Bed Corner for a Larger Build Volume

Posted by Andromodon

|

Bed Corner for a Larger Build Volume July 27, 2008 07:57PM |

Registered: 15 years ago Posts: 83 |

The current RepRap design, as fantastic as it is, does not seem to use the space it occupies as efficiently as it could. The build platform is 40cm x 40cm, and only about 25cm x 22 cm of it can be printed on (34%). Furthermore, while it looks at first glance like the bed should be able to go up and down a good 30cm or so, the Z pullies and printing head restrict the usable height to about half as much. In all, for machine that is 40cm on each side (measuring the smooth bars that make up the edges of the cube), only 18% of its volume can be printed in.

Here is one idea that might help improve this spec:

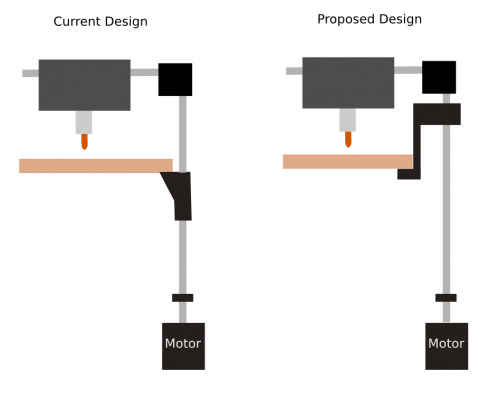

How about a bed corner that embraces the fact that our main obstacles on each end of the Z-axis, are complementary in nature? While the pullies and motor are on the outside of the bed, the extruder is on the inside. Therefore, a bracket that held its nuts up high to interface with the Z-posts, but held the printing bed down low, would have some advantages. Here is a very rough 2D sketch of what I'm talking about:

Such a bed corner would allow the build platform to lower all the way to the bottom of the machine without hitting the Z pullies or motor. Also, when the bed is in its top-most position, limited by the bed bracket bumping against the top corner bracket, the bed could just touch the extruder nozzle. While the bed would have to be slightly smaller to make room for the motor, the edges of the platform are not being printed on anyway, so a slightly smaller board would not impact the usable print area.

What do you think?

Here is one idea that might help improve this spec:

How about a bed corner that embraces the fact that our main obstacles on each end of the Z-axis, are complementary in nature? While the pullies and motor are on the outside of the bed, the extruder is on the inside. Therefore, a bracket that held its nuts up high to interface with the Z-posts, but held the printing bed down low, would have some advantages. Here is a very rough 2D sketch of what I'm talking about:

Such a bed corner would allow the build platform to lower all the way to the bottom of the machine without hitting the Z pullies or motor. Also, when the bed is in its top-most position, limited by the bed bracket bumping against the top corner bracket, the bed could just touch the extruder nozzle. While the bed would have to be slightly smaller to make room for the motor, the edges of the platform are not being printed on anyway, so a slightly smaller board would not impact the usable print area.

What do you think?

|

Re: Bed Corner for a Larger Build Volume July 27, 2008 09:03PM |

Admin Registered: 17 years ago Posts: 1,915 |

|

Re: Bed Corner for a Larger Build Volume July 27, 2008 09:07PM |

Registered: 16 years ago Posts: 370 |

|

Re: Bed Corner for a Larger Build Volume July 28, 2008 09:15AM |

Registered: 15 years ago Posts: 100 |

Very elegant.

The bracket will need to be rigid enough to avoid it flexing and then binding on the support.

kyle: if it works it could be used to make the machine smaller, if the printing area is already large enough.

The bracket will need to be rigid enough to avoid it flexing and then binding on the support.

kyle: if it works it could be used to make the machine smaller, if the printing area is already large enough.

|

Re: Bed Corner for a Larger Build Volume July 28, 2008 09:50AM |

Admin Registered: 16 years ago Posts: 13,884 |

... i'm thinking about a completely 'bed-less' construction, where the robot elevates himself with three rotating threaded rods.

Then you can use any plane surface you find, eventually lay a cover-sheet under for better adhesion and/or shielding the table-top.

Position the fabber with the extruder-tip touching the surface and let it roll ...

Viktor

Then you can use any plane surface you find, eventually lay a cover-sheet under for better adhesion and/or shielding the table-top.

Position the fabber with the extruder-tip touching the surface and let it roll ...

Viktor

|

Re: Bed Corner for a Larger Build Volume July 28, 2008 09:53AM |

Admin Registered: 17 years ago Posts: 7,879 |

The current brackets are deep enough for two nuts and a spring for anti-backlash. This does not seem necessary because gravity provides the anti-backlash on earth. Indeed I found the second nuts caused binding because studding is never very straight. Simply making the brackets flat would get a bit more travel without any loss in lateral rigidity. It would also reduce the build time significantly.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 12:10PM |

Registered: 16 years ago Posts: 622 |

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 12:18PM |

Registered: 17 years ago Posts: 550 |

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 12:24PM |

Registered: 15 years ago Posts: 78 |

Yes, its a goo idea.

To get over peteredworthy's bending issue simply add some webs (although this will be a compromise to clear the belt wheel and belt).

A compromise would simply to mount the build table and current brackets upside-down. THis would need the support nut/backlash spring reversing.

Also, is there any reason why the Z pulleys&belt cant be moved up to the top of the M8 studding ?

To get over peteredworthy's bending issue simply add some webs (although this will be a compromise to clear the belt wheel and belt).

A compromise would simply to mount the build table and current brackets upside-down. THis would need the support nut/backlash spring reversing.

Also, is there any reason why the Z pulleys&belt cant be moved up to the top of the M8 studding ?

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 12:34PM |

Registered: 17 years ago Posts: 550 |

I'm unsure if the antibacklash system is needed at all..

see, gravity will force the table down no matter what.

As you say compromise...

a compromise would be having the Driveing nut FLAT with the table, and because of gravity ( ) just ONE hole in the build table (per corner for sure) and one of those:

) just ONE hole in the build table (per corner for sure) and one of those:

maybe ?

because the studding isn't fixed at the top, I think there will be a problem with tension of the belt.

'sid

Edited 2 time(s). Last edit at 08/03/2008 12:36PM by sid.

see, gravity will force the table down no matter what.

As you say compromise...

a compromise would be having the Driveing nut FLAT with the table, and because of gravity (

) just ONE hole in the build table (per corner for sure) and one of those:

) just ONE hole in the build table (per corner for sure) and one of those:maybe ?

because the studding isn't fixed at the top, I think there will be a problem with tension of the belt.

'sid

Edited 2 time(s). Last edit at 08/03/2008 12:36PM by sid.

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 12:49PM |

Registered: 15 years ago Posts: 78 |

Sid, if the pulleys are moved up, move the little stays up too - they are designed to resist that inward pull from the belt. OR put the tops of the M8 threads into the upper corner blocks and not all the way through the bottom ones and dump the fiddly brackets.

As you say- gravity is our friend.

My repstrap Z axis is going to use 2 toothed belts in a figure 8 on each side of the build platform. (much like people have discussed using drafting machine wires). I have 8 small pulleys (not inexpensive) and four drive shafts. It is like the two Y belts, but two sets above each other and the table is to be clamped to the vertical sections of the belts.

I havnt decided if I will use one M8 drive on one side (the other crners will be synchronised by the belts) or to use a high ratio belt drive onto the end of one of the shafts. As nophead pointed out somwhere - he uses a rapid Z to lift the nozzle clear for moves - not so possible with a M8 (1.5mm/rev) feedscrew.

As you say- gravity is our friend.

My repstrap Z axis is going to use 2 toothed belts in a figure 8 on each side of the build platform. (much like people have discussed using drafting machine wires). I have 8 small pulleys (not inexpensive) and four drive shafts. It is like the two Y belts, but two sets above each other and the table is to be clamped to the vertical sections of the belts.

I havnt decided if I will use one M8 drive on one side (the other crners will be synchronised by the belts) or to use a high ratio belt drive onto the end of one of the shafts. As nophead pointed out somwhere - he uses a rapid Z to lift the nozzle clear for moves - not so possible with a M8 (1.5mm/rev) feedscrew.

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 01:39PM |

Registered: 17 years ago Posts: 550 |

M8 is 1.25mm/rev  at least all mine are.

at least all mine are.

Nevermind, bad if speed is needed,

But afair nophead lifts the nozzle by 0.4mm to clear,

that would be 64 steps.. with a 200step/rev stepper or 128 with the 400 step/rev stepper.

I think that shouldn't take too long

the controler is capable of at least 1500 pulses/sec (halfsteps or steps)

so it'll take a tenth of a second to raise or lower the plattform.

'sid

Edited 1 time(s). Last edit at 08/03/2008 01:42PM by sid.

at least all mine are.

at least all mine are.Nevermind, bad if speed is needed,

But afair nophead lifts the nozzle by 0.4mm to clear,

that would be 64 steps.. with a 200step/rev stepper or 128 with the 400 step/rev stepper.

I think that shouldn't take too long

the controler is capable of at least 1500 pulses/sec (halfsteps or steps)

so it'll take a tenth of a second to raise or lower the plattform.

'sid

Edited 1 time(s). Last edit at 08/03/2008 01:42PM by sid.

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 02:32PM |

Registered: 15 years ago Posts: 78 |

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 05:22PM |

Registered: 15 years ago Posts: 83 |

|

Re: Bed Corner for a Larger Build Volume August 03, 2008 05:35PM |

Registered: 15 years ago Posts: 83 |

sid Wrote:

-------------------------------------------------------

> it surely is!

>

> On the other hand that may (or may not) reduce the

> working volume by reducing the x*y table because

> of the cutouts (motor, cogwheels, the belt

> itself).

I'm not sure what you mean by cutouts, but it is my understanding that reducing the build platform by the necessary amount (about 2.5cm +- .5cm) would not significantly reduce the working volume. At least on my RepRap, the printing head cannot print within 3.5cm of three sides of the platform. On the fourth side, it's closer, but it's about 2.75cm away. At most we'd loose a couple tenths of a cm on one edge, in my judgment. Can anyone back me up on this?

-------------------------------------------------------

> it surely is!

>

> On the other hand that may (or may not) reduce the

> working volume by reducing the x*y table because

> of the cutouts (motor, cogwheels, the belt

> itself).

I'm not sure what you mean by cutouts, but it is my understanding that reducing the build platform by the necessary amount (about 2.5cm +- .5cm) would not significantly reduce the working volume. At least on my RepRap, the printing head cannot print within 3.5cm of three sides of the platform. On the fourth side, it's closer, but it's about 2.75cm away. At most we'd loose a couple tenths of a cm on one edge, in my judgment. Can anyone back me up on this?

|

Re: Bed Corner for a Larger Build Volume August 04, 2008 08:23AM |

Registered: 17 years ago Posts: 550 |

> but ...reducing the build platform

> by the necessary amount (about 2.5cm +- .5cm)

> would not significantly reduce the working volume.

> At least on my RepRap, the printing head cannot

> print within 3.5cm of three sides of the platform.

> On the fourth side, it's closer, but it's about

> 2.75cm away.

That's what I meant,

and first of all that's what I meant with "may not" too

Good to know!

'sid

> by the necessary amount (about 2.5cm +- .5cm)

> would not significantly reduce the working volume.

> At least on my RepRap, the printing head cannot

> print within 3.5cm of three sides of the platform.

> On the fourth side, it's closer, but it's about

> 2.75cm away.

That's what I meant,

and first of all that's what I meant with "may not" too

Good to know!

'sid

|

Re: Bed Corner for a Larger Build Volume August 04, 2008 07:04PM |

Registered: 15 years ago Posts: 83 |

|

Re: Bed Corner for a Larger Build Volume August 05, 2008 03:26AM |

Registered: 16 years ago Posts: 293 |

Very simple change, but very effective at improving the RepRap. Good thinking Andy! It's also nice to see a part reviewed by the entire group. I think that out of such discussions, there always comes a much better solution.

On this subject: I remember nophead saying that he discussed his 4 stepper approach (no belt drive and pulleys) and that the motors might fit well on the top brackets, creating more room at the bottom. Since "there's Plenty of Room at the Bottom"...

[en.wikipedia.org]

(Feynmann had already envisioned a nano-scale building reprap, I guess)

Fun quote from that lecture (linked at wikipedia):

"Well, I pointed out a few of the economic applications, but I know that the reason that you would do it might be just for fun. But have some fun! Let's have a competition between laboratories. Let one laboratory make a tiny motor which it sends to another lab which sends it back with a thing that fits inside the shaft of the first motor."

But don't let my hyjack your thread though

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

On this subject: I remember nophead saying that he discussed his 4 stepper approach (no belt drive and pulleys) and that the motors might fit well on the top brackets, creating more room at the bottom. Since "there's Plenty of Room at the Bottom"...

[en.wikipedia.org]

(Feynmann had already envisioned a nano-scale building reprap, I guess)

Fun quote from that lecture (linked at wikipedia):

"Well, I pointed out a few of the economic applications, but I know that the reason that you would do it might be just for fun. But have some fun! Let's have a competition between laboratories. Let one laboratory make a tiny motor which it sends to another lab which sends it back with a thing that fits inside the shaft of the first motor."

But don't let my hyjack your thread though

Regards,

Erik de Bruijn

[Ultimaker.com] - [blog.erikdebruijn.nl]

Sorry, only registered users may post in this forum.