Extremely Low Torque to Extruder Stepper Motor

Posted by swighton

|

Extremely Low Torque to Extruder Stepper Motor November 19, 2009 01:08AM |

Registered: 14 years ago Posts: 27 |

Hello,

I have just built a mendel and wired it up with the 5d firmware. Everything works perfectly - except for the pinch wheel extruder motor. It turns but has almost zero torque. I can easily stop it with my fingers and there is no way it can drive a filament at all. Is there a reason why the motor would do this? Is there something I can do to fix it?

Its a nema 17 driven by a motherboard version 2.2 and extruder controller 2.2.

I have just built a mendel and wired it up with the 5d firmware. Everything works perfectly - except for the pinch wheel extruder motor. It turns but has almost zero torque. I can easily stop it with my fingers and there is no way it can drive a filament at all. Is there a reason why the motor would do this? Is there something I can do to fix it?

Its a nema 17 driven by a motherboard version 2.2 and extruder controller 2.2.

|

Re: Extremely Low Torque to Extruder Stepper Motor November 19, 2009 03:13AM |

Admin Registered: 16 years ago Posts: 13,884 |

|

Re: Extremely Low Torque to Extruder Stepper Motor November 19, 2009 11:01AM |

Registered: 14 years ago Posts: 27 |

Where would I adjust that - in the firmware or on the reprap host properties file. I see three entries that might possibly change the torque to the motor:

Extruder0_hb (C)=20

Extruder0_hm(C/pwr)=0.86

(if pwr stand for power, and if you can define the power of the motor as I^2*R then this would make the C/pwr term larger. Though I have no idea waht C stands for.)

and

Extruder0_t0(0..255)=0

I initially thought that this set the initial temerature of the extruder, but because it has a value of 0..255 I'm thinking that perhaps it means something else? Maybe torque? Does anyone know what t0 adjusts?

Extruder0_hb (C)=20

Extruder0_hm(C/pwr)=0.86

(if pwr stand for power, and if you can define the power of the motor as I^2*R then this would make the C/pwr term larger. Though I have no idea waht C stands for.)

and

Extruder0_t0(0..255)=0

I initially thought that this set the initial temerature of the extruder, but because it has a value of 0..255 I'm thinking that perhaps it means something else? Maybe torque? Does anyone know what t0 adjusts?

|

Re: Extremely Low Torque to Extruder Stepper Motor November 19, 2009 04:13PM |

Registered: 14 years ago Posts: 27 |

I am not all that good at coding, but from this snippet from the extruder_class.pde sketch it appears that the pwm value for the extruder is set by the pot on the extruder controller board? Can anyone verify if this is the case? I don't want to just go turning pots on my extruder controller blindly.

int extruder::potVoltage()

{

return (int)analogRead(POT);

}

void extruder::setPWM(int p) //is the extruder current set by the pot value?

{

pwmValue = p;

}

int extruder::potVoltage()

{

return (int)analogRead(POT);

}

void extruder::setPWM(int p) //is the extruder current set by the pot value?

{

pwmValue = p;

}

|

Re: Extremely Low Torque to Extruder Stepper Motor November 19, 2009 10:12PM |

Registered: 14 years ago Posts: 27 |

Solution

There is a line tucked away in the configuration header file for the extruder controller that allows you to increase the motor power.

// Default pwm for the stepper motor

//*****perhaps change this to increase motor power*****

#define STEP_PWM 700

Now I have to figure out how to use the temperatuer tables because my thermistor must not match the one that the firmware comes pre-configured to use - I melted my teflon barrier.

There is a line tucked away in the configuration header file for the extruder controller that allows you to increase the motor power.

// Default pwm for the stepper motor

//*****perhaps change this to increase motor power*****

#define STEP_PWM 700

Now I have to figure out how to use the temperatuer tables because my thermistor must not match the one that the firmware comes pre-configured to use - I melted my teflon barrier.

|

Re: Extremely Low Torque to Extruder Stepper Motor November 20, 2009 03:05AM |

Admin Registered: 16 years ago Posts: 13,884 |

|

Re: Extremely Low Torque to Extruder Stepper Motor November 20, 2009 05:45PM |

Registered: 14 years ago Posts: 27 |

Do you mean that the torque to the stepper on the extruder is adjusted by the trim pot on the extruder controller board? I tried turning the pot to both maximum and minumin without seeing any effect.

Has anyone used a nema 17 stepper for a pinch wheel extruder? I can't get to to push the filament through no matter what I do.

Has anyone used a nema 17 stepper for a pinch wheel extruder? I can't get to to push the filament through no matter what I do.

|

Re: Extremely Low Torque to Extruder Stepper Motor November 20, 2009 07:23PM |

Admin Registered: 17 years ago Posts: 7,879 |

The Mendel extruder uses a NEMA17 with a small pinch wheel. They have quite a big range or torques though, about 0.1 to 0.3 Nm so you need a good one.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Extremely Low Torque to Extruder Stepper Motor November 20, 2009 08:22PM |

Registered: 14 years ago Posts: 27 |

I have the one from the makerbot store that allegedly has .26 Nm holding torque. I have tried adjusting every possible thing that I can think of, here is what I have deduced

-Adjusting the pot on the extruder controller board has zero effect on the output torque of the extruder stepper motor (is the firmware reading the right pin? in the firmware it says pin 0, I thought the pot was pin 23 - though changing it to 23 in the firmware didn't seem to have any effect)

-Changing the pwm value does have an impact on the torque output, but still cannot make the motor achieve enough torque to extrude

Is anyone using a nema 17 stepper motor driven extruder on the 5g firmware? If so what adjustments if any had to be made to make it work?

I've been trying to get my mendel to print for a week - I may have to scrap the whole stepper driven extruder and get a dc motor and use replicatorG... Though I would much prefer to avoid that and get this working

Edited 1 time(s). Last edit at 11/20/2009 08:23PM by swighton.

-Adjusting the pot on the extruder controller board has zero effect on the output torque of the extruder stepper motor (is the firmware reading the right pin? in the firmware it says pin 0, I thought the pot was pin 23 - though changing it to 23 in the firmware didn't seem to have any effect)

-Changing the pwm value does have an impact on the torque output, but still cannot make the motor achieve enough torque to extrude

Is anyone using a nema 17 stepper motor driven extruder on the 5g firmware? If so what adjustments if any had to be made to make it work?

I've been trying to get my mendel to print for a week - I may have to scrap the whole stepper driven extruder and get a dc motor and use replicatorG... Though I would much prefer to avoid that and get this working

Edited 1 time(s). Last edit at 11/20/2009 08:23PM by swighton.

|

Re: Extremely Low Torque to Extruder Stepper Motor November 22, 2009 05:30PM |

Registered: 14 years ago Posts: 27 |

I cannot get the nema 17 motor to work as a pinch wheel extruder - I don't know if it isn't getting enough current due to a hardware fault or a software fault, or if it just doesn't have enough torque by nature. Either way this a serious problem needs to be addressed so that other people who build the Mendel can get it to work without a lot of wasted time and hacking.

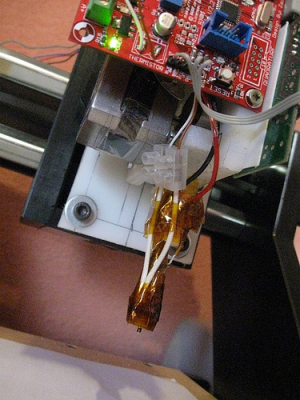

I've gotten the extruder to work barely with the setup below which has a 3:1 ratio. It can barely run in this setup so there is no hope of it extruding a filament in a direct drive setup.

I've gotten the extruder to work barely with the setup below which has a 3:1 ratio. It can barely run in this setup so there is no hope of it extruding a filament in a direct drive setup.

|

Re: Extremely Low Torque to Extruder Stepper Motor November 24, 2009 02:59PM |

Registered: 16 years ago Posts: 536 |

|

Re: Extremely Low Torque to Extruder Stepper Motor November 24, 2009 11:47PM |

Registered: 14 years ago Posts: 27 |

|

Re: Extremely Low Torque to Extruder Stepper Motor November 25, 2009 01:37PM |

Registered: 16 years ago Posts: 536 |

Have a look here:

[reprap.svn.sourceforge.net]

Not sure how well tested this code is yet, but M108 Sxx should set your extruder stepper current, 0 to 1, 1 being 100%, 0.5 being 50%.

Also, in the extruder firmware's configuration.h file:

[reprap.svn.sourceforge.net]

There are defines for the default PWM:

#define STEP_PWM 150

and full stepping to get more torque out of your extruder motor:

// Uncomment the next line to use full-stepping for the extrude motor

23 // Leave it commented for half stepping

24

25 //#define FULL_STEP

I've been having similar issues, and am reprapping a geared extruder drive not unlike yours.

Wade

[reprap.svn.sourceforge.net]

Not sure how well tested this code is yet, but M108 Sxx should set your extruder stepper current, 0 to 1, 1 being 100%, 0.5 being 50%.

Also, in the extruder firmware's configuration.h file:

[reprap.svn.sourceforge.net]

There are defines for the default PWM:

#define STEP_PWM 150

and full stepping to get more torque out of your extruder motor:

// Uncomment the next line to use full-stepping for the extrude motor

23 // Leave it commented for half stepping

24

25 //#define FULL_STEP

I've been having similar issues, and am reprapping a geared extruder drive not unlike yours.

Wade

|

Re: Extremely Low Torque to Extruder Stepper Motor December 05, 2009 03:31PM |

Registered: 14 years ago Posts: 356 |

swighton Wrote:

-------------------------------------------------------

> I have the one from the makerbot store that

> allegedly has .26 Nm holding torque. I have tried

> adjusting every possible thing that I can think

> of, here is what I have deduced

>

> -Adjusting the pot on the extruder controller

> board has zero effect on the output torque of the

> extruder stepper motor (is the firmware reading

> the right pin? in the firmware it says pin 0, I

> thought the pot was pin 23 - though changing it to

> 23 in the firmware didn't seem to have any

> effect)

>

> -Changing the pwm value does have an impact on the

> torque output, but still cannot make the motor

> achieve enough torque to extrude

>

> Is anyone using a nema 17 stepper motor driven

> extruder on the 5g firmware? If so what

> adjustments if any had to be made to make it work?

I bought from Makerstore that same motor and I were "wasting time" trying to put my extruder working :-( :-(

I have a 9mm wheel on it and it just can extrude at VERY LOW speed (F24) and at medium/low speed it makes some noise and starts skipping steps :-(

When motor is skipping steps, I can go with my hand and push the plastic filament, the motor then continue to rotating as normal and plastic get extruded... I can force plastic to extrude much more quick by hand than what Nema 17 motor can.

I made the math as explained on RepRap wiki, for the torque of this motor, having 9mm wheel and using ABS (near 0.5 N.m needed). It looks like it should work, but this motor have enough hold torque, but not the same torque while moving between steps!!! :-( :-(

And by the way, I used my oscilloscope to verify the wave on coils, and I have a 12V and no PWM, just the full power and running in full steps, since I were told that full steps have sqrt(2) more power than half steps.

I am not happy with this situation (I decided to buy Nema 17 for extruder after reading RepRap wiki for plastic extruder 2.0).

I am making a EMCRepStrap: [objects.reprap.org]

Pictures of my extruder here: [www.flickr.com]

> I've been trying to get my mendel to print for a

> week - I may have to scrap the whole stepper

> driven extruder and get a dc motor and use

> replicatorG... Though I would much prefer to avoid

> that and get this working

I will go for a DC motor, for sure ;-) I read somewhere that they (the used on Makerbot ??) have 9 times more torque than Nema 17...

Edited 3 time(s). Last edit at 12/06/2009 09:26AM by casainho.

-------------------------------------------------------

> I have the one from the makerbot store that

> allegedly has .26 Nm holding torque. I have tried

> adjusting every possible thing that I can think

> of, here is what I have deduced

>

> -Adjusting the pot on the extruder controller

> board has zero effect on the output torque of the

> extruder stepper motor (is the firmware reading

> the right pin? in the firmware it says pin 0, I

> thought the pot was pin 23 - though changing it to

> 23 in the firmware didn't seem to have any

> effect)

>

> -Changing the pwm value does have an impact on the

> torque output, but still cannot make the motor

> achieve enough torque to extrude

>

> Is anyone using a nema 17 stepper motor driven

> extruder on the 5g firmware? If so what

> adjustments if any had to be made to make it work?

I bought from Makerstore that same motor and I were "wasting time" trying to put my extruder working :-( :-(

I have a 9mm wheel on it and it just can extrude at VERY LOW speed (F24) and at medium/low speed it makes some noise and starts skipping steps :-(

When motor is skipping steps, I can go with my hand and push the plastic filament, the motor then continue to rotating as normal and plastic get extruded... I can force plastic to extrude much more quick by hand than what Nema 17 motor can.

I made the math as explained on RepRap wiki, for the torque of this motor, having 9mm wheel and using ABS (near 0.5 N.m needed). It looks like it should work, but this motor have enough hold torque, but not the same torque while moving between steps!!! :-( :-(

And by the way, I used my oscilloscope to verify the wave on coils, and I have a 12V and no PWM, just the full power and running in full steps, since I were told that full steps have sqrt(2) more power than half steps.

I am not happy with this situation (I decided to buy Nema 17 for extruder after reading RepRap wiki for plastic extruder 2.0).

I am making a EMCRepStrap: [objects.reprap.org]

Pictures of my extruder here: [www.flickr.com]

> I've been trying to get my mendel to print for a

> week - I may have to scrap the whole stepper

> driven extruder and get a dc motor and use

> replicatorG... Though I would much prefer to avoid

> that and get this working

I will go for a DC motor, for sure ;-) I read somewhere that they (the used on Makerbot ??) have 9 times more torque than Nema 17...

Edited 3 time(s). Last edit at 12/06/2009 09:26AM by casainho.

|

Re: Extremely Low Torque to Extruder Stepper Motor December 05, 2009 03:34PM |

Registered: 14 years ago Posts: 356 |

> I've gotten the extruder to work barely with the

> setup below which has a 3:1 ratio. It can barely

> run in this setup so there is no hope of it

> extruding a filament in a direct drive setup.

>

> [mechanicallyinclined.net]

> _extruder.JPG

I think you can't get more torque just because you speed up the motor...

And I read somewhere that stepper motor lower the torque as you go higher in velocity... no wonder why you barely put it working...

> setup below which has a 3:1 ratio. It can barely

> run in this setup so there is no hope of it

> extruding a filament in a direct drive setup.

>

> [mechanicallyinclined.net]

> _extruder.JPG

I think you can't get more torque just because you speed up the motor...

And I read somewhere that stepper motor lower the torque as you go higher in velocity... no wonder why you barely put it working...

|

Re: Extremely Low Torque to Extruder Stepper Motor December 06, 2009 11:08AM |

Admin Registered: 17 years ago Posts: 7,879 |

The NEMA17 that Adrian uses in his stepper extruder has more torque than the MakerBot NEMA17. It has 0.44Nm holding torque.

The MakerBot motor is actually a 14v motor so you don't get 0.26Nm at 12V, more like 0.22Nm, so half that of the recommended motor.

Gearing will increase the torque because the rotation is so slow that even 3 times faster is not fast enough to see the motor torque fall off due to inductance.

[www.hydraraptor.blogspot.com]

The MakerBot motor is actually a 14v motor so you don't get 0.26Nm at 12V, more like 0.22Nm, so half that of the recommended motor.

Gearing will increase the torque because the rotation is so slow that even 3 times faster is not fast enough to see the motor torque fall off due to inductance.

[www.hydraraptor.blogspot.com]

|

Re: Extremely Low Torque to Extruder Stepper Motor December 06, 2009 11:24AM |

Registered: 14 years ago Posts: 356 |

In reply to [dev.forums.reprap.org]

nophead Wrote:

-------------------------------------------------------

> The NEMA17 that Adrian uses in his stepper

> extruder has more torque than the MakerBot NEMA17.

> It has 0.44Nm holding torque.

Nophead, thanks for your help.

So, I shouldn't bought the Nema 17 motor from Makerbot store, for this application.

> The MakerBot motor is actually a 14v motor so you

> don't get 0.26Nm at 12V, more like 0.22Nm, so half

> that of the recommended motor.

Hmmm... I thought on that also. I don't know a simple way to have 14V, since I am using the PC power supply...

I could try to use 14V and get then more torque and even try to use the 5mm shaft instead of actual 9mm gear...

With all this maybe I could get about 2 times more the actual torque I have...

BUT, maybe would be better to go with a DC motor like the one on Makerbot... does anyone knows how much more torque it have when compared to this Nema 17? I made some math and looks to me that is about 3x times more... is this correct?

> Gearing will increase the torque because the

> rotation is so slow that even 3 times faster is

> not fast enough to see the motor torque fall off

> due to inductance.

So can this also be a solution? What can we win doing this?

I would like to have a comparative between this Nema 17 and DC motor, why try to figure out what can be more cheap, simple to assembly and to print quicker...

Thanks! ;-)

nophead Wrote:

-------------------------------------------------------

> The NEMA17 that Adrian uses in his stepper

> extruder has more torque than the MakerBot NEMA17.

> It has 0.44Nm holding torque.

Nophead, thanks for your help.

So, I shouldn't bought the Nema 17 motor from Makerbot store, for this application.

> The MakerBot motor is actually a 14v motor so you

> don't get 0.26Nm at 12V, more like 0.22Nm, so half

> that of the recommended motor.

Hmmm... I thought on that also. I don't know a simple way to have 14V, since I am using the PC power supply...

I could try to use 14V and get then more torque and even try to use the 5mm shaft instead of actual 9mm gear...

With all this maybe I could get about 2 times more the actual torque I have...

BUT, maybe would be better to go with a DC motor like the one on Makerbot... does anyone knows how much more torque it have when compared to this Nema 17? I made some math and looks to me that is about 3x times more... is this correct?

> Gearing will increase the torque because the

> rotation is so slow that even 3 times faster is

> not fast enough to see the motor torque fall off

> due to inductance.

So can this also be a solution? What can we win doing this?

I would like to have a comparative between this Nema 17 and DC motor, why try to figure out what can be more cheap, simple to assembly and to print quicker...

Thanks! ;-)

|

Re: Extremely Low Torque to Extruder Stepper Motor December 06, 2009 07:22PM |

Registered: 16 years ago Posts: 536 |

The Makerbot DC motor, the Kysan 37 mm DC Gearmotor, is listed as having 8.47 kg*cm of torque. That's 0.83 Nm, so it's about 3 times the torque of their Nema 17 motor.

I've ordered up some 5 kg*cm Kysan Nema 17 steppers to try out for stepper based extruders; the part number is 2BYGH4803; I'll let you know how they go.

I'm also noodling around with a geared extruder head, similar to Nophead's but using spur gears, but I haven't got it working yet. I want to avoid DC gear motors, due to the trouble starting and stopping the extruder quickly. Maybe if someone writes some kick-ass servo code, the DC motors will work better.

Wade

I've ordered up some 5 kg*cm Kysan Nema 17 steppers to try out for stepper based extruders; the part number is 2BYGH4803; I'll let you know how they go.

I'm also noodling around with a geared extruder head, similar to Nophead's but using spur gears, but I haven't got it working yet. I want to avoid DC gear motors, due to the trouble starting and stopping the extruder quickly. Maybe if someone writes some kick-ass servo code, the DC motors will work better.

Wade

|

Re: Extremely Low Torque to Extruder Stepper Motor December 07, 2009 02:44AM |

Registered: 14 years ago Posts: 356 |

|

Re: Extremely Low Torque to Extruder Stepper Motor December 07, 2009 05:08AM |

Admin Registered: 17 years ago Posts: 7,879 |

The detent torque is the torque the motor will hold with no power applied. I.e. just the torque due to the permanent magnets.

Not of much relevance to an extruder. It can be critical when desiging a z-axis that you don't want to fall when the power is removed though.

[www.hydraraptor.blogspot.com]

Not of much relevance to an extruder. It can be critical when desiging a z-axis that you don't want to fall when the power is removed though.

[www.hydraraptor.blogspot.com]

|

Re: Extremely Low Torque to Extruder Stepper Motor December 07, 2009 01:00PM |

Registered: 14 years ago Posts: 356 |

nophead Wrote:

-------------------------------------------------------

> The NEMA17 that Adrian uses in his stepper

> extruder has more torque than the MakerBot NEMA17.

> It has 0.44Nm holding torque.

>

> The MakerBot motor is actually a 14v motor so you

> don't get 0.26Nm at 12V, more like 0.22Nm, so half

> that of the recommended motor.

I ordered from RepRapsources here in Europe, the Kysan DC motor. But I will make another try with this Nema 17.

Yes, I have 12V instead of the 14V. I hope to be able to hack my PC PSU to put it with 14V.

Since power is equal to U², the delta of 2V may mean a bit of torque lost... Here is my math, that shows a lost of 26.5% power on that 2V, which may mean lost of 26.5% of torque.

R Nema 17 = 35 ohms

U = 14V

P = 14²/35 = 5.6W

R = 35 ohms

U = 12V

P = 12²/35 = 4.11W

5.6 --> 0.26 N.m

4.1 --> x ; x = 19.1 N.m

0.26 -- > 100 %

0.191 --> x ; x = 73.46%

So I will try to get the 100% of torque by using the 14V.

Also I will make tooths on shaft of 5mm diameter instead of using a wheel of 9mm diameter. With all this modifications I hope to double the torque of my actual extruder ;-)

-------------------------------------------------------

> The NEMA17 that Adrian uses in his stepper

> extruder has more torque than the MakerBot NEMA17.

> It has 0.44Nm holding torque.

>

> The MakerBot motor is actually a 14v motor so you

> don't get 0.26Nm at 12V, more like 0.22Nm, so half

> that of the recommended motor.

I ordered from RepRapsources here in Europe, the Kysan DC motor. But I will make another try with this Nema 17.

Yes, I have 12V instead of the 14V. I hope to be able to hack my PC PSU to put it with 14V.

Since power is equal to U², the delta of 2V may mean a bit of torque lost... Here is my math, that shows a lost of 26.5% power on that 2V, which may mean lost of 26.5% of torque.

R Nema 17 = 35 ohms

U = 14V

P = 14²/35 = 5.6W

R = 35 ohms

U = 12V

P = 12²/35 = 4.11W

5.6 --> 0.26 N.m

4.1 --> x ; x = 19.1 N.m

0.26 -- > 100 %

0.191 --> x ; x = 73.46%

So I will try to get the 100% of torque by using the 14V.

Also I will make tooths on shaft of 5mm diameter instead of using a wheel of 9mm diameter. With all this modifications I hope to double the torque of my actual extruder ;-)

|

Re: Extremely Low Torque to Extruder Stepper Motor December 07, 2009 02:21PM |

Admin Registered: 17 years ago Posts: 7,879 |

Torque is proportional to current, not power. Heating is proportional to power though.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Extremely Low Torque to Extruder Stepper Motor December 07, 2009 07:36PM |

Registered: 14 years ago Posts: 356 |

nophead Wrote:

-------------------------------------------------------

> Torque is proportional to current, not power.

> Heating is proportional to power though.

Ok, thanks. So, doing the math again in a correct way (I hope):

U = 14V ==> Nema 17 torque = 0.26 N.m

------------------------------------------------------------------------------

My actual situation:

U = 12V

Pulley diameter = 9mm

Torque = 12 * k

14 * k --> 0.26 N.m ;

12 * k --> x ; x = 0.22 N.m

Force = 0.22 / 0.0045 = 48.9 N.

------------------------------------------------------------------------------

Best situation:

U = 14V

Pulley diameter (original shaft with tooths) = 5mm

Torque = 14 * k

14V --> 0.26 N.m ;

Force = 0.26 / 0.0025 = 104 N.

So I think I can double the force by going to 14V and making tooths on original 5mm motor shaft. I will try this tomorrow.

-------------------------------------------------------

> Torque is proportional to current, not power.

> Heating is proportional to power though.

Ok, thanks. So, doing the math again in a correct way (I hope):

U = 14V ==> Nema 17 torque = 0.26 N.m

------------------------------------------------------------------------------

My actual situation:

U = 12V

Pulley diameter = 9mm

Torque = 12 * k

14 * k --> 0.26 N.m ;

12 * k --> x ; x = 0.22 N.m

Force = 0.22 / 0.0045 = 48.9 N.

------------------------------------------------------------------------------

Best situation:

U = 14V

Pulley diameter (original shaft with tooths) = 5mm

Torque = 14 * k

14V --> 0.26 N.m ;

Force = 0.26 / 0.0025 = 104 N.

So I think I can double the force by going to 14V and making tooths on original 5mm motor shaft. I will try this tomorrow.

|

Re: Extremely Low Torque to Extruder Stepper Motor December 07, 2009 11:29PM |

Registered: 16 years ago Posts: 1,094 |

I can't turn my steppers if I merely short the leads and at 250mA they feel fairly strong.. maybe you need a low voltage one? Mine are rated 0.44Nm, 1.68 ohm, 2.77v, 1.68A

Remember, you need more voltage when the stepper is moving to maintain the current into the winding inductance so try a laptop charger (usually 19v, 5A or so) and let the chopper on the stepper board handle current control.

Remember, you need more voltage when the stepper is moving to maintain the current into the winding inductance so try a laptop charger (usually 19v, 5A or so) and let the chopper on the stepper board handle current control.

|

Re: Extremely Low Torque to Extruder Stepper Motor December 09, 2009 10:23AM |

Registered: 14 years ago Posts: 356 |

Triffid_Hunter Wrote:

-------------------------------------------------------

> I can't turn my steppers if I merely short the

> leads and at 250mA they feel fairly strong.. maybe

> you need a low voltage one? Mine are rated 0.44Nm,

> 1.68 ohm, 2.77v, 1.68A

>

> Remember, you need more voltage when the stepper

> is moving to maintain the current into the winding

> inductance so try a laptop charger (usually 19v,

> 5A or so) and let the chopper on the stepper board

> handle current control.

That's something I don't know, but I think that using Extruder Controller V2.2 (for Mendel version) which uses A3949 IC, I must put the correct voltage for motor coils! or not? I would like to get help here. Also wiki page for the ThermoplastExtruder 2.0 should be updated with this information and details... I already sent an e-mail to Mr. Adrian Boywer asking for this.

Does the A3949 control the voltage and current for stepper motors? If so, how did it knows what the voltage and current is the stepper motor?

I got printing, by removing the tooth wheel of 9mm diameter I had to making splines on 5mm diameter motor shaft, like as written on Pinch_wheel_variations wiki page.

I have a nozzle with 1mm diameter hole, I bought another with 0.6mm, I will try it later.

For now, here is a picture and a video:

Edited 1 time(s). Last edit at 12/09/2009 10:27AM by casainho.

-------------------------------------------------------

> I can't turn my steppers if I merely short the

> leads and at 250mA they feel fairly strong.. maybe

> you need a low voltage one? Mine are rated 0.44Nm,

> 1.68 ohm, 2.77v, 1.68A

>

> Remember, you need more voltage when the stepper

> is moving to maintain the current into the winding

> inductance so try a laptop charger (usually 19v,

> 5A or so) and let the chopper on the stepper board

> handle current control.

That's something I don't know, but I think that using Extruder Controller V2.2 (for Mendel version) which uses A3949 IC, I must put the correct voltage for motor coils! or not? I would like to get help here. Also wiki page for the ThermoplastExtruder 2.0 should be updated with this information and details... I already sent an e-mail to Mr. Adrian Boywer asking for this.

Does the A3949 control the voltage and current for stepper motors? If so, how did it knows what the voltage and current is the stepper motor?

I got printing, by removing the tooth wheel of 9mm diameter I had to making splines on 5mm diameter motor shaft, like as written on Pinch_wheel_variations wiki page.

I have a nozzle with 1mm diameter hole, I bought another with 0.6mm, I will try it later.

For now, here is a picture and a video:

Edited 1 time(s). Last edit at 12/09/2009 10:27AM by casainho.

|

Re: Extremely Low Torque to Extruder Stepper Motor December 09, 2009 11:50AM |

Admin Registered: 17 years ago Posts: 7,879 |

The A3949 always applies the full voltage to the motor, i.e. it is constant voltage driver.

To keep the current within the limits of the motor and the A3949 you need to set the PWM value appropriately.

It's a hack. The extruder would work much better with a microstepping stepper motor driver rather than two DC motor drivers.

Edited 1 time(s). Last edit at 12/09/2009 11:52AM by nophead.

[www.hydraraptor.blogspot.com]

To keep the current within the limits of the motor and the A3949 you need to set the PWM value appropriately.

It's a hack. The extruder would work much better with a microstepping stepper motor driver rather than two DC motor drivers.

Edited 1 time(s). Last edit at 12/09/2009 11:52AM by nophead.

[www.hydraraptor.blogspot.com]

|

Re: Extremely Low Torque to Extruder Stepper Motor December 09, 2009 05:23PM |

Registered: 16 years ago Posts: 1,094 |

casainho, I'm aiming to use the A4983 for all my steppers, since it has 16x microstepping and current control. The current control is especially important since a stepper's torque is directly related to current, but the back EMF and winding inductance drastically reduce the current at speed, requiring an automatic boost in voltage to overcome. Just applying lots of current all the time doesn't really cut it since then the motor overheats when holding.

also, the 2.2 extruder controller has a couple of h-bridges instead of a stepper translator IC (not that that's much different to the A3949), so I'll be redesigning this a bit as well.

also, the 2.2 extruder controller has a couple of h-bridges instead of a stepper translator IC (not that that's much different to the A3949), so I'll be redesigning this a bit as well.

|

Re: Extremely Low Torque to Extruder Stepper Motor December 10, 2009 12:13AM |

Registered: 14 years ago Posts: 356 |

So I would not use a stepper motor of 2.77V with A3949! Even if using PWM...

So, what is the better board for using with a stepper motor that have lower voltage than 12V, like say that of 2.77V? Is there any board that controls current?

I decided to make a blog to document my findings... [casainho-emcrepstrap.blogspot.com]

So, what is the better board for using with a stepper motor that have lower voltage than 12V, like say that of 2.77V? Is there any board that controls current?

I decided to make a blog to document my findings... [casainho-emcrepstrap.blogspot.com]

|

Re: Extremely Low Torque to Extruder Stepper Motor December 10, 2009 01:39AM |

Registered: 15 years ago Posts: 478 |

I am was just about to build an Extruder controller 2.1 to run my extruder stepper with. As I have had virtualy no problems with any of the other Gen 2 and Gen 3 Electronics. I did not look in any deatail of the Extruder controller 2.1 schematics so I did not realize It's a hack untill reading these recent posts.

I staill have my unused solarbotics geard motor with shaft encoder I may have to revert to that drive system. Instead of my Nema 17 stepper.

I have 3 A4980 devices that I intend to use for the XY and Z drivers for my Mendel build I might re assign one to the extruder driver.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

I staill have my unused solarbotics geard motor with shaft encoder I may have to revert to that drive system. Instead of my Nema 17 stepper.

I have 3 A4980 devices that I intend to use for the XY and Z drivers for my Mendel build I might re assign one to the extruder driver.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: Extremely Low Torque to Extruder Stepper Motor December 10, 2009 01:47AM |

Registered: 16 years ago Posts: 1,094 |

Sorry, only registered users may post in this forum.