Printable PCB Mill

Posted by tmahring

|

Printable PCB Mill May 06, 2013 12:13PM |

Registered: 12 years ago Posts: 17 |

Hi guys

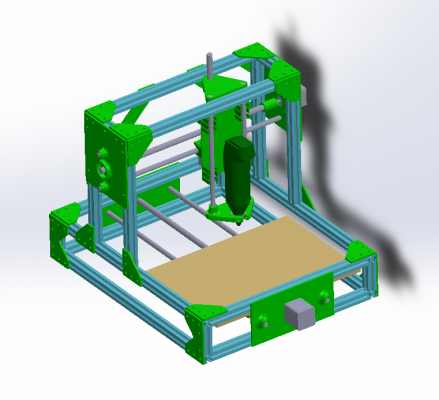

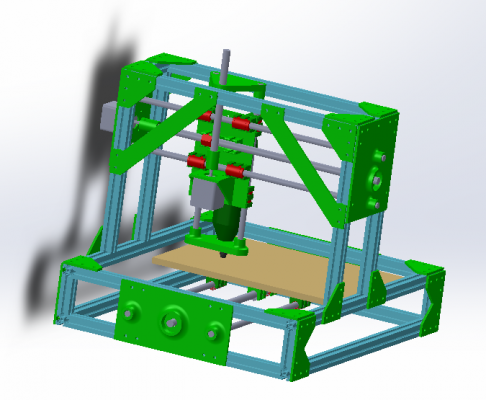

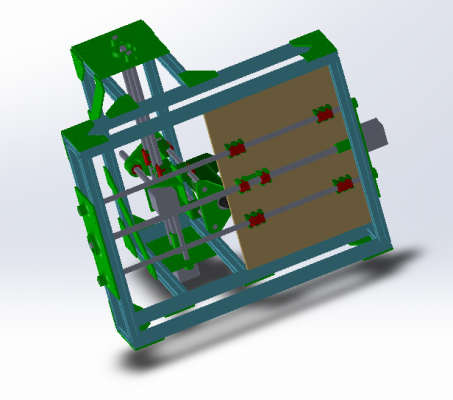

I'm working on a PCB mill that is designed like a reprap printer. All parts can eighter be printed or are easily avaliable. No special tools or machinery (besides a 3d printer of course) is required to build it.

Here are some pictures of my design:

All axes are guided by 10mm smooth steel rods and moved by 12mm trapezoidal spindles unsing nema17 steppers.

It will use a proxxon FBS 240/E micro drill for milling, but can easily be redesigned for other tools.

I have finished the design and just started printing the first parts. Most other parts are ordered and should arrive this week. If nothing goes wrong I will start assembling it by the end of this week.

Once I got everything working I will release the stl files, eighter here on the forum or in the reprap wiki.

Please tell me what you think or if you have any ideas.

I'm working on a PCB mill that is designed like a reprap printer. All parts can eighter be printed or are easily avaliable. No special tools or machinery (besides a 3d printer of course) is required to build it.

Here are some pictures of my design:

All axes are guided by 10mm smooth steel rods and moved by 12mm trapezoidal spindles unsing nema17 steppers.

It will use a proxxon FBS 240/E micro drill for milling, but can easily be redesigned for other tools.

I have finished the design and just started printing the first parts. Most other parts are ordered and should arrive this week. If nothing goes wrong I will start assembling it by the end of this week.

Once I got everything working I will release the stl files, eighter here on the forum or in the reprap wiki.

Please tell me what you think or if you have any ideas.

|

Re: Printable PCB Mill May 06, 2013 05:41PM |

|

Re: Printable PCB Mill May 07, 2013 07:35AM |

Registered: 11 years ago Posts: 82 |

|

Re: Printable PCB Mill May 07, 2013 11:57AM |

Registered: 12 years ago Posts: 17 |

I'm going to use ABS for most of the parts, though I may print some of the big flat parts in PLA if I have too much problems with warping.

I think the frame should handle the vibrations quite well, if it doesn't I can always drill some extra hole through and screw the aluminium profiles directly together.

The 10mm rods seem quite stong, I don't think they will bend too much at this lenght. If that becomes a problem I will eigher switch to bigger rods or scale the whole machine down.

I think the frame should handle the vibrations quite well, if it doesn't I can always drill some extra hole through and screw the aluminium profiles directly together.

The 10mm rods seem quite stong, I don't think they will bend too much at this lenght. If that becomes a problem I will eigher switch to bigger rods or scale the whole machine down.

|

Re: Printable PCB Mill May 22, 2013 10:35PM |

Registered: 10 years ago Posts: 38 |

I'm considering doing something similar (but only AFTER I've completed work on building the i3).

How are you going to keep the PCB itself from 'bowing up' and otherwise moving about on the bed? (All the FR4 I get has some degree of 'bow' in it along one axis).

Are you considering using the same tool / bit to perform both the routing of tracks and any through holes, or are you contemplating changing the tool / bit during the process?

I guess you could partially rely on the downforce from the cutting tip, but I suspect this would create far 'deeper' cuts where the natural PCB bowing caused it to exert more upward force against the cutting tip?

In my case, I'll probably keep a vacuum beneath the bed to keep if flat (and only drill the through holes AFTER I'm done with the copper removal process). Drilling through holes is more 'forgiving' if the board happens to bow up a little whilst drilling.

It will be VERY interesting to see how well the top-to-bottm registration works out (on a double sided board)... The alignment of the substrate onto the bed will need to be rather precise (unless I develop some form of custom 'edge sensing' mechanism to serve as an artifical 'home stop').

I guess it's also plausible to employ double sided routing (using a totally independent cutting head on each side of the board). Once properly aligned / calibrated, such a system could eliminate any top-to-bottom registration issues. (However, I don't think the concept would work too well in practice with the abovementioned 'bowed' substrates).

Don't forget to show us HEAPS of pix when you're done

How are you going to keep the PCB itself from 'bowing up' and otherwise moving about on the bed? (All the FR4 I get has some degree of 'bow' in it along one axis).

Are you considering using the same tool / bit to perform both the routing of tracks and any through holes, or are you contemplating changing the tool / bit during the process?

I guess you could partially rely on the downforce from the cutting tip, but I suspect this would create far 'deeper' cuts where the natural PCB bowing caused it to exert more upward force against the cutting tip?

In my case, I'll probably keep a vacuum beneath the bed to keep if flat (and only drill the through holes AFTER I'm done with the copper removal process). Drilling through holes is more 'forgiving' if the board happens to bow up a little whilst drilling.

It will be VERY interesting to see how well the top-to-bottm registration works out (on a double sided board)... The alignment of the substrate onto the bed will need to be rather precise (unless I develop some form of custom 'edge sensing' mechanism to serve as an artifical 'home stop').

I guess it's also plausible to employ double sided routing (using a totally independent cutting head on each side of the board). Once properly aligned / calibrated, such a system could eliminate any top-to-bottom registration issues. (However, I don't think the concept would work too well in practice with the abovementioned 'bowed' substrates).

Don't forget to show us HEAPS of pix when you're done

|

Re: Printable PCB Mill May 23, 2013 06:52AM |

Registered: 13 years ago Posts: 7,616 |

Quote

How are you going to keep the PCB itself from 'bowing up' and otherwise moving about on the bed?

The best solution I could find so far is to glue it down with double-sided adhesive tape. For more reliability, put a weight on the PCB for 30 minutes, adhesive tape needs some settling time with pressure for best performance. Also, don't forget to clean the board and the bed with acetone before applying the adhesive.

Getting it off again without breaking the PCB also needs some patience, sometimes 10 minutes. Press a wedge between bed and board as much as possible, then simply wait and press the wedge further in every minute or so.

Others use cyanoacrylate glue, a few drops at the edge between PCB and bed. Can be un-glued with a soldering iron or lots of acetone. I had difficulties with glue crawling unter the PCB, though, so sometimes it was difficult to get off the milled board.

The "professional" solution is a vacuum bed, of course. Can be combined with clamps for drilling.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Printable PCB Mill May 23, 2013 08:15AM |

Registered: 15 years ago Posts: 376 |

This is a good idea to develop one of these machines, particularly if it was capable of cutting steel as well as PCB. Your design is probably not the best configuration for a milling machine though. The part bed should be fixed and the head move in all axes. There are several benefits for this.

1) The machine footprint is much smaller for the same sized workpiece.

2) You get natural damping when machining as the part is solidly mounted to a heavy bed. In addition with milling, you often need a jig to hold an unusually shaped part. These jigs can be heavy and so can the clamps. A T slot bed is better as you can mount all sized boards and parts more easily.

3) You can increase the size of the design but still use the same basic head design.

4) The Y axes can be very long and you can support it in the middle. The design you have can only really be supported at either end.

5) Having a fixed bed means that you can also use it for applying surface mount parts. If you have the pcb moving, the parts would move.

do a google image search for "diy cnc router" and you will find that most are of the type I describe.

Helium Frog Website

1) The machine footprint is much smaller for the same sized workpiece.

2) You get natural damping when machining as the part is solidly mounted to a heavy bed. In addition with milling, you often need a jig to hold an unusually shaped part. These jigs can be heavy and so can the clamps. A T slot bed is better as you can mount all sized boards and parts more easily.

3) You can increase the size of the design but still use the same basic head design.

4) The Y axes can be very long and you can support it in the middle. The design you have can only really be supported at either end.

5) Having a fixed bed means that you can also use it for applying surface mount parts. If you have the pcb moving, the parts would move.

do a google image search for "diy cnc router" and you will find that most are of the type I describe.

Helium Frog Website

|

Re: Printable PCB Mill May 25, 2013 10:01PM |

Registered: 11 years ago Posts: 369 |

PCB mill is a in thing it seems ... i am making mine from WOOD ...  ... [3roomlabs.blogspot.sg]

... [3roomlabs.blogspot.sg]

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

... [3roomlabs.blogspot.sg]

... [3roomlabs.blogspot.sg]______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

|

Re: Printable PCB Mill May 28, 2013 11:36AM |

Registered: 12 years ago Posts: 17 |

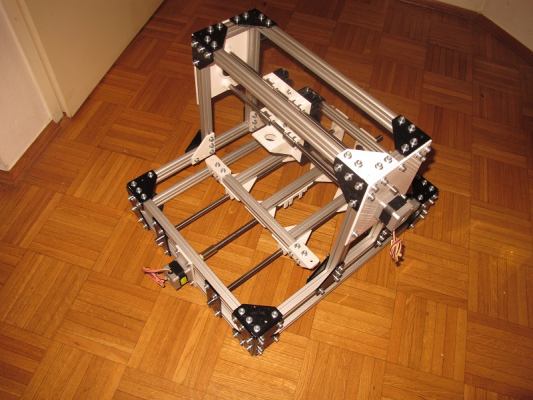

Hey guys, has been a while since I last posted, but here is a little progress update:

full res:

[i.imgur.com]

Things are coming along, though I run into some problems. The biggest one I have is that my X carriage seems a bit weak, I may have to redesign that completely, which will also result in other design changes.

I am quite confident that I can get this baby running though.

@TheRevva:

I'm going to try the method Traumflug allready described, adhesive tape and cyanoacrylate glue (which can easily be dissolved with hydrochloric acid as far as I know).

For drilling I want to be able to change the tools during the process.

Double sided PCB are not a mayor concern for me right now. I have done quite a lot of pcb etching and found that the mayor problem with double sided PCBs is not alignment but getting good contact on vias / pads. I have tried some DIY methods for that and none of them really worked well. My current approach for complicated designs is to use a single sided board and mix surface mounted and regular parts.

@martinprince2004:

I'm aware of the benefits of that design, but I think splitting the axes just makes it easier to design and build. I may build some other machines in the future with a fixed bed, but for now I'm going to stick with my design.

@redreprap:

Nice work !

The reason I prefere ABS over wood is that I simply don't have a workshop nor the tools to work properly with wood. I have built this whole thing in my living room and the only tools I have used, besides my reprap, are a simple power drill and metal handsaw.

full res:

[i.imgur.com]

Things are coming along, though I run into some problems. The biggest one I have is that my X carriage seems a bit weak, I may have to redesign that completely, which will also result in other design changes.

I am quite confident that I can get this baby running though.

@TheRevva:

I'm going to try the method Traumflug allready described, adhesive tape and cyanoacrylate glue (which can easily be dissolved with hydrochloric acid as far as I know).

For drilling I want to be able to change the tools during the process.

Double sided PCB are not a mayor concern for me right now. I have done quite a lot of pcb etching and found that the mayor problem with double sided PCBs is not alignment but getting good contact on vias / pads. I have tried some DIY methods for that and none of them really worked well. My current approach for complicated designs is to use a single sided board and mix surface mounted and regular parts.

@martinprince2004:

I'm aware of the benefits of that design, but I think splitting the axes just makes it easier to design and build. I may build some other machines in the future with a fixed bed, but for now I'm going to stick with my design.

@redreprap:

Nice work !

The reason I prefere ABS over wood is that I simply don't have a workshop nor the tools to work properly with wood. I have built this whole thing in my living room and the only tools I have used, besides my reprap, are a simple power drill and metal handsaw.

|

Re: Printable PCB Mill May 28, 2013 11:45AM |

Registered: 11 years ago Posts: 369 |

what kind of milling motor did you get?

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

|

Re: Printable PCB Mill May 28, 2013 12:37PM |

Registered: 12 years ago Posts: 17 |

|

Re: Printable PCB Mill June 02, 2013 09:16PM |

Registered: 11 years ago Posts: 369 |

ic, i had a dremel, but after reading many feedback abt proxxon/dremel ... i dont think you want to use it. you could try searching for some chat about it via google, something about the bearings and body, wearing out prematurely. for manual handiwork it is fine as our hands will adapt to the "play" of the wear, but as a miller seems to be giving problems to many who tried it before.

well i dont have much tool to work with, my best power tool is a jiggerly jigsaw (highly unprecised as it jigs and jumps all over the line i am trying to follow LOL!)

i think metal frame setup is fantastic, takes the rigidity problem off the problem list right from the start.

tmahring Wrote:

-------------------------------------------------------

> > what kind of milling motor did you get?

>

> I have a proxxon micromot, which i allready had

> lying around. I will try it with that, if it

> doesn't work I will get something better.

Edited 1 time(s). Last edit at 06/02/2013 09:17PM by redreprap.

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

well i dont have much tool to work with, my best power tool is a jiggerly jigsaw (highly unprecised as it jigs and jumps all over the line i am trying to follow LOL!)

i think metal frame setup is fantastic, takes the rigidity problem off the problem list right from the start.

tmahring Wrote:

-------------------------------------------------------

> > what kind of milling motor did you get?

>

> I have a proxxon micromot, which i allready had

> lying around. I will try it with that, if it

> doesn't work I will get something better.

Edited 1 time(s). Last edit at 06/02/2013 09:17PM by redreprap.

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

|

Re: Printable PCB Mill June 08, 2013 06:18AM |

Registered: 11 years ago Posts: 973 |

|

Re: Printable PCB Mill June 08, 2013 07:01AM |

Registered: 11 years ago Posts: 369 |

i think that will depend on the amount of -ve pressure and the way the bed is setup (placement of holes).

from what i know many industrial machines does it this way

i bet there is a way to calculate the pressure, air flow and bed hole dimensions. i bought an al cheapo china suction pump, yet to try anything ... hopefully have some time to do some real crap about it soon lol

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

from what i know many industrial machines does it this way

i bet there is a way to calculate the pressure, air flow and bed hole dimensions. i bought an al cheapo china suction pump, yet to try anything ... hopefully have some time to do some real crap about it soon lol

______________________________________

__my mixed bag blog || aka --> [http] || ___ so 3D printing is everywhere ... dont worry, hospitals can now 3Dprint body parts, they will charge you $1million excluding surgical fees ... you will die paying your debts. thats their aim ___ if every patent expires tomorrow, everybody will surely get a 3dprinter and make EVERYTHING ! ____ there is a "DIY-DTG" t shirt printing forum, you can mod an EPSON printer to PRINT like a pro. ___ CNCzone? overly commercialized it seems ___ my country? they will be taxing you for every cm of road you use and track you to your grave using GPS and its government authorized, now they will fire all the traffic wardens instead.___ EEVBLOG? there is only 1 way to do things --> take it apart like a pro

Sorry, only registered users may post in this forum.