Laser cutter focus help wanted

Posted by twofieros

|

Laser cutter focus help wanted January 09, 2015 07:56PM |

Registered: 9 years ago Posts: 13 |

I've got the laser add-on kit from Jtech. I created a mount to hold the diode on my 3d printer and one to hold the power supply for the laser. I've got it wired up to a PWM so I will be able to control the power. Everything looks good but now I'm trying to figure out how to set the focus and actually make my first cuts/engravings. I would like some input from you guys who have been down this road before.

Right now I have the laser roughly focused to about 4 inches below my nozzles. Z home is set to .1mm off the bed. This will cause interference if I placed a part to be cut below the nozzles and hit home or if my Gcode called for a home command at the start like it does now when printing. Obviously, I could just remove that command but I'm hoping to avoid having to modify the code manually beyond setting the height for the part I'm wanting to cut/engrave. How do you guys address this issue?

For setting the focus I plan to manually write a Gcode file to draw several lines with a Z change after each one. The line that is closest will be the one I use for setting the base Z and then I would have to manually add to that whatever thickness my part is.

Later I plan to add octoprint so that I can start and stop a cut without being in the room. I'm still a bit scared about laser light exposure. I have the goggles but I would just feel better if I was far enough away that I wouldn't even be exposed to the light. I would be able to monitor the print visually as well and send commands to it. The last thing I need is a fire to start when I'm not in the area!

Thanks for any advice you can provide.

Right now I have the laser roughly focused to about 4 inches below my nozzles. Z home is set to .1mm off the bed. This will cause interference if I placed a part to be cut below the nozzles and hit home or if my Gcode called for a home command at the start like it does now when printing. Obviously, I could just remove that command but I'm hoping to avoid having to modify the code manually beyond setting the height for the part I'm wanting to cut/engrave. How do you guys address this issue?

For setting the focus I plan to manually write a Gcode file to draw several lines with a Z change after each one. The line that is closest will be the one I use for setting the base Z and then I would have to manually add to that whatever thickness my part is.

Later I plan to add octoprint so that I can start and stop a cut without being in the room. I'm still a bit scared about laser light exposure. I have the goggles but I would just feel better if I was far enough away that I wouldn't even be exposed to the light. I would be able to monitor the print visually as well and send commands to it. The last thing I need is a fire to start when I'm not in the area!

Thanks for any advice you can provide.

|

Re: Laser cutter focus help wanted January 09, 2015 10:08PM |

Registered: 9 years ago Posts: 13 |

Also, what material should I use under an object I want to cut? I don't want to mess up the print bed. I also want to try etching mirrors which from what I understand need to be etched at an angle so that I don't reflect the light back into the laser and damage it. I would think you would then need something to block the laser so that it doesn't reflect and possibly damage something around the cutter. I've seen some high powered ruby lasers cutting through lots of crazy stuff and there is some sort of a pad on the other side which stops the laser. What can I use with a 445nm laser to do the same thing?

|

Re: Laser cutter focus help wanted January 10, 2015 12:14AM |

Registered: 11 years ago Posts: 1,049 |

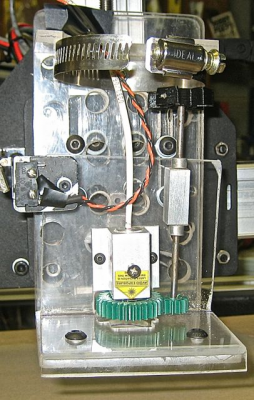

After diddleing with brass focus ring and the beam jumping all around

I rigged up some gearing to twist laser lens

My laser fits right in place of altocraft router mount for quick switch,

the micro switch turns ON/OFF laser on Z -- DOWN / UP move.

Plastic gear pressed over focus ring

and another gear to drive it from a shaft far away from beam

I run mine at about 50mm from work piece

and just twist focus during x or y travel till I get the finest line

or the width of burn I want

I use Z - axis travel while cutting down thru a piece

I rigged up some gearing to twist laser lens

My laser fits right in place of altocraft router mount for quick switch,

the micro switch turns ON/OFF laser on Z -- DOWN / UP move.

Plastic gear pressed over focus ring

and another gear to drive it from a shaft far away from beam

I run mine at about 50mm from work piece

and just twist focus during x or y travel till I get the finest line

or the width of burn I want

I use Z - axis travel while cutting down thru a piece

|

Re: Laser cutter focus help wanted January 10, 2015 05:04AM |

Admin Registered: 16 years ago Posts: 13,886 |

... I'm using a distance-measure, which represents the focus distance - place the 'measure' on the material and adjust the diode on top of it.

4 inches are a bit high - the focus would be more an oval (or a small bar), than round ... my distances are between 20mm (only engraving) and 50mm (+cutting) max.

My 'lasersafe' material under the parts to cut is mostly an aluminium sheet ... the diodes aren't sensitive to back-reflection like the fiber-lasers.

@cozmicray - your cooler is not big enough ... and without 'thermal mass' under the diode housing it will overheat soon at higher power settings ...

Edited 1 time(s). Last edit at 01/10/2015 05:07AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

4 inches are a bit high - the focus would be more an oval (or a small bar), than round ... my distances are between 20mm (only engraving) and 50mm (+cutting) max.

My 'lasersafe' material under the parts to cut is mostly an aluminium sheet ... the diodes aren't sensitive to back-reflection like the fiber-lasers.

@cozmicray - your cooler is not big enough ... and without 'thermal mass' under the diode housing it will overheat soon at higher power settings ...

Edited 1 time(s). Last edit at 01/10/2015 05:07AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Laser cutter focus help wanted January 10, 2015 04:36PM |

Registered: 11 years ago Posts: 1,049 |

It is stock JTech design -- are you saying JTech engineers did not design it correctly?

Why do I NOT have any thermal problems during a 1 hour laser cutting session at 1.75W?

VDX "@cozmicray - your cooler is not big enough ... and without 'thermal mass' under the diode housing it will overheat soon at higher power settings ..."

Why do I NOT have any thermal problems during a 1 hour laser cutting session at 1.75W?

VDX "@cozmicray - your cooler is not big enough ... and without 'thermal mass' under the diode housing it will overheat soon at higher power settings ..."

|

Re: Laser cutter focus help wanted January 10, 2015 05:44PM |

Admin Registered: 16 years ago Posts: 13,886 |

... have you measured the housing temperature?

The diode will run even with 50degC without visible changes ... but instead of lifeteime expectations of ">20k hours with 30degC" it can stop working after some hundreds to tens hours only

I've tested 2W- and 3.5W-diodes with their max. rated current (1,7A / 2,3A) and slightly overdriving (2A / 2,6A) - with a big thermal mass (and good connection to the aluminium housing of the Z-axis) the diodes got near to 35degC after some ten minutes, what's way too hot for them!

Edited 1 time(s). Last edit at 01/10/2015 05:53PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The diode will run even with 50degC without visible changes ... but instead of lifeteime expectations of ">20k hours with 30degC" it can stop working after some hundreds to tens hours only

I've tested 2W- and 3.5W-diodes with their max. rated current (1,7A / 2,3A) and slightly overdriving (2A / 2,6A) - with a big thermal mass (and good connection to the aluminium housing of the Z-axis) the diodes got near to 35degC after some ten minutes, what's way too hot for them!

Edited 1 time(s). Last edit at 01/10/2015 05:53PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.