Aixiz acrylic lens?

Posted by o_lampe

|

Aixiz acrylic lens? December 06, 2015 01:08PM |

Registered: 8 years ago Posts: 5,232 |

Hi,

I want to play around with DVD-laser diodes and wondered if the acrylic lens is useful for this small wattage ( 400mW max, so I've read )

I can get the Aixiz housing with that lens for only a few $, so for playing around, I hope it would do.

Also I'll try to use a A4988 stepstick as current control, haven't found anything about pros 'n cons?!

-Olaf

I want to play around with DVD-laser diodes and wondered if the acrylic lens is useful for this small wattage ( 400mW max, so I've read )

I can get the Aixiz housing with that lens for only a few $, so for playing around, I hope it would do.

Also I'll try to use a A4988 stepstick as current control, haven't found anything about pros 'n cons?!

-Olaf

|

Re: Aixiz acrylic lens? December 06, 2015 04:08PM |

Admin Registered: 16 years ago Posts: 13,886 |

... try it ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 10, 2015 07:14AM |

Registered: 8 years ago Posts: 5,232 |

Quote

Also I'll try to use a A4988 stepstick as current control, haven't found anything about pros 'n cons?!

Stepper drivers don't work, because they seem to provide negative voltage too. ( It's a H-bridge )

Also tried the LM317 as current control with a 3W wire wound potmeter as shunt. Worked good on a cree 1W LED.

-Olaf

|

Re: Aixiz acrylic lens? December 10, 2015 11:32AM |

Admin Registered: 16 years ago Posts: 13,886 |

... my first drivers were LM317 as current regulators -- not as voltage-regulators!!!

Best chance to wreck a laser-diode is driving it with a set voltage - the drawn current rises with temp, so when your cooling isn't enough or the ambient temp overgoes your 'calibration' level, it will degrade or burn for overcurrent.

With a set current you'll define the drawn current, so with rising temp you'll only notice (with instruments) change in wavelength or slight dimming of the diode.

And hold your diode below 30degC ... it will start to degrade, when more!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Best chance to wreck a laser-diode is driving it with a set voltage - the drawn current rises with temp, so when your cooling isn't enough or the ambient temp overgoes your 'calibration' level, it will degrade or burn for overcurrent.

With a set current you'll define the drawn current, so with rising temp you'll only notice (with instruments) change in wavelength or slight dimming of the diode.

And hold your diode below 30degC ... it will start to degrade, when more!

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 11, 2015 06:05AM |

Registered: 8 years ago Posts: 5,232 |

Regarding diode temp, I was wondering, why I haven't seen a thermistor controlled setup yet?

Assume you've set the current to max. and use a PWM signal to control momentary power.

A thermistor would measure diode temp and reduce PWM to avoid overheating the diode.

BTW. 30°C is almost impossible with air cooling. Is that the reason for using Peltier elements or water cooling?

-Olaf

Assume you've set the current to max. and use a PWM signal to control momentary power.

A thermistor would measure diode temp and reduce PWM to avoid overheating the diode.

BTW. 30°C is almost impossible with air cooling. Is that the reason for using Peltier elements or water cooling?

-Olaf

|

Re: Aixiz acrylic lens? December 11, 2015 06:21AM |

Admin Registered: 16 years ago Posts: 13,886 |

... comercial drivers have mostly peltiers to maintain the diode housing temp in a range around 20 - 25 degC - the crystal inside can heat up to 40 degC with this housing temp nevertheless!

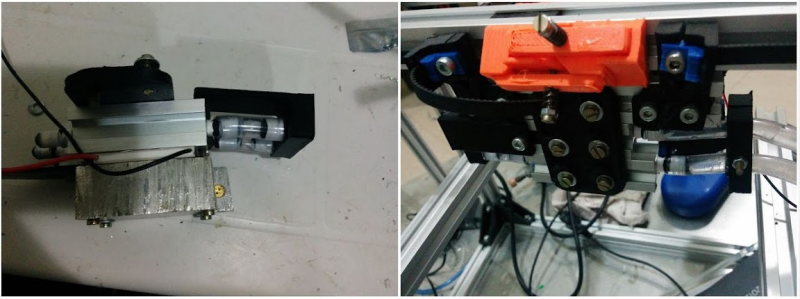

My drivers are clamped to massive aluminium chunks/coolers and then mounted onto the Z-axis-housing, whats an additional 'thermal mass' - the ambient temp in my basement is between 17 degC in winter and 22 degC in summer -- so mostly no additive cooling needed

With higher temps (in summer or with drawn powers of >>10W) I'm using aggressive air cooling (special coolers), or activate water coolers (have some old comercial water-coolers and modern types from PC-modding/overclocking). And I too have peltier coolers with >2kW thermal exchange ... but didn't use them yet.

If I'll get some future problems in summer with higher temps, then I have plans/options for thermal sensing and controlling/deactivating the modules in case of overtemps ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My drivers are clamped to massive aluminium chunks/coolers and then mounted onto the Z-axis-housing, whats an additional 'thermal mass' - the ambient temp in my basement is between 17 degC in winter and 22 degC in summer -- so mostly no additive cooling needed

With higher temps (in summer or with drawn powers of >>10W) I'm using aggressive air cooling (special coolers), or activate water coolers (have some old comercial water-coolers and modern types from PC-modding/overclocking). And I too have peltier coolers with >2kW thermal exchange ... but didn't use them yet.

If I'll get some future problems in summer with higher temps, then I have plans/options for thermal sensing and controlling/deactivating the modules in case of overtemps ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 11, 2015 08:56AM |

Registered: 9 years ago Posts: 346 |

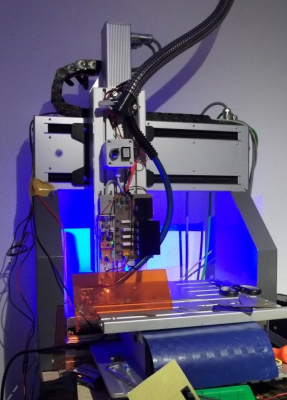

I do the Peltier thing in my setup.

It is 2x 2020 profiles held together, in the center of the 2020 I have water flowing. The water is pumped by a car sprinkler pump (12V connected to RAMPS as the fan). Then a thin alu plate to distribute the heat and a 12V Peltier element and finally a big block of alu with the diode directly integrated into.

I have my temp probe very close to the diode (but not touching the diode) and I get 15 to 20 C. I have an ambient temperature of 28 and above in my room. The alu block heats past 30 in minutes if the Peltier is turned off. I am running a 1.6W Osram diode, it is running at about the nominal 1.6W (as measured by current).

It has been difficult to make the water system so that it does not leak. The problem is that it needs to be small and compact and still flexible enough to move about. On the other hand, I feel that I have learned more about what is required now and if I were to do it again it would not be much of a problem. Like, printed parts are OK but needs to be 100% infill and threads with Teflon tape is the way to connect it to the alu, don't just try and push fit it in and hope that it holds.

My setup is finally working but still very much "beta" (or even Alpha)... Like, the way I fix my lens is no good right now and I need to get a better thermal contact between diode and alu.

I use a Chinese laser driver with variable current and power output (controlled by a potmeter). It works great. I have a 1 Ohm resistor in the laser circuit and two of the cheap voltmeters measure on either side of it. I then have to subtract the two numbers in my head and that gives the current that I am delivering to the laser - That could be made a lot smarter - Thus "beta" . I already purchased some ACS712 current monitoring chips which I plan to install to digitalize the process.

. I already purchased some ACS712 current monitoring chips which I plan to install to digitalize the process.

Before I installed a way to see the current I killed one of my diodes because I was just turning on that potmeter without a clue (in retrospec) what I was doing. I highly recommend that whatever electric control you make, then you need to install a way to directly monitor both Current and Voltage over the laser.

Oh. I have also installed a jumper on the laser circuit so I can take that out and then with that in my hand I am 100% sure the laser can't turn on. I find that a nice feature.

It is 2x 2020 profiles held together, in the center of the 2020 I have water flowing. The water is pumped by a car sprinkler pump (12V connected to RAMPS as the fan). Then a thin alu plate to distribute the heat and a 12V Peltier element and finally a big block of alu with the diode directly integrated into.

I have my temp probe very close to the diode (but not touching the diode) and I get 15 to 20 C. I have an ambient temperature of 28 and above in my room. The alu block heats past 30 in minutes if the Peltier is turned off. I am running a 1.6W Osram diode, it is running at about the nominal 1.6W (as measured by current).

It has been difficult to make the water system so that it does not leak. The problem is that it needs to be small and compact and still flexible enough to move about. On the other hand, I feel that I have learned more about what is required now and if I were to do it again it would not be much of a problem. Like, printed parts are OK but needs to be 100% infill and threads with Teflon tape is the way to connect it to the alu, don't just try and push fit it in and hope that it holds.

My setup is finally working but still very much "beta" (or even Alpha)... Like, the way I fix my lens is no good right now and I need to get a better thermal contact between diode and alu.

I use a Chinese laser driver with variable current and power output (controlled by a potmeter). It works great. I have a 1 Ohm resistor in the laser circuit and two of the cheap voltmeters measure on either side of it. I then have to subtract the two numbers in my head and that gives the current that I am delivering to the laser - That could be made a lot smarter - Thus "beta"

. I already purchased some ACS712 current monitoring chips which I plan to install to digitalize the process.

. I already purchased some ACS712 current monitoring chips which I plan to install to digitalize the process.Before I installed a way to see the current I killed one of my diodes because I was just turning on that potmeter without a clue (in retrospec) what I was doing. I highly recommend that whatever electric control you make, then you need to install a way to directly monitor both Current and Voltage over the laser.

Oh. I have also installed a jumper on the laser circuit so I can take that out and then with that in my hand I am 100% sure the laser can't turn on. I find that a nice feature.

|

Re: Aixiz acrylic lens? December 12, 2015 03:54AM |

Registered: 8 years ago Posts: 5,232 |

Thanks Lars,

for the detailed description of your setup. Your thermistor is just for your own control or did you integrate it in firmware too?

I had my fun with watercooled overclocked CPUs in the late '90s too. But I always was afraid of condense water from Peltier elements.

My water circuit had some leakage too, but with demineralized water it was no corrosion/shortcut problem.

Many overclockers completely isolated their Peltier elements with a thick layer of silicone.

Did you see any condense water in your setup?

You could place a thermistor on the cold side of the Peltier and keep the temp above 4°C to avoid condensation by reducing the Peltier current.

BTW:

What's the longest "print-" job you've done with a laser engraver/cutter? I can imagine it is mostly a few minutes job?!

-Olaf

for the detailed description of your setup. Your thermistor is just for your own control or did you integrate it in firmware too?

I had my fun with watercooled overclocked CPUs in the late '90s too. But I always was afraid of condense water from Peltier elements.

My water circuit had some leakage too, but with demineralized water it was no corrosion/shortcut problem.

Many overclockers completely isolated their Peltier elements with a thick layer of silicone.

Did you see any condense water in your setup?

You could place a thermistor on the cold side of the Peltier and keep the temp above 4°C to avoid condensation by reducing the Peltier current.

BTW:

What's the longest "print-" job you've done with a laser engraver/cutter? I can imagine it is mostly a few minutes job?!

-Olaf

|

Re: Aixiz acrylic lens? December 12, 2015 11:00AM |

Registered: 9 years ago Posts: 346 |

Hey, the thermistor is not connected yet ( other then raw temperature). I want to see if I can change the temperature output to negative ( multiply by -1) on the thermistor, that will trick the firmware into using the peltier as a heater while it will actually cool. Not done yet.

My first real task is to cut napkins for this year Christmas dinner. Instead of my wife sewing I laser cut. Takes some 10 min to cut one at 250x250. That can be optimised but it is beta

My first real task is to cut napkins for this year Christmas dinner. Instead of my wife sewing I laser cut. Takes some 10 min to cut one at 250x250. That can be optimised but it is beta

|

Re: Aixiz acrylic lens? December 12, 2015 05:17PM |

Admin Registered: 16 years ago Posts: 13,886 |

Hi Olaf,

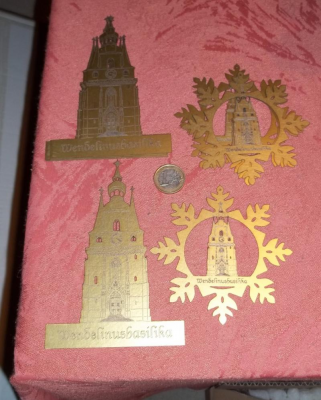

... i'ts near Christmas, so I'm engraving+cutting again cartonage parts for friends.

Yesterday night this was a 2-hours nearly continuous (some ten seconds for exchanging the used sheets) run for engraving+cutting a 10+12 series of this parts

... no extra coolers or sensing - and I didn't notice any heat -- but this narrow cooler on the left (the right module is an old prorotype as temporary current-control) is enough 'thermal mass' to distribute the excess heat through the material and up the Z-axis, so not more than some 20 degC from the housing

PS: for the power - the current regulator ist set to two Amps I'm only changing the pulse time for engraving (maybe 5 microseconds) and cutting (maybe 30 microseconds) ... with a pulse-rate of maybe 20 to 50kHz ...

Edited 2 time(s). Last edit at 12/12/2015 05:21PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

... i'ts near Christmas, so I'm engraving+cutting again cartonage parts for friends.

Yesterday night this was a 2-hours nearly continuous (some ten seconds for exchanging the used sheets) run for engraving+cutting a 10+12 series of this parts

... no extra coolers or sensing - and I didn't notice any heat -- but this narrow cooler on the left (the right module is an old prorotype as temporary current-control) is enough 'thermal mass' to distribute the excess heat through the material and up the Z-axis, so not more than some 20 degC from the housing

PS: for the power - the current regulator ist set to two Amps I'm only changing the pulse time for engraving (maybe 5 microseconds) and cutting (maybe 30 microseconds) ... with a pulse-rate of maybe 20 to 50kHz ...

Edited 2 time(s). Last edit at 12/12/2015 05:21PM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 13, 2015 04:09AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Aixiz acrylic lens? December 13, 2015 06:33AM |

Admin Registered: 16 years ago Posts: 13,886 |

... TTL is only the voltage spec for LOW and HIGH levels - so digitally switching in contrary to controlling with analogue voltage (0-5V most, but industrially often 0-10V too).

PWM is a methode to output different power levels by changing the pulse/pause ratio.

For example, I can run the same file with a PWM ratio of 1:20 (5µs pulse, 100µs pause) for engraving only, or 20:1 (inverted times) for cutting.

I'm using mostly a comercial CAD/CAM (IsyCAM) and engraving program (Editasc10) - but can do the same with Printrun/Pronterface and the pulse driver hooked to the extruder motor STEP-pin.

For setting the power or pulse-times/ratios I'm using a small Arduino (Wattuino, a Pro Mini Clone with 16MHz clocking speed) for pulses down to 5 microseconds, or a Due for Pulses down to 0.5 microseconds ... or a BeagleBoneBlack driver from HAlaser for even faster pulsing and special laser-driving modes ...

Edited 1 time(s). Last edit at 12/13/2015 06:37AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

PWM is a methode to output different power levels by changing the pulse/pause ratio.

For example, I can run the same file with a PWM ratio of 1:20 (5µs pulse, 100µs pause) for engraving only, or 20:1 (inverted times) for cutting.

I'm using mostly a comercial CAD/CAM (IsyCAM) and engraving program (Editasc10) - but can do the same with Printrun/Pronterface and the pulse driver hooked to the extruder motor STEP-pin.

For setting the power or pulse-times/ratios I'm using a small Arduino (Wattuino, a Pro Mini Clone with 16MHz clocking speed) for pulses down to 5 microseconds, or a Due for Pulses down to 0.5 microseconds ... or a BeagleBoneBlack driver from HAlaser for even faster pulsing and special laser-driving modes ...

Edited 1 time(s). Last edit at 12/13/2015 06:37AM by VDX.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 13, 2015 10:40AM |

Registered: 8 years ago Posts: 5,232 |

Quote

VDX

...the pulse driver hooked to the extruder motor STEP-pin.

I had the same idea, but was unsure how to set steps/mm. I think it should be as high as possible without slowing down the X/Y moves.

Also you can't reach 100% power.

Did you find out, for how long the step pin goes low?

-Olaf

|

Re: Aixiz acrylic lens? December 13, 2015 11:02AM |

Registered: 9 years ago Posts: 346 |

Hey, the driver I am using, that Chinese one, also supports TTL. Meaning it is turned on or off with a logic pin. I thought that if I called M42 P[pin nr] S[PWM] I could set the frequency - But that does not work. Either I call with 255 or it does not turn on, I think maybe the switching is too fast for the driver... I think maybe it works if done like VDX describes, using the step from the extruder pin. Not tried. At the moment I am just running 100%.

I have one very big regret about the M42 command - The Arduino does not default it to off when power off and on so it can be a bit surprising sometimes to find the laser "ON" when "arming" it with my jumper. More important, if you hit emergency stop from the PC host program it turns the laser back on after the reset... Not the best.

I have one very big regret about the M42 command - The Arduino does not default it to off when power off and on so it can be a bit surprising sometimes to find the laser "ON" when "arming" it with my jumper. More important, if you hit emergency stop from the PC host program it turns the laser back on after the reset... Not the best.

|

Re: Aixiz acrylic lens? December 13, 2015 11:38AM |

Admin Registered: 16 years ago Posts: 13,886 |

... with my 'comercial' software+board the pulsing is done 'automatically' with the encoder-clocking - this is a level change every 2.5 microns of travel or a fix set rate of 400 pulses per mm.

How fast you want to pulse depends on your spot size and the needed 'overlap' to get a smooth line - e.g. with a 0.1mm spot diameter you can go away with 20 pulses per mm (or 50% overlap).

With Printrun/Pronterface and Marlin4Due as CNC-controller I'm driving some paste-dispensers, which too rely on precise pulsing rates per mm to print uniform lines ... here I'm running mostly with 5 to 10 pulses per mm (droplet-diameter >0.2mm), but was testing with up to 1000 pulses per mm too without problems ... only the travel speed will then fall slow to meet the uniform Bresenham(?) distribution ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

How fast you want to pulse depends on your spot size and the needed 'overlap' to get a smooth line - e.g. with a 0.1mm spot diameter you can go away with 20 pulses per mm (or 50% overlap).

With Printrun/Pronterface and Marlin4Due as CNC-controller I'm driving some paste-dispensers, which too rely on precise pulsing rates per mm to print uniform lines ... here I'm running mostly with 5 to 10 pulses per mm (droplet-diameter >0.2mm), but was testing with up to 1000 pulses per mm too without problems ... only the travel speed will then fall slow to meet the uniform Bresenham(?) distribution ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 13, 2015 11:43AM |

Admin Registered: 16 years ago Posts: 13,886 |

Hi Olaf,

... with the Due the STEP pulse time is 500ns, with the older Arduinos this will be more like 4-5 micorseconds ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Quote

o_lampe

...did you find out, for how long the step pin goes low?

... with the Due the STEP pulse time is 500ns, with the older Arduinos this will be more like 4-5 micorseconds ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 14, 2015 08:22AM |

Registered: 9 years ago Posts: 346 |

Just getting back to my design and how not to do things

The 1 ohm resistor burned out after some time... Another testament to my none existing electronic skills. Obviously you can't have 1 amp at 4V continuously on a normal resistor... I am seeing to putting the hall current sensor now.

No progress on controlling the temperature on my peltier. I left it running some time between two cuts and it reached 0.25 deg C just standing still. The diodes are rated for operation down to -20 so I think I will be OK.

It does form condensation from the cooling but I don't think it is a problem. It is very little . at some point a water drop settled on the lens and I was clueless why the laser beam suddenly was so distorted - until I saw it and cleaned it away. I was cutting all day yesterday and that was the only condensation problem.

My lab was all Christmas yesterday. Printer making snowflake Christmas tree decorations and laser cutting napkins

Looking forward to hear where you go with your project. The laser cutter community is really small when not counting those who buy ready modules and cutters.

The 1 ohm resistor burned out after some time... Another testament to my none existing electronic skills. Obviously you can't have 1 amp at 4V continuously on a normal resistor... I am seeing to putting the hall current sensor now.

No progress on controlling the temperature on my peltier. I left it running some time between two cuts and it reached 0.25 deg C just standing still. The diodes are rated for operation down to -20 so I think I will be OK.

It does form condensation from the cooling but I don't think it is a problem. It is very little . at some point a water drop settled on the lens and I was clueless why the laser beam suddenly was so distorted - until I saw it and cleaned it away. I was cutting all day yesterday and that was the only condensation problem.

My lab was all Christmas yesterday. Printer making snowflake Christmas tree decorations and laser cutting napkins

Looking forward to hear where you go with your project. The laser cutter community is really small when not counting those who buy ready modules and cutters.

|

Re: Aixiz acrylic lens? December 14, 2015 01:10PM |

Admin Registered: 16 years ago Posts: 13,886 |

... don't cool down the diodes below 15degC for this condensation, or you'll wreck the window in the diodes housing by thermal stress!

My current regulator resistors are 0.12Ohm or lower 5W types or higher Ohms (max. 0.6 Ohms) and then metallic 15Watts types.

For higher currents (up to 100Amps) I'm parallelizing single current regulators built around LM317 (1A continuous) or LM338 (2.5A continuous) ... or built with OP-Amps and MOSFET's stated for 170Amps with perfect cooling - I'm driving them mostly in the range of 4-10Amps max -- already 'melted' two "170A-types" while regulationg them for around 20Amps ... they are meant for fast switching, not for regulating currents

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

My current regulator resistors are 0.12Ohm or lower 5W types or higher Ohms (max. 0.6 Ohms) and then metallic 15Watts types.

For higher currents (up to 100Amps) I'm parallelizing single current regulators built around LM317 (1A continuous) or LM338 (2.5A continuous) ... or built with OP-Amps and MOSFET's stated for 170Amps with perfect cooling - I'm driving them mostly in the range of 4-10Amps max -- already 'melted' two "170A-types" while regulationg them for around 20Amps ... they are meant for fast switching, not for regulating currents

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 14, 2015 04:39PM |

Registered: 8 years ago Posts: 5,232 |

I tried the STEP pin of extruder0, but wasn't happy with the power. The OFF time of the Mega board is probably too long.

Also tried the DIR pin, which only offers ON/OFF switching, but cools down the diode while retracting.

Thinking of combining the DIR pin and a unused PWM pin in a AND config to limit power and turn off during retraction.

I hope the unused PWM pin has a different timing, not written for the stepstick.

LarsK, it seems all three contributors to this thread are german?! Small world

-Olaf

Also tried the DIR pin, which only offers ON/OFF switching, but cools down the diode while retracting.

Thinking of combining the DIR pin and a unused PWM pin in a AND config to limit power and turn off during retraction.

I hope the unused PWM pin has a different timing, not written for the stepstick.

LarsK, it seems all three contributors to this thread are german?! Small world

-Olaf

|

Re: Aixiz acrylic lens? December 14, 2015 06:21PM |

Admin Registered: 16 years ago Posts: 13,886 |

... if so, then we can discuss some of this in German in the new started "Laser-Ecke" in the German Forum - [forums.reprap.org]

But for the international readers it's better here and in English

For the power-rates - you can change the steps_per_mm setting of the extruder to a faster value -- with the Due the pulse duration is only 0.5 microseconds, so not fast enough for the most drivers to get the power to the set level.

Can you make a scope image of your pulsing ratios?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But for the international readers it's better here and in English

For the power-rates - you can change the steps_per_mm setting of the extruder to a faster value -- with the Due the pulse duration is only 0.5 microseconds, so not fast enough for the most drivers to get the power to the set level.

Can you make a scope image of your pulsing ratios?

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 15, 2015 03:02AM |

Registered: 8 years ago Posts: 5,232 |

More steps also means more pauses, so I tried less steps. The LED only got darker.. It seems the ON time for stepstick related signals is fixed and the OFF time is Bresenham controlled?!

Actually I like the idea of Bresenham controlled Laser power. This way the beginning and end of a trace ( where XY-steppers are in the acceleration/deceleration phase) wouldn't get hotter that the middle of the trace.

But for lasers it should be the ON time that is extended. Maybe I use an optocoupler between STEP and TTL input. It would invert the signal and adds safety.

People who bought ready made laser moduls miss so much fun

-Olaf

Actually I like the idea of Bresenham controlled Laser power. This way the beginning and end of a trace ( where XY-steppers are in the acceleration/deceleration phase) wouldn't get hotter that the middle of the trace.

But for lasers it should be the ON time that is extended. Maybe I use an optocoupler between STEP and TTL input. It would invert the signal and adds safety.

People who bought ready made laser moduls miss so much fun

-Olaf

|

Re: Aixiz acrylic lens? December 15, 2015 04:19AM |

Admin Registered: 16 years ago Posts: 13,886 |

... no, for uniform power distribution over a line with acc-/deccelearion the ON-time should be constant, as this is the only geometric parameter, that counts

The pulse ON-time defines the 'energy density' of the laser when moving - it's essentially the number of pulses per mm and the averaged ON-time of all pulses, regardless, how long it's moving (or what's the averaged OFF-time) to draw the line.

So I'll get the same engravin or cutting result with a file, regardless, if I'm drawing it with 5mm/s without acc/decceleration, or 150mm/s with advanced acc's.

And your LED gets darker with lesser steps, because the ON/OFF ratio changes to longer averaged OFF-time, what's to be expected.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

The pulse ON-time defines the 'energy density' of the laser when moving - it's essentially the number of pulses per mm and the averaged ON-time of all pulses, regardless, how long it's moving (or what's the averaged OFF-time) to draw the line.

So I'll get the same engravin or cutting result with a file, regardless, if I'm drawing it with 5mm/s without acc/decceleration, or 150mm/s with advanced acc's.

And your LED gets darker with lesser steps, because the ON/OFF ratio changes to longer averaged OFF-time, what's to be expected.

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 17, 2015 03:51PM |

Registered: 8 years ago Posts: 5,232 |

Today, I finally tested the red LD from DVD burners instead of the 1W cree LED.

I have no idea how to determine max. power of these?

I ran 0.35A at 2.9V through it and it still got brighter at 0.45A. That's ca. 1W but it didn't feel warm after 5min. of full power. But from what I know, they can only handle 300-400mW.

How do I know the LD has reached it's limit?

Do I have to make a destruction test?

-Olaf

Edited 1 time(s). Last edit at 12/17/2015 03:52PM by o_lampe.

I have no idea how to determine max. power of these?

I ran 0.35A at 2.9V through it and it still got brighter at 0.45A. That's ca. 1W but it didn't feel warm after 5min. of full power. But from what I know, they can only handle 300-400mW.

How do I know the LD has reached it's limit?

Do I have to make a destruction test?

-Olaf

Edited 1 time(s). Last edit at 12/17/2015 03:52PM by o_lampe.

|

Re: Aixiz acrylic lens? December 17, 2015 05:01PM |

Admin Registered: 16 years ago Posts: 13,886 |

... roughly 30% of the electrical power will be converted into laser energy, so you should be at or beyound the max limit of 400mW output power, if this is stated for the diode.

With good cooling you can 'overdrive' the diode, but it will drecrease in lifetime, so better stay below the nominal values.

My wrecked diodes died mostly for overcurrent with melting/evaporating bond wires - when opening the housing and rebonding them, they should work again, when the gold vapour from the bond wires didn't contaminate the emitter surface

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

With good cooling you can 'overdrive' the diode, but it will drecrease in lifetime, so better stay below the nominal values.

My wrecked diodes died mostly for overcurrent with melting/evaporating bond wires - when opening the housing and rebonding them, they should work again, when the gold vapour from the bond wires didn't contaminate the emitter surface

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 18, 2015 02:45AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Aixiz acrylic lens? December 18, 2015 03:35AM |

Admin Registered: 16 years ago Posts: 13,886 |

... this "1A=1W"-RT could be from me too - I have some IR-diodes with 5W@5A and 9W@9A nominal values

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 18, 2015 05:39AM |

Registered: 9 years ago Posts: 346 |

The NDB7875 has an slope efficiency of 1 - 2 W/A. So 1W=1A does not hold at all. Same story (different slope) for my Osram diode.

It is a real headache and I am not sure how to handle it. The slope efficiency also changes with the power.

What I do, is follow the readings made by this guy and matches his currents. So he got 1.6W @ 1.1A.

It is my impression that if you want to push the limits on your diodes, then you need a way to measure the power, no way around it (?). Otherwise stay on the lower currents and keep an eye on the diode temperature.

Oh, no German for me, I am Danish

It is a real headache and I am not sure how to handle it. The slope efficiency also changes with the power.

What I do, is follow the readings made by this guy and matches his currents. So he got 1.6W @ 1.1A.

It is my impression that if you want to push the limits on your diodes, then you need a way to measure the power, no way around it (?). Otherwise stay on the lower currents and keep an eye on the diode temperature.

Oh, no German for me, I am Danish

|

Re: Aixiz acrylic lens? December 18, 2015 06:03PM |

Admin Registered: 16 years ago Posts: 13,886 |

... I have a professional power-meter with a slizium sensor for all wavelengths and powers from Milliwatts to some ten Watts CW or some Kilowatts pulsed, so a max. power spec would be enough to verify the slope or 'age' of a diode.

But for unknown diodes you have to guess ... or perform a 'letal' test to get the physical limits, if you have a bunch of the same type

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

But for unknown diodes you have to guess ... or perform a 'letal' test to get the physical limits, if you have a bunch of the same type

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Aixiz acrylic lens? December 19, 2015 03:57AM |

Registered: 8 years ago Posts: 5,232 |

I have two 2.4x dual layer DVDs and two 12x dual layer DVDs.

I think, I can lethal test one of the 2.4x LDs and be sure, the 12x LD will survive.

Can I use my Alu-heatbed to test CW-power? Aiming the laser close to the thermistor and see how far the temp rises?

-Olaf

Edited 1 time(s). Last edit at 12/19/2015 03:58AM by o_lampe.

I think, I can lethal test one of the 2.4x LDs and be sure, the 12x LD will survive.

Can I use my Alu-heatbed to test CW-power? Aiming the laser close to the thermistor and see how far the temp rises?

-Olaf

Edited 1 time(s). Last edit at 12/19/2015 03:58AM by o_lampe.

|

Re: Aixiz acrylic lens? December 19, 2015 04:16AM |

Registered: 8 years ago Posts: 5,232 |

Just found a 6mm glass collimator lens:

It's much cheaper than any other I've seen. Now I'm wondering if it would fit in the standard M9x0.5 lens holder?

-Olaf

It's much cheaper than any other I've seen. Now I'm wondering if it would fit in the standard M9x0.5 lens holder?

-Olaf

Sorry, only registered users may post in this forum.