Information needed before buying what I need

Posted by Ohmarinus

|

Re: Information needed before buying what I need December 27, 2014 08:55AM |

Admin Registered: 11 years ago Posts: 3,096 |

Okay, I have found a supplier which sells both goggles and a laser diode with everything included:

Laser diode:

[odicforce.com]

Goggles:

[odicforce.com]

The laser diode is a 1.6W one, but it is run at 1W.

The Only thing is, that the driver asks for a 'TTL' signal to reduce the power. How would I sent a power signal from the Ramps to the driver? Or is it no problem to just use the laser with full power always 'on'?

And how do I switch the power with the Ramps? Should it be done with a Solid State Relay, or can one of the outputs of the Ramps turn the laser on/off? This is still unclear to me.

I feel comfortable ordering my laser parts at that shop since they sell both glasses and laser kit, and I decided maybe it doesn't matter so much if I get a 2W laser or a 1W laser. Both will cut cardboard perfectly fine right? Or is it a big difference?

Sorry for all my questions, I just don't want to buy the 'wrong' thing

I'm just doubting between buying the 2W laser at the German store together with the 60€ goggles, or get everything in the UK store and have 1W less power.

German store will cost me:

330 euros for 2W laser and safety goggles.

UK store will cost me:

~195 euros for 1W laser and safety goggles.

If it is really worth to spend an extra 135 euros to get a 2W laser, let me know.

I'm also looking for the right kind of material for making a safety window. I have already designed a box, but I need some kind of protecting material to make a window. I don't want any guests, or my cat, going blind from a stupid mistake.

Edited 1 time(s). Last edit at 12/27/2014 08:57AM by Ohmarinus.

http://www.marinusdebeer.nl/

Laser diode:

[odicforce.com]

Goggles:

[odicforce.com]

The laser diode is a 1.6W one, but it is run at 1W.

The Only thing is, that the driver asks for a 'TTL' signal to reduce the power. How would I sent a power signal from the Ramps to the driver? Or is it no problem to just use the laser with full power always 'on'?

And how do I switch the power with the Ramps? Should it be done with a Solid State Relay, or can one of the outputs of the Ramps turn the laser on/off? This is still unclear to me.

I feel comfortable ordering my laser parts at that shop since they sell both glasses and laser kit, and I decided maybe it doesn't matter so much if I get a 2W laser or a 1W laser. Both will cut cardboard perfectly fine right? Or is it a big difference?

Sorry for all my questions, I just don't want to buy the 'wrong' thing

I'm just doubting between buying the 2W laser at the German store together with the 60€ goggles, or get everything in the UK store and have 1W less power.

German store will cost me:

330 euros for 2W laser and safety goggles.

UK store will cost me:

~195 euros for 1W laser and safety goggles.

If it is really worth to spend an extra 135 euros to get a 2W laser, let me know.

I'm also looking for the right kind of material for making a safety window. I have already designed a box, but I need some kind of protecting material to make a window. I don't want any guests, or my cat, going blind from a stupid mistake.

Edited 1 time(s). Last edit at 12/27/2014 08:57AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need December 27, 2014 10:35AM |

Registered: 11 years ago Posts: 195 |

Does this 1.6W one cut the same types of materials as the 2W and 3W, but in more passes?

You can also use cat goggles: [images2.fanpop.com]

Edited 1 time(s). Last edit at 12/27/2014 10:38AM by MPower.

http://www.i3d.ro

You can also use cat goggles: [images2.fanpop.com]

Edited 1 time(s). Last edit at 12/27/2014 10:38AM by MPower.

http://www.i3d.ro

|

Re: Information needed before buying what I need December 27, 2014 11:19AM |

Admin Registered: 16 years ago Posts: 13,884 |

... my experience with 'needed power to cut' is roughly: - 2x power = 4x cutting depth.

Check the needed current to switch the module - I'm driving all my modules with TTL-level (5V) and only some Mikro- to Milliamperes switching current, so any I/O-port can handle this ...

Edited 1 time(s). Last edit at 12/27/2014 11:19AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Check the needed current to switch the module - I'm driving all my modules with TTL-level (5V) and only some Mikro- to Milliamperes switching current, so any I/O-port can handle this ...

Edited 1 time(s). Last edit at 12/27/2014 11:19AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Information needed before buying what I need December 27, 2014 12:15PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

VDX

... my experience with 'needed power to cut' is roughly: - 2x power = 4x cutting depth.

Check the needed current to switch the module - I'm driving all my modules with TTL-level (5V) and only some Mikro- to Milliamperes switching current, so any I/O-port can handle this ...

I might go for the German laser then. Since the power modulation is done by voltage level (analog):

Quote

Analoge Modulation bedeutet, dass man mit einer Spannung welche sich zwischen 0 – 5V bewegt, die Laserdiode

zwischen 0 – 100% ihrer Leistung einstellen kann.

Wenn man also zum Beispiel 2.5V an den Modulationseingang anlegt, läuft die Laserdiode mit 50 % Ihrer Leistung.

So, 'Analog modulation means that by switching with a voltage between 0-5V, you can switch the laser module between 0-100% power.

This means that when you deliver 2.5V to the modulation input, the laserdiode will output 50% of it's power.'

This is possible to do with the German one correct?

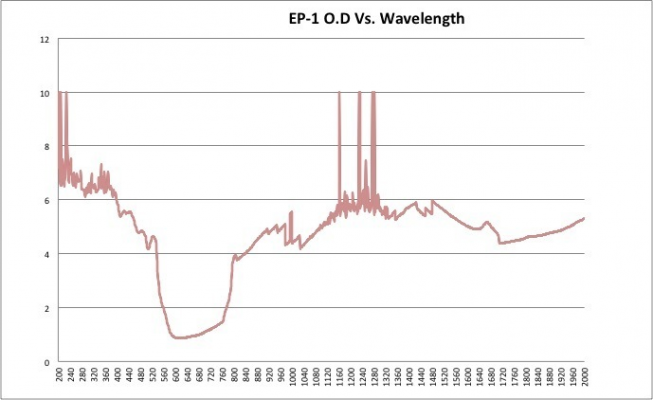

Very curious about the glasses too: [www.insaneware.de] it seems they have linked a chart with it.

Edited 2 time(s). Last edit at 12/27/2014 12:16PM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need December 27, 2014 01:35PM |

Admin Registered: 16 years ago Posts: 13,884 |

... yes, 2,5V means 50% power.

What's the meaning of the left side numbers? - if percents/10, then this glasses will only shield 50% of the 445nm-light

Edited 1 time(s). Last edit at 12/27/2014 01:35PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

What's the meaning of the left side numbers? - if percents/10, then this glasses will only shield 50% of the 445nm-light

Edited 1 time(s). Last edit at 12/27/2014 01:35PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Information needed before buying what I need December 27, 2014 01:53PM |

Registered: 11 years ago Posts: 195 |

Definitely not percent/10 as it goes to 12. The column is probably that "O.D.", whatever OD means

Later edit: oh yeah, optical density.

[www.lia.org]

so you are fine with 5 at 445nm using around 1W.

Edited 3 time(s). Last edit at 12/27/2014 01:56PM by MPower.

http://www.i3d.ro

Later edit: oh yeah, optical density.

[www.lia.org]

so you are fine with 5 at 445nm using around 1W.

Edited 3 time(s). Last edit at 12/27/2014 01:56PM by MPower.

http://www.i3d.ro

|

Re: Information needed before buying what I need December 27, 2014 02:29PM |

Admin Registered: 11 years ago Posts: 3,096 |

Quote

MPower

Definitely not percent/10 as it goes to 12. The column is probably that "O.D.", whatever OD means

Later edit: oh yeah, optical density.

[www.lia.org]

so you are fine with 5 at 445nm using around 1W.

Thanks for that link, in the site I've input the laser at 2W and it says I only need 3.3 O.D. so that would still be safe even at 2W

I have to keep in mind that the glasses above 450nm go down rapidly in protection rate.

Will order the laser kit and glasses a.s.a.p.

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need December 27, 2014 07:13PM |

Registered: 11 years ago Posts: 1,049 |

Control from RAMPS?

How?

No G-code for Laser ON/OFF

Will you use Extruder ON/OFF?

What software will you be using to design

your laser cuts? What in software turns laser ON/OFF

My Laser on a Shapeoko 2 router rig

Down command (to zero) trips micro switch to apply 12V to

turn ON laser ---- Up command (router moves clear in Z to translate) laser OFF.

Extrude / retract on 3D printer PWM to step stepper motor

not what laser wants?

My process

Inkscape

----draw path

--- save .svg

makercam

------open .svg define path, pocket, etc

-----calculate, export g-code (.nc file)

Universal G-code sender GRBL --- G-shield --- machine

Good luck

How?

No G-code for Laser ON/OFF

Will you use Extruder ON/OFF?

What software will you be using to design

your laser cuts? What in software turns laser ON/OFF

My Laser on a Shapeoko 2 router rig

Down command (to zero) trips micro switch to apply 12V to

turn ON laser ---- Up command (router moves clear in Z to translate) laser OFF.

Extrude / retract on 3D printer PWM to step stepper motor

not what laser wants?

My process

Inkscape

----draw path

--- save .svg

makercam

------open .svg define path, pocket, etc

-----calculate, export g-code (.nc file)

Universal G-code sender GRBL --- G-shield --- machine

Good luck

|

Re: Information needed before buying what I need December 27, 2014 08:22PM |

Admin Registered: 11 years ago Posts: 3,096 |

I would expect it to be possible to use some pinouts to provide the needed current. Not that I know how to do that, but Ramps is placed on top of an Arduino, so there should surely be some way possible to modify Marlin to run a laser. All I need is to have it output a certain voltage to set the % of the laser power.

How hard can that be?

About workflow, I have no idea, the lasercutter I use at the academy has a plugin in Adobe Illustrator from where you can immediately send your line data to the lasercutter. I assume it will be different with this selfmade cutter.

Thanks for sharing your workflow

http://www.marinusdebeer.nl/

How hard can that be?

About workflow, I have no idea, the lasercutter I use at the academy has a plugin in Adobe Illustrator from where you can immediately send your line data to the lasercutter. I assume it will be different with this selfmade cutter.

Thanks for sharing your workflow

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need December 28, 2014 02:10PM |

Registered: 11 years ago Posts: 195 |

Just curious, but what is the estimated cost of the complete machine in your case? And by complete I mean everything, including tiny little aspects such as cooling, smoke filtering, etc.

http://www.i3d.ro

http://www.i3d.ro

|

Re: Information needed before buying what I need December 28, 2014 05:19PM |

Admin Registered: 11 years ago Posts: 3,096 |

I don't have a complete list ad the 3D-printer I was building has been bought in a lot of different moments throughout the year. My estimate would be that the cost are around 600 euros now, but that's only because I spent a lot of money on building the printer. It's a CoreXY machine.

The 600 euros is including the laser which totals at around 330 euros with glasses.

I have not been able to find a window for my casing yet, I have the materials laying around for a case though, they are basically 'free' since they are waste from an older project.

I ordered most of my parts at RobotDIGG in China. Still need a filter, but for now I will not cut in my house and I will not cut plastics for the time being until I get a good way of moving the fumes to outside. I have read about certain types of plastics that create gases that can really damage your health badly like cyanide (ABS), I am not sure if this is true but I am not willing to take any risk

Here's a nice list of what it does per material:

[www.noisebridge.net]

The list contains 'Pure Chlorine gas' and Cyanide gas. Both are very dangerous. Besides that it will ruin your optics.

http://www.marinusdebeer.nl/

The 600 euros is including the laser which totals at around 330 euros with glasses.

I have not been able to find a window for my casing yet, I have the materials laying around for a case though, they are basically 'free' since they are waste from an older project.

I ordered most of my parts at RobotDIGG in China. Still need a filter, but for now I will not cut in my house and I will not cut plastics for the time being until I get a good way of moving the fumes to outside. I have read about certain types of plastics that create gases that can really damage your health badly like cyanide (ABS), I am not sure if this is true but I am not willing to take any risk

Here's a nice list of what it does per material:

[www.noisebridge.net]

The list contains 'Pure Chlorine gas' and Cyanide gas. Both are very dangerous. Besides that it will ruin your optics.

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need December 28, 2014 06:08PM |

Admin Registered: 16 years ago Posts: 13,884 |

... this list is meant for a CO2-laser, so should be different for the 445nm-diodes ... but not less toxic

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Information needed before buying what I need December 28, 2014 06:37PM |

Registered: 11 years ago Posts: 1,049 |

My Laser machine cost

Shapeoko 2 kit $550

[www.inventables.com]

overkill for pushing around a laser but solid kit 280 x 280mm cut area

J Tech Photonics

1.7W Laser Diode and 2.5 Amp Driver Kit, withPower Adapter

$245

[jtechphotonics.com]

Acrylic mount

gears for focus of laser head

$20

smoke control used muffin fan Free

Activated carbon air purifier (I had it anyway) free ($30)

GRBL 0.9 for controller Free

Inkscape Free

Makercam Free

Universal G-code sender Free

$815 plus shipping and taxes

Only 1.7 w blue laser

enough to have a lot of fun

and long for 500 w laser to cut thru concret floor?

Shapeoko 2 kit $550

[www.inventables.com]

overkill for pushing around a laser but solid kit 280 x 280mm cut area

J Tech Photonics

1.7W Laser Diode and 2.5 Amp Driver Kit, withPower Adapter

$245

[jtechphotonics.com]

Acrylic mount

gears for focus of laser head

$20

smoke control used muffin fan Free

Activated carbon air purifier (I had it anyway) free ($30)

GRBL 0.9 for controller Free

Inkscape Free

Makercam Free

Universal G-code sender Free

$815 plus shipping and taxes

Only 1.7 w blue laser

enough to have a lot of fun

and long for 500 w laser to cut thru concret floor?

|

Re: Information needed before buying what I need December 29, 2014 02:56AM |

Registered: 11 years ago Posts: 195 |

I was comparing the cost with the cheap 40W CO2 Chinese lasers. They seem to go around 700 EURO and change in Europe, so you don't have to wait for shipping and then pay custom fees.

Most of us already have the printer and we just need to swap the hotend with the diode, so it actually is not a big investment. But then again, it's a 2W diode against 40W CO2. If you could find a way of recovering the investment by offering a cutting/engraving service, it would probably make more sense going for the cheap CO2.

http://www.i3d.ro

Most of us already have the printer and we just need to swap the hotend with the diode, so it actually is not a big investment. But then again, it's a 2W diode against 40W CO2. If you could find a way of recovering the investment by offering a cutting/engraving service, it would probably make more sense going for the cheap CO2.

http://www.i3d.ro

|

Re: Information needed before buying what I need December 29, 2014 06:26AM |

Admin Registered: 11 years ago Posts: 3,096 |

True, however, doing it myself is something I like!  I like to learn to make, not to learn how to use a machine that's already put together.

I like to learn to make, not to learn how to use a machine that's already put together.

If it turns out I can earn money with lasercutting of course, I might buy a CO2, but it's not in the planning and since I'm still a student, I have more time to build things right now

If I hadn't already had the printer, then yes it would've been a serious consideration to buy the CO2 laser.

Oh, and I found this:

[sourceforge.net]

Still looking on, I realize it's harder to make it function with Ramps as I initially thought

Edited 1 time(s). Last edit at 12/29/2014 06:51AM by Ohmarinus.

http://www.marinusdebeer.nl/

I like to learn to make, not to learn how to use a machine that's already put together.

I like to learn to make, not to learn how to use a machine that's already put together.If it turns out I can earn money with lasercutting of course, I might buy a CO2, but it's not in the planning and since I'm still a student, I have more time to build things right now

If I hadn't already had the printer, then yes it would've been a serious consideration to buy the CO2 laser.

Oh, and I found this:

[sourceforge.net]

Still looking on, I realize it's harder to make it function with Ramps as I initially thought

Edited 1 time(s). Last edit at 12/29/2014 06:51AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need December 29, 2014 06:49AM |

Registered: 11 years ago Posts: 195 |

Yes, there is always the DIY factor. And pre-owning a 3D printer already gets you the positioning system ready. However, I find the prices for diodes kinda ridiculous. To be more specific, you would expect that at the technology state of 2014-2015 a tiny 2W diode would cost way less then 300 EURO. That also applies for the driver - after you receive it, try to look up the costs for the components on your favorite electronic components supplier and add a few cents for the tiny PCB. The highest gain I see with diodes would be etching PCBs, diodes having a much finer dot.

http://www.i3d.ro

http://www.i3d.ro

|

Re: Information needed before buying what I need December 29, 2014 12:50PM |

Registered: 11 years ago Posts: 1,049 |

IMHO

Laser Diode prices are very cheap.

everyone wants something for nothing.

I can remember when a common red LED was $5

There are not millions of people out there buying laser diodes.

Industry pays $100000 for a laser diode

and

you are crying about a 300 euro diode.

When DPSS devices and driver electronics become within the means of hobbyist that will be neat.

Look at the price of single resistors or capacitors and cry!

Maybe you should be happy with Christmas light LEDs

Laser Diode prices are very cheap.

everyone wants something for nothing.

I can remember when a common red LED was $5

There are not millions of people out there buying laser diodes.

Industry pays $100000 for a laser diode

and

you are crying about a 300 euro diode.

When DPSS devices and driver electronics become within the means of hobbyist that will be neat.

Look at the price of single resistors or capacitors and cry!

Maybe you should be happy with Christmas light LEDs

Quote

MPower

Yes, there is always the DIY factor. And pre-owning a 3D printer already gets you the positioning system ready. However, I find the prices for diodes kinda ridiculous. To be more specific, you would expect that at the technology state of 2014-2015 a tiny 2W diode would cost way less then 300 EURO. That also applies for the driver - after you receive it, try to look up the costs for the components on your favorite electronic components supplier and add a few cents for the tiny PCB. The highest gain I see with diodes would be etching PCBs, diodes having a much finer dot.

|

Re: Information needed before buying what I need December 29, 2014 03:54PM |

Admin Registered: 11 years ago Posts: 3,096 |

Calm down cozmicray

I think I will buy the laser. The only thing I don't know still is if it's possible to have the Ramps control the laser's power. Have contacted a few people who have been working on this, but so far no reply.

http://www.marinusdebeer.nl/

I think I will buy the laser. The only thing I don't know still is if it's possible to have the Ramps control the laser's power. Have contacted a few people who have been working on this, but so far no reply.

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need December 29, 2014 04:31PM |

Registered: 11 years ago Posts: 195 |

Wouldn't analogWrite() work? Such as:

Edited 1 time(s). Last edit at 12/29/2014 04:32PM by MPower.

http://www.i3d.ro

analogWrite(SomePin, Voltage * 255 / 5);if you want to set it by voltage value, or

analogWrite(SomePin, Percent * 255 / 100);if you want to set it by power percent value, considering 5V (255 full duty cycle) as 100% power.

Edited 1 time(s). Last edit at 12/29/2014 04:32PM by MPower.

http://www.i3d.ro

|

Re: Information needed before buying what I need December 29, 2014 07:55PM |

Admin Registered: 11 years ago Posts: 3,096 |

|

Re: Information needed before buying what I need December 29, 2014 09:09PM |

Registered: 11 years ago Posts: 1,049 |

Make sure you mod the Marlin or Repetier Firmware

to use D9 as "Fan control" and NOT 2nd extruder heater

Hey Mpower says laser diodes are too expensive

Get one for $68

[www.ebay.com]

Probably has to save lunch money for 4 months??

to use D9 as "Fan control" and NOT 2nd extruder heater

Hey Mpower says laser diodes are too expensive

Get one for $68

[www.ebay.com]

Probably has to save lunch money for 4 months??

|

Re: Information needed before buying what I need December 30, 2014 07:06AM |

Admin Registered: 11 years ago Posts: 3,096 |

Hi Ray, I saw the $68 one, but it doesn't have all the parts included. I have been looking for drivers, but they are either underpowered, or overpowered. I don't want to run the risk of blowing the diode, so I figured it was better to start with a kit that has all the parts that are already a perfect fit for each other. Since I'm not so good with electronics, I think it's better to be safe than sorry. I have done a lot of basic projects with electronics, but the laser cutter world is still something unclear to me.

Right now I'm already preparing a workflow. However, InkScape doesn't want to work well on my Mac (hear me swear and curse), it doesn't start up unless I go into the internals of the program and start it from there, it's an XQuartz/X11 problem. The command line errors just keep coming, so I can't find a fix for it.

The plugin exports empty files, and I've installed the plugin to generate the codes with M106/M107 but still it outputs the M03/M05 commands.

Got the plugin to work, but the plugin doesn't save the path I've defined and always uses c:\output as a standard folder. I've been messing with the plugins' internal settings with a code editor and have edited out a few standard setting so that I don't have to 'manage' all my files all the time. I've also made it so that it outputs to a gcode file instead of an nc file.

I don't want to use my Z-axis in the machine. It is disabled, I hope the machine will work with the GCODE I am supplying. Right now I'm just going to put this data in my Ramps 1.4 and see what it does

Edited 1 time(s). Last edit at 12/30/2014 07:14AM by Ohmarinus.

http://www.marinusdebeer.nl/

Right now I'm already preparing a workflow. However, InkScape doesn't want to work well on my Mac (hear me swear and curse), it doesn't start up unless I go into the internals of the program and start it from there, it's an XQuartz/X11 problem. The command line errors just keep coming, so I can't find a fix for it.

Got the plugin to work, but the plugin doesn't save the path I've defined and always uses c:\output as a standard folder. I've been messing with the plugins' internal settings with a code editor and have edited out a few standard setting so that I don't have to 'manage' all my files all the time. I've also made it so that it outputs to a gcode file instead of an nc file.

I don't want to use my Z-axis in the machine. It is disabled, I hope the machine will work with the GCODE I am supplying. Right now I'm just going to put this data in my Ramps 1.4 and see what it does

Edited 1 time(s). Last edit at 12/30/2014 07:14AM by Ohmarinus.

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need December 30, 2014 02:10PM |

Registered: 11 years ago Posts: 1,049 |

For a driver $12 gets you (and use a 12V 3A wallwart for 12V supply)

12VDC TTL 1w-2w Blue 445nm 450nm Laser Diode LD Driver Power Supply

Besam makes a lot of laser products

[www.ebay.com]

$25

2W 445nm Blue Laser Diode Driver/8-14V Step-Down Circuit w/ <2.5A Output

[www.ebay.com]

Yes inkscape on mac runs under X11 --- runs much better on PC windoze

What OSX ? What X11 version --- check for a better version of inkscape tweeked for mac

Any drawing program that produces an .svg and produces paths,

output can be sucked into makercam to produce g-code

[www.makercam.com]

You have to find a 2D CAM program that will allow you to use laser ON/OFF commands.

and then another program to modulate laser for photo type etching?

I would use your Z axis --- powered focus?

Are you using Marlin or Repetier in RAMPS

What are you using for software to run your machine?

Repetier-Host with slicer settings for 1 slice and one z setting might do it

[forums.reprap.org]

Wear the red glasses --- makes you look kewl --- like Bono?

12VDC TTL 1w-2w Blue 445nm 450nm Laser Diode LD Driver Power Supply

Besam makes a lot of laser products

[www.ebay.com]

$25

2W 445nm Blue Laser Diode Driver/8-14V Step-Down Circuit w/ <2.5A Output

[www.ebay.com]

Yes inkscape on mac runs under X11 --- runs much better on PC windoze

What OSX ? What X11 version --- check for a better version of inkscape tweeked for mac

Any drawing program that produces an .svg and produces paths,

output can be sucked into makercam to produce g-code

[www.makercam.com]

You have to find a 2D CAM program that will allow you to use laser ON/OFF commands.

and then another program to modulate laser for photo type etching?

I would use your Z axis --- powered focus?

Are you using Marlin or Repetier in RAMPS

What are you using for software to run your machine?

Repetier-Host with slicer settings for 1 slice and one z setting might do it

[forums.reprap.org]

Wear the red glasses --- makes you look kewl --- like Bono?

|

Re: Information needed before buying what I need December 30, 2014 10:55PM |

Registered: 11 years ago Posts: 1,049 |

You could get in on this

[www.kickstarter.com]

Solid State Laser attachment to fit Shapeoko 2 CNC. Provides Laser cutting and engraving. Software support for photos.

[www.kickstarter.com]

Solid State Laser attachment to fit Shapeoko 2 CNC. Provides Laser cutting and engraving. Software support for photos.

|

Re: Information needed before buying what I need January 01, 2015 07:18PM |

Admin Registered: 11 years ago Posts: 3,096 |

Found one more supplier:

[robots-everywhere.com]

Anyone have experience with this one?

http://www.marinusdebeer.nl/

[robots-everywhere.com]

Anyone have experience with this one?

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need January 02, 2015 06:43PM |

Admin Registered: 11 years ago Posts: 3,096 |

I've been reading about the L-cheapo. To be honest, so much can be found about using it with Ramps 1.4 that I've decided to go ahead and order one. It's not expensive, but most of all, there is a lot of information to be found about the cute little laser so I'm sure that I can make this work with Ramps 1.4.

Will update on how it goes after I receive the laser!

Marinus

http://www.marinusdebeer.nl/

Will update on how it goes after I receive the laser!

Marinus

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need January 03, 2015 07:31PM |

Registered: 11 years ago Posts: 1,049 |

With L-Cheapo you get cheap!

L-Cheapo's heat sink around diode seems woefully inadequate.

and very little interface diode to sink.

I would have a much larger block of aluminium around it

with a finned outside to take advantage of fan cooling.

The one I use is 18 x 18 x 30 mm block of aluminium

with hole machined in center and thermal paste used

in diode to block fit.

So can you machine a hole in the sink to accept diode with a tight fit?

Controller board looks like just a 12V to 3.3V power regulator

without much power capability

and

there should be supply wires and trigger wires?

This is a ON/OFF laser 12V power ON laser diode ON.

I don't know if you would want to PWM the supply.

I would wire it up so fan is on constantly

Well you can always get the drive I suggested after this one poops out?

A $68 diode and $12 driver (much better than L-Cheapo) ans a good heat sink from eBay = Better than L-Cheapo??

Let us know how it works out ---- wear those red glasses

burned fingers are just a part of the focus process

L-Cheapo's heat sink around diode seems woefully inadequate.

and very little interface diode to sink.

I would have a much larger block of aluminium around it

with a finned outside to take advantage of fan cooling.

The one I use is 18 x 18 x 30 mm block of aluminium

with hole machined in center and thermal paste used

in diode to block fit.

So can you machine a hole in the sink to accept diode with a tight fit?

Controller board looks like just a 12V to 3.3V power regulator

without much power capability

and

there should be supply wires and trigger wires?

This is a ON/OFF laser 12V power ON laser diode ON.

I don't know if you would want to PWM the supply.

I would wire it up so fan is on constantly

Well you can always get the drive I suggested after this one poops out?

A $68 diode and $12 driver (much better than L-Cheapo) ans a good heat sink from eBay = Better than L-Cheapo??

Let us know how it works out ---- wear those red glasses

burned fingers are just a part of the focus process

|

Re: Information needed before buying what I need January 03, 2015 08:07PM |

Admin Registered: 11 years ago Posts: 3,096 |

I think you're seeing bears on the road  (Dutch expression)

(Dutch expression)

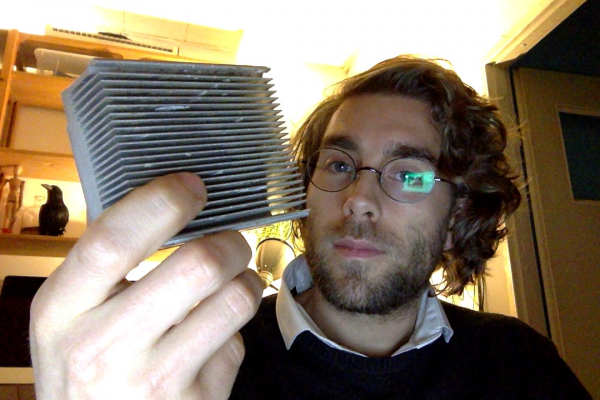

The laser will do fine, however, I have an old CPU element that will be able to cool it down way better. The academy will open up next week again, so I can immediately start milling a 9mm hole in the cooling element. It is huge, and meant to cool a Pentium 3. I also have cooling paste, however it's quite watery, but it will work.

I've seen plenty of people working with the laser, and haven't found any negative comment on the L-cheapo yet!

http://www.marinusdebeer.nl/

(Dutch expression)

(Dutch expression)The laser will do fine, however, I have an old CPU element that will be able to cool it down way better. The academy will open up next week again, so I can immediately start milling a 9mm hole in the cooling element. It is huge, and meant to cool a Pentium 3. I also have cooling paste, however it's quite watery, but it will work.

I've seen plenty of people working with the laser, and haven't found any negative comment on the L-cheapo yet!

http://www.marinusdebeer.nl/

|

Re: Information needed before buying what I need January 03, 2015 09:35PM |

Registered: 11 years ago Posts: 1,049 |

Taking problems much too seriously?

Maybe the bears can provide some laser experience.

Ok we will not use good engineering sense any more

and

just fool around with high power lasers?

Does your huge cpu cooler have an area that a 9mm hole can surround the diode case?

I wonder if a laser diode can be over cooled!

Maybe the bears can provide some laser experience.

Ok we will not use good engineering sense any more

and

just fool around with high power lasers?

Does your huge cpu cooler have an area that a 9mm hole can surround the diode case?

I wonder if a laser diode can be over cooled!

|

Re: Information needed before buying what I need January 04, 2015 05:35AM |

Admin Registered: 11 years ago Posts: 3,096 |

For the cooling part, I will cut a slice off of the cooler. Then, in the metal workshop I will mill out a hole from the bottom through to the top. If you look to the left side of the cooler, on the bottom you see a thick piece of aluminium. I will drill the hole straight through that thick piece. The diodes housing will be placed in the thick part with cooler paste.

Can't wait till that laser gets here! The CoreXY setup is almost finished too! Cutting area will be 220x280mm. This is expandable if I buy longer rods and longer aluminium extrusions. Sizing it up is a simple process with the machine I've built now. The only thing I should do when I make it bigger, is to go to 10 or 12 mm chromed rods instead of the 8mm I use now. Deflection right now is unnoticeable but will be an issue if sized up.

The CoreXY setup is almost finished too! Cutting area will be 220x280mm. This is expandable if I buy longer rods and longer aluminium extrusions. Sizing it up is a simple process with the machine I've built now. The only thing I should do when I make it bigger, is to go to 10 or 12 mm chromed rods instead of the 8mm I use now. Deflection right now is unnoticeable but will be an issue if sized up.

I will use this material for underneath the material:

[www.marktplaats.nl]

Guess I have to see if the material doesn't reflect the laserbeam upwards. I might have to paint it black and twist the ribs by hand so they are vertical instead of 45º.

Edited 1 time(s). Last edit at 01/04/2015 08:48AM by Ohmarinus.

http://www.marinusdebeer.nl/

Can't wait till that laser gets here!

The CoreXY setup is almost finished too! Cutting area will be 220x280mm. This is expandable if I buy longer rods and longer aluminium extrusions. Sizing it up is a simple process with the machine I've built now. The only thing I should do when I make it bigger, is to go to 10 or 12 mm chromed rods instead of the 8mm I use now. Deflection right now is unnoticeable but will be an issue if sized up.

The CoreXY setup is almost finished too! Cutting area will be 220x280mm. This is expandable if I buy longer rods and longer aluminium extrusions. Sizing it up is a simple process with the machine I've built now. The only thing I should do when I make it bigger, is to go to 10 or 12 mm chromed rods instead of the 8mm I use now. Deflection right now is unnoticeable but will be an issue if sized up.I will use this material for underneath the material:

[www.marktplaats.nl]

Guess I have to see if the material doesn't reflect the laserbeam upwards. I might have to paint it black and twist the ribs by hand so they are vertical instead of 45º.

Edited 1 time(s). Last edit at 01/04/2015 08:48AM by Ohmarinus.

http://www.marinusdebeer.nl/

Sorry, only registered users may post in this forum.