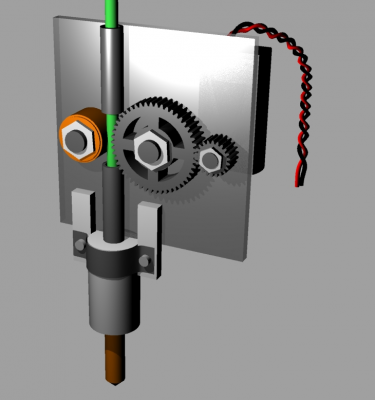

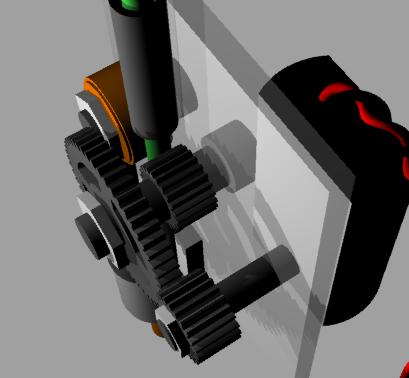

Extruder Head without printed parts - concept

Posted by jeffpark_

|

Extruder Head without printed parts - concept March 10, 2009 04:51PM |

Registered: 16 years ago Posts: 106 |

Hello All!

So far my attempts to make a new extruder that works for more than a day have not been successful. I modeled this up in some free time today and was wondering if some of you could give me some feedback before I spend all the time into actually building this thing.

My goal is to build an extruder with parts I already have and without any printed parts. This extruder is based on the 2.0 extruder as well (although I'm using the old solarbotics motor).

The back plate would be made of some sturdy material (lexan / aluminum / steel) that I have in abundance. Gears would be salvaged...most likely from busted drills. The tubes would probably be steel tubes. The gold thing is an extra skate bearing I have from building my repstrap. I have two or three nozzle/heater barrels working so that part is already complete.

The main problem I have with my design is attaching the heater to the rest of it. Any ideas on where I can improve?

Another concern was the speed of the motor, the gear ratio could be adjusted; this is just a proof of concept to better visualize the design.

Thanks!

Edit for spelling...

Edited 4 time(s). Last edit at 04/22/2009 04:57PM by Jeff.

----

[www.binaryconstruct.com]

So far my attempts to make a new extruder that works for more than a day have not been successful. I modeled this up in some free time today and was wondering if some of you could give me some feedback before I spend all the time into actually building this thing.

My goal is to build an extruder with parts I already have and without any printed parts. This extruder is based on the 2.0 extruder as well (although I'm using the old solarbotics motor).

The back plate would be made of some sturdy material (lexan / aluminum / steel) that I have in abundance. Gears would be salvaged...most likely from busted drills. The tubes would probably be steel tubes. The gold thing is an extra skate bearing I have from building my repstrap. I have two or three nozzle/heater barrels working so that part is already complete.

The main problem I have with my design is attaching the heater to the rest of it. Any ideas on where I can improve?

Another concern was the speed of the motor, the gear ratio could be adjusted; this is just a proof of concept to better visualize the design.

Thanks!

Edit for spelling...

Edited 4 time(s). Last edit at 04/22/2009 04:57PM by Jeff.

----

[www.binaryconstruct.com]

|

Re: Extruder Head without printed parts - concept March 10, 2009 06:11PM |

Admin Registered: 17 years ago Posts: 7,879 |

The feed rate is in the order of about 0.5 mm/s so the GM3 will be way too fast. You need at least one more pair of gears or a worm drive I think.

The big gear doesn't do much other than increase the contact area of the teeth.

If that is PTFE you will struggle to clamp it with friction alone. Some designs use a flange at the top. Some put screws or pins through it.

[www.hydraraptor.blogspot.com]

The big gear doesn't do much other than increase the contact area of the teeth.

If that is PTFE you will struggle to clamp it with friction alone. Some designs use a flange at the top. Some put screws or pins through it.

[www.hydraraptor.blogspot.com]

|

Re: Extruder Head without printed parts - concept March 11, 2009 11:45AM |

Registered: 16 years ago Posts: 106 |

|

Re: Extruder Head without printed parts - concept March 11, 2009 11:49AM |

Admin Registered: 17 years ago Posts: 7,879 |

On a lathe with a knurling tool. [blog.reprap.org]

I have been experimenting with a splined shaft, which has the advantage that you can buy stepper motors already splined.

It gives resonable grip with ABS but doesn't seem to grip PCL very well at all, which is probably why pinch wheel was originally dropped in favour of threaded drive. PCL is both soft and slippery and needs more force to extrude compared to ABS.

Edited 2 time(s). Last edit at 03/11/2009 11:52AM by nophead.

[www.hydraraptor.blogspot.com]

I have been experimenting with a splined shaft, which has the advantage that you can buy stepper motors already splined.

It gives resonable grip with ABS but doesn't seem to grip PCL very well at all, which is probably why pinch wheel was originally dropped in favour of threaded drive. PCL is both soft and slippery and needs more force to extrude compared to ABS.

Edited 2 time(s). Last edit at 03/11/2009 11:52AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Extruder Head without printed parts - concept March 11, 2009 12:26PM |

Registered: 15 years ago Posts: 401 |

|

Re: Extruder Head without printed parts - concept March 11, 2009 01:37PM |

Admin Registered: 17 years ago Posts: 1,915 |

Annirak: I think you need to take another look at that big gear and how it moves. Using the small gear to turn the big one will indeed slow down the rotational rate of the shaft. The angular velocity at the edge of the big gear, however, will be the same as your small gear.

If you mount a small gear on the same shaft as your big gear and use that to move the filament you will, I think, get the much reduced angular velocity that you are looking for.

I've been designing and milling a LOT of gears lately. I've made MORE than a few mistakes like that in the past couple of months. Hell, I usually didn't catch the mistakes till I'd actually built the gear series and was moving it my hand.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

If you mount a small gear on the same shaft as your big gear and use that to move the filament you will, I think, get the much reduced angular velocity that you are looking for.

I've been designing and milling a LOT of gears lately. I've made MORE than a few mistakes like that in the past couple of months. Hell, I usually didn't catch the mistakes till I'd actually built the gear series and was moving it my hand.

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Extruder Head without printed parts - concept March 11, 2009 01:50PM |

Registered: 15 years ago Posts: 88 |

I've been working on something similar, intended to be driven by a stepper.

I believe I may have come up with a new thermal break (at any rate I haven't seen anyone else talk about having made anything like it, though I'm sure it's been suggested at one point) that you may want to consider - I have an airgap of about 2/3" (which could be made a lot less, I'm still experimenting) between my hot zone and a wood block (I recommend oak if you want to try it) with a hole in it the filament runs through. The welding tip is mounted to 1/16" aluminum, with two 4-40 threaded rod (couldn't get bolts long enough at the local hardware store) holding it out from the wood. As a result my hot zone is exactly the length of the welding tip and in hand-driven testing the wooden block remains safe to touch.

Currently I'm set up with 4 ohms of nichrome wrapped on a welding tip with ultra-high temperature RTV silicone to hold it on, it seems to work well.

Btw, the steel tubes are kind of excessive - much heavier than necessary for what they're doing.

I believe I may have come up with a new thermal break (at any rate I haven't seen anyone else talk about having made anything like it, though I'm sure it's been suggested at one point) that you may want to consider - I have an airgap of about 2/3" (which could be made a lot less, I'm still experimenting) between my hot zone and a wood block (I recommend oak if you want to try it) with a hole in it the filament runs through. The welding tip is mounted to 1/16" aluminum, with two 4-40 threaded rod (couldn't get bolts long enough at the local hardware store) holding it out from the wood. As a result my hot zone is exactly the length of the welding tip and in hand-driven testing the wooden block remains safe to touch.

Currently I'm set up with 4 ohms of nichrome wrapped on a welding tip with ultra-high temperature RTV silicone to hold it on, it seems to work well.

Btw, the steel tubes are kind of excessive - much heavier than necessary for what they're doing.

|

Re: Extruder Head without printed parts - concept March 11, 2009 02:50PM |

Registered: 16 years ago Posts: 106 |

Steel was just something I had laying around, I'm trying to design something without buying anything...a near impossible task.

You are right about the gears, I hadn't though of that. I may have to dig through some boxes for parts.Quote

If you mount a small gear on the same shaft as your big gear and use that to move the filament you will, I think, get the much reduced angular velocity that you are looking for.

|

Re: Extruder Head without printed parts - concept March 11, 2009 02:55PM |

Registered: 16 years ago Posts: 106 |

|

Re: Extruder Head without printed parts - concept March 11, 2009 03:04PM |

Registered: 15 years ago Posts: 401 |

Forrest Higgs Wrote:

-------------------------------------------------------

> Annirak: I think you need to take another look at

> that big gear and how it moves.

Mistaken identity?

> If you mount a small gear on the same shaft as

> your big gear and use that to move the filament

> you will, I think, get the much reduced angular

> velocity that you are looking for.

Yep. And to expand on that,

The velocity of the large gear (call it teeth per second) is exactly the same as the velocity of the small gear. You're looking to use a gear ratio to lower the velocity of the filament and increase the force applied to the filament. To accomplish this, you need a reduction gear, which is the combination of a large gear and a small gear on the same shaft. You drive the large gear with the motor and use the small gear to drive either the filament or another gear if that makes the design easier (I think it will).

For ease of integrating the gears and the filament feed together, I would recommend using this sequence:

Motor drive gear -> (large-side) reduction gear (small-side) -> transfer gear -> filament.

If you want to reduce the velocity using a more reliable method, which requires less holding torque, I suggest replacing the reduction gear with a worm gear arrangement. Or you could apply the worm gear directly to the filament. Hey, look, it's a Darwin extruder!

Edited 1 time(s). Last edit at 03/11/2009 05:21PM by Annirak.

-------------------------------------------------------

> Annirak: I think you need to take another look at

> that big gear and how it moves.

Mistaken identity?

> If you mount a small gear on the same shaft as

> your big gear and use that to move the filament

> you will, I think, get the much reduced angular

> velocity that you are looking for.

Yep. And to expand on that,

The velocity of the large gear (call it teeth per second) is exactly the same as the velocity of the small gear. You're looking to use a gear ratio to lower the velocity of the filament and increase the force applied to the filament. To accomplish this, you need a reduction gear, which is the combination of a large gear and a small gear on the same shaft. You drive the large gear with the motor and use the small gear to drive either the filament or another gear if that makes the design easier (I think it will).

For ease of integrating the gears and the filament feed together, I would recommend using this sequence:

Motor drive gear -> (large-side) reduction gear (small-side) -> transfer gear -> filament.

If you want to reduce the velocity using a more reliable method, which requires less holding torque, I suggest replacing the reduction gear with a worm gear arrangement. Or you could apply the worm gear directly to the filament. Hey, look, it's a Darwin extruder!

Edited 1 time(s). Last edit at 03/11/2009 05:21PM by Annirak.

|

Re: Extruder Head without printed parts - concept March 11, 2009 03:05PM |

Registered: 15 years ago Posts: 401 |

|

Re: Extruder Head without printed parts - concept March 11, 2009 03:51PM |

Admin Registered: 17 years ago Posts: 1,915 |

Annirak Wrote:

-------------------------------------------------------

> Forrest Higgs Wrote:

> --------------------------------------------------

> -----

> > Annirak: I think you need to take another look

> at

> > that big gear and how it moves.

>

Sorry... I should have said "Jeff" up there. {cleans reading glasses}

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

-------------------------------------------------------

> Forrest Higgs Wrote:

> --------------------------------------------------

> -----

> > Annirak: I think you need to take another look

> at

> > that big gear and how it moves.

>

Sorry... I should have said "Jeff" up there. {cleans reading glasses}

-------------------------------------------------------

Hell, there are no rules here - we're trying to accomplish something.

Opportunity is missed by most people because it is dressed in overalls and looks like work.

Thomas A. Edison

|

Re: Extruder Head without printed parts - concept March 11, 2009 04:48PM |

Registered: 16 years ago Posts: 106 |

The main problem I've had with worm gear drives is friction increasing the force needed to push the filament. I have no way of extruding an extruder, and the materials I have used aren't slippery enough once you get enough pressure to hold the filament against the worm drive without excess slipping.

Perhaps I could modify my v1-ish extruder to use a skate bearing or two to apply the pressure instead of the main structure pressing against the filament.

Perhaps I could modify my v1-ish extruder to use a skate bearing or two to apply the pressure instead of the main structure pressing against the filament.

|

Re: Extruder Head without printed parts - concept March 11, 2009 05:19PM |

Registered: 15 years ago Posts: 401 |

jeffpark_ Wrote:

-------------------------------------------------------

> The main problem I've had with worm gear drives is

> friction increasing the force needed to push the

> filament. I have no way of extruding an extruder,

> and the materials I have used aren't slippery

> enough once you get enough pressure to hold the

> filament against the worm drive without excess

> slipping.

Jeff,

I like pinch-wheel extruders. I think they're a better solution, in general, they're easier to make, etc. That being said, the mechanism in a worm-gear extruder should be simpler, which was the point I was trying to make.

For your situation, I would say that the best bet is the pinch-wheel extruder. I There are a couple things to take into account when you design it, though:

1) A worm gear is simpler than a reduction gear. The a worm gear directly on the motor would replace the motor gear and the reduction gear.

2) The drive gear which contacts the feedstock must have an extra strong axle and bearing because, in addition to the forces the gearing creates, it has the pressure against the feedstock. This makes for considerable force on the feed gear. This is the reason that I suggested a transfer gear, you could use a heavy bearing and brace the transfer gear from both sides.

Annirak

-------------------------------------------------------

> The main problem I've had with worm gear drives is

> friction increasing the force needed to push the

> filament. I have no way of extruding an extruder,

> and the materials I have used aren't slippery

> enough once you get enough pressure to hold the

> filament against the worm drive without excess

> slipping.

Jeff,

I like pinch-wheel extruders. I think they're a better solution, in general, they're easier to make, etc. That being said, the mechanism in a worm-gear extruder should be simpler, which was the point I was trying to make.

For your situation, I would say that the best bet is the pinch-wheel extruder. I There are a couple things to take into account when you design it, though:

1) A worm gear is simpler than a reduction gear. The a worm gear directly on the motor would replace the motor gear and the reduction gear.

2) The drive gear which contacts the feedstock must have an extra strong axle and bearing because, in addition to the forces the gearing creates, it has the pressure against the feedstock. This makes for considerable force on the feed gear. This is the reason that I suggested a transfer gear, you could use a heavy bearing and brace the transfer gear from both sides.

Annirak

|

Re: Extruder Head without printed parts - concept March 11, 2009 05:44PM |

Admin Registered: 17 years ago Posts: 7,879 |

Quote

The main problem I've had with worm gear drives is friction increasing the force needed to push the filament. I have no way of extruding an extruder, and the materials I have used aren't slippery enough once you get enough pressure to hold the filament against the worm drive without excess slipping.

The ideal material to push against seems to be HDPE. It is almost as slippery as PTFE but much harder. Sharpening the drive screw thread reduces the force and hence the friction. Also angling it so that the thread bites gradually helps a lot. Only a few mm of engaged thread is needed.

[www.hydraraptor.blogspot.com]

|

Re: Extruder Head without printed parts - concept March 15, 2009 10:24AM |

Registered: 15 years ago Posts: 52 |

Just wanted to let you know that I was pretty intrigued by your idea and after I couple hours in the machine shop yesterday I got a working prototype using just some sheet metal, hollowed out 8mm rod, and one piece of scrap aluminum. I'll post pics in a few days once I get around to testing it

[cpwebste.blogspot.com]

[cpwebste.blogspot.com]

|

Re: Extruder Head without printed parts - concept March 15, 2009 02:06PM |

Registered: 16 years ago Posts: 29 |

I have just built a pinch wheel extruder using a stepper a bracket from B and Q, two pieces of turned down brass bar and several nuts and bolts. It works pretty well and was easy to make. See my blog for details- one key part was using the tap in the lathe to machine a surface on the gear as this keeps the plastic in a groove (as by Andy Kirby (http://kirbyandco.blogspot.com/2009/01/cutting-worm-gears-on-lathe.html).

I found that any DC motor I used - no matter on the gearing or the size had a variable feedrate under load thus giving poor quality. Stepppers or DC motors with feedback seem to me to be the best way foward.

See my blog for details.[emcreprap.blogspot.com]

Andy

I found that any DC motor I used - no matter on the gearing or the size had a variable feedrate under load thus giving poor quality. Stepppers or DC motors with feedback seem to me to be the best way foward.

See my blog for details.[emcreprap.blogspot.com]

Andy

|

Re: Extruder Head without printed parts - concept April 21, 2009 11:37PM |

Registered: 15 years ago Posts: 62 |

Kind of unrelated but, What CAD did you use to design this? It looks much better than anything I can seem to make in AOI or Blender (though I know blender has this functionality I just dont know how to use it). The extruder looks good to me but I probably dont know what I'm talking about  .

.

_______________________________________________________________________________________________________

Yes my Avatar is My RepStrap.....Isn't it pretty

For the latest Updates check my main site [www.repstrap.weebly.com] or my blog [www.pingiscoolest.blogspot.com].

.

._______________________________________________________________________________________________________

Yes my Avatar is My RepStrap.....Isn't it pretty

For the latest Updates check my main site [www.repstrap.weebly.com] or my blog [www.pingiscoolest.blogspot.com].

|

Re: Extruder Head without printed parts - concept April 22, 2009 11:32AM |

Registered: 16 years ago Posts: 106 |

|

Re: Extruder Head without printed parts - concept April 22, 2009 10:55PM |

Registered: 15 years ago Posts: 62 |

Thanks for the info Jeff ill check into it

EDIT: Now that I have checked into it I guess I will be sticking to blender, though I probably qualify for the educational version ($195), that is about $185 out of my price range (I have a very low budget). Anyway thanks for the info.

(I have a very low budget). Anyway thanks for the info.

Edited 1 time(s). Last edit at 04/22/2009 11:02PM by pingiscoolest.

_______________________________________________________________________________________________________

Yes my Avatar is My RepStrap.....Isn't it pretty

For the latest Updates check my main site [www.repstrap.weebly.com] or my blog [www.pingiscoolest.blogspot.com].

EDIT: Now that I have checked into it I guess I will be sticking to blender, though I probably qualify for the educational version ($195), that is about $185 out of my price range

(I have a very low budget). Anyway thanks for the info.

(I have a very low budget). Anyway thanks for the info.Edited 1 time(s). Last edit at 04/22/2009 11:02PM by pingiscoolest.

_______________________________________________________________________________________________________

Yes my Avatar is My RepStrap.....Isn't it pretty

For the latest Updates check my main site [www.repstrap.weebly.com] or my blog [www.pingiscoolest.blogspot.com].

Sorry, only registered users may post in this forum.