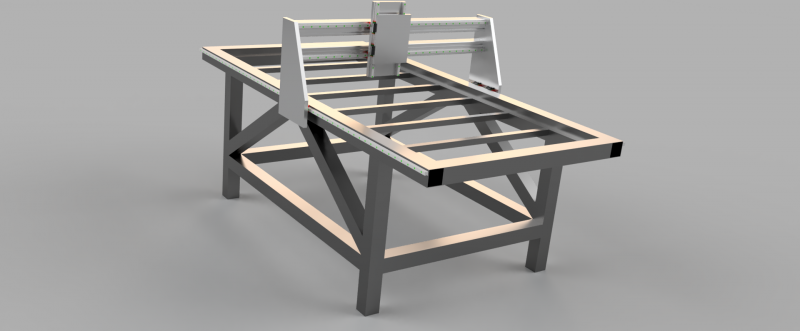

CNC milling/router DIY build WIP

Posted by Desertboy

|

Re: CNC milling/router DIY build WIP October 03, 2017 05:58AM |

Registered: 7 years ago Posts: 142 |

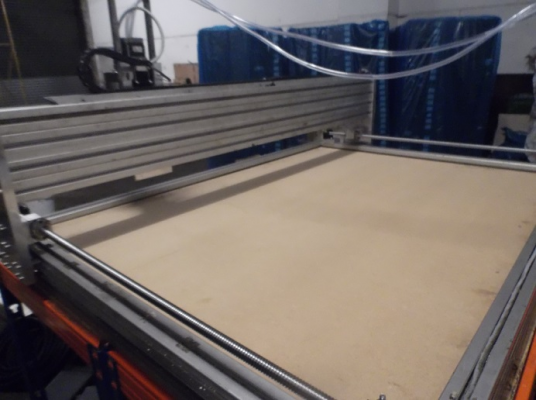

There's 2 reasons to do the gantry like I did

1. I was going to use 1.2m SBR25 rail which is heavy so I decided this should be the bottom axis and use Hiwin clone (1.5m) for the gantry since then I got Hiwin's all round so this is no longer a good reason but I already cut the frame.

2. I didn't realise this until I mounted it on the table but having the gantry the long way gives you much better access to the cnc bed as I only have to stretch 1m instead of 1.5m's lol.

I think given this is a mostly wood router gantry flex won't be a big issue.

The big advantage of getting a 2.2kw spindle like I did is it has an ER20 collect.

My spindle weighs 6kg's, I would use 16mm ballscrews price difference is minimal and if I built again 1610 ballscrews NOT 1605 price is identical but speed is doubled.

Resolution is lowered but since the resolution is far higher than the machines tolerances you'll never see a real world difference.

My gantry weighs around 25kg's in total.

Edited 2 time(s). Last edit at 10/03/2017 06:40AM by Desertboy.

1. I was going to use 1.2m SBR25 rail which is heavy so I decided this should be the bottom axis and use Hiwin clone (1.5m) for the gantry since then I got Hiwin's all round so this is no longer a good reason but I already cut the frame.

2. I didn't realise this until I mounted it on the table but having the gantry the long way gives you much better access to the cnc bed as I only have to stretch 1m instead of 1.5m's lol.

I think given this is a mostly wood router gantry flex won't be a big issue.

The big advantage of getting a 2.2kw spindle like I did is it has an ER20 collect.

My spindle weighs 6kg's, I would use 16mm ballscrews price difference is minimal and if I built again 1610 ballscrews NOT 1605 price is identical but speed is doubled.

Resolution is lowered but since the resolution is far higher than the machines tolerances you'll never see a real world difference.

My gantry weighs around 25kg's in total.

Edited 2 time(s). Last edit at 10/03/2017 06:40AM by Desertboy.

|

Re: CNC milling/router DIY build WIP October 03, 2017 12:50PM |

Registered: 8 years ago Posts: 1,671 |

|

Re: CNC milling/router DIY build WIP October 12, 2017 10:45AM |

Registered: 7 years ago Posts: 142 |

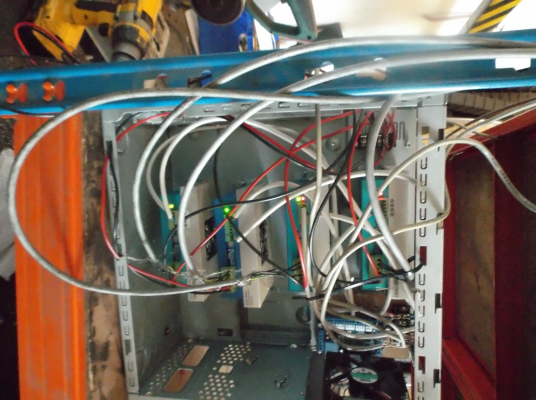

Started to wire it up and immediately hit issues, £25 later with rapidonline

Missing some connectors off the AM882's, 2 I bought from China are missing both 6 pin connectors & the 2 pin, of the one's from HK is missing the 2pin but the 2 pin is not needed for my application.

Also not enough CY cable bought as much again lol.

Missing some connectors off the AM882's, 2 I bought from China are missing both 6 pin connectors & the 2 pin, of the one's from HK is missing the 2pin but the 2 pin is not needed for my application.

Also not enough CY cable bought as much again lol.

|

Re: CNC milling/router DIY build WIP October 19, 2017 07:43AM |

Registered: 7 years ago Posts: 142 |

Slowly getting there's not enough CY cable for the spindle now ordered another 5m's, had to order another pc £100 as well to control this machine. The orignal PC I had set aside for linuxcnc has no parallel port so rather than much about I bought a 2nd hand Core I7 3.4ghz with 4gig of ram so I can run Fusion 360 on it for Cam and it has a parallel port

My main PC is 6 miles (10km) from the router and a desktop so I wasn't going to have fusion where the router was which is obviously a bad idea.

Got a 2.93ghz I7 with 4gb of ram for £90 so can't grumble too much, have a gfx card to drop into it if the one in it won't run Fusion 360 and a parallel port so will have a solution for cam and control by Tuesday next week

Machine has crept to £1650 now but I hadn't expected to buy a new machine to run it.

If budget is a biggie building your own I'd say you need to go with single ballscrew on the bottom axis saves on stepper drivers, the ballscrew and a nema.

Edited 2 time(s). Last edit at 10/19/2017 12:42PM by Desertboy.

My main PC is 6 miles (10km) from the router and a desktop so I wasn't going to have fusion where the router was which is obviously a bad idea.

Got a 2.93ghz I7 with 4gb of ram for £90 so can't grumble too much, have a gfx card to drop into it if the one in it won't run Fusion 360 and a parallel port so will have a solution for cam and control by Tuesday next week

Machine has crept to £1650 now but I hadn't expected to buy a new machine to run it.

If budget is a biggie building your own I'd say you need to go with single ballscrew on the bottom axis saves on stepper drivers, the ballscrew and a nema.

Edited 2 time(s). Last edit at 10/19/2017 12:42PM by Desertboy.

|

Re: CNC milling/router DIY build WIP November 03, 2017 01:24PM |

Registered: 7 years ago Posts: 142 |

|

Re: CNC milling/router DIY build WIP November 05, 2017 12:08PM |

Registered: 7 years ago Posts: 142 |

[www.youtube.com]

Spindle works, was struggling to get a suitable pc to control the machine so came home but found a motherboard with parallel port and my windows vista 32 bit CD between them should be able to get something talking

Will need to get a better controller soonish.

Edited 4 time(s). Last edit at 11/05/2017 12:12PM by Desertboy.

Spindle works, was struggling to get a suitable pc to control the machine so came home but found a motherboard with parallel port and my windows vista 32 bit CD between them should be able to get something talking

Will need to get a better controller soonish.

Edited 4 time(s). Last edit at 11/05/2017 12:12PM by Desertboy.

|

Re: CNC milling/router DIY build WIP November 06, 2017 01:56AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CNC milling/router DIY build WIP November 08, 2017 02:50AM |

Registered: 7 years ago Posts: 142 |

Having spent 3 days playing I have more idea now, it's windows 64bit that doesn't support parallel port cards properly (No TTL) which means no windows 64bit system works with parallel port breakout boards if I had a usb breakout board 64 bit works fine. I got linuxcnc installed but couldn't get it to work with the pci parallel port card and then last night discovered that's because the cheap ass PCI parallel port card I bought only works in serial mode!

Was given a pc with a parallel port but in pieces so will see if I can resurrect it today with linuxcnc.

Was given a pc with a parallel port but in pieces so will see if I can resurrect it today with linuxcnc.

|

Re: CNC milling/router DIY build WIP November 08, 2017 03:19AM |

Registered: 8 years ago Posts: 5,232 |

Sounds like, you want to win the race with a dead horse....

LinuxCNC also has a USB-support branch, but IDK how well that works.

Seems the critical mass to develop some uptodate hobby-CNC stuff hasn't been reached yet. Except dc42, who's downgrading his RepRepFirmware to work with CNC code.

I'm glad we had Marlin&Ramps to get 3D-things started...

LinuxCNC also has a USB-support branch, but IDK how well that works.

Seems the critical mass to develop some uptodate hobby-CNC stuff hasn't been reached yet. Except dc42, who's downgrading his RepRepFirmware to work with CNC code.

I'm glad we had Marlin&Ramps to get 3D-things started...

|

Re: CNC milling/router DIY build WIP November 08, 2017 04:21AM |

Admin Registered: 16 years ago Posts: 13,884 |

... I've stopped developing for the LPT-port since maybe 25 years (for problems with real-time controlling) and switched to separate microcontrollers and "high-level"-communications like G-code or special NC-formats.

My first µC's were C51 and PIC's per RS232, now there are several much faster platforms around ... mostly using ArduinoDue-, STM32F4- or BeagleBoneBlack-based boards to control my laser- and CNC-machines per USB or LAN/WLAN ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My first µC's were C51 and PIC's per RS232, now there are several much faster platforms around ... mostly using ArduinoDue-, STM32F4- or BeagleBoneBlack-based boards to control my laser- and CNC-machines per USB or LAN/WLAN ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: CNC milling/router DIY build WIP November 24, 2017 01:08PM |

Registered: 7 years ago Posts: 142 |

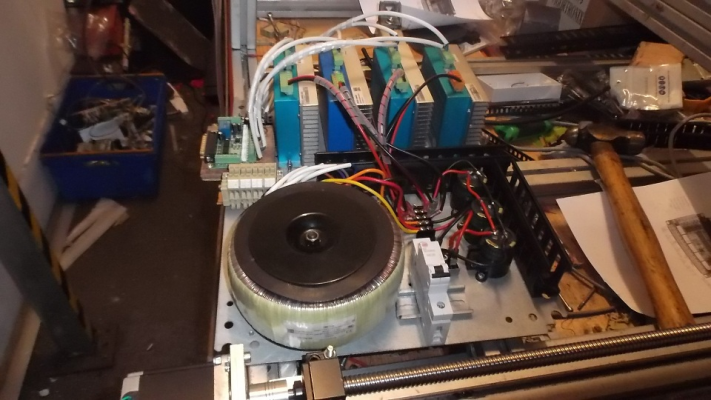

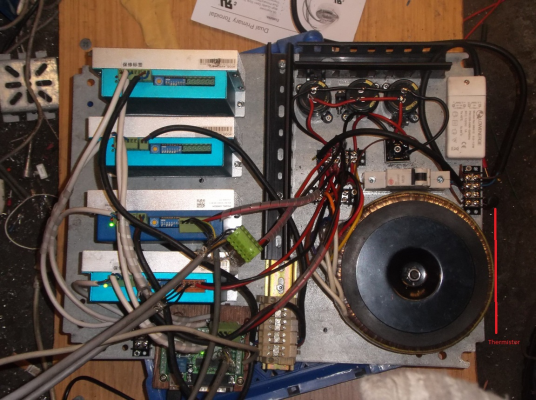

Found a GRP enclosure in a skip with minor damage

So transferring the electronics over, got the correct current limit thermistor on order for the toroidal transformer so I can use a standard 6 amp house mcb as a breaker. Have a switch to go on the box as well to turn power on/off. Adding a AC to 12v DC LED transformer (£3) so I can power the fans (One in, one out) and the BOB needs 12v to control spindle speed.

Still ticking along one of the AM882's was dodgy so had to order new one from China still waiting for delivery but should be next week.

It's relatively easy to connect the AM882's to grbl so I will have a go after Xmas have an idea to make my own pcb with the correct sockets so I have my own breakout board for UNO to plug into the existing AM882 sockets which would make switching from linuxcnc to grbl as simple as changing 8 sockets.

I certainly have nothing against grbl I have never cut with it or linuxcnc I would love to try them both out I have a feeling they both fulfil different niches with a certain amount of overlap.

Not so keen on Mach 3 as it's commercialised closed source but I've heard it's very good but since both grbl and linuxcnc are very good as well I can take the open source options without compromise.

Edited 1 time(s). Last edit at 11/24/2017 01:08PM by Desertboy.

So transferring the electronics over, got the correct current limit thermistor on order for the toroidal transformer so I can use a standard 6 amp house mcb as a breaker. Have a switch to go on the box as well to turn power on/off. Adding a AC to 12v DC LED transformer (£3) so I can power the fans (One in, one out) and the BOB needs 12v to control spindle speed.

Still ticking along one of the AM882's was dodgy so had to order new one from China still waiting for delivery but should be next week.

It's relatively easy to connect the AM882's to grbl so I will have a go after Xmas have an idea to make my own pcb with the correct sockets so I have my own breakout board for UNO to plug into the existing AM882 sockets which would make switching from linuxcnc to grbl as simple as changing 8 sockets.

I certainly have nothing against grbl I have never cut with it or linuxcnc I would love to try them both out I have a feeling they both fulfil different niches with a certain amount of overlap.

Not so keen on Mach 3 as it's commercialised closed source but I've heard it's very good but since both grbl and linuxcnc are very good as well I can take the open source options without compromise.

Edited 1 time(s). Last edit at 11/24/2017 01:08PM by Desertboy.

|

Re: CNC milling/router DIY build WIP November 26, 2017 03:39PM |

Registered: 7 years ago Posts: 142 |

|

Re: CNC milling/router DIY build WIP November 27, 2017 11:51AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CNC milling/router DIY build WIP November 30, 2017 08:14AM |

Registered: 7 years ago Posts: 142 |

Added a current limited thermistor and MCB type B to the toroidal transformer tested works ok. Without the thermistor the transformer trips the MCB with it works fine.

I've got it wired to a 13amp light switch at moment but will get a switch for the box and the 13amp switch can then be used to turn the vacuum bed on/off.

It's really annoying that one of the AM882h's was dodgy as I'm now playing the waiting game again with Mr Postman only this time it's Xmas, grrr.

I have a project I want to finish before Xmas and this is really slowing me down.

Edited 2 time(s). Last edit at 11/30/2017 09:09AM by Desertboy.

I've got it wired to a 13amp light switch at moment but will get a switch for the box and the 13amp switch can then be used to turn the vacuum bed on/off.

It's really annoying that one of the AM882h's was dodgy as I'm now playing the waiting game again with Mr Postman only this time it's Xmas, grrr.

I have a project I want to finish before Xmas and this is really slowing me down.

Edited 2 time(s). Last edit at 11/30/2017 09:09AM by Desertboy.

|

Re: CNC milling/router DIY build WIP December 02, 2017 03:57AM |

Registered: 7 years ago Posts: 142 |

My new AM882 came yesterday so I got the Y motors linked and working we have 4 working motors and 3 moving axis

Now it's working time to take it apart lol so I can fit it properly into the box and hopefully by Monday we can start our first cutting.

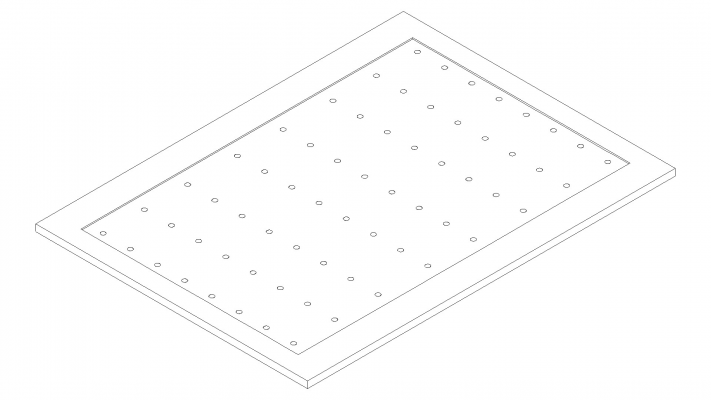

The bed is the first job obviously

Will get a video today before I unwire the motors again a long time coming and we need to cut with it yet but I think I did a better job than I did with my printer lol and this one I made it as I went along.

Now it's working time to take it apart lol so I can fit it properly into the box and hopefully by Monday we can start our first cutting.

The bed is the first job obviously

Will get a video today before I unwire the motors again a long time coming and we need to cut with it yet but I think I did a better job than I did with my printer lol and this one I made it as I went along.

|

Re: CNC milling/router DIY build WIP December 02, 2017 10:13AM |

Registered: 7 years ago Posts: 142 |

|

Re: CNC milling/router DIY build WIP December 11, 2017 05:09PM |

Registered: 7 years ago Posts: 142 |

Almost finished now just waiting for roller microswitches so I can sort the homing out and we can start cutting

Got a new toy £60 2nd hand on ebay

A 3dconnexion space pilot , loving it so far cannot recommend it enough for fusion 360 but they're expensive new.

[www.ebay.co.uk]

took me about 30 mins to get used to navigating 3d space with it the key seems to be very subtle moves.

Got a new toy £60 2nd hand on ebay

A 3dconnexion space pilot , loving it so far cannot recommend it enough for fusion 360 but they're expensive new.

[www.ebay.co.uk]

took me about 30 mins to get used to navigating 3d space with it the key seems to be very subtle moves.

|

Re: CNC milling/router DIY build WIP December 12, 2017 02:57AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CNC milling/router DIY build WIP December 13, 2017 05:26AM |

Registered: 7 years ago Posts: 142 |

Quote

o_lampe

I'd like to have a jog panel to manually move the spindle. But has to be Duet/RRF compatible. There are Mach3 joysticks out there, but I don't trust their compatiblity.

The 3dconnexion is a 3d mouse (Really an analog joystick) for navigating 3d space in Fusion 360 (Or supported cad program), it's only does one thing but it does it well

[www.3dconnexion.co.uk]

They're quite expensive new so I bought 2nd hand space pilot (£60 delivered which is an excellent price) to see if I would get on with it and I love it not sure how I lived without it

It would make an excellent jog wheel!

Edited 4 time(s). Last edit at 12/13/2017 06:08AM by Desertboy.

|

Re: CNC milling/router DIY build WIP December 13, 2017 10:01AM |

Admin Registered: 16 years ago Posts: 13,884 |

... I have the 3dconnexion space-navigator, but don't use it most of the time - have more precise position controlling in most of my 3D-programs with normal mouse and key-board ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: CNC milling/router DIY build WIP December 15, 2017 03:20AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CNC milling/router DIY build WIP December 15, 2017 10:27AM |

Registered: 7 years ago Posts: 142 |

They're all renders in Fusion, I thought that was obvious.

If I want to cut the last piece I'd remove any detail that was too fine, I was more interested in how you did it (Extracting usable geometry from bitmaps) than actually doing it lol. You glue 2 pieces of wood together and mill through the top piece if you're interested. You can't inlay this easily.

I only started with fusion in October so still learning how to use it

I'm probably going to make this first for a friend

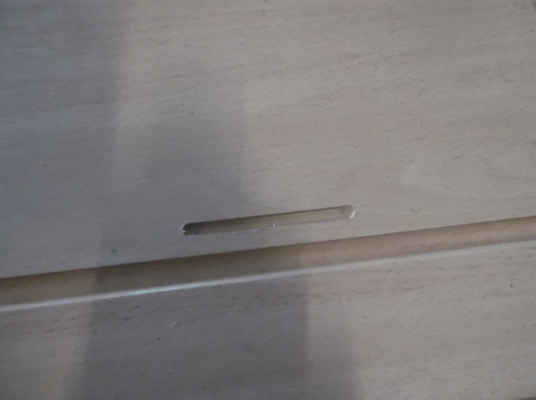

I have her cutting now and done some test cutting with her but still need to get the homing switches on so I can sort squaring the gantry out and I still have no bed.

In Linuxcnc when I home my Y axis (2 ballscrews, 2 motors, & 2 limit switches) it homes the axis until it touches both switches then adjust each side to presets to square the gantry every home cycle.

If I want to cut the last piece I'd remove any detail that was too fine, I was more interested in how you did it (Extracting usable geometry from bitmaps) than actually doing it lol. You glue 2 pieces of wood together and mill through the top piece if you're interested. You can't inlay this easily.

I only started with fusion in October so still learning how to use it

I'm probably going to make this first for a friend

I have her cutting now and done some test cutting with her but still need to get the homing switches on so I can sort squaring the gantry out and I still have no bed.

In Linuxcnc when I home my Y axis (2 ballscrews, 2 motors, & 2 limit switches) it homes the axis until it touches both switches then adjust each side to presets to square the gantry every home cycle.

|

Re: CNC milling/router DIY build WIP December 15, 2017 09:38PM |

Registered: 7 years ago Posts: 142 |

Just playing in fusion but one day an 8*4 I can make money from

Edited 1 time(s). Last edit at 12/15/2017 10:06PM by Desertboy.

Edited 1 time(s). Last edit at 12/15/2017 10:06PM by Desertboy.

|

Re: CNC milling/router DIY build WIP December 16, 2017 03:33AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CNC milling/router DIY build WIP December 17, 2017 12:36AM |

Registered: 7 years ago Posts: 142 |

|

Re: CNC milling/router DIY build WIP December 18, 2017 01:22PM |

Registered: 7 years ago Posts: 142 |

|

Re: CNC milling/router DIY build WIP December 19, 2017 06:27AM |

Registered: 7 years ago Posts: 142 |

|

Re: CNC milling/router DIY build WIP December 20, 2017 01:49AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: CNC milling/router DIY build WIP December 20, 2017 05:19AM |

Admin Registered: 16 years ago Posts: 13,884 |

... ... or "used her teeth" for the first time

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: CNC milling/router DIY build WIP December 21, 2017 06:20AM |

Registered: 7 years ago Posts: 142 |

I'm making this sign to put on the wall next to the machine to tell the other people at work exactly what me and Betty think of them lol

I'll make it as an engraving then paint it.

I did a simple spline trace on a canvas in Fusion then extruded.

Edited 1 time(s). Last edit at 12/21/2017 06:21AM by Desertboy.

I'll make it as an engraving then paint it.

I did a simple spline trace on a canvas in Fusion then extruded.

Edited 1 time(s). Last edit at 12/21/2017 06:21AM by Desertboy.

Sorry, only registered users may post in this forum.