Making PCB's with a diodelaser

Posted by VDX

|

Making PCB's with a diodelaser August 12, 2013 04:19PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi all,

... today I've tested a simpler methode for making PCB's than milling the outlines.

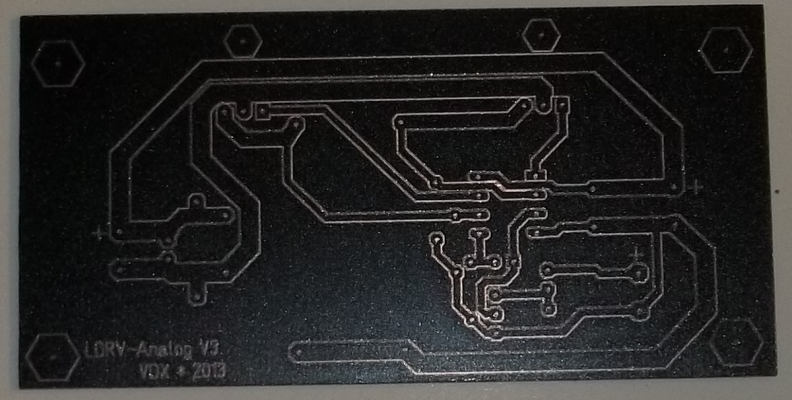

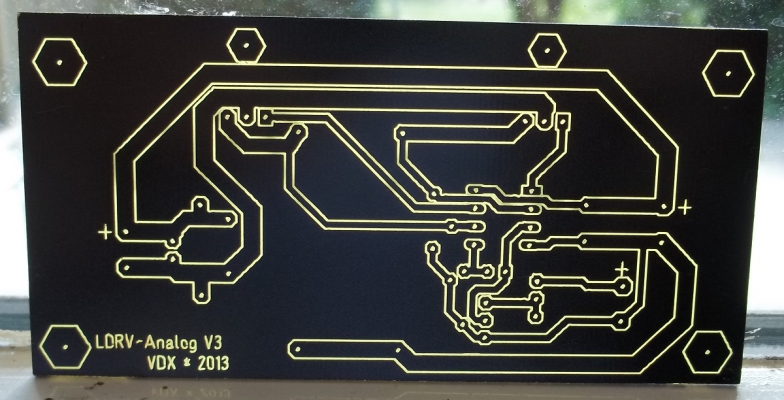

First I've coated some copper-clad PCB's with black paint ...

... then engraved the outlines with a diodelaser with around 2Watts of 975nm-IR-light on a spot of 0.15mm instead of milling them:

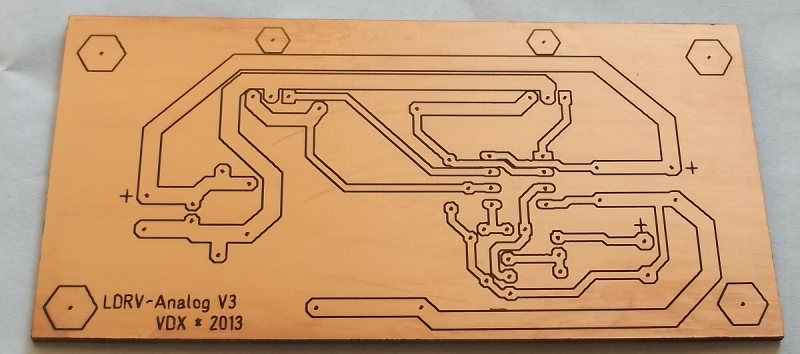

... mixed some hydrochloric acid with hydrogen peroxide and water and etched the freed copper complete away in maybe 40 seconds!:

... last removed the paint with acetone:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

... today I've tested a simpler methode for making PCB's than milling the outlines.

First I've coated some copper-clad PCB's with black paint ...

... then engraved the outlines with a diodelaser with around 2Watts of 975nm-IR-light on a spot of 0.15mm instead of milling them:

... mixed some hydrochloric acid with hydrogen peroxide and water and etched the freed copper complete away in maybe 40 seconds!:

... last removed the paint with acetone:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser August 14, 2013 10:44AM |

Registered: 11 years ago Posts: 142 |

|

Re: Making PCB's with a diodelaser August 14, 2013 11:03AM |

Admin Registered: 16 years ago Posts: 13,884 |

... it's evaporating the paint (or the plastic when sheet-cutting) and burning it with some weird 'high-temp chemistry' (chemical reactions => toxic + carcinogenic), so exhausting and filtering is a must!

I have a big fume-absorber with charcoal filter, but for a smaller amount of fumes a DIY charcoal-filter made from fry-pan filter cartouches and a ventilator for 'sucking' the fumes through the filter and exhausting through the next window would do it ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I have a big fume-absorber with charcoal filter, but for a smaller amount of fumes a DIY charcoal-filter made from fry-pan filter cartouches and a ventilator for 'sucking' the fumes through the filter and exhausting through the next window would do it ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser August 20, 2013 05:18PM |

Admin Registered: 16 years ago Posts: 13,884 |

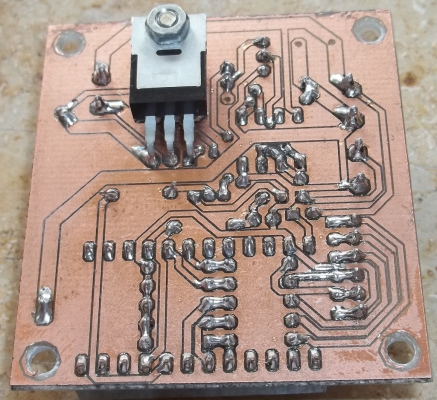

... made a new driver in less than 2 hours (design/layout, laser-engraving, etching, drilling, populating, testing)

- with smaller footprint (55x50mm)

- only one MOSFET (capable of some ten to hundred Amperes though)

- attached from the bottom to mount on an underlying cooler

- and an onboard Arduino Mini for programmatically controlling the current!

... it's essentially an ArduinoMini-shield for all sorts of high-current applications, not only laser-diodes

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

- with smaller footprint (55x50mm)

- only one MOSFET (capable of some ten to hundred Amperes though)

- attached from the bottom to mount on an underlying cooler

- and an onboard Arduino Mini for programmatically controlling the current!

... it's essentially an ArduinoMini-shield for all sorts of high-current applications, not only laser-diodes

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser August 26, 2013 04:02PM |

Registered: 13 years ago Posts: 1,918 |

Is there a way you can do this without etching? We shouldn't forget that in case of milling no etching is required ...

Detlef

Detlef

| Excalibur Hotend |

reprapzone.blogspot.de |

|

Re: Making PCB's with a diodelaser August 26, 2013 05:33PM |

Admin Registered: 16 years ago Posts: 13,884 |

... for engraving copper you need much higher energy densities than possible with this diodelasers -- this sorts of ultrashort-pulse lasers, capable of engraving PCB's (without cutting through the basis material) costs >20k€

The etching isn't a big deal - I have two bottles with acid and peroxide and a plastic dish in my garden shed and it lasts maybe three to five minutes flooding the bottom of the dish with some of the last used mixture, inserting the PCB and adding some fresh acid and/or peroxide if it won't start instantly ...

... with milling I have to replace the mill-bits regularly ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The etching isn't a big deal - I have two bottles with acid and peroxide and a plastic dish in my garden shed and it lasts maybe three to five minutes flooding the bottom of the dish with some of the last used mixture, inserting the PCB and adding some fresh acid and/or peroxide if it won't start instantly ...

... with milling I have to replace the mill-bits regularly ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser September 03, 2013 06:54PM |

Registered: 12 years ago Posts: 85 |

|

Re: Making PCB's with a diodelaser September 04, 2013 08:17AM |

Admin Registered: 16 years ago Posts: 13,884 |

... yes, I had the same idea too

Actually I'm removing the paint with acetone and spraying the PCB with solder-lacquer (Lötlack in German)

Will try "Green Coat" sometimes: [www.bungard.de]〈=english

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Actually I'm removing the paint with acetone and spraying the PCB with solder-lacquer (Lötlack in German)

Will try "Green Coat" sometimes: [www.bungard.de]〈=english

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser September 04, 2013 04:01PM |

Admin Registered: 16 years ago Posts: 13,884 |

... found an interesting comparison between isolation-milling and etching: [www.bungard.de]〈=english

My methode seems to 'average' this dispute ... or bring some new aspects into the game

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My methode seems to 'average' this dispute ... or bring some new aspects into the game

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser September 18, 2013 11:23AM |

Registered: 10 years ago Posts: 2 |

VDX Wrote:

-------------------------------------------------------

> Hi all,

>

> ... today I've tested a simpler methode for making

> PCB's than milling the outlines.

>

> First I've coated some copper-clad PCB's with

> black paint ...

>

> ... then engraved the outlines with a diodelaser

> with around 2Watts of 975nm-IR-light on a spot of

> 0.15mm instead of milling them:

I'm impressed by the results ! Good job.

I would like to try the same. I've looked at different diodes/lasers. Do you have a link on what you got? It seems that most lasers are sold without a driver. It seems that you made your own.

How did you get the spot this small?

Did you pick at "random" the laser wavelength? Seems like it depends on the pain you are using.

Cheers

Edited 1 time(s). Last edit at 09/18/2013 11:51AM by RepRaper007.

-------------------------------------------------------

> Hi all,

>

> ... today I've tested a simpler methode for making

> PCB's than milling the outlines.

>

> First I've coated some copper-clad PCB's with

> black paint ...

>

> ... then engraved the outlines with a diodelaser

> with around 2Watts of 975nm-IR-light on a spot of

> 0.15mm instead of milling them:

I'm impressed by the results ! Good job.

I would like to try the same. I've looked at different diodes/lasers. Do you have a link on what you got? It seems that most lasers are sold without a driver. It seems that you made your own.

How did you get the spot this small?

Did you pick at "random" the laser wavelength? Seems like it depends on the pain you are using.

Cheers

Edited 1 time(s). Last edit at 09/18/2013 11:51AM by RepRaper007.

|

Re: Making PCB's with a diodelaser September 18, 2013 12:38PM |

Admin Registered: 16 years ago Posts: 13,884 |

... depends on the material and application you aim on - dark or IR-absorbing materials can be done with IR-diodes that are available with powers up to 100Watts out from a 0.1mm fiber (what's good to focus again), for bright materials you'll need a CO2-laser or a blue or UV laserdiode, but here the available powers are in the single watt-range only.

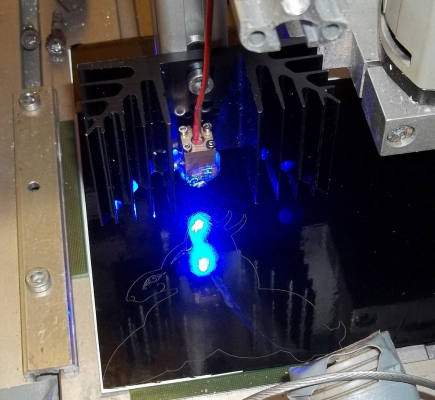

But you can do some cutting/engraving with a 445nm-diode with only 1 Watt of power too - here some sample I did today for a the fair presentation tomorrow:

... and one of the blue diodes burning the bigger rabbit-knot (the upper blue flare is the spot, the lower the reflection of the laser output):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But you can do some cutting/engraving with a 445nm-diode with only 1 Watt of power too - here some sample I did today for a the fair presentation tomorrow:

... and one of the blue diodes burning the bigger rabbit-knot (the upper blue flare is the spot, the lower the reflection of the laser output):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser November 21, 2013 09:39AM |

Admin Registered: 16 years ago Posts: 13,884 |

... here the link to a video showing a 2W445nm-module engraving black anodized aluminium: [vimeo.com]

Attached an image of the complete machine - a modified Isel ICP4030 ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Attached an image of the complete machine - a modified Isel ICP4030 ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser November 22, 2013 06:22PM |

Registered: 10 years ago Posts: 134 |

That is very cool!

I've been looking at different etching solutions and it seems like the hydrochloric acid + hydrogen peroxide gives the lowest cost of consumables. It sounds like that's what you're using for PCB etching.

I'm also considering trying this method on other metals (such as brass) for engraving. Have you found particular paints that are more resistant to acid? What about simple spray enamel paint? It seems like you could use the laser + chemical etching method for other materials such as certain types of stone.

I've been looking at different etching solutions and it seems like the hydrochloric acid + hydrogen peroxide gives the lowest cost of consumables. It sounds like that's what you're using for PCB etching.

I'm also considering trying this method on other metals (such as brass) for engraving. Have you found particular paints that are more resistant to acid? What about simple spray enamel paint? It seems like you could use the laser + chemical etching method for other materials such as certain types of stone.

|

Re: Making PCB's with a diodelaser November 22, 2013 06:40PM |

Admin Registered: 16 years ago Posts: 13,884 |

... yes, I'm using (1:1:1) hydrochloric acid + hydrogen peroxide + distilled water.

Common spray-paints can withstand some minutes until they start eroding ... depends on temperature of the solution ...

For stone and other brittle materials I'll suggest lasercutting thin layers of previously laminated elastic sheets, remove the parts you want to mark and use sandblasting ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Common spray-paints can withstand some minutes until they start eroding ... depends on temperature of the solution ...

For stone and other brittle materials I'll suggest lasercutting thin layers of previously laminated elastic sheets, remove the parts you want to mark and use sandblasting ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser December 04, 2013 04:23PM |

Admin Registered: 16 years ago Posts: 13,884 |

... her a video of one of the 2W-modules engraving black anodized aluminium:

[www.youtube.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[www.youtube.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser January 07, 2014 04:46PM |

Registered: 10 years ago Posts: 19 |

Hi,

Very interesting!

As a beginner in electronics, I'm looking for equipment to start doing my own pcb... and I already built a laser engraver module for my reprap 3d printer. You saved me from buying an UV revelator :-)

One question: What kind of paint are you using? I guess some kind of paints may not support the acid and melt...I have a spray of black paint for plastic which I used to paint a dvd drive face...can i use it for that purpose?

Thanks.

[vvinch.blogspot.com] - [vvinch-diy.blogspot.com]

Very interesting!

As a beginner in electronics, I'm looking for equipment to start doing my own pcb... and I already built a laser engraver module for my reprap 3d printer. You saved me from buying an UV revelator :-)

One question: What kind of paint are you using? I guess some kind of paints may not support the acid and melt...I have a spray of black paint for plastic which I used to paint a dvd drive face...can i use it for that purpose?

Thanks.

[vvinch.blogspot.com] - [vvinch-diy.blogspot.com]

|

Re: Making PCB's with a diodelaser January 08, 2014 11:10AM |

Admin Registered: 16 years ago Posts: 13,884 |

... test it - I've tested several 'fast drying' spray-paints ... all worked ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser February 06, 2014 10:31AM |

Registered: 10 years ago Posts: 2 |

Hi Victor, very nice job! Could you please fill us in on what program/programs used for making the PC board circuit.

I am especially interested in the one that made the track outlines.

My previous experience with making PCB boards usually required much more copper to be etched away and therefore took much longer.

I was using the free Express PCB program, which I found very easy to use.

Rolf

I am especially interested in the one that made the track outlines.

My previous experience with making PCB boards usually required much more copper to be etched away and therefore took much longer.

I was using the free Express PCB program, which I found very easy to use.

Rolf

|

Re: Making PCB's with a diodelaser February 06, 2014 03:16PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Rolf,

I'm using Target - the free version's is limited in pad counts (max. 250 pads) and only two copper layers and one sheet, but not in size, as Eagle

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I'm using Target - the free version's is limited in pad counts (max. 250 pads) and only two copper layers and one sheet, but not in size, as Eagle

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser February 06, 2014 07:51PM |

Registered: 10 years ago Posts: 12 |

Viktor,

This is very cool stuff. Thanks for sharing.

I am also curious about your tool chain.

My plan for doing my own PCB are to strap a extra fine sharpie to my reprap and then etch the board.

I am having a hard time finding a toolchain to go from PCB layout -> Gerber -> Gcode for the reprap.

Can you please enlighten us all on your process?

Many thanks, Prost!,

-Erik

This is very cool stuff. Thanks for sharing.

I am also curious about your tool chain.

My plan for doing my own PCB are to strap a extra fine sharpie to my reprap and then etch the board.

I am having a hard time finding a toolchain to go from PCB layout -> Gerber -> Gcode for the reprap.

Can you please enlighten us all on your process?

Many thanks, Prost!,

-Erik

|

Re: Making PCB's with a diodelaser February 07, 2014 03:08AM |

Admin Registered: 16 years ago Posts: 13,884 |

... with Target it's as simple as selecting isolation milling and then the wished output format.

Beside the NCP-format for my Isel CNC-mill there is GCode-output or EMC^2 or many other exchange variations.

Attached images from the (German) output selections ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Beside the NCP-format for my Isel CNC-mill there is GCode-output or EMC^2 or many other exchange variations.

Attached images from the (German) output selections ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser February 07, 2014 03:09PM |

Registered: 10 years ago Posts: 12 |

Got it, thanks Viktor.

I was hoping to hear you were using a reprap with a laser on it but that is ok.

I had an idea last night and i think i can turn a 2D image of the PCB layout into a 3d STL file and slice it with really small layer heights to get multiple passes with the Sharpie.

If all goes well i will post some pic here or start a new post.

Thanks

-Erik

I was hoping to hear you were using a reprap with a laser on it but that is ok.

I had an idea last night and i think i can turn a 2D image of the PCB layout into a 3d STL file and slice it with really small layer heights to get multiple passes with the Sharpie.

If all goes well i will post some pic here or start a new post.

Thanks

-Erik

|

Re: Making PCB's with a diodelaser February 22, 2014 05:22PM |

Admin Registered: 16 years ago Posts: 13,884 |

... attached a video of a 'refurbished' servo-CNC-mill engraving wood with 30mm/s:

[vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 15, 2014 04:01PM |

Admin Registered: 16 years ago Posts: 13,884 |

... attached some examples of engraving with a DIY-XY-galvoscanner (first two images) and the CNC-mill (last three images), both equipped with the same fiberlaser and around 5-7Watts of power ... more would evaporate the small mirors of the scanners or 'explode' the tiles surface, so the fine details were wrecked ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 19, 2014 05:29PM |

Admin Registered: 16 years ago Posts: 13,884 |

... some more samples with ceramic tiles and metal (linked from a post in the German RUG)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser July 08, 2014 10:05AM |

Admin Registered: 16 years ago Posts: 13,884 |

... attached two videos showing laserengraving of a ring and PU-foam with a 445nm-diode @700mW:

[vimeo.com]

[vimeo.com]

... an the results:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[vimeo.com]

[vimeo.com]

... an the results:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser July 14, 2014 03:11PM |

Admin Registered: 16 years ago Posts: 13,884 |

... for making some more LD-drivers I've used this time one of the 445nm-diodes:

[vimeo.com]

Here the result:

... and after etching ... paint removed on the left side:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[vimeo.com]

Here the result:

... and after etching ... paint removed on the left side:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser July 15, 2014 10:46AM |

Registered: 10 years ago Posts: 814 |

Hey Viktor, Great work... I know this section seems a little slow, but there are some of us lurkers here that check everyday for updates. I'm gathering parts for a 9mm 445nm diode laser build. So, when it gets a bit closer to starting I'll start a thread.

I do have a question, and it's purely from ignorance... Can you use the same style mirror system with diode lasers as with the CO2 ones where the laser is mounted in a fixed position and mirrors/lenses are mounted on X/Y gantry? I know it would be more complex, but it would allow a larger heatsink without moving the weight around. Worth it?

Thanks

Edited 2 time(s). Last edit at 07/15/2014 10:49AM by madmike8.

I do have a question, and it's purely from ignorance... Can you use the same style mirror system with diode lasers as with the CO2 ones where the laser is mounted in a fixed position and mirrors/lenses are mounted on X/Y gantry? I know it would be more complex, but it would allow a larger heatsink without moving the weight around. Worth it?

Thanks

Edited 2 time(s). Last edit at 07/15/2014 10:49AM by madmike8.

|

Re: Making PCB's with a diodelaser July 15, 2014 12:08PM |

Admin Registered: 16 years ago Posts: 13,884 |

... the beam-quality of the diodes is not as good as with CO2- or gas-lasers -- so feeding mirrors won't be a good alternative

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser July 15, 2014 02:21PM |

Registered: 10 years ago Posts: 814 |

Sorry, only registered users may post in this forum.