XYZ axis stop when Spindle is powered up

Posted by Electric ant

|

XYZ axis stop when Spindle is powered up June 22, 2020 11:10AM |

Registered: 8 years ago Posts: 39 |

Hi folks, I am in need of help with my DIY CNC Router project.

I have built myself a mini desktop router for making PCBs that runs on GRBL 1.1.

CNC v3 grbl shield is powered by a 12v - 5A - 60W psu, and the spindle (an Eleksmaker 555 mini spindle) has another psu of the same spec to itself.

I have good speed, good clearance and good power. I have tried numerous different endstops and nothing changes. It was suggested to me to put a diode on the endstop line to stop unwanted signals, but this also stops the signals that are needed for homing.

When I googled it, all I found were people saying it is most likely a power issue, but there is plenty of power. And still nothing changes.

This cnc build has been a When I do a test cut above the pcb with the spindle off, everything works as it should in UGCS, GRBL Controller and Chillipeppr (all that I have tried for now). Autolevel in chillipeppr even works.

Then as soon as I put power to the spindle, the XYZ axis all stop moving, I get an error stating 'Endstop Triggered' but the program still runs according to the visuals. None of the endstops are anywhere near a trigger point.

nightmare from the start. Every time I fix a problem, something else goes wrong with it. And as for windows 10, I can't even move the steppers in UGCS, Chillipeppr and Mach3.

I'm now using windows 7 x64 and that has solved quite a few issues I was having with win 10. Mach3 is still not working though.

Has anyone got any ideas to what could be causing this to happen ?.

Hopefully this will be my final problem and I can get on with cutting some PCBs (he says with his fingers crossed). I am willing to try just about anything now, this project is really getting to me, I have been working on this for over 3 months and haven't even come close to milling a PCB yet.

PLEASE SOMEBODY HELP ME !!!

All suggestions will be tried (logical suggestions only please).

Thanks to all who answer this, or even read it.

Eternally grateful,

Electric ant.

I have built myself a mini desktop router for making PCBs that runs on GRBL 1.1.

CNC v3 grbl shield is powered by a 12v - 5A - 60W psu, and the spindle (an Eleksmaker 555 mini spindle) has another psu of the same spec to itself.

I have good speed, good clearance and good power. I have tried numerous different endstops and nothing changes. It was suggested to me to put a diode on the endstop line to stop unwanted signals, but this also stops the signals that are needed for homing.

When I googled it, all I found were people saying it is most likely a power issue, but there is plenty of power. And still nothing changes.

This cnc build has been a When I do a test cut above the pcb with the spindle off, everything works as it should in UGCS, GRBL Controller and Chillipeppr (all that I have tried for now). Autolevel in chillipeppr even works.

Then as soon as I put power to the spindle, the XYZ axis all stop moving, I get an error stating 'Endstop Triggered' but the program still runs according to the visuals. None of the endstops are anywhere near a trigger point.

nightmare from the start. Every time I fix a problem, something else goes wrong with it. And as for windows 10, I can't even move the steppers in UGCS, Chillipeppr and Mach3.

I'm now using windows 7 x64 and that has solved quite a few issues I was having with win 10. Mach3 is still not working though.

Has anyone got any ideas to what could be causing this to happen ?.

Hopefully this will be my final problem and I can get on with cutting some PCBs (he says with his fingers crossed). I am willing to try just about anything now, this project is really getting to me, I have been working on this for over 3 months and haven't even come close to milling a PCB yet.

PLEASE SOMEBODY HELP ME !!!

All suggestions will be tried (logical suggestions only please).

Thanks to all who answer this, or even read it.

Eternally grateful,

Electric ant.

|

Re: XYZ axis stop when Spindle is powered up June 22, 2020 12:33PM |

Admin Registered: 16 years ago Posts: 13,884 |

... if not for power loss, then possibly "noise" on the data/endstop lines.

This can be reduced by better shielding the data lines and/or noise-filters for the spindle ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

This can be reduced by better shielding the data lines and/or noise-filters for the spindle ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: XYZ axis stop when Spindle is powered up June 23, 2020 02:32AM |

Registered: 8 years ago Posts: 39 |

@VDX.... All my endstop wires are in twisted pairs and each pair are rooted different from the guy b GT other and their corresponding axis motor.

A good suggestion though, but all endstop wiring is rooted different to each other and to their corresponding axis motor.

Thanks for the reply

Edited 1 time(s). Last edit at 06/23/2020 08:54AM by Electric ant.

A good suggestion though, but all endstop wiring is rooted different to each other and to their corresponding axis motor.

Thanks for the reply

Edited 1 time(s). Last edit at 06/23/2020 08:54AM by Electric ant.

|

Re: XYZ axis stop when Spindle is powered up June 23, 2020 06:18AM |

Admin Registered: 16 years ago Posts: 13,884 |

... further measures could be conductive tubing around and connected to ground near the power supply ... and/or a resistor between 19 and 50 Ohm soldered into the data line (this reduces "noise" and EMI-interferences) ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: XYZ axis stop when Spindle is powered up June 23, 2020 06:53AM |

Admin Registered: 13 years ago Posts: 6,998 |

|

Re: XYZ axis stop when Spindle is powered up June 23, 2020 09:28AM |

Registered: 8 years ago Posts: 39 |

@ VDX When you say put a resistor on the data line, what are you calling the data line ? I have 6 wires for each axis, 2 on the endstops and 4 on the stepper motors. I am fairly new to the CNC shield. What is this conductive tubing that I have never heard of ?

@Dust. This is the first time I have had that suggestion. I have never used 2 psu's on the same project. I will definitely be trying it when I get home.

More suggestions please guys. The more stuff I have to try gives me a better chance of solving the issue

Thanks for the answers guys, I will post results when I get some.

Regards, Electric Ant

@Dust. This is the first time I have had that suggestion. I have never used 2 psu's on the same project. I will definitely be trying it when I get home.

More suggestions please guys. The more stuff I have to try gives me a better chance of solving the issue

Thanks for the answers guys, I will post results when I get some.

Regards, Electric Ant

|

Re: XYZ axis stop when Spindle is powered up June 23, 2020 01:25PM |

Admin Registered: 16 years ago Posts: 13,884 |

... search for "shield braid" or "braided shield" ... e.g. here, from Amazon: [www.amazon.com]

Small resistors inserted into a signal line can reduce "noise" to some decades -- used this to elongate DMA cables (1MHz data clock) from max. 500mm to above one meter ... or high-speed serial communications to some ten meters lengths

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Small resistors inserted into a signal line can reduce "noise" to some decades -- used this to elongate DMA cables (1MHz data clock) from max. 500mm to above one meter ... or high-speed serial communications to some ten meters lengths

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: XYZ axis stop when Spindle is powered up June 23, 2020 03:29PM |

Registered: 8 years ago Posts: 39 |

@VDX. I totally understand what you are saying about the resistors filtering noise, but which wires do I put the resistors on ? My stepper motors have the standard Red - Blue - Green - Black wires and the endstops are Black - Yellow. None of the wires are over 500mm, most are under 400mm.

Eventually I will get to the bottom of this, I am not 1 to give up so easily.

Thanks for all your suggestions so far. I have not tried Dust's suggestion yet but I will post results here when test has been done.

I really need to get this router going because toner transfer never works for me.

Thanks again, Electric Ant.

Eventually I will get to the bottom of this, I am not 1 to give up so easily.

Thanks for all your suggestions so far. I have not tried Dust's suggestion yet but I will post results here when test has been done.

I really need to get this router going because toner transfer never works for me.

Thanks again, Electric Ant.

|

Re: XYZ axis stop when Spindle is powered up June 23, 2020 04:57PM |

Admin Registered: 16 years ago Posts: 13,884 |

... not the stepper wires, but the "signal" lines for all 3.3V or 5V signal levels ... e.g. the wires to/from the end-switches or eventual external stepper drivers with the STEP/CLOCK signals.

Every wire to/from the Arduino is potentially an "antenna" for EMI or inductive power surges ... GND wires aren't so sensitive, but could be problematic too, if near to stepper wires or motor lines, like your spindle - here short connections to a main GND point and grounded shielding (e.g. braided shield) are best to avoid noise ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Every wire to/from the Arduino is potentially an "antenna" for EMI or inductive power surges ... GND wires aren't so sensitive, but could be problematic too, if near to stepper wires or motor lines, like your spindle - here short connections to a main GND point and grounded shielding (e.g. braided shield) are best to avoid noise ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: XYZ axis stop when Spindle is powered up June 25, 2020 10:59PM |

Registered: 8 years ago Posts: 39 |

Well, I have grounded the 2 psu's together and still get the same thing happening. I put a 50 ohm resistor on each endstop, nothing changed. I have tried a different spindle motor, same result. It is making me think that my GRBL shield is somehow faulty.

I also have the grbl shield for the Nano, but I know that one was made wrong. I have had to do the track cutting mod on it but I don't really want to use a shield that was made wrong in the first place.

It now feels like there is a little glimmer of light at the end of the tunnel after my latest attempt to get my cnc working right.

Some time ago I started to make a grbl controller board (on perf board) for easy drivers. I found it again yesterday. Only the stepper motors are connected for now. After I plugged stepper motors in I put a board into UGCS and set it going through the motion of cutting a pcb. Then I put power to the spindle, guess what........NO ERRORS. With no power to the steppers, and no endstops connected, there were no errors.

When I did the same thing with the Uno shield (no stepper power and no endstops), the spindle still triggered it to stop.

Next I am going to make a fully functional easy driver circuit on the breadboard and test cnc with all power points and endstops connected.

If it works, I can then make a proper pcb for it.

I will post results tomorrow.

Has anyone got any tips on how to set up an easy driver ?

Really got high hopes for this now.

Thanks Electric Ant.

I also have the grbl shield for the Nano, but I know that one was made wrong. I have had to do the track cutting mod on it but I don't really want to use a shield that was made wrong in the first place.

It now feels like there is a little glimmer of light at the end of the tunnel after my latest attempt to get my cnc working right.

Some time ago I started to make a grbl controller board (on perf board) for easy drivers. I found it again yesterday. Only the stepper motors are connected for now. After I plugged stepper motors in I put a board into UGCS and set it going through the motion of cutting a pcb. Then I put power to the spindle, guess what........NO ERRORS. With no power to the steppers, and no endstops connected, there were no errors.

When I did the same thing with the Uno shield (no stepper power and no endstops), the spindle still triggered it to stop.

Next I am going to make a fully functional easy driver circuit on the breadboard and test cnc with all power points and endstops connected.

If it works, I can then make a proper pcb for it.

I will post results tomorrow.

Has anyone got any tips on how to set up an easy driver ?

Really got high hopes for this now.

Thanks Electric Ant.

|

Re: XYZ axis stop when Spindle is powered up June 26, 2020 03:11AM |

Admin Registered: 16 years ago Posts: 13,884 |

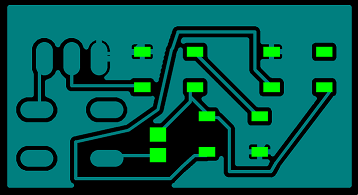

... I've received best results with "isolation traces" and GND areas otherwise, as shown here - [reprap.org]

It's even better with double-layer PCB's, where I could connect smaller "islands" too with the GND from the other side.

Imagine this as "Faraday cages" around sensitive signal lines on the PCB

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

It's even better with double-layer PCB's, where I could connect smaller "islands" too with the GND from the other side.

Imagine this as "Faraday cages" around sensitive signal lines on the PCB

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: XYZ axis stop when Spindle is powered up June 26, 2020 10:55AM |

Registered: 8 years ago Posts: 39 |

@VDX I am very impressed with your laser results, that is the same type of pcb (isolation traces with gnd plain.) that I am wanting to make. What is the minimum power of a laser capable of doing this ?.

My first goal is to make a single sided pcb and my first test pcb is to be a simple 35mm x 20mm Neopixel tester consisting of a 3 pin power/data pin header(top left), a tactile push button(bottom left), 1 smd resistor(bottom centre-ish), 2 Neopixels and space for another neopixel.

The top 2 sets of pads will have neopixels 0 and 2 soldered in place, the pads below them are for neopixel 1 (the one being tested) to be placed on. Run a rainbow sketch and press the button, if neopixel 2 doesn't light then neopixel 1 has a bad D- pin.

If I get success with this first board, I will have to watch more Eaglecad and Flatcam videos to learn how to make a double sided pcb because I will need to make a proper driver board for the Easydrivers and the Nano to run the cnc.

If, for some reason (touch wood it doesn't happen) all this fails, I think my last free option will be to try and get my diy i3 based 3d printer to work as a cnc machine.

I'm thinking that if I raised the bed by adding a piece of 10mm MDF and enable the Z-axis to go below zero (with Gcode), then it will go to the -0.05 mm cutting depth that I require.My biggest problem with this though is that I may not get an auto level to work. That is the main reason I have been trying for so long to get my cnc working.

I will post results of my easydriver breadboard test when I have completed it, fingers crossed it will all work.

Regards, Electric Ant.

My first goal is to make a single sided pcb and my first test pcb is to be a simple 35mm x 20mm Neopixel tester consisting of a 3 pin power/data pin header(top left), a tactile push button(bottom left), 1 smd resistor(bottom centre-ish), 2 Neopixels and space for another neopixel.

The top 2 sets of pads will have neopixels 0 and 2 soldered in place, the pads below them are for neopixel 1 (the one being tested) to be placed on. Run a rainbow sketch and press the button, if neopixel 2 doesn't light then neopixel 1 has a bad D- pin.

If I get success with this first board, I will have to watch more Eaglecad and Flatcam videos to learn how to make a double sided pcb because I will need to make a proper driver board for the Easydrivers and the Nano to run the cnc.

If, for some reason (touch wood it doesn't happen) all this fails, I think my last free option will be to try and get my diy i3 based 3d printer to work as a cnc machine.

I'm thinking that if I raised the bed by adding a piece of 10mm MDF and enable the Z-axis to go below zero (with Gcode), then it will go to the -0.05 mm cutting depth that I require.My biggest problem with this though is that I may not get an auto level to work. That is the main reason I have been trying for so long to get my cnc working.

I will post results of my easydriver breadboard test when I have completed it, fingers crossed it will all work.

Regards, Electric Ant.

|

Re: XYZ axis stop when Spindle is powered up June 26, 2020 02:53PM |

Admin Registered: 16 years ago Posts: 13,884 |

... for removing the (dark) paint from coated PCB's a 2W-laserdiode is enough ... for directly removing the copper, I've used a 20Watt fiberlaser with a galvoscanner head

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: XYZ axis stop when Spindle is powered up July 02, 2020 05:33PM |

Registered: 8 years ago Posts: 39 |

Well, after extensive testing I have finally given up all hope of getting my GRBL shield working on my cnc. I have set up a small circuit on the breadboard using 3x Easy-drivers and an Arduino Uno.

Apart from a couple of issues everything is running great so far.

The first problem I have is that the stepper motors are always engaged from the instant the power is connected, when I was using the grbl shield with the A4988 drivers, the motors only engaged when I connected the cnc to the PC. Now they engage as soon as the power is plugged in and the driver IC's are getting quite hot. A heat sink and a fan should deal with that.

If I connect the easy-driver enable pins to pin D8 on the uno the steppers only engage when they move, and shut down as soon as they stop. Joining the sleep and reset pins on the easy-drivers, instead, also gives the same results.

My other problem is with the power to the easy-drivers. My X-axis is powered by the same 12v psu as the spindle, the Y-axis is powered by the 5v Arduino pin and the Z-axis is powered by a 5v regulator that comes from the 12v x-axis psu. I can live with that for now though because this is the only way I have been able to get all 3 motors moving together. My LM7805 only kicks out 4.85v but when measured at the z easy-driver it only reads at 4.76v. What size and type of capacitors would work best ? Too many different combinations to achieve the same thing, One of them must be better than all the others.

As it is now it is very usable, it's just taking some time to get the cutting depth and speed right now.

Thanks for the input guys and does anyone know how to fix my first problem ?

Regards, Electric Ant

Apart from a couple of issues everything is running great so far.

The first problem I have is that the stepper motors are always engaged from the instant the power is connected, when I was using the grbl shield with the A4988 drivers, the motors only engaged when I connected the cnc to the PC. Now they engage as soon as the power is plugged in and the driver IC's are getting quite hot. A heat sink and a fan should deal with that.

If I connect the easy-driver enable pins to pin D8 on the uno the steppers only engage when they move, and shut down as soon as they stop. Joining the sleep and reset pins on the easy-drivers, instead, also gives the same results.

My other problem is with the power to the easy-drivers. My X-axis is powered by the same 12v psu as the spindle, the Y-axis is powered by the 5v Arduino pin and the Z-axis is powered by a 5v regulator that comes from the 12v x-axis psu. I can live with that for now though because this is the only way I have been able to get all 3 motors moving together. My LM7805 only kicks out 4.85v but when measured at the z easy-driver it only reads at 4.76v. What size and type of capacitors would work best ? Too many different combinations to achieve the same thing, One of them must be better than all the others.

As it is now it is very usable, it's just taking some time to get the cutting depth and speed right now.

Thanks for the input guys and does anyone know how to fix my first problem ?

Regards, Electric Ant

|

Re: XYZ axis stop when Spindle is powered up January 04, 2021 12:24PM |

Registered: 3 years ago Posts: 22 |

Sorry, only registered users may post in this forum.