single z drive screw?

Posted by Buback

|

single z drive screw? November 29, 2011 04:06PM |

Registered: 13 years ago Posts: 601 |

With a properly constrained z axis, is the second z drive screw and motor(for prusa) or belt(for sells) necessary? The community momentum is going towards lm8uu linear bearings, which, with a properly designed z carriage, should be very well constrained.

Of course, the screw won't be at the center of gravity, so I can imagine some minor torquing about the y axis, but I don't know if it will be enough to cause any binding.

Yes, this would eliminate one motor and screw, making a cheaper machine. But i'm really thinking that it will make moving to acme/trapezoid threaded rod or ballscrew/ballnut cheaper.

That's how I imagine it, at least. What do you think?

Edited 2 time(s). Last edit at 11/29/2011 04:28PM by Buback.

Of course, the screw won't be at the center of gravity, so I can imagine some minor torquing about the y axis, but I don't know if it will be enough to cause any binding.

Yes, this would eliminate one motor and screw, making a cheaper machine. But i'm really thinking that it will make moving to acme/trapezoid threaded rod or ballscrew/ballnut cheaper.

That's how I imagine it, at least. What do you think?

Edited 2 time(s). Last edit at 11/29/2011 04:28PM by Buback.

|

Re: single z drive screw? November 29, 2011 10:46PM |

Registered: 13 years ago Posts: 485 |

|

Re: single z drive screw? November 30, 2011 10:21AM |

Registered: 13 years ago Posts: 601 |

|

Re: single z drive screw? November 30, 2011 10:43AM |

Registered: 13 years ago Posts: 485 |

|

Re: single z drive screw? November 30, 2011 11:13AM |

Registered: 13 years ago Posts: 601 |

I ordered some lm8uu's a week ago, and I'll try when they come in and I've printed appropriate parts.

I have a Sells mendel, and for me the 2 lead screws easily get out of sync and i have to re-align every time i want to print. it's very tedious. As i understand it the prusa design is less susceptible to this issue.

Even if it did sag a couple tenths of a mm, as long as it was consistent (especially as the x carriage moves around) and i could align the print bed to it it would be an improvement for me.

I have a Sells mendel, and for me the 2 lead screws easily get out of sync and i have to re-align every time i want to print. it's very tedious. As i understand it the prusa design is less susceptible to this issue.

Even if it did sag a couple tenths of a mm, as long as it was consistent (especially as the x carriage moves around) and i could align the print bed to it it would be an improvement for me.

|

Re: single z drive screw? November 30, 2011 12:17PM |

Admin Registered: 17 years ago Posts: 7,879 |

How do the lead screws get out of sync on a Sells Mendel? I find the opposite, they can get out of sync on a Prusa but never on my Mendel.

If you remove one of the leadscrews on a Prusa the x-axis droops a few mm at that end.

Not sure why we would want to move to acme/trapezoid threaded rod or ballscrew/ballnut. I attached a digital scale to my Prusa and found the z-axis to be very linear and accurate using cheap stainless steel studding and brass nuts.

[www.hydraraptor.blogspot.com]

If you remove one of the leadscrews on a Prusa the x-axis droops a few mm at that end.

Not sure why we would want to move to acme/trapezoid threaded rod or ballscrew/ballnut. I attached a digital scale to my Prusa and found the z-axis to be very linear and accurate using cheap stainless steel studding and brass nuts.

[www.hydraraptor.blogspot.com]

|

Re: single z drive screw? November 30, 2011 01:14PM |

Registered: 13 years ago Posts: 601 |

Well there was a lot of talk 6 months to a year ago about ball screws and acme screws. ball screws are overkill for the z, but I've seen trapezoidal for about $12/ft which isn't too bad if you only need 1 foot of it. And there's a OpenScad module for printing lead screw nuts on thingiverse, so it might be a cheap future upgrade. I was also thinking it would be smoother, especially with all the weight and friction on one screw.

A few mm is too much. But, maybe have the leadscrew nut on a pivot, with a screw for minor adjustment to the angle?

As for my problem, it seems to be a combination of bad pulleys, binding, improper tensioning, etc. I've spent too much time troubleshooting with little or no improvement, and the next step for me is major renovation, so I'm spending some time trying to think of potentially simpler solutions.

A few mm is too much. But, maybe have the leadscrew nut on a pivot, with a screw for minor adjustment to the angle?

As for my problem, it seems to be a combination of bad pulleys, binding, improper tensioning, etc. I've spent too much time troubleshooting with little or no improvement, and the next step for me is major renovation, so I'm spending some time trying to think of potentially simpler solutions.

|

Re: single z drive screw? November 30, 2011 04:04PM |

Admin Registered: 17 years ago Posts: 7,879 |

I think if you only have one lead screw, but the carriage transfers its significant weight from one end to the other, you would need almost infinite stiffness in the rods and zero play in the bearings to keep the axis from sea-sawing, especially when one considers people are using 0.1mm layers heights and less these days. Even when the x - bars are supported a both ends, there is some sag in the middle.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: single z drive screw? December 01, 2011 03:57AM |

Registered: 13 years ago Posts: 7,616 |

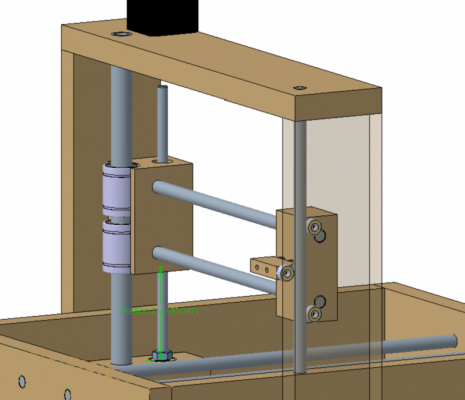

That's just what I designed a few weeks ago. Not a LM8UU, but a LM16UU for increased stiffness. It turned out, complexity isn't reduced as much as one can think, as you still need a vertival rod on the other end - or two very stiff rods at one end. I've put this aside, a double drive mechanism is simpler.

The black box at the top is the stepper motor. The bar in the front is made transparent to view what's behind it. All brown parts are meant to be made from wood. The rod are smooth, except the one below the stepper.

I might be wrong with abandoning this, though. If somebody wants to try the design, I can send a STEP file. The CAD used is proprietary, sorry.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: single z drive screw? December 01, 2011 11:01AM |

Registered: 13 years ago Posts: 601 |

That's a nice design!

I assume you moved the drive screw in order to reduce size and maximize build space per volume, though I would think it's probably stiffer when all the bars are in the same plane.

And i think the undriven side would benefit from a pair of lm8uu instead of the 624 (or whatever) in order to fully constrain that end.

I like the idea of beefing up one of the rods.

I assume you moved the drive screw in order to reduce size and maximize build space per volume, though I would think it's probably stiffer when all the bars are in the same plane.

And i think the undriven side would benefit from a pair of lm8uu instead of the 624 (or whatever) in order to fully constrain that end.

I like the idea of beefing up one of the rods.

|

Re: single z drive screw? December 02, 2011 03:41AM |

Registered: 13 years ago Posts: 7,616 |

If you use LM8UUs on the undriven side you overconstrain the whole thing and you likely get even more issues with sticking. Ideally, the far side is totally free of any vertical rods.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: single z drive screw? December 02, 2011 10:55AM |

Registered: 13 years ago Posts: 601 |

Just a bit off topic, but:

nophead Wrote:

-------------------------------------------------------

> Not sure why we would want to move to

> acme/trapezoid threaded rod or ballscrew/ballnut.

> I attached a digital scale to my Prusa and found

> the z-axis to be very linear and accurate using

> cheap stainless steel studding and brass nuts.

It just hit me that i'm using stainless nuts. Steel on steel has a high CoF. I am using lubricant, though, so maybe this is a non-issue.

Should I try brass or plastic nuts?

nophead Wrote:

-------------------------------------------------------

> Not sure why we would want to move to

> acme/trapezoid threaded rod or ballscrew/ballnut.

> I attached a digital scale to my Prusa and found

> the z-axis to be very linear and accurate using

> cheap stainless steel studding and brass nuts.

It just hit me that i'm using stainless nuts. Steel on steel has a high CoF. I am using lubricant, though, so maybe this is a non-issue.

Should I try brass or plastic nuts?

|

Re: single z drive screw? December 03, 2011 05:52AM |

Registered: 13 years ago Posts: 7,616 |

I happen to have both here  Steel on steel works, but requires very careful lubrication. Oil or simple grease isn't sufficient, this will wear quickly. You want grease with graphite or MoS2 in it.

Steel on steel works, but requires very careful lubrication. Oil or simple grease isn't sufficient, this will wear quickly. You want grease with graphite or MoS2 in it.

Steel on steel works, but requires very careful lubrication. Oil or simple grease isn't sufficient, this will wear quickly. You want grease with graphite or MoS2 in it.

Steel on steel works, but requires very careful lubrication. Oil or simple grease isn't sufficient, this will wear quickly. You want grease with graphite or MoS2 in it.| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

Sorry, only registered users may post in this forum.