A high-density PVC Frame and precision linear bearings.

2. Stainless steel components

3. Includes Anti-backlash lead screw nut

4. F8 Lead Screws with ball bearing end support for all 3 axis (X, Y, Z),

5. NEMA 17 stepper motors included for each axis.

6. Offers a 7”x7”x5” cutting area.

7. Complete assembly guide

Hope this might help others to decide whether to buy it or not.

Sorry, only registered users may post in this forum.