|

Accuracies and Flatness May 29, 2009 08:30AM |

Registered: 16 years ago Posts: 113 |

I haven't seen much information on this lately, so are we (probably mostly nophead) still seeing bowing in large objects?

I'm working on a conceptual RepRap design that is similar to the triangular frame on the new Reprap concept. However, it involves each side being made of two right angle triangles. Between the uprights in the center of the triangles we have the vertical lifts clamped. The triangles have flanges for fixturing to the Z axis screws and to underside braces. Some screws may be used, but hopefully many connections can be built using U shaped snap clips and thin plastic shims. The insides of the triangles should have HDPE shoes so that they can be used for linear slides for the bed.

The trick is that I'm trying to make sure that all components can be built on the bed. This should allow reduction of hardware to a few screws and the motion drive hardware itself. It all depends on whether we can get consisten dimensional accuracy, and make certain that the longest part fits cross-wise on the bed build-area.

I'll add drawings when I have a chance to finish the rough initial design.

I also have another idea that may be interesting. It's a partial delta robot. Take the bed and put two screws on it. Put each side on a parallelogram hinge facing opposite ways. Drive the two screws in the same direction and you get bed lateral motion. Drive the screws in opposite directions, and you get bed vertical motion. With the reprap needing 2.5D motion, this could easily make a collapsible reprap.

I'm working on a conceptual RepRap design that is similar to the triangular frame on the new Reprap concept. However, it involves each side being made of two right angle triangles. Between the uprights in the center of the triangles we have the vertical lifts clamped. The triangles have flanges for fixturing to the Z axis screws and to underside braces. Some screws may be used, but hopefully many connections can be built using U shaped snap clips and thin plastic shims. The insides of the triangles should have HDPE shoes so that they can be used for linear slides for the bed.

The trick is that I'm trying to make sure that all components can be built on the bed. This should allow reduction of hardware to a few screws and the motion drive hardware itself. It all depends on whether we can get consisten dimensional accuracy, and make certain that the longest part fits cross-wise on the bed build-area.

I'll add drawings when I have a chance to finish the rough initial design.

I also have another idea that may be interesting. It's a partial delta robot. Take the bed and put two screws on it. Put each side on a parallelogram hinge facing opposite ways. Drive the two screws in the same direction and you get bed lateral motion. Drive the screws in opposite directions, and you get bed vertical motion. With the reprap needing 2.5D motion, this could easily make a collapsible reprap.

|

Re: Accuracies and Flatness May 30, 2009 12:02PM |

Registered: 15 years ago Posts: 251 |

SOI Sentinel Wrote:

> I also have another idea that may be interesting.

> It's a partial delta robot. Take the bed and put

> two screws on it. Put each side on a

> parallelogram hinge facing opposite ways. Drive

> the two screws in the same direction and you get

> bed lateral motion. Drive the screws in opposite

> directions, and you get bed vertical motion. With

> the reprap needing 2.5D motion, this could easily

> make a collapsible reprap.

Could you please post a sketch of this? It sounds good, but (unless I'm missing something) it seems to me that two parallelogram linkages would either bind one another's motions, or will duplicate the motion exactly. Perhaps you mean two pairs of stacked parallelograms, or something else.... ?

Thanks,

Larry Pfeffer,

My blog about building repstrap Cerberus:

[repstrap-cerberus.blogspot.com]

> I also have another idea that may be interesting.

> It's a partial delta robot. Take the bed and put

> two screws on it. Put each side on a

> parallelogram hinge facing opposite ways. Drive

> the two screws in the same direction and you get

> bed lateral motion. Drive the screws in opposite

> directions, and you get bed vertical motion. With

> the reprap needing 2.5D motion, this could easily

> make a collapsible reprap.

Could you please post a sketch of this? It sounds good, but (unless I'm missing something) it seems to me that two parallelogram linkages would either bind one another's motions, or will duplicate the motion exactly. Perhaps you mean two pairs of stacked parallelograms, or something else.... ?

Thanks,

Larry Pfeffer,

My blog about building repstrap Cerberus:

[repstrap-cerberus.blogspot.com]

|

Re: Accuracies and Flatness June 01, 2009 12:56AM |

Registered: 16 years ago Posts: 113 |

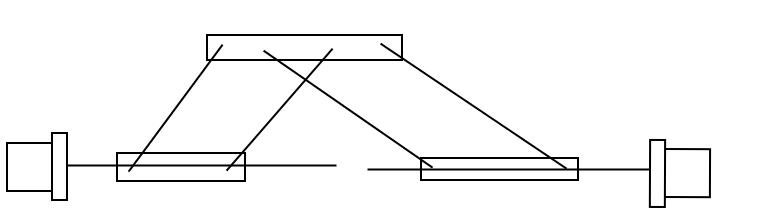

Here's the basic idea. Imagine that I actually drew these in CAD and didn't get over-detailed to the point where he didn't even get one parallelogram leg finished.

If the motors move in parallel, we get X motion. If they move in opposite directions, we get Z motion. Now, as the object gets taller, the build area shrinks. You'd also have to account for increasing static torques as the force vectors rotate towards the horizontal. However, by flipping up some "emergency stops" it becomes possible to fold the entire X-Z axis down flat. If the Y axis is on a simple hinged gantry, you could easily also fold it down flat on top of the table. Given that the core RepRap is not meant for 3D extruding, but works in the 2.5D realm, if it was found feasible, a half-nut or geared nut "drive" on one side and a dedicated slot "lock" on that side would allow one motor and one or two solenoids to run both the X and the Z axis. Again, what makes this feasible with the current hardware is that either a) the computer does the arctan calculations to tell the robot exactly how many steps to move to drop the platform the specified distance, or b) the Arduino/PIC drivers have plenty of time to compute the same value since they are not doing it on the fly.

Issues to consider are the already mentioned torques required to keep the platform aloft. You just can't run the platform down to zero, but, oddly, a few springs underneath or at the coupling joints may provide the "oomph" to raise it up out of the motor-toggle position without any helping hands. The second issue is the varying height per step. This shouldn't be much of a problem, but it may become apparent at the tallest build parameters if the step size grows to be close to the size of a layer transition.

Edited 2 time(s). Last edit at 06/01/2009 12:59AM by SOI Sentinel.

If the motors move in parallel, we get X motion. If they move in opposite directions, we get Z motion. Now, as the object gets taller, the build area shrinks. You'd also have to account for increasing static torques as the force vectors rotate towards the horizontal. However, by flipping up some "emergency stops" it becomes possible to fold the entire X-Z axis down flat. If the Y axis is on a simple hinged gantry, you could easily also fold it down flat on top of the table. Given that the core RepRap is not meant for 3D extruding, but works in the 2.5D realm, if it was found feasible, a half-nut or geared nut "drive" on one side and a dedicated slot "lock" on that side would allow one motor and one or two solenoids to run both the X and the Z axis. Again, what makes this feasible with the current hardware is that either a) the computer does the arctan calculations to tell the robot exactly how many steps to move to drop the platform the specified distance, or b) the Arduino/PIC drivers have plenty of time to compute the same value since they are not doing it on the fly.

Issues to consider are the already mentioned torques required to keep the platform aloft. You just can't run the platform down to zero, but, oddly, a few springs underneath or at the coupling joints may provide the "oomph" to raise it up out of the motor-toggle position without any helping hands. The second issue is the varying height per step. This shouldn't be much of a problem, but it may become apparent at the tallest build parameters if the step size grows to be close to the size of a layer transition.

Edited 2 time(s). Last edit at 06/01/2009 12:59AM by SOI Sentinel.

|

Re: Accuracies and Flatness June 01, 2009 07:20AM |

Registered: 15 years ago Posts: 251 |

Thanks for the sketch; *now* I see what you'r thinking of!

OK, that mechanism does what you said. However, it needs two sliding bearings (that can share the same "track") plus eight rotary bearings (that had better not have off-axis play.) I'm not sure whether that's really easier than a pair of linear bearings, though the notion of sharing one motor between two degrees of freedom is certainly an interesting notion. Thanks again for presenting (and clarifying) your idea.

Larry Pfeffer,

My blog about building repstrap Cerberus:

[repstrap-cerberus.blogspot.com]

OK, that mechanism does what you said. However, it needs two sliding bearings (that can share the same "track") plus eight rotary bearings (that had better not have off-axis play.) I'm not sure whether that's really easier than a pair of linear bearings, though the notion of sharing one motor between two degrees of freedom is certainly an interesting notion. Thanks again for presenting (and clarifying) your idea.

Larry Pfeffer,

My blog about building repstrap Cerberus:

[repstrap-cerberus.blogspot.com]

|

Re: Accuracies and Flatness June 01, 2009 09:58AM |

Admin Registered: 16 years ago Posts: 13,886 |

... look at the image "Tripod-2.jpg" ( [forums.reprap.org] ) and maybe the complete thread ( [forums.reprap.org] )

Viktor

Viktor

|

Re: Accuracies and Flatness June 01, 2009 02:03PM |

Registered: 16 years ago Posts: 536 |

Interesting idea. That software will take some work though; I wonder what the build area compared to the footprint will be?

About Reprap being 2.5 dimensions - doesn't that generally refer to a 3d object that is projected from a plane, with no overhangs at all? The parts I've been building generally have lots of overhangs, and even 90 deg overhangs work fine when there are supports on either side using Enrique's bridging code.

Stretching the filament lets you get away with a lot. Also, the internal voids and details (ie, horizontal bolt holes) are very useful, and not possible with a traditional 2.5d milling setup. Seems to me that there's quite a difference between 2.5d milling and what we can build on a RepRap. Have a look at a corner block, for instance.

Wade

About Reprap being 2.5 dimensions - doesn't that generally refer to a 3d object that is projected from a plane, with no overhangs at all? The parts I've been building generally have lots of overhangs, and even 90 deg overhangs work fine when there are supports on either side using Enrique's bridging code.

Stretching the filament lets you get away with a lot. Also, the internal voids and details (ie, horizontal bolt holes) are very useful, and not possible with a traditional 2.5d milling setup. Seems to me that there's quite a difference between 2.5d milling and what we can build on a RepRap. Have a look at a corner block, for instance.

Wade

|

Re: Accuracies and Flatness June 01, 2009 05:59PM |

Registered: 16 years ago Posts: 113 |

I do understand, and it appears that I brought the misunderstanding. With a single X-Z motor, what I meant for 2.5 D is that you cannot move more than 2 axes simultaneously in that configuration, especially since Z motions would not be orthogonal. Full 3D motion would be possible in the 3 motor system, but the varying velocity due to Z motion travel would be a challenge to code to provide linear velocity control over the work head.

The 2.5D firmware would not be too horrible, You'd have to calculate the inverse kinematics of the system, but once that equation is set up, it would just be a few questions about bar lengths. With this being done only once per layer, it wouldn't be too bad. If you had to close it in the control loops, it's time to upgrade to something more powerful.

As for build area, that will depend on the base. Going with a simple example where bar length = table length, if the base slide area is 2x the table, you will (ideally) get a roughly half-cylinder build area, widest at the table height. Realistically it would be truncated slightly on each end due to the positional singularities located there. By expanding the base length, you would stretch this area, forming a box with rounded corners.

The 2.5D firmware would not be too horrible, You'd have to calculate the inverse kinematics of the system, but once that equation is set up, it would just be a few questions about bar lengths. With this being done only once per layer, it wouldn't be too bad. If you had to close it in the control loops, it's time to upgrade to something more powerful.

As for build area, that will depend on the base. Going with a simple example where bar length = table length, if the base slide area is 2x the table, you will (ideally) get a roughly half-cylinder build area, widest at the table height. Realistically it would be truncated slightly on each end due to the positional singularities located there. By expanding the base length, you would stretch this area, forming a box with rounded corners.

Sorry, only registered users may post in this forum.