Z-axis

Posted by coil

Hi guys, im new on this forum, and planing to build my first 3d printer.

My question is, can i use [www.openbuilds.com] for my z-axis. If i use 16T pulley my full step will be 0.16mm.

Thanks for your help.

My question is, can i use [www.openbuilds.com] for my z-axis. If i use 16T pulley my full step will be 0.16mm.

Thanks for your help.

|

Re: Z-axis March 03, 2014 09:03PM |

Registered: 13 years ago Posts: 2,947 |

Although I am all for belt Z axis I do not think that would be the best for Z since you would have the weight of the motors on the Z axis which would mean most of the motors holding torque would be used up just holding them up.

On a slight side note, the commercial rack and pinion belt systems have teeth that the belt sits in on the track that prevent the belt from stretching anywhere except between the rollers and the pulley on the motor. But with this system the belt can stretch between the roller and the fixed points at the ends which kind of defeats the purpose of a rack and pinion belt system.

On a slight side note, the commercial rack and pinion belt systems have teeth that the belt sits in on the track that prevent the belt from stretching anywhere except between the rollers and the pulley on the motor. But with this system the belt can stretch between the roller and the fixed points at the ends which kind of defeats the purpose of a rack and pinion belt system.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Z-axis March 03, 2014 11:25PM |

Registered: 10 years ago Posts: 1,381 |

Neat linear drive-guide integration.

The available length of belt that can stretch is cut in half with a rack and pinion linear belt (ServoBelt, Belt-on-Belt drive, Tractoring) drive arrangement compared to a static motor.

I imagine that there is an on line calculator to help determine how much mass/weight the drive line/transmission/stepper motor could move, and the output torque, force, etc. Josef Prusa calculator is close, probably wouldn't take much to modify it.

Calculator, Steps per millimeter - belt driven systems

[calculator.josefprusa.cz]

Triffid Hunter's Calibration Guide

[reprap.org]

ServoBelt, Belt-on-Belt drive, Tractoring videos:

[forums.reprap.org]

Quote

Sublime

But with this system the belt can stretch between the roller and the fixed points at the ends

which kind of defeats the purpose of a rack and pinion belt system.

The available length of belt that can stretch is cut in half with a rack and pinion linear belt (ServoBelt, Belt-on-Belt drive, Tractoring) drive arrangement compared to a static motor.

Quote

Sublime

most of the motors holding torque would be used up just holding them up.

I imagine that there is an on line calculator to help determine how much mass/weight the drive line/transmission/stepper motor could move, and the output torque, force, etc. Josef Prusa calculator is close, probably wouldn't take much to modify it.

Calculator, Steps per millimeter - belt driven systems

[calculator.josefprusa.cz]

Triffid Hunter's Calibration Guide

[reprap.org]

ServoBelt, Belt-on-Belt drive, Tractoring videos:

[forums.reprap.org]

|

Re: Z-axis March 04, 2014 12:21AM |

Registered: 13 years ago Posts: 2,947 |

Quote

A2

Neat linear drive-guide integration.

Quote

Sublime

But with this system the belt can stretch between the roller and the fixed points at the ends

which kind of defeats the purpose of a rack and pinion belt system.

The available length of belt that can stretch is cut in half with a rack and pinion linear belt (ServoBelt, Belt-on-Belt drive, Tractoring) drive arrangement compared to a static motor.

Are you meaning simply because the belt is only half the length it will have half the stretch of a conventional belt system? I can see how that would be true and an improvement. But with a Servo belt the available length of belt that can stretch is only the length between the rollers and the pulley since the rest of the belts teeth are engaged into the rack which is what I was comparing this system with in my original statement.

Quote

A2

Quote

Sublime

most of the motors holding torque would be used up just holding them up.

I imagine that there is an on line calculator to help determine how much mass/weight the drive line/transmission/stepper motor could move, and the output torque, force, etc. Josef Prusa calculator is close, probably wouldn't take much to modify it.

This was a question about using it for the Z axis and myself having a couple of machines with Z axis that rely on the motors holding torque I can say that putting the weight of the motor on the platform would make it really easy to overcome the holding torque. That is not to say you could not get motors with enough torque, but at what cost. Also if this is for a Mendel style machine with the X axis motor and the extruder motor all being held up too I would be really worried. At that point I think you would need to gear it down.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Z-axis March 04, 2014 02:37AM |

Registered: 10 years ago Posts: 1,381 |

Quote

Sublime

Are you meaning simply because the belt is only half the length it will have half the stretch of a conventional belt system?

I can see how that would be true and an improvement.

Yes

Quote

Sublime

putting the weight of the motor on the platform would make it really easy to overcome the holding torque.

if this is for a Mendel style machine with the X axis motor and the extruder motor all being held up too I would be really worried.

At that point I think you would need to gear it down.

Tks for you feed back, and I've not found an example of the rack and pinion linear belt drive being used on the Z axis.

I'm thinking of a Prusa i3 style bot.

I like the clean lines of the rack and pinion linear belt drive, it looks professional without much effort.

Unfortunately some thing ($) needs to be added to make it work in the Z axis.

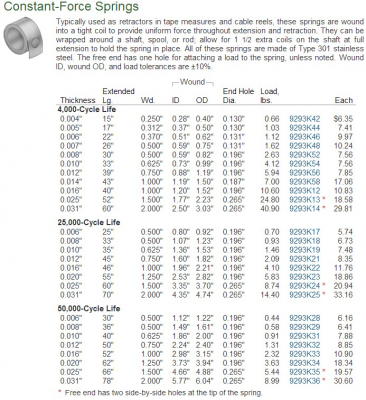

For +$15.00 usd, you could add two constant force springs to counter balance up to 8 lbs to support the X axis.

[www.mcmaster.com]

Edited 3 time(s). Last edit at 03/04/2014 05:42AM by A2.

|

Re: Z-axis March 04, 2014 05:41AM |

Registered: 10 years ago Posts: 4 |

|

Re: Z-axis March 04, 2014 12:20PM |

Registered: 13 years ago Posts: 2,947 |

If what you are looking for is the system that will give the best surface finish I would go with a belt or cable driven Z axis, just not one that has to lift the weight of the motors. Have a read through here [forums.reprap.org] at his attempts to get rid of Z banding. He tried threaded rod lead screw, a ball screw and then a cable Z axis which gave the best results.

I would also go for a machine that does not have a bed that moves in X or Y, only vertical if at all. That is a Delta bot or the etch-a-sketch style (Tantillus, Ultimaker) or a Core XY machine.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Z-axis March 04, 2014 02:07PM |

Registered: 10 years ago Posts: 4 |

@Sublime - thanks for reply, this is my first build and i had in mind the shape of (ord bot hadron) build with vslots from openbuilds, a was planning to use single ballscrew in the middle for z axis.

I have looked at designs that uses Z bed that only move up/down and head that moves in X/Y like Solidoodle, makerbot 5, ultimaker 2... do you guys think that is better way to go.

That looks way more complicated to build right, that vslot design that i looked

I have looked at designs that uses Z bed that only move up/down and head that moves in X/Y like Solidoodle, makerbot 5, ultimaker 2... do you guys think that is better way to go.

That looks way more complicated to build right, that vslot design that i looked

|

Re: Z-axis March 04, 2014 02:55PM |

Registered: 13 years ago Posts: 2,947 |

Yes the other designs are more complicated to build but easier to get square. The machines that have a large moving mass like the bed moving in X/Y or like the makerbot that has the X motor on the Y axis as well as the extruder motors all have the issue of limited acceleration and speed due to the extra weight. This speed limit obviously limits the max speed you can print which is not that big of issue since the real limit is the extruder. But the acceleration limit can result in rounded corners and a lot longer print times. If you do not limit the speed and acceleration then you get ghosting or waves in the print from the motor acting like a spring while changing direction.

In the end for a beginner I would recommend building a pre-existing design and skip designing your own until you have experience with printing and how different geometries and settings effect the outcome of a print. Once you have built one of the existing designs you will come to your own conclusion on what is best and can then use the current machine to print the parts for the new machine. You will then be able to use the electronics and hotend etc from the old machine in the new machine.

If you insist on building a new machine or a cutting edge machine I would recommend Ingentis. It is loosely based on my Tantillus design and an Ultimaker. It has a large build area, made of T-slot, a belt driven Z axis and a carriage that fits a Kraken quad extruder (still experimental).

In the end for a beginner I would recommend building a pre-existing design and skip designing your own until you have experience with printing and how different geometries and settings effect the outcome of a print. Once you have built one of the existing designs you will come to your own conclusion on what is best and can then use the current machine to print the parts for the new machine. You will then be able to use the electronics and hotend etc from the old machine in the new machine.

If you insist on building a new machine or a cutting edge machine I would recommend Ingentis. It is loosely based on my Tantillus design and an Ultimaker. It has a large build area, made of T-slot, a belt driven Z axis and a carriage that fits a Kraken quad extruder (still experimental).

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Z-axis March 04, 2014 03:42PM |

Registered: 10 years ago Posts: 4 |

Thanks for the input... Then i think that is the best if i do a ord bot brother with single ballscrew... I already sourced most of the components, and have a reference design to look up to.

It is a straightforward build in my mind, i have CNC mill at home and can do some of the components at home. I can go from there in the future.

Edited 1 time(s). Last edit at 03/04/2014 03:42PM by coil.

It is a straightforward build in my mind, i have CNC mill at home and can do some of the components at home. I can go from there in the future.

Edited 1 time(s). Last edit at 03/04/2014 03:42PM by coil.

|

Re: Z-axis March 04, 2014 06:55PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Z-axis March 04, 2014 07:06PM |

Registered: 13 years ago Posts: 2,947 |

Quote

A2

Quote

Sublime

If what you are looking for is the system that will give the best surface finish I would go with a belt or cable driven Z axis

Do you have a link that demonstrate how to implement a cable driven Z axis.

Tks.

You can check out my thread from when I released Tantillus's cable Z axis [forums.reprap.org]

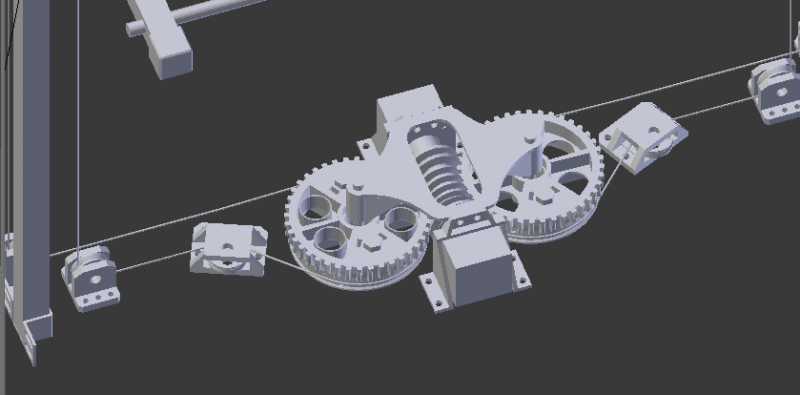

I also have a large unfinished machine with a Cable driven Z that uses a worm drive to prevent the bed from dropping while giving it a mechanical advantage and higher Z resolution.

The Ingentis thread has a lot discussion on the design process which lead him to make a belt Z.

[forums.reprap.org]

Also Printxel has a belt z. [printxel.blogspot.ca]

The last one to look at would be the up or Afina printer which uses a belt Z axis.

If you would like to discuss it further we can always start a dedicated thread.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Z-axis March 04, 2014 09:17PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: Z-axis March 26, 2014 03:24AM |

Registered: 10 years ago Posts: 239 |

|

Re: Z-axis March 28, 2014 03:22PM |

Registered: 14 years ago Posts: 800 |

i am thinking about going to this type of z axis lift system, but i was thinking about just going to a pulley over a geared stepper, i have one an they are remarkably stiff.

or do you have stl files of your parts there a guy could try to print first.?

[mike-mack.blogspot.com]

or do you have stl files of your parts there a guy could try to print first.?

[mike-mack.blogspot.com]

|

Re: Z-axis March 29, 2014 11:07AM |

Registered: 13 years ago Posts: 2,947 |

Quote

dissidence

i am thinking about going to this type of z axis lift system, but i was thinking about just going to a pulley over a geared stepper, i have one an they are remarkably stiff.

or do you have stl files of your parts there a guy could try to print first.?

If you are talking about the Worm drive one I posted the picture of I can provide the STL's but they are very large parts and most likely would not fit in most machines. The machine it is part of is 500mm wide and moves 700mm in Z. I think the parts for Ingentis would be easier to modify to fit the average machine and it uses belts instead of cables. [www.youmagine.com]

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

Sorry, only registered users may post in this forum.