Open Source Hardware Framework Protoyping for reprap?

Posted by riley porter

|

Open Source Hardware Framework Protoyping for reprap? October 29, 2009 11:16AM |

Hello guys,

I am one of the founders of contraptor.org I thought about reaching out to the reprap community to show you guys our progress and possible reprap applications.

The framework is all easily made from local hardware stores or can be bought pre-made.

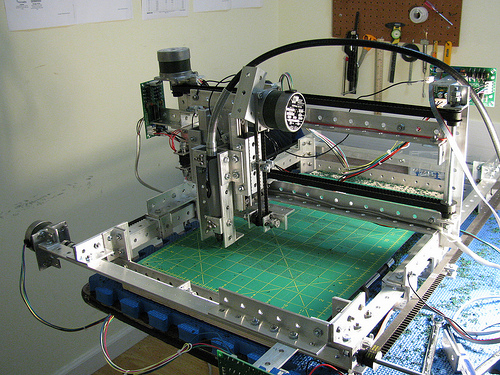

This is a dremel based CNC mini router we have tried out.

I am in the process of designing a contraptor compatible extruder however I have not got a chance to pickup the new version (2.2?) hardware yet. Anyhow, I just wanted to reach out and tell the community about our progress and I hope we can possibly work together soon.

ril3y

contraptor.org

I am one of the founders of contraptor.org I thought about reaching out to the reprap community to show you guys our progress and possible reprap applications.

The framework is all easily made from local hardware stores or can be bought pre-made.

This is a dremel based CNC mini router we have tried out.

I am in the process of designing a contraptor compatible extruder however I have not got a chance to pickup the new version (2.2?) hardware yet. Anyhow, I just wanted to reach out and tell the community about our progress and I hope we can possibly work together soon.

ril3y

contraptor.org

|

Re: Open Source Hardware Framework Protoyping for reprap? October 29, 2009 06:14PM |

Admin Registered: 17 years ago Posts: 1,791 |

Very neat! How is the aluminum angle working out? I'm thinking of using steel square section tubing for a 2ft by 4ft scale (~600mm x ~1200mm) router/reprap/powder bed machine, maybe.

Sort of like this:

[lumenlab.com]

Note the way the three square beams lock against each other in that joint.

The neat thing is mcmaster (and other commercial and building supply steel suppliers) sell perforated steel square tube. Although using a drill press is cheaper.

I'll tack up contraptor on the wiki on our 'list of open source cnc projects'

(Coming soon.)

I need to do a survey of the available plans and projects, anyway.

Regarding

I am in the process of designing a contraptor compatible extruder.

you may just want to use ours; it's pretty mature.

Sort of like this:

[lumenlab.com]

Note the way the three square beams lock against each other in that joint.

The neat thing is mcmaster (and other commercial and building supply steel suppliers) sell perforated steel square tube. Although using a drill press is cheaper.

I'll tack up contraptor on the wiki on our 'list of open source cnc projects'

(Coming soon.)

I need to do a survey of the available plans and projects, anyway.

Regarding

I am in the process of designing a contraptor compatible extruder.

you may just want to use ours; it's pretty mature.

|

Re: Open Source Hardware Framework Protoyping for reprap? October 29, 2009 06:50PM |

Registered: 14 years ago Posts: 33 |

I used aluminum tubing and channel for my repstrap. Check this post for some pics:

[bothacker.com]

Architectural aluminum is a great building material, and it usually available at your local hardware store. I found that the 1/16" walled stuff was plenty strong enough, and much lighter than the 1/8" walled. The one benefit of 1/8" wall is that it is thick enough to tap, so you can connect parts with fewer fasteners.

-Tim

[bothacker.com]

Architectural aluminum is a great building material, and it usually available at your local hardware store. I found that the 1/16" walled stuff was plenty strong enough, and much lighter than the 1/8" walled. The one benefit of 1/8" wall is that it is thick enough to tap, so you can connect parts with fewer fasteners.

-Tim

|

Re: Open Source Hardware Framework Protoyping for reprap? November 10, 2009 05:15PM |

Registered: 15 years ago Posts: 104 |

|

Re: Open Source Hardware Framework Protoyping for reprap? November 12, 2009 07:40PM |

Hi everyone,

Aluminum angle is pretty good material for prototyping things - it's light, easily drilled/sawn/filed, widely available (hardware store) and very cheap (especially online). It's not very stiff but we're not exceeding 2ft lengths using 1/8" thickness, so it works out pretty well. The angle is also compatible with 80/20 (series 10), which can be used for longer/sturdier beams: [www.flickr.com]

The angle is combined with other widely available aluminum profiles to create basic linear motion elements: [www.contraptor.org]

@Lawrence, actually we have tried and built a contraption for drilling the angle [www.garagefab.cc]; it worked but it was fairly slow - you either need a lot of force or a lot of time to drill through 1/8" aluminum. This was earlier in the project and we ended up doing most drilling on a drill press, but now that I think about it, perhaps it could be done a lot faster with more powerful steppers (we're using flimsy but cheap 60 oz*in). Right now we're about to drill a lot of angle using Shopbot (tooling/jig files will be open source, too).

@Tim, this looks like very neat machine! I watched the video, it sounds very quiet. Do you get any vibration/resonance from steppers? This is one of the issues we're working through..

@Sebastien, thank you for adding this to the wiki. For 2'x4' I'd think either steel or 80/20 should be appropriate, though I guess it depends on the application/personal prefs. I figured that for this size I could get away with using 2x1 or 3x1 AL channel of 1/8" thickness, provided that the loads are very light (like maybe a vinyl/fabric cutter). Something like router would of course require sturdier frame.

RE extruder, sure - we wouldn't want to reinvent the bicycle especially with a lot of work already put in by many people, e.g. Nophead whose blog I always read with interest.

Aluminum angle is pretty good material for prototyping things - it's light, easily drilled/sawn/filed, widely available (hardware store) and very cheap (especially online). It's not very stiff but we're not exceeding 2ft lengths using 1/8" thickness, so it works out pretty well. The angle is also compatible with 80/20 (series 10), which can be used for longer/sturdier beams: [www.flickr.com]

The angle is combined with other widely available aluminum profiles to create basic linear motion elements: [www.contraptor.org]

@Lawrence, actually we have tried and built a contraption for drilling the angle [www.garagefab.cc]; it worked but it was fairly slow - you either need a lot of force or a lot of time to drill through 1/8" aluminum. This was earlier in the project and we ended up doing most drilling on a drill press, but now that I think about it, perhaps it could be done a lot faster with more powerful steppers (we're using flimsy but cheap 60 oz*in). Right now we're about to drill a lot of angle using Shopbot (tooling/jig files will be open source, too).

@Tim, this looks like very neat machine! I watched the video, it sounds very quiet. Do you get any vibration/resonance from steppers? This is one of the issues we're working through..

@Sebastien, thank you for adding this to the wiki. For 2'x4' I'd think either steel or 80/20 should be appropriate, though I guess it depends on the application/personal prefs. I figured that for this size I could get away with using 2x1 or 3x1 AL channel of 1/8" thickness, provided that the loads are very light (like maybe a vinyl/fabric cutter). Something like router would of course require sturdier frame.

RE extruder, sure - we wouldn't want to reinvent the bicycle especially with a lot of work already put in by many people, e.g. Nophead whose blog I always read with interest.

|

Re: Open Source Hardware Framework Protoyping for reprap? November 13, 2009 03:12AM |

Admin Registered: 16 years ago Posts: 13,888 |

... a hint for making aluminium-constructions much more stiffer/sturdier: - build your frame with thin angles and sheets, insert some crossing threaded rods or long screws for fixing the outer dimensions and then fill the hollow frame with a sand-epoxy mixture (e.g. 32%-34% coarse sand, 60% fine sand and 8%-6% 2K-epoxy).

So you'll get a solid frame with better mechanical properties than concrete or natural stone

Viktor

So you'll get a solid frame with better mechanical properties than concrete or natural stone

Viktor

Sorry, only registered users may post in this forum.