Rep(St)rap design

Posted by sid

|

Rep(St)rap design June 25, 2008 02:25PM |

Registered: 17 years ago Posts: 550 |

Hi,

I'm currently ordering some items to build my (yet very) own RepStrap.

The design itself is almost done, based on a 3cm thick chopping board made of PE I'm pretty sure it can also be done in ABS or PCL.

Now I'm wondering if that is a RepStrap (because it should build a complete RepRap) or is it a RepRap (becaus it can duplicate itself too) ?

Well, nevermind what it's called, tell me what you think:

Everything is designed for a simple buildup process, just a saw and a drill(press) and you're ready to go...

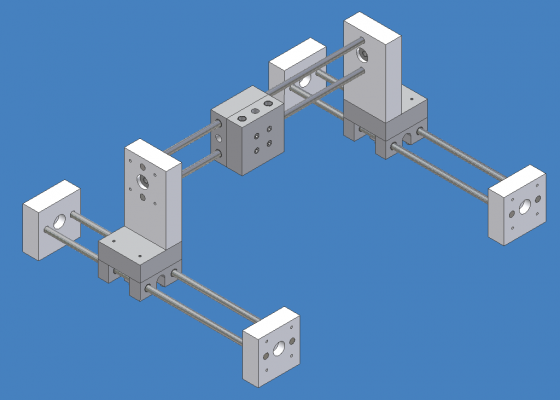

upper isometric view

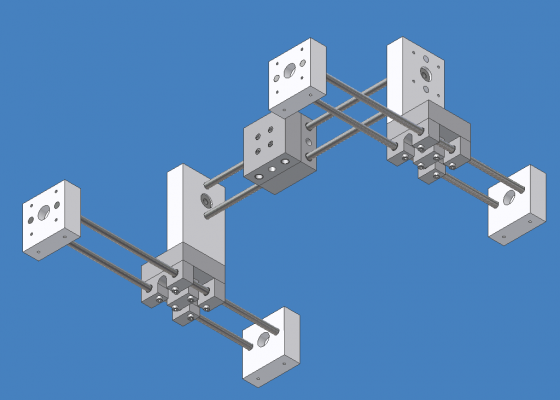

and a look from below:

yeah I know, the z-axis is still missing and there are no lead screws,

also there will be some stiffening for the y-Axis.

If you need to know:

machine travel intended: 400 x 300 x 100 mm

interchangeable tools:

simple dremel (for making the pcbs)

and the v1.1 thermoplast extruder.

'sid

I'm currently ordering some items to build my (yet very) own RepStrap.

The design itself is almost done, based on a 3cm thick chopping board made of PE I'm pretty sure it can also be done in ABS or PCL.

Now I'm wondering if that is a RepStrap (because it should build a complete RepRap) or is it a RepRap (becaus it can duplicate itself too) ?

Well, nevermind what it's called, tell me what you think:

Everything is designed for a simple buildup process, just a saw and a drill(press) and you're ready to go...

upper isometric view

and a look from below:

yeah I know, the z-axis is still missing and there are no lead screws,

also there will be some stiffening for the y-Axis.

If you need to know:

machine travel intended: 400 x 300 x 100 mm

interchangeable tools:

simple dremel (for making the pcbs)

and the v1.1 thermoplast extruder.

'sid

|

Re: Rep(St)rap design June 25, 2008 02:36PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Rep(St)rap design June 25, 2008 02:47PM |

Registered: 17 years ago Posts: 550 |

|

Re: Rep(St)rap design June 26, 2008 07:11AM |

Registered: 16 years ago Posts: 161 |

|

Re: Rep(St)rap design June 26, 2008 08:21AM |

Registered: 17 years ago Posts: 550 |

for the x-Axis ? yes.

but only to synchronize the leadscrews.

But only to not have to mount a fourth stepper.

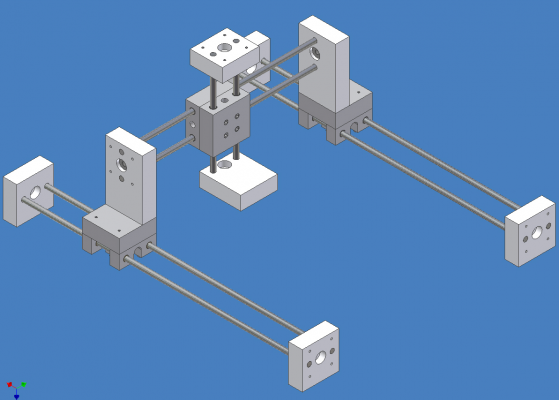

[Update]

Now, guide rails are approximately the correct length and z-Axis is present:

still without leadscrews and Motors and so forth.

Today I'm going to cut and drill my chopping board to pieces (hopefully)

I'll keep you updated

'sid

Edited 1 time(s). Last edit at 07/10/2008 08:15AM by sid.

but only to synchronize the leadscrews.

But only to not have to mount a fourth stepper.

[Update]

Now, guide rails are approximately the correct length and z-Axis is present:

still without leadscrews and Motors and so forth.

Today I'm going to cut and drill my chopping board to pieces (hopefully)

I'll keep you updated

'sid

Edited 1 time(s). Last edit at 07/10/2008 08:15AM by sid.

|

Re: Rep(St)rap design July 21, 2008 02:19PM |

Registered: 17 years ago Posts: 550 |

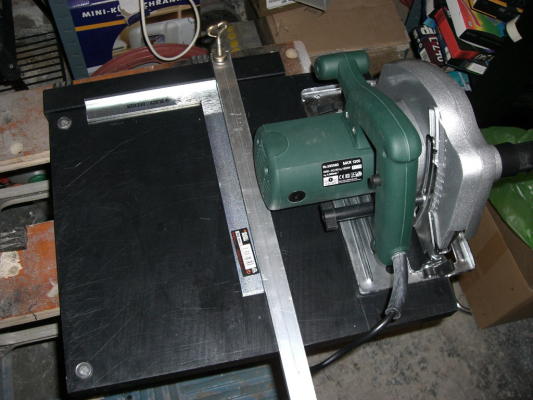

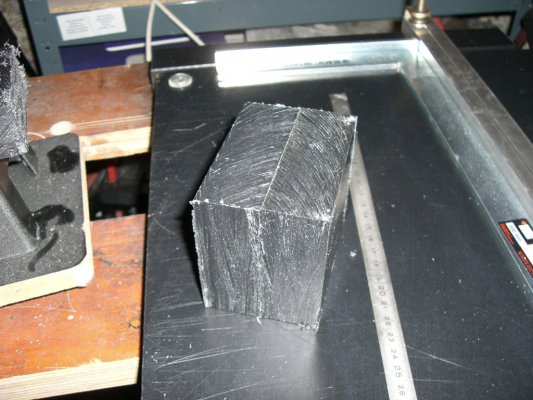

Nasty little bastard (chopping board) clogged my buzz-saw whilst cutting.

(one cut, ten minutes cleaning, another cut, another ten minutes... five times )

)

just a small piece of squared rod as a guide firmly attached

and then the smaller cuts by hand

Nevertheless, it's cut into pieces finally

They wont win no beauty award, but they are good to go.

Next time I'll ask a pro

Don't miss next week when there are black holes, ball bearings and bushings

Wish me luck

'sid

(one cut, ten minutes cleaning, another cut, another ten minutes... five times

)

)just a small piece of squared rod as a guide firmly attached

and then the smaller cuts by hand

Nevertheless, it's cut into pieces finally

They wont win no beauty award, but they are good to go.

Next time I'll ask a pro

Don't miss next week when there are black holes, ball bearings and bushings

Wish me luck

'sid

|

Re: Rep(St)rap design July 21, 2008 03:24PM |

Admin Registered: 16 years ago Posts: 13,886 |

Hi sid,

... 20 years ago i built the cartesian mechanic of a laser-plotter out from white POM/Delrin - your black stuff looks cutted the same way, so i'ts maybe POM too.

When drilling holes, you need a very stable press-drill or the drill-holes wouldn't be exact aligned.

Another question: where are you located? - when in Germany (as your images imply), then maybe i can help you with some spare parts and a CNC-mill ...

Viktor

... 20 years ago i built the cartesian mechanic of a laser-plotter out from white POM/Delrin - your black stuff looks cutted the same way, so i'ts maybe POM too.

When drilling holes, you need a very stable press-drill or the drill-holes wouldn't be exact aligned.

Another question: where are you located? - when in Germany (as your images imply), then maybe i can help you with some spare parts and a CNC-mill ...

Viktor

|

Re: Rep(St)rap design July 21, 2008 06:34PM |

Registered: 17 years ago Posts: 550 |

|

Re: Rep(St)rap design July 22, 2008 03:42AM |

Admin Registered: 16 years ago Posts: 13,886 |

Sorry, only registered users may post in this forum.