I need a lathe/mill recommendation

Posted by cptwinder

|

I need a lathe/mill recommendation May 22, 2009 03:09PM |

Registered: 15 years ago Posts: 42 |

I'm looking to purchase and lathe/mill combo for my home shop. But I don't have a lot of room. My "tool room" is a 7 foot x 7 foot shed; however, for the most part all of my current tools fit along one wall or only get setup when needed. I have been doing a lot of searching for good, small, yet inexpensive lathes and it seems everyone has an option. So to confuse matters worse, I invite anyone who has a small lathe and/or lathe/mill combo machine to chime in.

The one I'm leaning towards is this one [www.harborfreight.com] for no particular reason.

Also, are their any accessories I should pick up right away?

Thanks in advance,

Jeremy

The one I'm leaning towards is this one [www.harborfreight.com] for no particular reason.

Also, are their any accessories I should pick up right away?

Thanks in advance,

Jeremy

|

Re: I need a lathe/mill recommendation May 22, 2009 03:37PM |

Registered: 16 years ago Posts: 49 |

I don't have any first-hand experience with this sort of thing, but Nophead made a post about this very thing last year. He also made a followup post describing the accessories that he thought worthwhile to buy as well.

|

Re: I need a lathe/mill recommendation May 22, 2009 05:14PM |

Registered: 16 years ago Posts: 41 |

If at all possible, try to get a separate lathe and mill.

I have had a Smithy 1220 for about 15 years. The lathe part has worked quite well, but the mill part is absolutely worthless. I used the mill very little. The problems included lack of rigidity and table space. It is also very inconvenient to always pull the chuck to setup the mill and vice versa. I finally was able to get a used bridgeport type mill(a Lagun) and it has been wonderful to have.

I will also add that I think Smithy has good customer service. If that is important to you, you still might want to look at one of their standalone lathes.

Keep an eye on craigslist for your area. That is how I got my mill. It is thirty years old, but it is still in very good condition and great for use in a hobbyist type environment. Obviously something that big will not fit in your toolroom, but you may be able to get something smaller at a good price. Ebay is another option, but watch for shipping costs and scams. I bid on what seemed like a too good to be true bridgeport mill and after corresponding with the seller a few times I started getting bad vibes. Fortunately I was outbid by somebody else, so I did not have to back out of the deal.

As for the getting items from Harbor Freight. I looked at a harbor freight lathe from craigslist. I decided not to buy the lathe because it had some plastic gearing in it, which owner said will break from time to time. My Smithy has a round toothless belt that will slip if I make too deep of a cut. I think I prefer that to having broken plastic gears. If there is a harbor freight store nearby you, go there and open of the access panel on the end and see what they are using.

Edited 1 time(s). Last edit at 05/22/2009 05:16PM by damonb.

I have had a Smithy 1220 for about 15 years. The lathe part has worked quite well, but the mill part is absolutely worthless. I used the mill very little. The problems included lack of rigidity and table space. It is also very inconvenient to always pull the chuck to setup the mill and vice versa. I finally was able to get a used bridgeport type mill(a Lagun) and it has been wonderful to have.

I will also add that I think Smithy has good customer service. If that is important to you, you still might want to look at one of their standalone lathes.

Keep an eye on craigslist for your area. That is how I got my mill. It is thirty years old, but it is still in very good condition and great for use in a hobbyist type environment. Obviously something that big will not fit in your toolroom, but you may be able to get something smaller at a good price. Ebay is another option, but watch for shipping costs and scams. I bid on what seemed like a too good to be true bridgeport mill and after corresponding with the seller a few times I started getting bad vibes. Fortunately I was outbid by somebody else, so I did not have to back out of the deal.

As for the getting items from Harbor Freight. I looked at a harbor freight lathe from craigslist. I decided not to buy the lathe because it had some plastic gearing in it, which owner said will break from time to time. My Smithy has a round toothless belt that will slip if I make too deep of a cut. I think I prefer that to having broken plastic gears. If there is a harbor freight store nearby you, go there and open of the access panel on the end and see what they are using.

Edited 1 time(s). Last edit at 05/22/2009 05:16PM by damonb.

|

Re: I need a lathe/mill recommendation May 22, 2009 09:34PM |

Registered: 15 years ago Posts: 251 |

Jeremy,

For what it's worth, I second the above advice that combo tools can be a real pain! If you only have space for one, the conventional wisdom seems to be to get a lathe and a milling attachment for it. It's not a great milling setup, but it's better than trying to do lathe work on a mill. And if you get a combo machine, I suggest trying hard to get one with separate motors. (Easier to switch over, from what I understand.) And if you do get a combo, get the biggest, heaviest machine you possibly can. I won't say there's never been anybody who's bought too big a machine, but I will say that (of people who change machines), they overwhelmingly replace with a larger machine, not a smaller one.

When I was looking (in the US), Jet and Lathemaster looked to be a bit above the HF (sometimes referred to as "horrible freight") in various machining forums. If you go for a (Chinese) import tool (whatever the brand), read some online reviews

(and accounts of cleaning/re-fitting) them before you lay out your money. Some people like imports (as good value), but the quality is sometime lacking. If you can get hardened ways (and avoid round-column mill/drills), you'll likely be happier.

Used tools are your friend!

Repeat: **** USED TOOLS ARE YOUR FRIEND! ****

Watch eBay and/or Craigslist. -- And try your best to be patient.

Since these are heavy beasts, shipping can add quite a bit; that's another reason to look locally. Sometimes you can get tooling with a used machine that's a great value. Esp. compared to what you'd pay buying them new.

If you buy used, I advise that you only consider machines you can see under power.

(And take a couple practice cuts, too.)

Check the power requirements carefully, voltage, current and phases. And check your circuit breakers to see what you have available.

(Three phase requires either a rotary phase converter or a VFD. In the US, it's virtually impossible to get three phase in a resedential location, without paying thousands of dollars.)

If you have a garage, take a careful look at what you might squeeze in there, even if the bumper is kissing your mill/lathe/combo when it's inside.

The car can stand the rain or snow occasionally, when you have the urge to cut metal.

Benchtop machines (up to ~300 lbs or so) can be moved in a station wagon with a couple buddies -- if you do it carefully and slowly. Bigger than that gets tricky. Plan the moving out ahead, and in detail -- with your worry/caution turned up to the max! And if it (still) gets away from you, jump out of the way and let it fall! A scrapped machine is vastly preferable to a crushed foot! I do *not* recommend moving a bench-top machine solo -- I did it (once only!) and lived to tell the tale, but in retrospect it was a stupid risk.

IMHO, belt-driven tools will survive crashes much better than gear-driven tools.

And if you're learning, you are likely to crash your machine at least once.

If you break a gear, you'll be off the air until you can get a replacement part -- and that's not always easy or cheap.

If you go import, be sure to look at littlemachineshop.com -- a good source for info and replacement parts.

Side note: Please don't try to do milling (or anything other than drilling) with a drill press: Side loads on a drillpress chuck can loosen the chuck, and one can be badly injured by a flying chuck/cutter combo.

For a mill, I recommend going for an R-8 Collet machine (in the US; don't know about elsewhere.) The tooling seems much more common and thus lower in price.

My $0.02

Larry Pfeffer,

My blog about building repstrap Cerberus:

[repstrap-cerberus.blogspot.com]

For what it's worth, I second the above advice that combo tools can be a real pain! If you only have space for one, the conventional wisdom seems to be to get a lathe and a milling attachment for it. It's not a great milling setup, but it's better than trying to do lathe work on a mill. And if you get a combo machine, I suggest trying hard to get one with separate motors. (Easier to switch over, from what I understand.) And if you do get a combo, get the biggest, heaviest machine you possibly can. I won't say there's never been anybody who's bought too big a machine, but I will say that (of people who change machines), they overwhelmingly replace with a larger machine, not a smaller one.

When I was looking (in the US), Jet and Lathemaster looked to be a bit above the HF (sometimes referred to as "horrible freight") in various machining forums. If you go for a (Chinese) import tool (whatever the brand), read some online reviews

(and accounts of cleaning/re-fitting) them before you lay out your money. Some people like imports (as good value), but the quality is sometime lacking. If you can get hardened ways (and avoid round-column mill/drills), you'll likely be happier.

Used tools are your friend!

Repeat: **** USED TOOLS ARE YOUR FRIEND! ****

Watch eBay and/or Craigslist. -- And try your best to be patient.

Since these are heavy beasts, shipping can add quite a bit; that's another reason to look locally. Sometimes you can get tooling with a used machine that's a great value. Esp. compared to what you'd pay buying them new.

If you buy used, I advise that you only consider machines you can see under power.

(And take a couple practice cuts, too.)

Check the power requirements carefully, voltage, current and phases. And check your circuit breakers to see what you have available.

(Three phase requires either a rotary phase converter or a VFD. In the US, it's virtually impossible to get three phase in a resedential location, without paying thousands of dollars.)

If you have a garage, take a careful look at what you might squeeze in there, even if the bumper is kissing your mill/lathe/combo when it's inside.

The car can stand the rain or snow occasionally, when you have the urge to cut metal.

Benchtop machines (up to ~300 lbs or so) can be moved in a station wagon with a couple buddies -- if you do it carefully and slowly. Bigger than that gets tricky. Plan the moving out ahead, and in detail -- with your worry/caution turned up to the max! And if it (still) gets away from you, jump out of the way and let it fall! A scrapped machine is vastly preferable to a crushed foot! I do *not* recommend moving a bench-top machine solo -- I did it (once only!) and lived to tell the tale, but in retrospect it was a stupid risk.

IMHO, belt-driven tools will survive crashes much better than gear-driven tools.

And if you're learning, you are likely to crash your machine at least once.

If you break a gear, you'll be off the air until you can get a replacement part -- and that's not always easy or cheap.

If you go import, be sure to look at littlemachineshop.com -- a good source for info and replacement parts.

Side note: Please don't try to do milling (or anything other than drilling) with a drill press: Side loads on a drillpress chuck can loosen the chuck, and one can be badly injured by a flying chuck/cutter combo.

For a mill, I recommend going for an R-8 Collet machine (in the US; don't know about elsewhere.) The tooling seems much more common and thus lower in price.

My $0.02

Larry Pfeffer,

My blog about building repstrap Cerberus:

[repstrap-cerberus.blogspot.com]

|

Re: I need a lathe/mill recommendation May 24, 2009 07:25AM |

Registered: 15 years ago Posts: 242 |

I have a friend who set up an X-Y table using hex x-section steel. You can make interlocking parts quite easily with hex, without the need for special groove cutting, and you don't need any special tools other than drills, file, tap, hacksaw and a drill press. You can buy washers, nuts and screw thread, and bodgy a handle up out of something, and make your own X-Y table simply like this yourself.

|

Re: I need a lathe/mill recommendation May 25, 2009 03:37PM |

Registered: 15 years ago Posts: 18 |

I have no first hand experience with Harbor Freight but I've heard from people who have that the quality of their machine tools is very hit and miss. I guess it's a quality control issue with the manufacturer in China, some machines will be perfect and do a great job for a long time while another of the same model will be sloppy with poor tolerances and overall be a piece of junk. That's pretty much the story I've heard with all their power tools too, their prices are great but you take a chance.

I guess my very unqualified advice would be that if you do buy from them give said item a REALLY good workout, see how it goes and be ready to bring it back right away if it's a problem.

I guess my very unqualified advice would be that if you do buy from them give said item a REALLY good workout, see how it goes and be ready to bring it back right away if it's a problem.

|

Anonymous User

Re: I need a lathe/mill recommendation May 26, 2009 07:20AM |

As someone said, if you decide to go for a combo machine, make sure it's actually two separate machnies sharing the base - i.e., not like the one you linked to. The nophead's combo lathe/mill is relatively OK, other than not having that much free space under the milling chuck. Still, it's not necessary to remove one chuck to use the other one safely, as is the case with this "Multipurpose Machine". On a related note, what nophead has is actually a Sieg Industries M1 machine, it's as much Clarke-something as the sticker goes. Sieg does a pretty decent job for a chinese manufacturer, so if you're going for something cheap, I'd look for their products - take a look at [www.siegind.com] for a visual reference, as they're sometimes sold rebranded.

Myself, I've got a Sieg C0 lathe from Arc Euro Trade (UK) that was sold as a Sieg, and have used the X1 mill - both are OK. The lathe is capable of less than 0.02mm runout with an ER16 collet chuck (that's ~0.7 thous for the metric-impaired) and about 0.10 with a 3-jaw chuck, I'd call that pretty good for a cheap hobby machine. I've heard that from time to time, they made a dud at Sieg - a lathe with bent ways, a mill with out-of-round spindle and such, so be cautious, but reportedly, their QC improved and it's rare nowadays. Nevetheless, at Arc they offer a preparation service that includes cleaning, adjustment and checking for quality problems - see if Harbor does something like that, just to be sure.

Myself, I've got a Sieg C0 lathe from Arc Euro Trade (UK) that was sold as a Sieg, and have used the X1 mill - both are OK. The lathe is capable of less than 0.02mm runout with an ER16 collet chuck (that's ~0.7 thous for the metric-impaired) and about 0.10 with a 3-jaw chuck, I'd call that pretty good for a cheap hobby machine. I've heard that from time to time, they made a dud at Sieg - a lathe with bent ways, a mill with out-of-round spindle and such, so be cautious, but reportedly, their QC improved and it's rare nowadays. Nevetheless, at Arc they offer a preparation service that includes cleaning, adjustment and checking for quality problems - see if Harbor does something like that, just to be sure.

|

Re: I need a lathe/mill recommendation May 30, 2009 12:48AM |

Registered: 15 years ago Posts: 42 |

I want to thank everyone for the comments and suggestions. It has be a great help. The main reason why I was looking at Harbor Freight was because they have an outlet store a couple hours from here. I had made a list of things to check for on a machine, like belt driven instead of gear driven and adjustment screws to remove slop as the grooves in the bed wear down. However, it won't matter how close the store is if the product is iffy and to be honest, I haven't even used a lathe before so I probably wouldn't know there was a problem until it was to late to return the lathe.

From the reading I have been doing it seems the Grizzly lathes get good reviews. As anyone heard or had bad experiences with them?

I haven't had a chance to read up on all of the specs regarding my list of things to check, but at first glace I'm leaning towards this one. [www.grizzly.com] It also looks a lot like the Sieg models, Enleth recommended.

Thanks again,

Jeremy

From the reading I have been doing it seems the Grizzly lathes get good reviews. As anyone heard or had bad experiences with them?

I haven't had a chance to read up on all of the specs regarding my list of things to check, but at first glace I'm leaning towards this one. [www.grizzly.com] It also looks a lot like the Sieg models, Enleth recommended.

Thanks again,

Jeremy

|

Re: I need a lathe/mill recommendation May 30, 2009 11:37AM |

Registered: 15 years ago Posts: 251 |

Jeremy,

From your last message, I'll assume you're in the (continental) US.

I urge you to take a look at used machines and/or get ahold of some instructional material on the basics of machining before you finalize your purchase selection(s.) If you're within an hour's drive of a good-sized city, watch

eBay and/or the local craigslist site for machines even remotely like what you want. You might find a good deal, and in just looking, you'll refine your real criteria -- separate the needs from the wants....

If you end up buying non-locally, take a look at amazon, of all places. They sell (re-sell really) both Jet and Grizzly machines, and the prices/shipping might be better than going directly to either.

I haven't used any grizzly tools, but if you're stuck on getting a combo machine, the [www.grizzly.com]

has (a) separate motors and (b) puts the mill's spindle in the middle of the ways, not way over on the headstock end. And, once you get sick of the constraints of sharing the saddle between lathe and mill, you could buy a base for the mill (with X and Y travel), and have two separate machines, either from [littlemachineshop.com], or buy an (compound, X/Y or mill/drill) table from another vendor. I bought one from [www.shars.com], and and am fitting it with stepper motors for my reprap.

(Caution here -- one of the leadscrews is slightly bent, and I'll probably have to replace it or get a stronger stepper for that axis.)

Hope this helps,

Larry Pfeffer,

My blog about building repstrap Cerberus:

[repstrap-cerberus.blogspot.com]

From your last message, I'll assume you're in the (continental) US.

I urge you to take a look at used machines and/or get ahold of some instructional material on the basics of machining before you finalize your purchase selection(s.) If you're within an hour's drive of a good-sized city, watch

eBay and/or the local craigslist site for machines even remotely like what you want. You might find a good deal, and in just looking, you'll refine your real criteria -- separate the needs from the wants....

If you end up buying non-locally, take a look at amazon, of all places. They sell (re-sell really) both Jet and Grizzly machines, and the prices/shipping might be better than going directly to either.

I haven't used any grizzly tools, but if you're stuck on getting a combo machine, the [www.grizzly.com]

has (a) separate motors and (b) puts the mill's spindle in the middle of the ways, not way over on the headstock end. And, once you get sick of the constraints of sharing the saddle between lathe and mill, you could buy a base for the mill (with X and Y travel), and have two separate machines, either from [littlemachineshop.com], or buy an (compound, X/Y or mill/drill) table from another vendor. I bought one from [www.shars.com], and and am fitting it with stepper motors for my reprap.

(Caution here -- one of the leadscrews is slightly bent, and I'll probably have to replace it or get a stronger stepper for that axis.)

Hope this helps,

Larry Pfeffer,

My blog about building repstrap Cerberus:

[repstrap-cerberus.blogspot.com]

|

Re: I need a lathe/mill recommendation May 30, 2009 01:32PM |

Registered: 16 years ago Posts: 41 |

Another option you might consider is find out if there is some kind of radio control airplane, helicopter or car club in your area. Most likely someone already has a small machine shop setup and they will probably be happy to show it to you. That way you can find out what kind of equipment someone else is using and the limitations they have run into. You might even be able to find a good deal on some used equipment that way. If by some remote chance you are in the area of central Oklahoma I would be happy to show you my setup.

Another advantage of buying used locally is that the person you are buying from probably already has some machining experience and might help you in getting started. The person I bought my mill from is a professional machinist and has been more than happy to answer the occasional machining question.

Another advantage of buying used locally is that the person you are buying from probably already has some machining experience and might help you in getting started. The person I bought my mill from is a professional machinist and has been more than happy to answer the occasional machining question.

|

Anonymous User

Re: I need a lathe/mill recommendation May 30, 2009 06:28PM |

This G8688 is really a Sieg C1.

Here's a good review: [www.mini-lathe.com]

Actually, the whole mini-lathe.org website is a must to read for you - I don't think there's a better website on the topic out there, and the guy is working with exactly the kind of hardware you're going to buy - low-cost, hobby mini-lathes.

Here's a good review: [www.mini-lathe.com]

Actually, the whole mini-lathe.org website is a must to read for you - I don't think there's a better website on the topic out there, and the guy is working with exactly the kind of hardware you're going to buy - low-cost, hobby mini-lathes.

|

Re: I need a lathe/mill recommendation May 31, 2009 08:13PM |

Registered: 15 years ago Posts: 42 |

|

Re: I need a lathe/mill recommendation December 16, 2009 02:22PM |

We have a Harbour Freight mill/drill in the shop and I am just not impressed with it. I got it used for $100. We do use it a lot and the guys like it. I guess all of those years with Bridgeport mills have spoiled me.

I am looking at buying a metal lathe 12 x 36 or 40. I a looking hard at the Griz lathes. Any feed back on the bigger Griz mills an lathes?

I have purchased smaller tols from both Harbour Freight and Griz and have found the later to be much better n quality. But cheap is still cheap.

I am looking at buying a metal lathe 12 x 36 or 40. I a looking hard at the Griz lathes. Any feed back on the bigger Griz mills an lathes?

I have purchased smaller tols from both Harbour Freight and Griz and have found the later to be much better n quality. But cheap is still cheap.

|

Re: I need a lathe/mill recommendation March 07, 2010 01:14AM |

|

does any one know the center height of seig lathe March 25, 2011 09:33AM |

|

Re: I need a lathe/mill recommendation May 16, 2011 12:48PM |

Hi- I was wondering if you found the mill/drill you were looking for? My husband has a brand new VersaMill with alot of attachments and it can be used as a stand alone as well. I know you said you were chencking into Harbor Freight, I imagin their price is probably lower then what my husband is selling his for ($2000.) But, I thought I would mention this to you because I know just from the research Ive done so far, its an excellent deal, especially because it include some high priced attachments. Also I believe it would work in nicely to your tool room. Give him a call if your still looking. Glen: (801)787-6560

|

Re: I need a lathe/mill recommendation April 28, 2012 10:37PM |

hi everybody, I live 3 hrs. from grizzly in pa. I have bought a lot of equipment from grizzly. I bought a G4016 last year. This is the second lathe I have bought from them. No complaints.So far. I saved freight by going up and getting it. I had a reversing switch go bad. Emailed them. They called me and sent a new one out no charge. No matter where you buy a machine there's going to be someone who will have a problem. You can buy a used one and have no problems. Or have all kind of problems. Oh well good luck. Tom in PA

|

Re: I need a lathe/mill recommendation November 05, 2012 11:46AM |

I have worked as a machinist and tool maker for 30 years on a large variety of machine tools. A small mill table with these multi-purpose machines is mostly a drill press. Side thrusts while milling are substantial. Your mill will begin to chatter, and that is like working on the edge of failure and poor finishes. However, If you plan to mill with mills not more than .250 inch diameter in steel or .375 inch in diameter in aluminum, minimal and time consuming milling work can be done on these machines. But you will find out progress is too time consuming unless your work remains very small in size. If you push it with these toys, as mentioned, something dangerous can happen. I would invest in a bigger shed, then decide to get a used lathe or a used mill, or both to put in the shed. I worked with a Bridgeport vertical mill, a lathe measuring 14" swing by 40" length capacity with a drill press, vertical band saw, inspection equipment, tool bench, etc. in a space measuring 12' X 20' pretty well. By the way, if you go to three phase, get a rotary phase converter a couple horse power moire than your maximum machine rating. Electronic phase converters do not work well at all for any length of time. If you have time, a person can do a lot of work with a drill press, vertical band saw, files, lay out tools, a precision surface plate, a height gauge, precision inspection tools, and a standard 4 piece machinist's square set. Not counting the shed, I invested about $25K for my little home shop that I used to help make ends meet while working full time elsewhere. You can some times find a tool maker or machinist that is retiring, and then buy his tools and boxes for a bargain. Make sure the tools are not too worn out though. Even a micrometer can wear out or be misaligned if it is dropped. Go to a library and read up on standard machine tool use and practice, or buy a used text book at a local college for references. This will give you a good start, but these books are usually out of date and they leave our hundreds of tricks a person learns in the trade from others or by trial and error. Good luck, and have some fun!

|

Re: I need a lathe/mill recommendation January 13, 2013 11:12PM |

Registered: 11 years ago Posts: 7 |

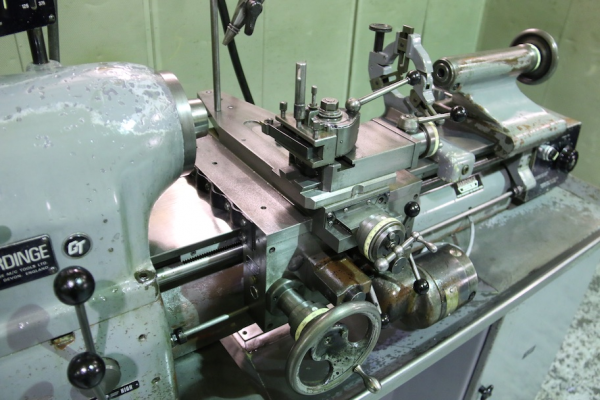

I am a journeyman machinist and graduated through the years to engineer and designer. At 60 years old I have run a lot of machines but the best combination machine I ever ran was an EMCO lathe to which a really nice milling attachment could be added. The EMCO is a good solid small lathe capable of decent work. I did not have an opportunity to try a milling attachment though, but based on the quality of the lathe I expect it would be very good as the lathe was well built, solid, accurate and rigid.

Please realize that all-in-one tools rarely meet the performance of a task-designed machine. And expect to pay more for actual usfullness than any Grizzly or Harbor Freight machine which are very entry level at best. I don't think either offers a mill/lathe combo besides.

Anyway, if you can find one, jump on an EMCO. They are made in Europe and are high quality tools.

Check out this forum and I am sure you will learn a lot more:

[www.practicalmachinist.com]

Email me if you want more info.

bassic*@*isp.*com

(no stars)

Randy

Please realize that all-in-one tools rarely meet the performance of a task-designed machine. And expect to pay more for actual usfullness than any Grizzly or Harbor Freight machine which are very entry level at best. I don't think either offers a mill/lathe combo besides.

Anyway, if you can find one, jump on an EMCO. They are made in Europe and are high quality tools.

Check out this forum and I am sure you will learn a lot more:

[www.practicalmachinist.com]

Email me if you want more info.

bassic*@*isp.*com

(no stars)

Randy

|

Re: I need a lathe/mill recommendation May 13, 2013 03:13AM |

|

Re: I need a lathe/mill recommendation January 22, 2017 05:42AM |

Registered: 7 years ago Posts: 1 |

Hello everyone, I also need recommendations on what brand of metal lathe to buy.

I decided to join here because me and the topic poster wanted advice from anyone who has experience.

I have found this review but I'm at a lost at which one to choose.

Can you please tell me which metal lathe is good to buy in this review?

Metal Lathe Selection

Thank you.

I decided to join here because me and the topic poster wanted advice from anyone who has experience.

I have found this review but I'm at a lost at which one to choose.

Can you please tell me which metal lathe is good to buy in this review?

Metal Lathe Selection

Thank you.

|

Re: I need a lathe/mill recommendation October 13, 2017 04:14PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: I need a lathe/mill recommendation October 24, 2017 02:50PM |

Registered: 7 years ago Posts: 94 |

That is a quality kit!

I have a Simonet, very similar to the Schaublin 102.

At the moment. I need the space. But just can not sell it.

Simonet is very unusual to get hold of. But schaublins 102. Are quite common.

Have a constant search on eBay ect. When you find one that is well tooled. and good condition.

A abused one is worthless.

But, buy one, you will never regret it. Atleast as long as you need it now and then.

I have a Simonet, very similar to the Schaublin 102.

At the moment. I need the space. But just can not sell it.

Simonet is very unusual to get hold of. But schaublins 102. Are quite common.

Have a constant search on eBay ect. When you find one that is well tooled. and good condition.

A abused one is worthless.

But, buy one, you will never regret it. Atleast as long as you need it now and then.

Sorry, only registered users may post in this forum.