Milling and laser engraving on one machine

Posted by o_lampe

|

Milling and laser engraving on one machine May 15, 2017 08:50AM |

Registered: 8 years ago Posts: 5,232 |

I have lots of 2020 and 2040 extrusion laying around and also three 600mm mgn12 rails plus three 400mm ballscrews.

My plan is to build a frame with a dual X-gantry:

One is for milling with the ballscrews and NEMA23

The other is a lightweight beltdriven gantry for a laser engraver.

My concern is the mgn12 rail. Is it strong enough for milling aluminum, plastic, wood, FR4-PCBs?

Should I go for two carriers on one rail for the milling gantry?

My plan is to build a frame with a dual X-gantry:

One is for milling with the ballscrews and NEMA23

The other is a lightweight beltdriven gantry for a laser engraver.

My concern is the mgn12 rail. Is it strong enough for milling aluminum, plastic, wood, FR4-PCBs?

Should I go for two carriers on one rail for the milling gantry?

|

Re: Milling and laser engraving on one machine May 15, 2017 02:10PM |

Admin Registered: 16 years ago Posts: 13,884 |

... depends on the expected forces - no problem for high-speed engraving (>20krpm) ... but the dust will be a problem for the laser optics ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Milling and laser engraving on one machine May 16, 2017 03:19AM |

Registered: 8 years ago Posts: 5,232 |

The dust/ashes was actually the reason, why I didn't want to put the laser on my printer.

The mill and the laser can share a vacuum cleaner now. But I agree, the laser could benefit from a protection-cap for the lens.

If only I had a 3D printer to make one..... oh wait

Edited 1 time(s). Last edit at 05/16/2017 03:21AM by o_lampe.

The mill and the laser can share a vacuum cleaner now. But I agree, the laser could benefit from a protection-cap for the lens.

If only I had a 3D printer to make one..... oh wait

Edited 1 time(s). Last edit at 05/16/2017 03:21AM by o_lampe.

|

Re: Milling and laser engraving on one machine May 17, 2017 01:15PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Milling and laser engraving on one machine May 18, 2017 02:39AM |

Registered: 8 years ago Posts: 5,232 |

Thanks cozmicray for the links.

I've studied the shapeoko and x-carver before and I'm not happy with their v-roller concept. I've seen huge improvement when I changed my delta from v-rollers to linear rails. How much more of a difference will I see on a mill, where real sideloads happen to the bearings? ( Does any of the above mentioned mills have axial load bearings in their rollers? )

I also read some basic advice threads in cnczone forum and it seems, in their world dovetail guides are the way to go.

That was the reason behind my question about mgn12 rails stiffness.

I've studied the shapeoko and x-carver before and I'm not happy with their v-roller concept. I've seen huge improvement when I changed my delta from v-rollers to linear rails. How much more of a difference will I see on a mill, where real sideloads happen to the bearings? ( Does any of the above mentioned mills have axial load bearings in their rollers? )

I also read some basic advice threads in cnczone forum and it seems, in their world dovetail guides are the way to go.

That was the reason behind my question about mgn12 rails stiffness.

|

Re: Milling and laser engraving on one machine May 18, 2017 01:43PM |

Registered: 11 years ago Posts: 1,049 |

FWIW

Shapeoko 2 having 4 two bearing V rollers with eccentric bolt mounts on each Y carriage

and 8 two bearing V rollers on Y axis carriage

-- with the wide spacing of rollers

there is no slop in the movement

I have routed hardwood, Aluminum with no problem

a 1 m makerslide can be had for $21

Z tilt (Y-Z plane) twist of the gantry, Spindle and cutters most problematic.

but shapeoko 3 and X carve with beefer gantry may have solved that.

DD has convinced me that linear rails are great -- but are a art of their own

Shapeoko 2 having 4 two bearing V rollers with eccentric bolt mounts on each Y carriage

and 8 two bearing V rollers on Y axis carriage

-- with the wide spacing of rollers

there is no slop in the movement

I have routed hardwood, Aluminum with no problem

a 1 m makerslide can be had for $21

Z tilt (Y-Z plane) twist of the gantry, Spindle and cutters most problematic.

but shapeoko 3 and X carve with beefer gantry may have solved that.

DD has convinced me that linear rails are great -- but are a art of their own

|

Re: Milling and laser engraving on one machine May 20, 2017 02:58AM |

Registered: 7 years ago Posts: 142 |

I was going to go makerslide route but £100 ($130) delivered by the time you factor in the extras needed for makeslide +P&P to get the same sized profile sourced in UK would cost 80% of what the hiwin's cost so it was a no brainer.

[www.ebay.co.uk]

at this price for 2 1500mm Hiwin rails with 4 blocks makerslide became a lot less attractive, especially as it was EU shipped and I had them within 3 days no tax. £100 is crazy cheap even on alixpress expect to pay at least double that. They are lovely as well!

My machine will cost me ~2/3 what an xcarve is in the UK with much better slides, much better extrusion (Using heavy duty 4.5cm*9cm T slot profile), 3 proper 1605 ballscrew drives on 2 axis and 20mm ballscrew on the z, nema 23's all round, a 2,2kw water cooled spindle with vfd and a bigger work area. I've found buy from China, split your orders up to reduce the chance of import tax and you're onto a winner

Back to the original question though it's easy to add a laser diode (Up to 5w) but really you need a lot more power than that if you intend to be processing anything other than balsa wood or light engraving.

For the hassle I'd just buy a cheap chinese 40w laser cutter and have 2 machines but a decent router will do 99% of what a laser cutter will do for home use so a better choice I think.

If you're struggling to find slides at a good price, alixpress and ebay are your friend.

You definitely want 2 slides per axis even if you were using 25mm Hiwin's at 12mm it will be essential.

Personally if I were you I'd sell the slides you have and get bigger ones.

Edited 7 time(s). Last edit at 05/20/2017 07:15AM by Desertboy.

[www.ebay.co.uk]

at this price for 2 1500mm Hiwin rails with 4 blocks makerslide became a lot less attractive, especially as it was EU shipped and I had them within 3 days no tax. £100 is crazy cheap even on alixpress expect to pay at least double that. They are lovely as well!

My machine will cost me ~2/3 what an xcarve is in the UK with much better slides, much better extrusion (Using heavy duty 4.5cm*9cm T slot profile), 3 proper 1605 ballscrew drives on 2 axis and 20mm ballscrew on the z, nema 23's all round, a 2,2kw water cooled spindle with vfd and a bigger work area. I've found buy from China, split your orders up to reduce the chance of import tax and you're onto a winner

Back to the original question though it's easy to add a laser diode (Up to 5w) but really you need a lot more power than that if you intend to be processing anything other than balsa wood or light engraving.

For the hassle I'd just buy a cheap chinese 40w laser cutter and have 2 machines but a decent router will do 99% of what a laser cutter will do for home use so a better choice I think.

If you're struggling to find slides at a good price, alixpress and ebay are your friend.

You definitely want 2 slides per axis even if you were using 25mm Hiwin's at 12mm it will be essential.

Personally if I were you I'd sell the slides you have and get bigger ones.

Edited 7 time(s). Last edit at 05/20/2017 07:15AM by Desertboy.

|

Re: Milling and laser engraving on one machine May 20, 2017 11:29AM |

Registered: 11 years ago Posts: 1,049 |

Perhaps this should be titled "very expensive British build"

Confounds me how a $21 USD item becomes $130 (100 pound) in UK

They make sure you don't use anything outside the island?

but

The proper UK linear slides should thrill the Queen?

£99.00 with the £500.00 Economy Delivery (used Rolls Royce)

Where is the linear rail production factory located in the UK?

Alternative V rail

[vgrooverail.com]

Confounds me how a $21 USD item becomes $130 (100 pound) in UK

They make sure you don't use anything outside the island?

but

The proper UK linear slides should thrill the Queen?

£99.00 with the £500.00 Economy Delivery (used Rolls Royce)

Where is the linear rail production factory located in the UK?

Alternative V rail

[vgrooverail.com]

|

Re: Milling and laser engraving on one machine May 20, 2017 02:20PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Milling and laser engraving on one machine May 20, 2017 02:37PM |

Registered: 7 years ago Posts: 142 |

Quote

cozmicray

Perhaps this should be titled "very expensive British build"

Confounds me how a $21 USD item becomes $130 (100 pound) in UK

They make sure you don't use anything outside the island?

but

The proper UK linear slides should thrill the Queen?

£99.00 with the £500.00 Economy Delivery (used Rolls Royce)

Where is the linear rail production factory located in the UK?

Alternative V rail

[vgrooverail.com]

[amberspyglass.co.uk]

You can't buy 1.5m makerslide here so you would have to buy 2m and cut it down so that's £48 as I have 2 1.5m (5ft) rails before we add any carriages, bearings, etc.

Add delivery and we get to ~£70

those slides were Chinese obviously but came from Germany (Was on delivery invoice) and delivery was free to the UK and because they came from Germany no import tax.

So £30 extra for hiwin vs makerslide as I said decision was easy

We always get screwed in the UK you should see how much we pay for fuel and electricity lol.

If $21 for 1m makerslide with all the bearings and mounting plate in US you are getting a great deal.

Edited 6 time(s). Last edit at 05/20/2017 02:55PM by Desertboy.

|

Re: Milling and laser engraving on one machine May 20, 2017 02:41PM |

Registered: 7 years ago Posts: 142 |

Quote

o_lampe

I'm also concerned about dust and debris contaminating the rail carriers. My mgn12 have dust covers on the sides, but you can see the balls from below.

They should have greasing point the greasing pushes debris out (It might be blanked off and you need to add a grease nipple mine are) but mounting the rails sideways on outside the frame also reduces debris and of course a dust shoe with a dyson style vacuum cleaner + home made cyclone will keep the area clean.

If you intend to do aluminium you should use compressed air if possible to clear the chips by mounting a solenoid pointing at the drill head.

NEVER TAKE THE BLOCKS off the rail!!!!

Edited 2 time(s). Last edit at 05/20/2017 02:46PM by Desertboy.

|

Re: Milling and laser engraving on one machine May 20, 2017 05:18PM |

Registered: 11 years ago Posts: 1,049 |

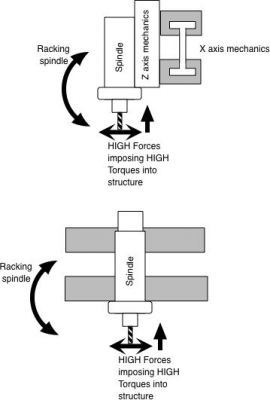

Your build is the two extremes in design

Laser -- no cutting forces on mechanics Z axis not necessary

mill --- extreme forces on the mechanics Z axis important

My plan is to build a frame with a dual X-gantry:

How will you "switch" gantries?

Laser -- no cutting forces on mechanics Z axis not necessary

mill --- extreme forces on the mechanics Z axis important

My plan is to build a frame with a dual X-gantry:

How will you "switch" gantries?

|

Re: Milling and laser engraving on one machine May 21, 2017 04:08AM |

Registered: 8 years ago Posts: 5,232 |

Both gantrys are always mounted. I'll park the unused gantry at either end in Y-direction. That way, I only loose a few centimeters of build plate, but don't have to deal with two machines/controllers/working area.

Would you use two rails with two carriers each for the Z-gantry? ( four carriers in total )

I already did many times ...and I replaced the balls with A+ quality balls, so I have HIWIN quality at chinese prices :p

...and I replaced the balls with A+ quality balls, so I have HIWIN quality at chinese prices :p

Just make sure, the bearings have ball retainers.

Would you use two rails with two carriers each for the Z-gantry? ( four carriers in total )

Quote

NEVER TAKE THE BLOCKS off the rail!!!!

I already did many times

...and I replaced the balls with A+ quality balls, so I have HIWIN quality at chinese prices :p

...and I replaced the balls with A+ quality balls, so I have HIWIN quality at chinese prices :pJust make sure, the bearings have ball retainers.

|

Re: Milling and laser engraving on one machine May 21, 2017 01:21PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Milling and laser engraving on one machine May 22, 2017 03:28AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Milling and laser engraving on one machine June 03, 2017 03:12AM |

Registered: 8 years ago Posts: 5,232 |

There is a shapeoko-T(rapez) at myhobby-cnc.de

I will contact the guy and ask if I could use my 1204 ballscrews instead.

Reason behind this is, I got a bit overboard and bought a 1.5kW watercooled spindle with VFD, which is huuuge and heavy. No way my 2040 extrusion or mgn12 rails will be able to handle that beast.

I will contact the guy and ask if I could use my 1204 ballscrews instead.

Reason behind this is, I got a bit overboard and bought a 1.5kW watercooled spindle with VFD, which is huuuge and heavy. No way my 2040 extrusion or mgn12 rails will be able to handle that beast.

|

Re: Milling and laser engraving on one machine June 03, 2017 04:19AM |

Registered: 7 years ago Posts: 142 |

I just got my spindle mount for a 2.2kw and was shocked how big the mount is alone lol, water cooled is best way if you want to stay sane as they are far quieter but have a lot of other advantages as well. Make sure you get a pot for the vfd to control spindle speed but sure you're on it

The extrusion can take the weight no problems but it's the flex, if you have access drill press and are ok with marking out and drilling you can strengthen up the shell with angle steel and t nuts for cheap but you must inspect every angle you buy to ensure it's straight. This won't work for the extrusion with the bearings on of course.

You might be able to use more bearings to spread the weight you need to check the mounting plate but it does look like you have options to use more.

[www.amazon.co.uk]

This is the standard router I see people bolting on and it weighs 2.5kg's and of course routers vibrate a lot more than spindles which adds considerable stresses so I would think unless the spindle is heavier than 2.5kg's it will perform better than a router in a stock machine. Those metal plates holding it together look a rather skinny are they aluminium or steel?

Good luck with your build.

Edited 1 time(s). Last edit at 06/03/2017 04:25AM by Desertboy.

The extrusion can take the weight no problems but it's the flex, if you have access drill press and are ok with marking out and drilling you can strengthen up the shell with angle steel and t nuts for cheap but you must inspect every angle you buy to ensure it's straight. This won't work for the extrusion with the bearings on of course.

You might be able to use more bearings to spread the weight you need to check the mounting plate but it does look like you have options to use more.

[www.amazon.co.uk]

This is the standard router I see people bolting on and it weighs 2.5kg's and of course routers vibrate a lot more than spindles which adds considerable stresses so I would think unless the spindle is heavier than 2.5kg's it will perform better than a router in a stock machine. Those metal plates holding it together look a rather skinny are they aluminium or steel?

Good luck with your build.

Edited 1 time(s). Last edit at 06/03/2017 04:25AM by Desertboy.

|

Re: Milling and laser engraving on one machine June 03, 2017 08:30AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Milling and laser engraving on one machine June 04, 2017 03:43AM |

Registered: 7 years ago Posts: 142 |

I'll be interested how it works? I have a spare ramps, mega & steppers but I also have an uno so I bought a cnc shield (£3.50). I have a 24v power supply so it's probably easier to use the cnc shield as I would have to do some minor mod to the ramps to use the 24v power supply. I'm sure I will end up with the same make of inverter but I haven't bought the spindle/inverter combo yet so will remember that tip when it comes

I read on another forum someone saying adding a pot to his VFD was the best 75p he ever spent lol so I figured I'd do it anyway as it can still be controlled by the software as well.

At some point I intend to upgrade to better stepper drivers and a breakout board so I can try linuxcnc but gbrl will be fine for my uses until I get a 4th axis. My nema 23 stepper motors are 3+ amp so would benefit from better drivers and 36v+ power supply. I believe I can still run something like a TB6600 (£5 a driver up to 4 amps) from a cnc shield but needs some creative wiring to interface with the stepper sockets and directly to supply power by passing the cnc shield for stepper motor power.

I doubt it's worth upgrading the z axis drivers unless I beef the frame up with steel first.

Edited 2 time(s). Last edit at 06/04/2017 03:48AM by Desertboy.

I read on another forum someone saying adding a pot to his VFD was the best 75p he ever spent lol so I figured I'd do it anyway as it can still be controlled by the software as well.

At some point I intend to upgrade to better stepper drivers and a breakout board so I can try linuxcnc but gbrl will be fine for my uses until I get a 4th axis. My nema 23 stepper motors are 3+ amp so would benefit from better drivers and 36v+ power supply. I believe I can still run something like a TB6600 (£5 a driver up to 4 amps) from a cnc shield but needs some creative wiring to interface with the stepper sockets and directly to supply power by passing the cnc shield for stepper motor power.

I doubt it's worth upgrading the z axis drivers unless I beef the frame up with steel first.

Edited 2 time(s). Last edit at 06/04/2017 03:48AM by Desertboy.

|

Re: Milling and laser engraving on one machine June 05, 2017 03:37AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Milling and laser engraving on one machine June 05, 2017 03:54AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Milling and laser engraving on one machine June 05, 2017 07:30AM |

Registered: 7 years ago Posts: 142 |

I'm sure that it would work very well, I was considering raising and lowering the gantry arm like a prusa but not this time maybe next build. Means 2 motors, 2 ballscrews and supports/rails for z axis but has the advantage that you just bolt the spindle mount to the gantry and flex on the gantry is reduced (Like a vertical machining centre).

Having a z axis for your laser is also great as the cheap diode laser we would use are a bitch to get the focus right unless you have a z axis.

How big a working area are you after?

Edited 3 time(s). Last edit at 06/06/2017 12:15AM by Desertboy.

Having a z axis for your laser is also great as the cheap diode laser we would use are a bitch to get the focus right unless you have a z axis.

How big a working area are you after?

Edited 3 time(s). Last edit at 06/06/2017 12:15AM by Desertboy.

|

Re: Milling and laser engraving on one machine June 07, 2017 07:45AM |

Registered: 8 years ago Posts: 5,232 |

I only ordered the shapeoko trapez sheetmetal- and z-axis-upgrade kits today.

No v-wheels, no nuts'n'bolts. I found the makerslide profile is 2040, just like the extrusions I already have. I think, the drillholes in the sheetmetall will match my extrusions.

So I stick to the plan of using mgn12 rails.

The sheets are 3mm steel btw.

No v-wheels, no nuts'n'bolts. I found the makerslide profile is 2040, just like the extrusions I already have. I think, the drillholes in the sheetmetall will match my extrusions.

So I stick to the plan of using mgn12 rails.

The sheets are 3mm steel btw.

|

Re: Milling and laser engraving on one machine June 09, 2017 06:53AM |

Registered: 7 years ago Posts: 142 |

I think you will have a very nice cutter there, I've just ordered aluminium tooling plate to make my mounts from cost me £90 delivered plus the processing costs (we shall see next week but a friend works for a large cnc firm and is going to get it done on the cheap).

I went with 20mm thick unsure how that compares to 3mm steel but my gantry will be heavy as I'm going to strengthen it with 10mm steel angle and the material costs between 10mm and 20mm was about 40% so I figured it was worth the extra cost for the future proofing.

The pressure is on me though to get my cad models for the mounting plates right and I have non standard supported rail (No existing cad model) so it's all down to my measuring skills lol.

Edited 1 time(s). Last edit at 06/09/2017 07:04AM by Desertboy.

I went with 20mm thick unsure how that compares to 3mm steel but my gantry will be heavy as I'm going to strengthen it with 10mm steel angle and the material costs between 10mm and 20mm was about 40% so I figured it was worth the extra cost for the future proofing.

The pressure is on me though to get my cad models for the mounting plates right and I have non standard supported rail (No existing cad model) so it's all down to my measuring skills lol.

Edited 1 time(s). Last edit at 06/09/2017 07:04AM by Desertboy.

|

Re: Milling and laser engraving on one machine June 09, 2017 11:43AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Milling and laser engraving on one machine June 10, 2017 07:25AM |

Registered: 7 years ago Posts: 142 |

Quote

o_lampe

I think 3mm steel will be strong enough to reproduce the brackets in 10mm aluminum. It's like "pulling yourself out of the mud on your own hair" ( quote from Baron Munchhausen stories )

Why tooling plate?

Tooling plate is ground flat both sides, aluminium plate is surprisingly wobbly (20mm thick over 1m can be up to 0.2mm deviation) so I'm using tooling plate to mount the gantry to the supported rail (Makes things much easier I've been told by experienced builders on other forums) and for the z axis (Mine is a custom z axis made from freebie parts) but I will use 6082 (Machining aluminium) for the nema 23 mounts and the ballscrew drive mounts.

I only started building mine because I had a score of 25mm supported rail and I already had the extrusion, T nuts, etc neither of which cost me any money just my own time I never intended to build it the way I am or spend the amount I am although I will still spend under £850 in total for everything including £210 on the spindle so I think I will have got good bang for buck. When I saw the Hiwin for £100 for 1.5m I just couldn't resist.

The other reason to use tooling plate is I have 45*90 heavy duty extrusion (Twice the wall thickness) all round, 25mm supported rail, 15mm hiwin, 4 nema 23's (Bought a matching pair, recovered 2 for free), ballscrew drive all round, a ground ballscrew on the Z axis! I think since things got upgraded a lot from the original plan I can justify the expense on the tooling plate.

I'm going to call her Betty in honour of Frank Spencer

I need to mount mine like this

These are just scrap pieces of aluminium I'm using to measure it out so I can then cad it and send the plate and models to my mate and hopefully in 3-5 days I will have it back ready to go

Edited 5 time(s). Last edit at 06/10/2017 09:37AM by Desertboy.

|

Re: Milling and laser engraving on one machine June 11, 2017 12:14AM |

Registered: 7 years ago Posts: 142 |

|

Re: Milling and laser engraving on one machine June 11, 2017 06:25AM |

Admin Registered: 16 years ago Posts: 13,884 |

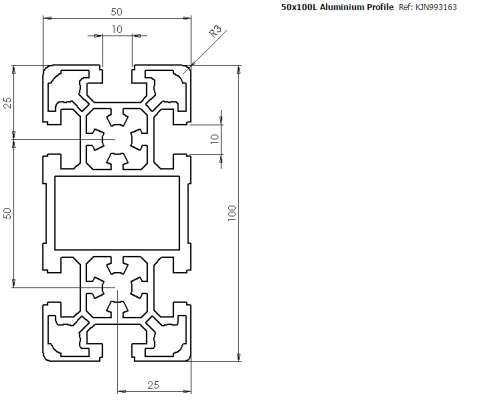

... the cavities in the common extrusion profiles aren't wide enough to give much of stiffness - better search "light" types with big caities and thin walls.

You can use any 2K epoxy resin with sand - it should be roughly 6% of the resin, compared to the sand volume, for highest stiffnes values ...

Edited 1 time(s). Last edit at 06/11/2017 06:26AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

You can use any 2K epoxy resin with sand - it should be roughly 6% of the resin, compared to the sand volume, for highest stiffnes values ...

Edited 1 time(s). Last edit at 06/11/2017 06:26AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Milling and laser engraving on one machine June 11, 2017 12:29PM |

Registered: 7 years ago Posts: 142 |

Quote

VDX

... the cavities in the common extrusion profiles aren't wide enough to give much of stiffness - better search "light" types with big caities and thin walls.

You can use any 2K epoxy resin with sand - it should be roughly 6% of the resin, compared to the sand volume, for highest stiffnes values ...

My gantry has a large cavity

|

Re: Milling and laser engraving on one machine June 11, 2017 12:58PM |

Admin Registered: 16 years ago Posts: 13,884 |

... this type looks pretty good! - sand-epoxy in the middle cavity, and inserting clamped steel-rods in the 4 outer and maybe too in the two medium "round" holes ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.