Another Remote Extruder

Posted by THE_SHRUB

Another Remote Extruder  March 22, 2014 12:05AM |

Registered: 10 years ago Posts: 14 |

Hi all,

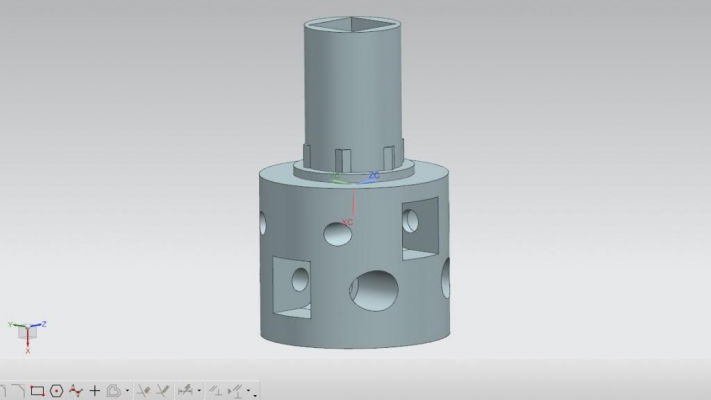

I've been working on this design on and off for the past 8 months now and although the design is not completely finished I wanted to post this up to see what you all think. From the start I have kept my expectations low for whether this system will actually work but I am really enjoying designing the system and testing my 3d problem solving skills.

The extruder is designed to be utilized on a prusa i3. Power is transmitted from an offset stepper motor to a 300mm square carbon fiber shaft, which is then transferred to the extrusion shaft via a second set of gears onboard the x-carriage. Currently I am designing the hotend mount around the ubis hotend which therefore means that the hotend is screw-mounted not groovemounted (which I will eventually remodel to allow.) The shaft mounts (in pink) are going to have position adjustable bearings to allow for easy setup and alignment of the drive shaft relative to the x-rods and the x-carriage. The extruder will feature 30mm spaced mounting slots so that it can be aligned in the vertical axis relative to the drive shaft.

So far my greatest obstacle has been getting my prusa i3 to print PLA without the parts lifting off the bed. I have now begun using the "gluestick" method to prep my print surface and have noticed a significant improvement. I have now decided to return to working on this project as I can now move forward with prototyping the models.

So what do you all think? anyone wanna put bets down on whether or not this will work?

Thx,

Shrub

I've been working on this design on and off for the past 8 months now and although the design is not completely finished I wanted to post this up to see what you all think. From the start I have kept my expectations low for whether this system will actually work but I am really enjoying designing the system and testing my 3d problem solving skills.

The extruder is designed to be utilized on a prusa i3. Power is transmitted from an offset stepper motor to a 300mm square carbon fiber shaft, which is then transferred to the extrusion shaft via a second set of gears onboard the x-carriage. Currently I am designing the hotend mount around the ubis hotend which therefore means that the hotend is screw-mounted not groovemounted (which I will eventually remodel to allow.) The shaft mounts (in pink) are going to have position adjustable bearings to allow for easy setup and alignment of the drive shaft relative to the x-rods and the x-carriage. The extruder will feature 30mm spaced mounting slots so that it can be aligned in the vertical axis relative to the drive shaft.

So far my greatest obstacle has been getting my prusa i3 to print PLA without the parts lifting off the bed. I have now begun using the "gluestick" method to prep my print surface and have noticed a significant improvement. I have now decided to return to working on this project as I can now move forward with prototyping the models.

So what do you all think? anyone wanna put bets down on whether or not this will work?

Thx,

Shrub

Re: Another Remote Extruder  March 22, 2014 09:15AM |

Registered: 12 years ago Posts: 799 |

Also had this idea long time ago but the problem is the friction when extruding and making a movement at the same time.

You would need some kinde of sqare ball/rollbearing but i never found a compact enough solution.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

You would need some kinde of sqare ball/rollbearing but i never found a compact enough solution.

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Re: Another Remote Extruder  March 22, 2014 10:51AM |

Registered: 11 years ago Posts: 5,780 |

I think it can be made to work. Even if mechanical losses are high, you can use a bigger motor and more current to drive it. If you had to you could mount a set of bearings in the gear to reduce sliding friction along the square rod. It may not be necessary to make the square hole in the gear all that close fitting on the square rod. The whole carriage is going to be moving smoothly on the guide rails anyway.

Yup. Doable!

Yup. Doable!

Re: Another Remote Extruder  March 22, 2014 10:53AM |

Registered: 10 years ago Posts: 1,381 |

Re: Another Remote Extruder  March 22, 2014 12:21PM |

Registered: 10 years ago Posts: 14 |

Quote

the_digital_dentist

I think it can be made to work. Even if mechanical losses are high, you can use a bigger motor and more current to drive it. If you had to you could mount a set of bearings in the gear to reduce sliding friction along the square rod. It may not be necessary to make the square hole in the gear all that close fitting on the square rod. The whole carriage is going to be moving smoothly on the guide rails anyway.

Yup. Doable!

something like this?

I am planning on using some compact needle roller bearings that will slot into what I am currently calling the "square bearing" which will hopefully keep frictional forces at a minimum while still keeping the weight down. Thx for the suggestion though!

Re: Another Remote Extruder  March 22, 2014 12:30PM |

Registered: 10 years ago Posts: 14 |

Quote

A2

Idea: To remotely drive the extruder use a flex shaft from a rotary hand tool, e.g. Dremel.

I had this thought too, and while I have never actually tried it myself, my first thoughts are that flex-cable type drive systems are not designed for precision control. The reason why they lend themselves so well to the type power transmission a dremel flex shaft sees is because they operate at a high rpm and see relatively small torque forces (dremels use their speed, not their torque to cut objects as their motors quickly stall out when too much force is applied to them). When you take a flexshaft and put it in a scenario where it is operating at low rpm and high torque I feel like there would be a large amount of axial torsion observed (meaning that if the motor turns the nylon shaft 1 revolution, the shaft will deflect and only turn the driven device, in this case an extruder bolt 0.95 of a revolution). I am not saying that it cannot be done (in fact I am pretty sure it has been done), but I feel like a solid drive shaft lends itself better to precision power transmission as required for accurate filament extrusion.

Re: Another Remote Extruder  March 23, 2014 04:07PM |

Registered: 11 years ago Posts: 15 |

Re: Another Remote Extruder  March 25, 2014 11:37AM |

Registered: 10 years ago Posts: 239 |

Re: Another Remote Extruder  March 25, 2014 12:03PM |

Registered: 10 years ago Posts: 106 |

Re: Another Remote Extruder  March 26, 2014 02:00PM |

Registered: 10 years ago Posts: 14 |

Quote

Bill Clark

there is a device called a "ball spline" that does what you are doing above. Typically a grooved round shaft with a bearing that allows rotation with linear travel. I am exploring the idea of using one to move an axis while eliminating the need to carry the mass of the stepper motor.

I've looked into them before but so far I have not been able to find an off the shelf ball spline shaft small enough to suit the application.. Having one custom made is also an option but it would be mighty expensive!

EDIT: I stand corrected regarding the size requirements for a ball spline. It appears that you can purchase them, however I am still wary of how much one would cost.. I may end up looking into this however as it would save a great deal of time and effort trying to achieve reasonable tolerances.

Edited 1 time(s). Last edit at 03/26/2014 02:09PM by THE_SHRUB.

Re: Another Remote Extruder  March 27, 2014 08:37AM |

Registered: 10 years ago Posts: 239 |

check this out [forums.reprap.org]

the ball spline/nut I am looking at is 225$. with the 150$ discount its $75

the ball spline/nut I am looking at is 225$. with the 150$ discount its $75

Re: Another Remote Extruder  June 05, 2014 08:25AM |

Registered: 9 years ago Posts: 2 |

I considered driving my extruder in a similar way to this thread but was worried by friction and finally went with a chain drive extruder and parallel bars - it works well and I'm very happy with the result. I don't think that this has been tried before. See video below:

[www.youtube.com]

[www.youtube.com]

Re: Another Remote Extruder  June 05, 2014 11:19AM |

Registered: 11 years ago Posts: 1,865 |

hi,

as altogether original, but I do not think that we can eliminate weight from the x axis, in fact, the weight varies depending on the position of the carriage.

Increasing the complexity of the system, also, the total weight bearing on is greater.

Enrico

[www.dapa3dservice.it] [www.studiodapa.it]

repstrap dApA, Ramps 1.4, MarlinKimbra / scanner 3D Cubify Sense / Formlabs Form 2

as altogether original, but I do not think that we can eliminate weight from the x axis, in fact, the weight varies depending on the position of the carriage.

Increasing the complexity of the system, also, the total weight bearing on is greater.

Enrico

[www.dapa3dservice.it] [www.studiodapa.it]

repstrap dApA, Ramps 1.4, MarlinKimbra / scanner 3D Cubify Sense / Formlabs Form 2

Re: Another Remote Extruder  June 07, 2014 04:42AM |

Registered: 12 years ago Posts: 799 |

the Idea with the mounting of the Stepper and the Bar to let it always stay in the same distance itself is not bad at all

but as anricodare said, the weight of the carrier itself seems to be still very heavy because of the use of metal parts.

secondary when the carrier is moving the filament bolt will be moved also a little bit because of the different angle, so there should be an algorithm within the gcode-generator to compensate this.

my suggestions for douglator`s type:

* use 1,75mm Filament -> less force necessary design can be sleeker

* use a propellor shaft system instead of the chaindrive -> no chaintensioner needed, and no additional guide rails, also no massive parts needed.

* with a propellershaft you can mount the stepper 90° turned down, so it show`s direct to the carrier -> less parts

* at the extruder carrier you can make a geared drive for more force

* maybe use a Nema14 Stepper, will reduces the weight that needs to be moved up/down while the carrier is moving sideways

* new g-code algorythm for "anglecompensation"

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

but as anricodare said, the weight of the carrier itself seems to be still very heavy because of the use of metal parts.

secondary when the carrier is moving the filament bolt will be moved also a little bit because of the different angle, so there should be an algorithm within the gcode-generator to compensate this.

my suggestions for douglator`s type:

* use 1,75mm Filament -> less force necessary design can be sleeker

* use a propellor shaft system instead of the chaindrive -> no chaintensioner needed, and no additional guide rails, also no massive parts needed.

* with a propellershaft you can mount the stepper 90° turned down, so it show`s direct to the carrier -> less parts

* at the extruder carrier you can make a geared drive for more force

* maybe use a Nema14 Stepper, will reduces the weight that needs to be moved up/down while the carrier is moving sideways

* new g-code algorythm for "anglecompensation"

Chri

[chrisu02.wordpress.com] Quadmax Intel Delid Tools

Re: Another Remote Extruder  June 08, 2014 10:03AM |

Registered: 9 years ago Posts: 2 |

Thanks for your comments on my extruder drive.

I admit that by using printed parts and a belt drive it could be made lighter. This is my first printer so I couldn't print my own printer parts so used aluminium!

I must stress that movement of the X axis DOES NOT affect the extruder in any way. As the X axis moves the chain unwraps from one sprocket and wraps onto the other and the net result is that the extruder spindle does not turn unless instructed to by the extruder stepper motor.

To make this work the two sprockets must be the same diameter and the parallel bars must be parallel, the same length and on the same horizontal axis as the sprocket spindles.

Enricodare's comment that the force on the X axis increases as the carriage moves away from the central position is correct but this is compensated by a pair of horizontal springs connecting the X carriage to either end of the X axis. These were not fitted at the time of the video as they look unsightly.

Using a propeller shaft is an interesting idea that I hadn't considered. I must think about that....!

I believe that reducing moving mass is very important to increasing print speed/quality. 3D printing is a slow process, anything that can speed it up can only be a good thing.

Edited 1 time(s). Last edit at 06/08/2014 10:04AM by Douglater.

I admit that by using printed parts and a belt drive it could be made lighter. This is my first printer so I couldn't print my own printer parts so used aluminium!

I must stress that movement of the X axis DOES NOT affect the extruder in any way. As the X axis moves the chain unwraps from one sprocket and wraps onto the other and the net result is that the extruder spindle does not turn unless instructed to by the extruder stepper motor.

To make this work the two sprockets must be the same diameter and the parallel bars must be parallel, the same length and on the same horizontal axis as the sprocket spindles.

Enricodare's comment that the force on the X axis increases as the carriage moves away from the central position is correct but this is compensated by a pair of horizontal springs connecting the X carriage to either end of the X axis. These were not fitted at the time of the video as they look unsightly.

Using a propeller shaft is an interesting idea that I hadn't considered. I must think about that....!

I believe that reducing moving mass is very important to increasing print speed/quality. 3D printing is a slow process, anything that can speed it up can only be a good thing.

Edited 1 time(s). Last edit at 06/08/2014 10:04AM by Douglater.

Re: Another Remote Extruder  July 25, 2014 02:25AM |

Registered: 12 years ago Posts: 300 |

Just to say that I'm also trying both technics described here (square shaft and flexible shaft).

I designed the ChickenStruder, using a square shaft:

[www.thingiverse.com]

I still need to make the motor fixation, but I successuflly printed a part. The idea, now, is to use IGUS filament to print the little gear, or at least the square part sliding of the shaft, to decrease friction. This allows to put multiple extruders with only 1 motor. A servo can move the little gear against different extruder gear...

A2, I also tried to use a flexible shaft (a suiss company kindly sent me a sample). I used a worm gearbox to put the flexible shaft vertical. But it does not works fine: worm gear has a lot of friction, and the tork on the flexible shaft leads to a kind of 'slip-stick'... I may try to rebuild the gearbox using bevel gears...

But I'm much more confident in the square shaft transmission, for mutliple extruders config.

Frédéric

I designed the ChickenStruder, using a square shaft:

[www.thingiverse.com]

I still need to make the motor fixation, but I successuflly printed a part. The idea, now, is to use IGUS filament to print the little gear, or at least the square part sliding of the shaft, to decrease friction. This allows to put multiple extruders with only 1 motor. A servo can move the little gear against different extruder gear...

A2, I also tried to use a flexible shaft (a suiss company kindly sent me a sample). I used a worm gearbox to put the flexible shaft vertical. But it does not works fine: worm gear has a lot of friction, and the tork on the flexible shaft leads to a kind of 'slip-stick'... I may try to rebuild the gearbox using bevel gears...

But I'm much more confident in the square shaft transmission, for mutliple extruders config.

Frédéric

Re: Another Remote Extruder  July 25, 2014 02:50AM |

Registered: 12 years ago Posts: 300 |

Quote

THE_SHRUB

Quote

the_digital_dentist

I think it can be made to work. Even if mechanical losses are high, you can use a bigger motor and more current to drive it. If you had to you could mount a set of bearings in the gear to reduce sliding friction along the square rod. It may not be necessary to make the square hole in the gear all that close fitting on the square rod. The whole carriage is going to be moving smoothly on the guide rails anyway.

Yup. Doable!

something like this?

I am planning on using some compact needle roller bearings that will slot into what I am currently calling the "square bearing" which will hopefully keep frictional forces at a minimum while still keeping the weight down. Thx for the suggestion though!

I'm not sure you will improve anything with bearings on 1 side only: the torque on the gear will push it against the square shaft, and you will still have a lot of friction there. You need to put bearings on both sides, to maintain the gear away from the shaft.

Or maybe designing something with balls, like in commercial ball splines, but keeping the square shaft...

BTW, where did you buy the carbon square shaft? Does it have a low friction? Is it better used against ABS or PLA?

Frédéric

Re: Another Remote Extruder  July 29, 2014 08:00AM |

Registered: 9 years ago Posts: 3 |

Re: Another Remote Extruder  September 16, 2014 09:21AM |

Registered: 9 years ago Posts: 135 |

Sorry, only registered users may post in this forum.