Making PCB's with a diodelaser

Posted by VDX

|

Re: Making PCB's with a diodelaser February 17, 2017 04:28PM |

Admin Registered: 16 years ago Posts: 13,884 |

... thought, would be good, to share this here too

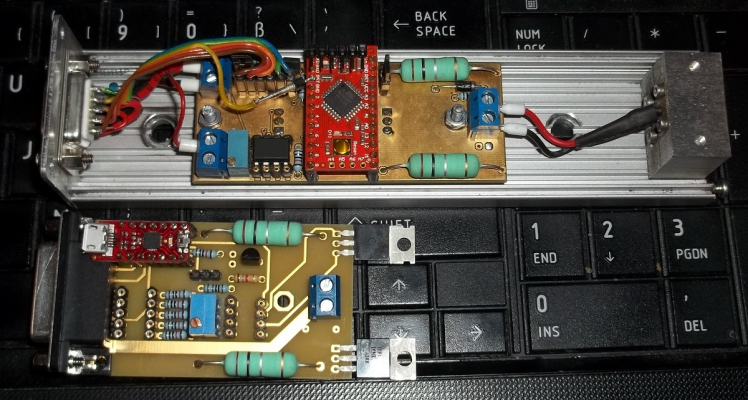

Redeveloped my "intelligent" high-current LD driver for better assembly and controlling options -- the housing will be milled from two halves ... will show it later ...

First try was with Nanite841 controllers:

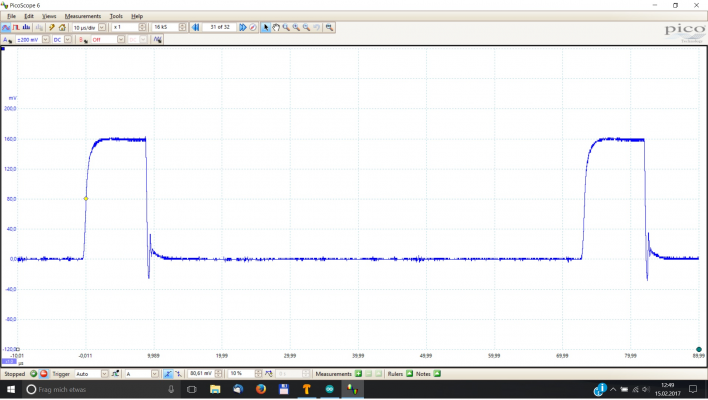

- fine enough for the common blue 2W- and 3.5W-diodes -- here the curves when pulsing at 1,6 Ampere, what's good for the 2W-diode:

... but seems, the smaller controller was not so a good idea - when switching around 100kHz with pulsed currents of above 2,6 Amperes (needed for the 6W-diodes or the IR-diodes), I've managed to delete the program and even the bootloader inside the Nanite841 !!!

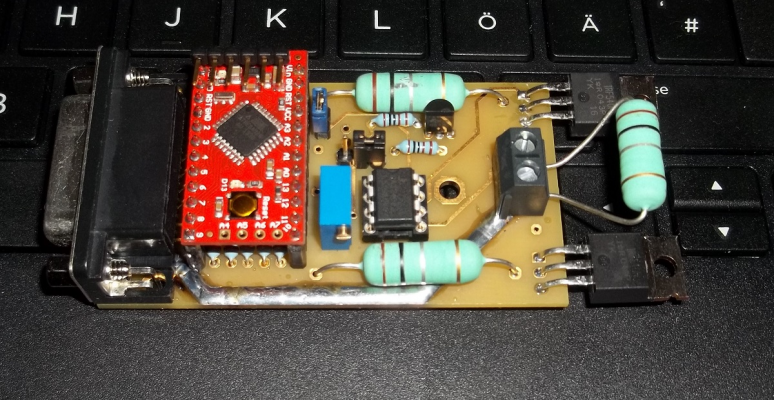

Then tested and changed back to the Wattuino, which seems to be much more robust to EMP effects:

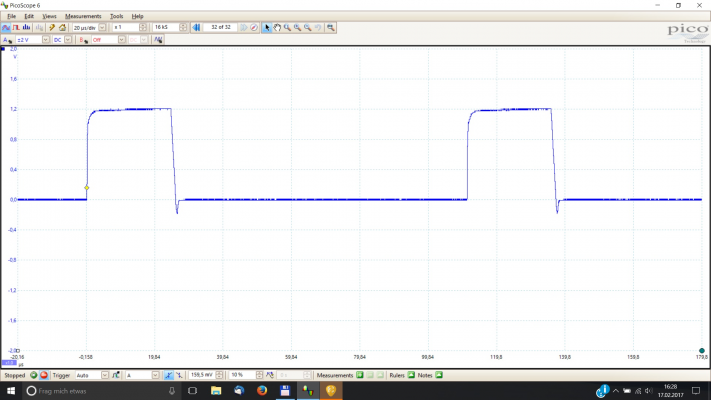

... here it's happy pulsing with 12 Amperes:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Redeveloped my "intelligent" high-current LD driver for better assembly and controlling options -- the housing will be milled from two halves ... will show it later ...

First try was with Nanite841 controllers:

- fine enough for the common blue 2W- and 3.5W-diodes -- here the curves when pulsing at 1,6 Ampere, what's good for the 2W-diode:

... but seems, the smaller controller was not so a good idea - when switching around 100kHz with pulsed currents of above 2,6 Amperes (needed for the 6W-diodes or the IR-diodes), I've managed to delete the program and even the bootloader inside the Nanite841 !!!

Then tested and changed back to the Wattuino, which seems to be much more robust to EMP effects:

... here it's happy pulsing with 12 Amperes:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser February 19, 2017 08:41AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Making PCB's with a diodelaser February 19, 2017 08:52AM |

Admin Registered: 16 years ago Posts: 13,884 |

... no, it's the small "transistor-like" MOSFET below the upper big resistor - didn't measure any negtive transients on this line too

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser February 20, 2017 08:40AM |

Registered: 8 years ago Posts: 35 |

Quote

brunobasto

Hey @lukie80, keep us posted on your progress. It's looking beautiful. Do you have pictures of your results and printer? Maybe a video?

Thanks. And thanks to VDX for his idea, publishing and support.

So far I only removed the RC paint using nitro diluent. It looks OK although I seem to have some backlash issues. . Next step will be drilling which will show if my PCB alignment was OK.

The printer I use is a cheap Prusa i3 clone with some minor improvements: Geeetech i3 Pro X. The biggest change I made was designing a quick fit carriage system which allows a quick change of tool heads (i.e. print head, laser head, mill head). There you can see the heads I use: Quick Fit Carriage and Laser Head. The precision of my printer is not ideal (see PCB ) and it is not rigid enough for deep or fast milling.

|

Re: Making PCB's with a diodelaser February 20, 2017 09:14AM |

Registered: 7 years ago Posts: 2 |

Quote

lukie80

Quote

brunobasto

Hey @lukie80, keep us posted on your progress. It's looking beautiful. Do you have pictures of your results and printer? Maybe a video?

Thanks. And thanks to VDX for his idea, publishing and support.

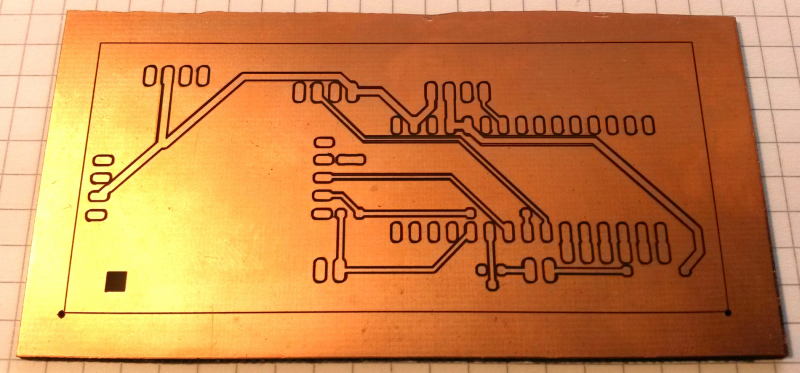

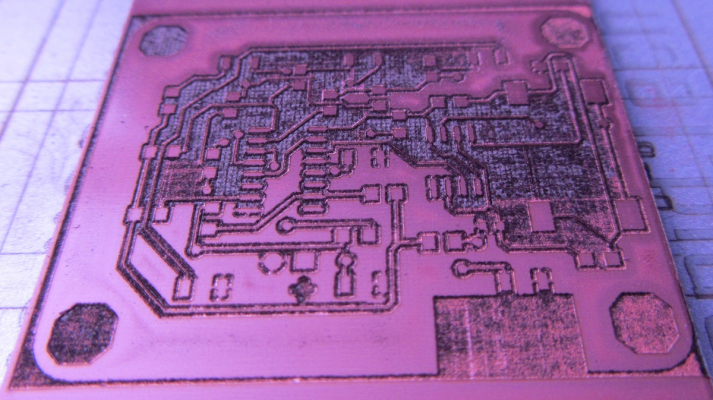

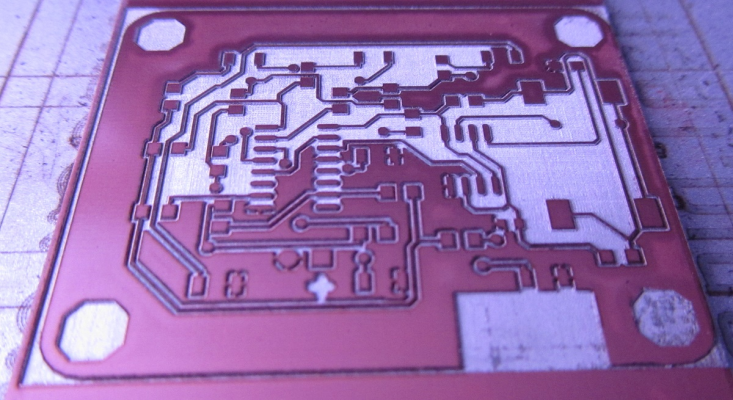

So far I only removed the RC paint using nitro diluent. It looks OK although I seem to have some backlash issues. [attachment 90941 etched.jpg]. Next step will be drilling which will show if my PCB alignment was OK.

The printer I use is a cheap Prusa i3 clone with some minor improvements: Geeetech i3 Pro X. The biggest change I made was designing a quick fit carriage system which allows a quick change of tool heads (i.e. print head, laser head, mill head). There you can see the heads I use: Quick Fit Carriage and Laser Head. The precision of my printer is not ideal (see PCB ) and it is not rigid enough for deep or fast milling.

Cool. Thx for the info. Yeah, for drilling I plan to build one of those: Cyclone-PCB-Factory. It maybe ok to drill using a 3d printer, but I don't wanna mess up mine. It's already not rigid enough. I have a modified Printrbot Makers Edition with 200mm x 200mm build area. Plan to build a VORON, but so far I only have the frame assembled.

|

Re: Making PCB's with a diodelaser February 23, 2017 06:18AM |

Registered: 9 years ago Posts: 93 |

Nice keep it up

I got finally in to PCB with my laser

that firs one I managed to do

Would 2W laser penetrate FR1 Board???

Regards

I got finally in to PCB with my laser

that firs one I managed to do

Would 2W laser penetrate FR1 Board???

Regards

|

Re: Making PCB's with a diodelaser February 23, 2017 06:54AM |

Admin Registered: 16 years ago Posts: 13,884 |

Quote

rastaman46

Would 2W laser penetrate FR1 Board???

... no - not enough absorption and energy density ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 08, 2017 04:52PM |

Admin Registered: 16 years ago Posts: 13,884 |

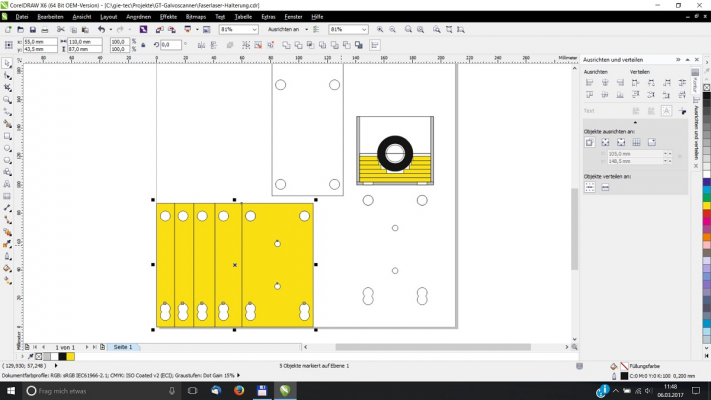

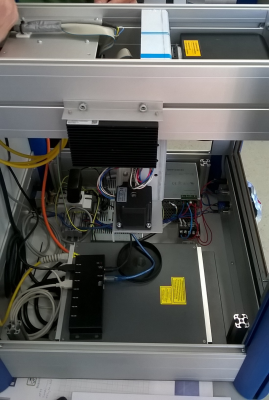

... my latest (semi-comercial) project is a fiber-laser armed galvo-scanner used for "local ablating" of metal surfaces.

The core project isn't open, but I can show some images and videos of the common parts ...

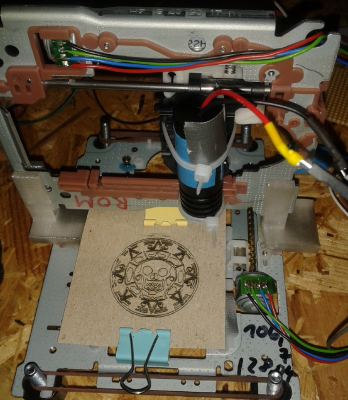

- for a fast provisoric fixation of the fiber-laser head -- construction of a "3D-LOM-part" in Corel and export as HPGL:

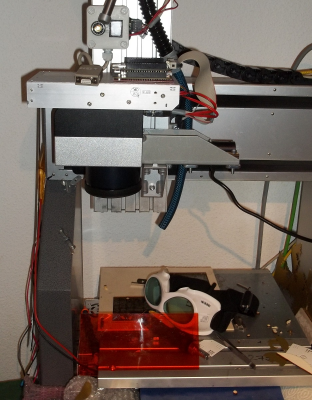

- lasercutting the LOM-slices with the blue diode-module:

- assembled/stacked the slices and inserted holder for the collimator-head:

- mounted galvo-head:

- a video showing some testing on a piece of iron sheet:

[vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The core project isn't open, but I can show some images and videos of the common parts ...

- for a fast provisoric fixation of the fiber-laser head -- construction of a "3D-LOM-part" in Corel and export as HPGL:

- lasercutting the LOM-slices with the blue diode-module:

- assembled/stacked the slices and inserted holder for the collimator-head:

- mounted galvo-head:

- a video showing some testing on a piece of iron sheet:

[vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 23, 2017 08:43AM |

Registered: 8 years ago Posts: 5,232 |

Quote

VDX

... yes, I'm using (1:1:1) hydrochloric acid + hydrogen peroxide + distilled water.

Common spray-paints can withstand some minutes until they start eroding ... depends on temperature of the solution ...

For stone and other brittle materials I'll suggest lasercutting thin layers of previously laminated elastic sheets, remove the parts you want to mark and use sandblasting ...

That's a quote of 2013 and I'm curious, if these fluids are still available for the average customer?

Especially hydrogen peroxide is available in different grades, from 2% to ~30% maybe.

What is the type H2O2 you are using?

Same for the acid: Do I need a certain mixture, is it powder of bottled?

THX

Olaf

|

Re: Making PCB's with a diodelaser March 23, 2017 08:57AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Olaf,

... both around 30% and should be still available, bottled ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

... both around 30% and should be still available, bottled ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 30, 2017 10:29AM |

Admin Registered: 16 years ago Posts: 13,884 |

... tested stripping black paint (development for cleaning metal surfaces):

[vimeo.com]

The result: - on the left a black tile -- on the right the black painted aluminum sheet (Dibond)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[vimeo.com]

The result: - on the left a black tile -- on the right the black painted aluminum sheet (Dibond)

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser April 20, 2017 02:08PM |

Admin Registered: 16 years ago Posts: 13,884 |

... actually assembling a more "professional" looking marking laser for an exhibition on saturday  -- will post some more images and videos of the results later on ...

-- will post some more images and videos of the results later on ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

-- will post some more images and videos of the results later on ...

-- will post some more images and videos of the results later on ...Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser April 23, 2017 05:32PM |

Admin Registered: 16 years ago Posts: 13,884 |

... a video of the laser-engraver "in action"

[vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser April 25, 2017 06:01PM |

Admin Registered: 16 years ago Posts: 13,884 |

... tested to cut 0,3mm thick brass sheets - it's much easier to cut and finer result than with Aluminium!

Here a "mini-elk-bow":

... and the video showing the (pretty slow) cutting - [vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Here a "mini-elk-bow":

... and the video showing the (pretty slow) cutting - [vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser May 03, 2017 03:59PM |

Admin Registered: 16 years ago Posts: 13,884 |

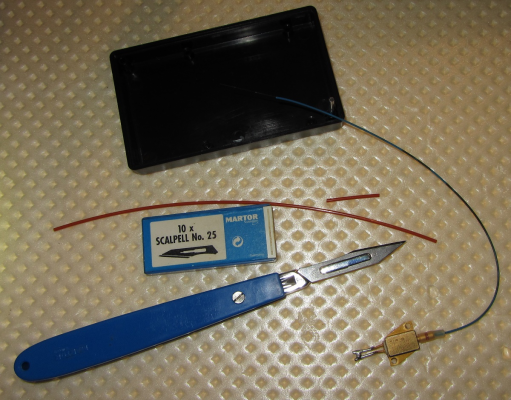

... the "Aztek Kodex" in metallic coated plastic:

- and in 0,2mm thick steel plate:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

- and in 0,2mm thick steel plate:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser May 04, 2017 02:39AM |

Registered: 8 years ago Posts: 5,232 |

That's awesome!

Reminds me a bit of the Pirates of the caribbean coin.

...now make some Krugerrand coins from Brass and see, how realistic they look.

Edited 1 time(s). Last edit at 05/04/2017 02:45AM by o_lampe.

Reminds me a bit of the Pirates of the caribbean coin.

...now make some Krugerrand coins from Brass and see, how realistic they look.

Edited 1 time(s). Last edit at 05/04/2017 02:45AM by o_lampe.

|

Re: Making PCB's with a diodelaser May 04, 2017 09:30AM |

Admin Registered: 16 years ago Posts: 13,884 |

... for "realistic" coins you'll need a picosecond-pulse-laser with much higher peak energy, what's on my long-term agenda too

So it's capable of 3D-engraving in brass and high carbon loaded steel, but need pretty much time ... for this not really suited to make money coins

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

So it's capable of 3D-engraving in brass and high carbon loaded steel, but need pretty much time ... for this not really suited to make money coins

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser May 12, 2017 06:29AM |

Admin Registered: 16 years ago Posts: 13,884 |

... did some tests, "engraving" a coin - not exactly what you'll want to make them with

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser May 13, 2017 03:00AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Making PCB's with a diodelaser May 13, 2017 09:44AM |

Admin Registered: 16 years ago Posts: 13,884 |

... as already said, this isn't an Ultra-Short-Pulse-laser, so not suited for creating optical finishes.

With more time for testing and tweaking the parameters, it could make much better "finishing" results ... but it's not my intention to show, how to counterfeit coins ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

With more time for testing and tweaking the parameters, it could make much better "finishing" results ... but it's not my intention to show, how to counterfeit coins ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser August 07, 2017 01:17PM |

Admin Registered: 16 years ago Posts: 13,884 |

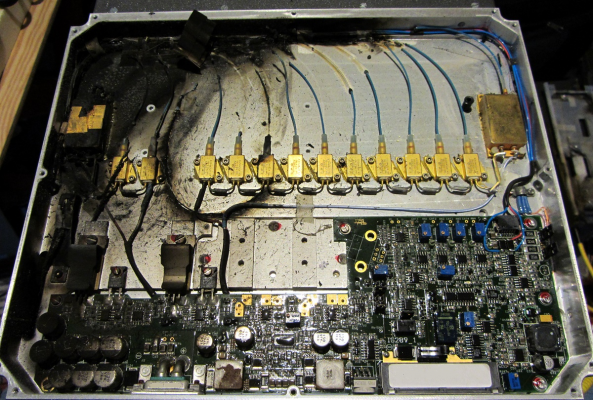

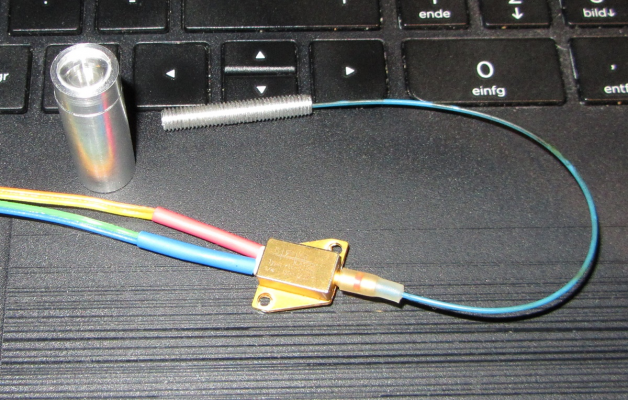

... again received two broken fiberlasers to extract the IR-diodes from - one is really hefty damaged, the other not so bad:

I'm actually runnig a "DIY-lasermodule-with-driver" project in the German sub-forum and a CNC-forum, which is only meant for local distribution, so no international shipping or such.

But some of the basic info is open, (schematics/layout, sketches, hints), so could be used for other DIY projects too ...

[forums.reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

I'm actually runnig a "DIY-lasermodule-with-driver" project in the German sub-forum and a CNC-forum, which is only meant for local distribution, so no international shipping or such.

But some of the basic info is open, (schematics/layout, sketches, hints), so could be used for other DIY projects too ...

[forums.reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser August 21, 2017 10:18AM |

Admin Registered: 16 years ago Posts: 13,884 |

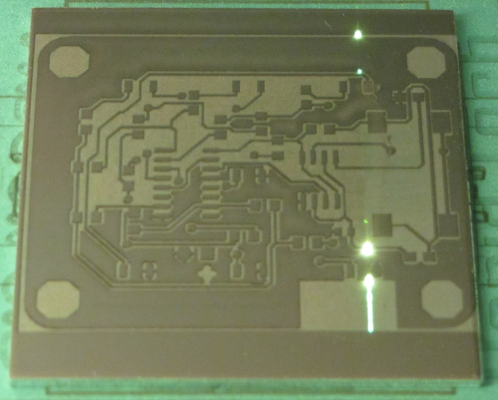

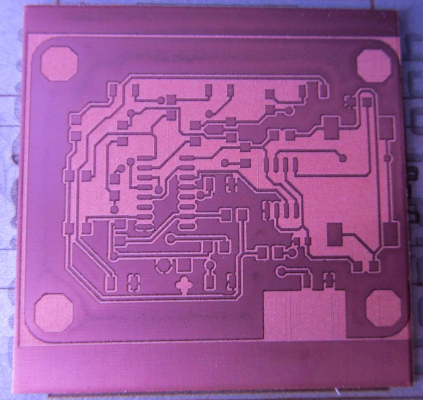

... I've tested PCB-engraving with my marking laser too ...

- engraving:

- first pass - removed the lackuer and some of the copper (so it would be perfect for etching too!):

- after 3 passes most of the copper is removed:

- after 5 passes all the copper and bond (and a thin sheet of ceramic) is stripped:

... and a video showing the first pass and the results - [vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

- engraving:

- first pass - removed the lackuer and some of the copper (so it would be perfect for etching too!):

- after 3 passes most of the copper is removed:

- after 5 passes all the copper and bond (and a thin sheet of ceramic) is stripped:

... and a video showing the first pass and the results - [vimeo.com]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser September 03, 2017 10:28AM |

Admin Registered: 16 years ago Posts: 13,884 |

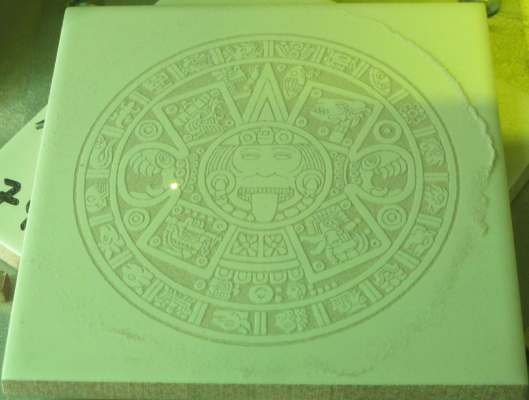

... to try out the 60Watt fiber laser -- here's another video of the engraving of the "Aztec Codex"center part on a white 100x100mm tile without pre-coating:

[vimeo.com]

When engraving (recorded through a laser protection window):

... and done (still with the dust on it):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

[vimeo.com]

When engraving (recorded through a laser protection window):

... and done (still with the dust on it):

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser October 15, 2017 01:09PM |

Admin Registered: 16 years ago Posts: 13,884 |

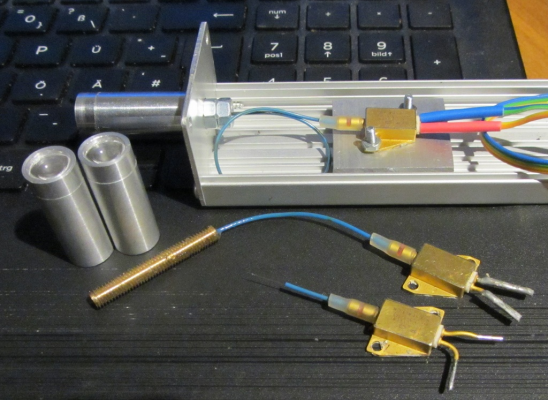

... back to the IR-diodes -- assembled three of the "simple high current drivers", which are meant to drive the 9W-diodes with PWM-pulsing pre-selectable (spike free) currents from 0.6A to 8.4A:

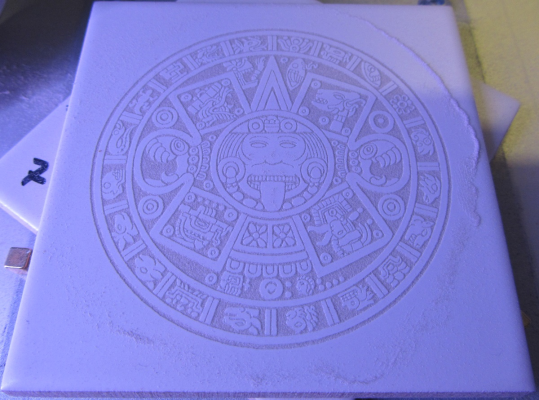

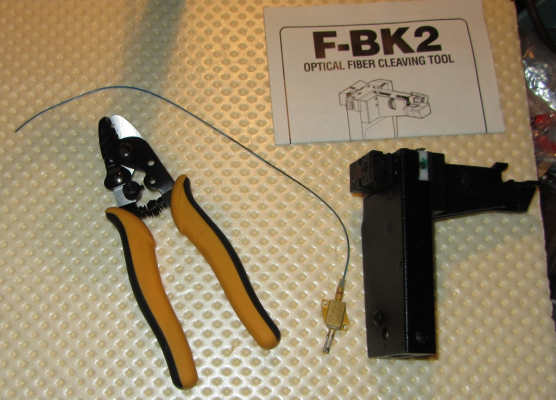

Will cleave and assemble several of the fibercoupled 9W-IR-diodes and one or more of the 25W-diodes in the next days/weeks and make some tests for stability and usability ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Will cleave and assemble several of the fibercoupled 9W-IR-diodes and one or more of the 25W-diodes in the next days/weeks and make some tests for stability and usability ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser October 16, 2017 06:44PM |

Admin Registered: 16 years ago Posts: 13,884 |

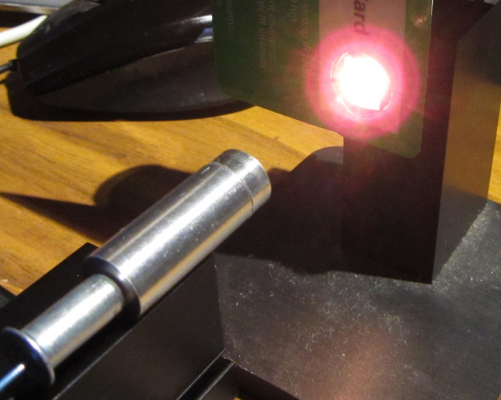

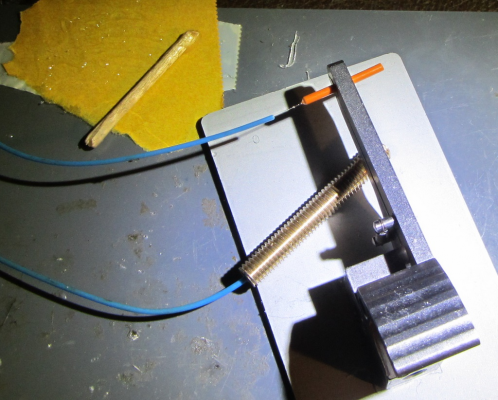

... and here cleaving, assembling and testing one of the 9watt-IR-diodes:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser November 04, 2017 01:11PM |

Admin Registered: 16 years ago Posts: 13,884 |

... today received the first "small series" (10 sets) of the focussing heads:

But actually in a hurry to finish the machines for the next exhibition from 14. Nov. in Munich ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But actually in a hurry to finish the machines for the next exhibition from 14. Nov. in Munich ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser January 05, 2018 03:36AM |

Admin Registered: 16 years ago Posts: 13,884 |

... actually busy to "manufacture" the first series of diode modules:

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser March 31, 2019 10:18AM |

Admin Registered: 16 years ago Posts: 13,884 |

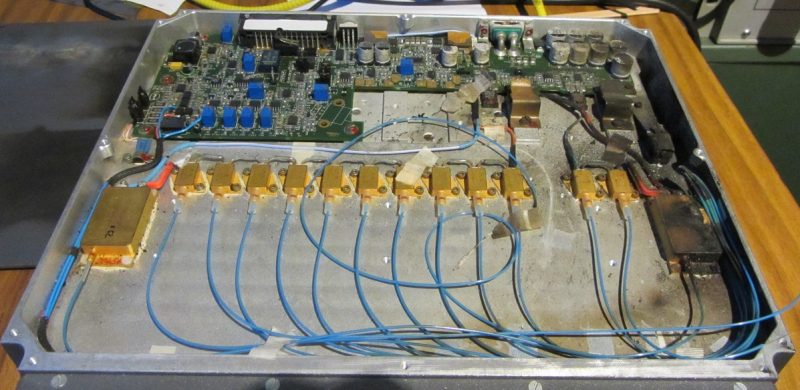

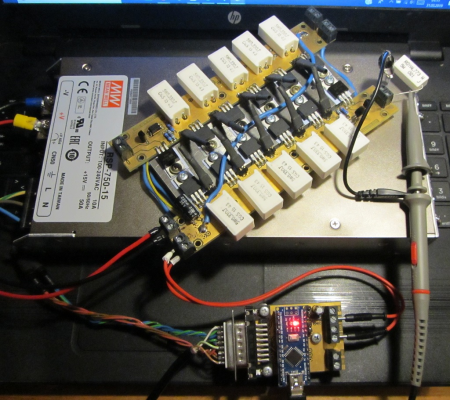

... actually developing+building some high-power diode modules with 200Watt IR-diodes, which needs CW-currents with 40 Amps!! - they will not only mark, but even cut through the PCB's

The drivers are sort of "beefy":

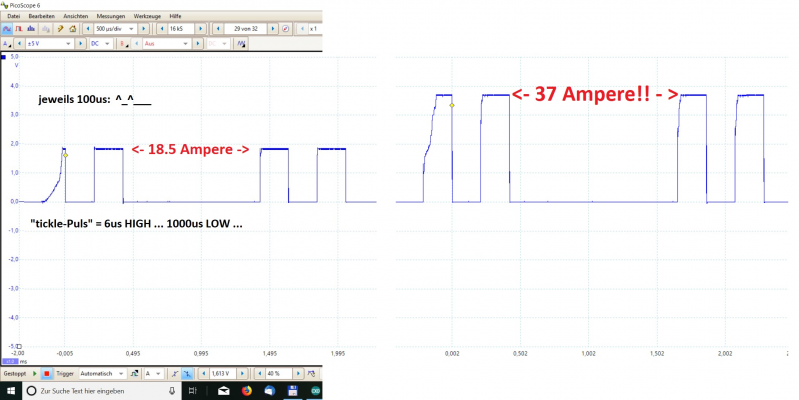

And the pulsed or CW current can be set in 10 steps from 3.7 Amperes to 37 !!! - here two videos while pulsing with half power on cardboard and steel:

[vimeo.com]

[vimeo.com]

... and a scope-diagram measured across a shunt resistor with half and full power:

Edited 1 time(s). Last edit at 03/31/2019 10:20AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The drivers are sort of "beefy":

And the pulsed or CW current can be set in 10 steps from 3.7 Amperes to 37 !!! - here two videos while pulsing with half power on cardboard and steel:

[vimeo.com]

[vimeo.com]

... and a scope-diagram measured across a shunt resistor with half and full power:

Edited 1 time(s). Last edit at 03/31/2019 10:20AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser April 01, 2019 04:59AM |

Admin Registered: 16 years ago Posts: 13,884 |

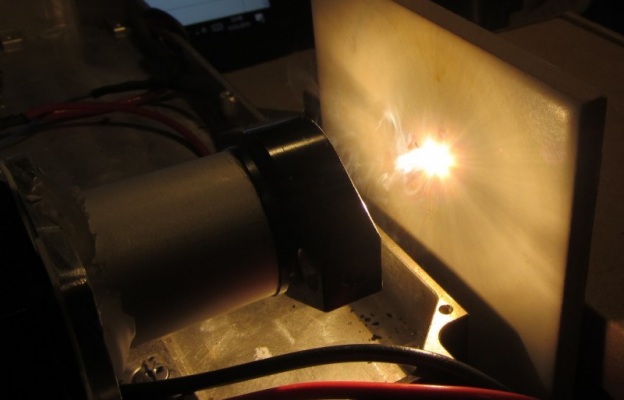

... I tried a few things this morning with one of the 200W-diodes in the "DDL"-module -- and now I don't know if I should be happy or rather cry ... or if soon people from the secret service or from the Nobel Prize Committee will ring the doorbell

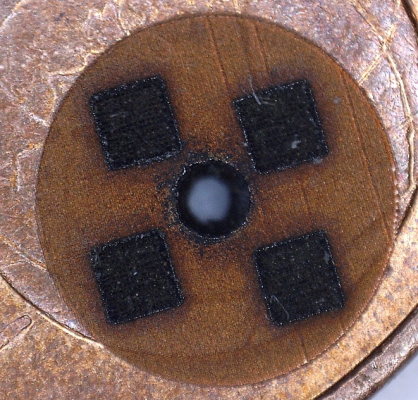

From the previous tests I already knew that it "flashes" quite well on the tile - here a picture of one of the previous "tile flares":

After some adjustments to the cable routing and the use of a larger filter capacitor and a choke as counter-induction, I got out some pretty good "flashes" and wanted to make a video of them.

As I start the video and trigger the first slightly longer pulse, I hear a very short "hiss" from the direction of the diode and the power supply and then the powerful bangs on the tile and also on the power supply, which was positioned about 15 centimeters behind the tile!!!

Here the pictures of the mishap - the laser pulse has shot a small hole completely through the tile:

- and then the display of the power supply melted down!

Also the decoupling protection window in the diode has gotten some evaporating and melting damage:

The diode still seems to be working (at least it still pulses visibly on the tile, although not as violently as the "Mega-Blitz"), but I'll have to replace the protection window.

Now I'm wondering how I managed to get this "mega pulse" right at all ... and if I can reproduce that again ... and if I should follow it up at all, because it's going quite violently in the direction of "weapon development", which I've always rejected

Edited 1 time(s). Last edit at 04/01/2019 05:01AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

From the previous tests I already knew that it "flashes" quite well on the tile - here a picture of one of the previous "tile flares":

After some adjustments to the cable routing and the use of a larger filter capacitor and a choke as counter-induction, I got out some pretty good "flashes" and wanted to make a video of them.

As I start the video and trigger the first slightly longer pulse, I hear a very short "hiss" from the direction of the diode and the power supply and then the powerful bangs on the tile and also on the power supply, which was positioned about 15 centimeters behind the tile!!!

Here the pictures of the mishap - the laser pulse has shot a small hole completely through the tile:

- and then the display of the power supply melted down!

Also the decoupling protection window in the diode has gotten some evaporating and melting damage:

The diode still seems to be working (at least it still pulses visibly on the tile, although not as violently as the "Mega-Blitz"), but I'll have to replace the protection window.

Now I'm wondering how I managed to get this "mega pulse" right at all ... and if I can reproduce that again ... and if I should follow it up at all, because it's going quite violently in the direction of "weapon development", which I've always rejected

Edited 1 time(s). Last edit at 04/01/2019 05:01AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Making PCB's with a diodelaser April 01, 2019 02:22PM |

Admin Registered: 16 years ago Posts: 13,884 |

... so, before this goes even bigger, like in some of the other forums, I'll clarify it

The "Mega-Pulse" with "Tile-Shot through" is (actually very, very sad) only a "1. April" joke with half-truths

The tile looks like this in the original - the two holes in the lower left corner are only about 1mm deep and it took some 100Watt pulses:

The "molten power supply display" I have also only "painted".

The burned resistors are real -- but when testing with the broken(?) switching MOSFET's it was on "permanent ON" where the resistors survived about 1 second before the resistor wire was burned away ... but, the "orange glow" out of the ceramic was really nice

Edited 1 time(s). Last edit at 04/01/2019 02:23PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The "Mega-Pulse" with "Tile-Shot through" is (actually very, very sad) only a "1. April" joke with half-truths

The tile looks like this in the original - the two holes in the lower left corner are only about 1mm deep and it took some 100Watt pulses:

The "molten power supply display" I have also only "painted".

The burned resistors are real -- but when testing with the broken(?) switching MOSFET's it was on "permanent ON" where the resistors survived about 1 second before the resistor wire was burned away ... but, the "orange glow" out of the ceramic was really nice

Edited 1 time(s). Last edit at 04/01/2019 02:23PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Sorry, only registered users may post in this forum.