Complex LOM-Objects made from laminated steel

Posted by VDX

|

Complex LOM-Objects made from laminated steel September 25, 2007 04:04PM |

Admin Registered: 16 years ago Posts: 13,884 |

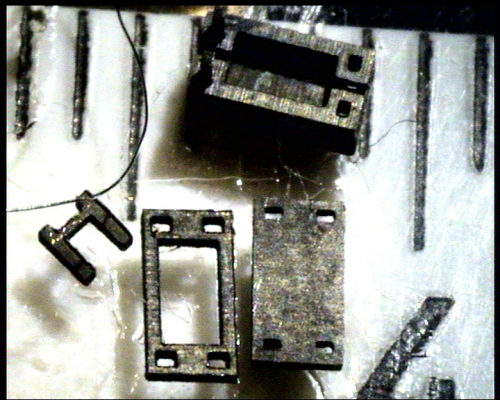

... in the appended image is a sample of a LOM(Laminated-Object-Modelling)-housing, i stacked with lasercutted 0,1mm steel-sheets. The housing is 3x2 millimeters big, has 6 slices and two troughputs for glass-fibres.

I made this as a prototype for a ultraprecise fiber-sensor/switch because of the high-temp form-stability of tempered steel (the milled PEEK-housing, which was used before, was to instable)

You can see the holes on the corners and the H-shaped structure, i inserted for fitting and fixing.

With the same principle you can make every structure from every material, which should only be cutted in the right slices.

A friend of mine has a laser-engraving company, so i can try for free, but normally a legal-sice sheet of every cuttable material would cost 20 to 30 Euros.

With the ability of manually laminating all types of materials to every shape i can build very complex and reliable parts (maybe for heated extruderheads, gears or precise fittings) which normally have to be milled or made with an other expensive process.

This could mean, you download the needed STL-data or the ready parted contour-slices, buy some sheets of Steel or other materials and make a run at your local laser-engraver.

With glueing or soldering the slices to a stable LOM there should be no practical limit in shape or stability ...

Viktor

Edited 1 time(s). Last edit at 03/15/2017 11:40AM by VDX.

I made this as a prototype for a ultraprecise fiber-sensor/switch because of the high-temp form-stability of tempered steel (the milled PEEK-housing, which was used before, was to instable)

You can see the holes on the corners and the H-shaped structure, i inserted for fitting and fixing.

With the same principle you can make every structure from every material, which should only be cutted in the right slices.

A friend of mine has a laser-engraving company, so i can try for free, but normally a legal-sice sheet of every cuttable material would cost 20 to 30 Euros.

With the ability of manually laminating all types of materials to every shape i can build very complex and reliable parts (maybe for heated extruderheads, gears or precise fittings) which normally have to be milled or made with an other expensive process.

This could mean, you download the needed STL-data or the ready parted contour-slices, buy some sheets of Steel or other materials and make a run at your local laser-engraver.

With glueing or soldering the slices to a stable LOM there should be no practical limit in shape or stability ...

Viktor

Edited 1 time(s). Last edit at 03/15/2017 11:40AM by VDX.

|

Re: Complex LOM-Objects made from laminated steel September 25, 2007 04:31PM |

Admin Registered: 17 years ago Posts: 1,487 |

wow, thats a really cool technique. and think... when one day reprap has a laser cutting head, it could make any of these parts itself!

viktor... you sure do know alot about this stuff and have some interesting links. i really hope you stick around with this project for a long time. we may struggle at times with this difficult engineering, but we're driven by a desire and a passion for cool technology like this.

cheers!

viktor... you sure do know alot about this stuff and have some interesting links. i really hope you stick around with this project for a long time. we may struggle at times with this difficult engineering, but we're driven by a desire and a passion for cool technology like this.

cheers!

|

Re: Complex LOM-Objects made from laminated steel September 25, 2007 05:02PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Zach,

... i was playing with rapid prototyping since nearly 30 years, but then the CAD- and encoding-software wasn't really capable and i had to sell my 3D-mill in exchange for other ressources ...

With first attempts in CO2-laser-cutting with a 'cheap' gaslaser for 1.500 DM i invented the LOM-technique for me in 1989 or so, but it wasn't so easy to earn enough money with the selfmade systems and then companies from US and Japan invaded the fairs with professional desiged systems, so i changed my focus.

In '98 i went back to my 'roots' as physicist and now i'm in developing (and inventing) solutions for micro- and nanotech ...

For Lasers in reprap: - last week i found in a link-page infos from a guy, which distracted high-power (200mW) laserdiodes from a DVD-writer and cut holes in plastic-sheets wit it.

I think, this idea is the way to laser-sintering or contour-cutting with the reprap!

When i get some broken DVD-RW's, then i try to sinter some powders or cut plastic-sheets with the RW-laserdiodes ...

Viktor

... i was playing with rapid prototyping since nearly 30 years, but then the CAD- and encoding-software wasn't really capable and i had to sell my 3D-mill in exchange for other ressources ...

With first attempts in CO2-laser-cutting with a 'cheap' gaslaser for 1.500 DM i invented the LOM-technique for me in 1989 or so, but it wasn't so easy to earn enough money with the selfmade systems and then companies from US and Japan invaded the fairs with professional desiged systems, so i changed my focus.

In '98 i went back to my 'roots' as physicist and now i'm in developing (and inventing) solutions for micro- and nanotech ...

For Lasers in reprap: - last week i found in a link-page infos from a guy, which distracted high-power (200mW) laserdiodes from a DVD-writer and cut holes in plastic-sheets wit it.

I think, this idea is the way to laser-sintering or contour-cutting with the reprap!

When i get some broken DVD-RW's, then i try to sinter some powders or cut plastic-sheets with the RW-laserdiodes ...

Viktor

|

Re: Complex LOM-Objects made from laminated steel September 26, 2007 06:32AM |

Registered: 16 years ago Posts: 120 |

Hello!

I though I'd ask a few more stupid questions when we have an export present.

Say you want to build an object of about a cubic centimeter in size.

Then you need to make about 100 laminated plates. How is this all put together?

One steelplate at a time? Or do you trim each plate after it has been placed on the object?

How is the precision achived when aligning the plates?

I though I'd ask a few more stupid questions when we have an export present.

Say you want to build an object of about a cubic centimeter in size.

Then you need to make about 100 laminated plates. How is this all put together?

One steelplate at a time? Or do you trim each plate after it has been placed on the object?

How is the precision achived when aligning the plates?

|

Re: Complex LOM-Objects made from laminated steel September 26, 2007 08:00AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi mimarob,

... for bigger objects i can cut thicker sheets, so the amount of stacking is variable. Maybe in coarser regions without overlapping i use 1 millimeter and in finer segments 10 micron thick laminates ...

The slices are cut out from the sheet and laminated/stacked one after the other.

For high accuracy in the slices are fitting-holes, in which i insert small sticks - e.q. 0,3 mm thick wolfram-pins (from a project with Osram), which are very hard and have a smooth surface, so with a bit smaller holes with square-shape (and a bit more inserting-force ) the fitting can be the fixing/joining of the slices too ...

) the fitting can be the fixing/joining of the slices too ...

The hole-/pin-fitting is best used for manually laminating - if you have a precise automated pick'n-placer, then you can stack the slices without fitting-pins, then the accuracy of the automat and the precise aligning of the slices in the sheet is your limit.

For another highspeed/high-accuracy LOM-process i would have a 'endless' sheet of material, which i laminate on a roll (like a printer-feed or video-tape), glue/fuse the slices together and cut the contour-holes with a cutting laser in the same task.

Then i have an absolute accuracy of the encoder of the roll and of the thickness of the sheets, but the slicing/laminating is not plain, but slightly curved, as the age-rings in a wood-carving ...

Viktor

... for bigger objects i can cut thicker sheets, so the amount of stacking is variable. Maybe in coarser regions without overlapping i use 1 millimeter and in finer segments 10 micron thick laminates ...

The slices are cut out from the sheet and laminated/stacked one after the other.

For high accuracy in the slices are fitting-holes, in which i insert small sticks - e.q. 0,3 mm thick wolfram-pins (from a project with Osram), which are very hard and have a smooth surface, so with a bit smaller holes with square-shape (and a bit more inserting-force

) the fitting can be the fixing/joining of the slices too ...

) the fitting can be the fixing/joining of the slices too ...The hole-/pin-fitting is best used for manually laminating - if you have a precise automated pick'n-placer, then you can stack the slices without fitting-pins, then the accuracy of the automat and the precise aligning of the slices in the sheet is your limit.

For another highspeed/high-accuracy LOM-process i would have a 'endless' sheet of material, which i laminate on a roll (like a printer-feed or video-tape), glue/fuse the slices together and cut the contour-holes with a cutting laser in the same task.

Then i have an absolute accuracy of the encoder of the roll and of the thickness of the sheets, but the slicing/laminating is not plain, but slightly curved, as the age-rings in a wood-carving ...

Viktor

Sorry, only registered users may post in this forum.