SnakeBite Extruder

Posted by the_digital_dentist

|

SnakeBite Extruder March 22, 2014 09:36AM |

Registered: 11 years ago Posts: 5,780 |

I've been testing a new extruder design that uses counter-rotating nuts to drive 3mm filament into a Budaschnozzle clone hot-end. I was originally posting under this topic: "new light extruder concept".

Summary:

A simple differential gear arrangement drives two, 6-32 nuts in opposite directions. One nut is left hand threaded and the other is right hand threaded. The reason for using two nuts is to cancel the torque that would twist the filament instead of pushing it forward through the hot-end.

Design files for the SnakeBiter are here: [www.thingiverse.com]

Video of the SnakeBiter (the part that drives the filament) is here: [vimeo.com]

First print: [vimeo.com]

More first print: [vimeo.com]

Second test print: [vimeo.com]

Latest test results indicate that the calibration is off and I need to tweak the steps/mm setting to get the device to lay down more plastic.

More to follow...

Summary:

A simple differential gear arrangement drives two, 6-32 nuts in opposite directions. One nut is left hand threaded and the other is right hand threaded. The reason for using two nuts is to cancel the torque that would twist the filament instead of pushing it forward through the hot-end.

Design files for the SnakeBiter are here: [www.thingiverse.com]

Video of the SnakeBiter (the part that drives the filament) is here: [vimeo.com]

First print: [vimeo.com]

More first print: [vimeo.com]

Second test print: [vimeo.com]

Latest test results indicate that the calibration is off and I need to tweak the steps/mm setting to get the device to lay down more plastic.

More to follow...

|

Re: SnakeBite Extruder March 22, 2014 10:50AM |

Registered: 10 years ago Posts: 1,381 |

|

Re: SnakeBite Extruder March 22, 2014 11:27AM |

Registered: 11 years ago Posts: 5,780 |

Compact and lighter will come later. I do have a slightly more compact version that uses 20 tooth gears on the nuts with a 30 tooth gear on the motor, and smaller bearings. That reduces size and should increase speed by about 50%. I'll be testing that later. Right now I have to figure out the firmware and slicing tweaks to get quality out of this one and test its speed limits.

|

Re: SnakeBite Extruder March 23, 2014 10:05PM |

Registered: 11 years ago Posts: 5,780 |

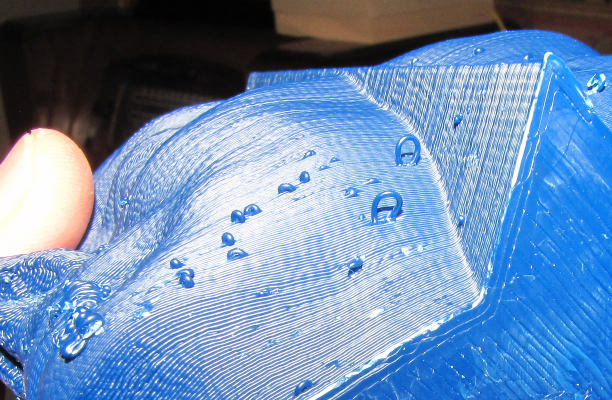

I spent most of yesterday experimenting with firmware and slicer settings to get good quality prints from the SnakeBite extruder.

I'm getting closer- video of latest print here: [vimeo.com]

This print took about 11 hours to complete. There are numerous small blebs in the surface, many of which were carried there from the support material, but some others that are loops that I don't know how to explain. There is also some delamination. It seems more work is needed...

I'm getting closer- video of latest print here: [vimeo.com]

This print took about 11 hours to complete. There are numerous small blebs in the surface, many of which were carried there from the support material, but some others that are loops that I don't know how to explain. There is also some delamination. It seems more work is needed...

|

Re: SnakeBite Extruder March 25, 2014 08:57AM |

Registered: 10 years ago Posts: 239 |

|

Re: SnakeBite Extruder March 25, 2014 03:52PM |

Registered: 11 years ago Posts: 1,049 |

I have been trying to follow this extruder build?

I can't find all the info.

what thread is inside pushing filiment (one RH, one LH)

what is threaded in each gear (nut insert or shaft)

are the bevel gears printable?

what bearings? What shafts? 5mm on Nema 17

Please gather all the info together

I'd like to build one

Tnx

I can't find all the info.

what thread is inside pushing filiment (one RH, one LH)

what is threaded in each gear (nut insert or shaft)

are the bevel gears printable?

what bearings? What shafts? 5mm on Nema 17

Please gather all the info together

I'd like to build one

Tnx

|

Re: SnakeBite Extruder March 25, 2014 04:44PM |

Registered: 11 years ago Posts: 5,780 |

The specs are all in the instructions page at thingiverse.

These are the gears I used: [www.sciplus.com]

These are the gears I used: [www.sciplus.com]

|

Re: SnakeBite Extruder March 25, 2014 04:49PM |

Registered: 11 years ago Posts: 5,780 |

Quote

Bill Clark

those loops on the surface are strange. I'm wondering if the (scanned?) surface is just "dirty".

The object was made by extracting soft tissue data from a CT scan. [www.thingiverse.com]

I have printed it before with no issues. The loops are definitely a problem related to the SnakeBiter or firmware settings or both.

|

Re: SnakeBite Extruder March 26, 2014 02:04PM |

Registered: 11 years ago Posts: 1,049 |

If one were to use a solid shaft (Brass, Al, Steel)

with a hole drilled in it,

What length of threads should be tapped into the shaft.

Are the 3 or four threads of a nut optimum?

Would you open the drilled diameter above threaded section, ow much?

Bottom tap or standard tap?

Is 6-32 the optimum tap for 1.75 mm filament?

Tnx

with a hole drilled in it,

What length of threads should be tapped into the shaft.

Are the 3 or four threads of a nut optimum?

Would you open the drilled diameter above threaded section, ow much?

Bottom tap or standard tap?

Is 6-32 the optimum tap for 1.75 mm filament?

Tnx

|

Re: SnakeBite Extruder March 26, 2014 05:27PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: SnakeBite Extruder April 05, 2014 11:10PM |

Registered: 11 years ago Posts: 5,780 |

I have been out of town for the last couple weeks, but I'm back and ready to start again...

I have no idea what is optimum. I started with off-the-shelf stuff to see if it would work at all. If you get too many threads the drag will become too high and the motor may stall/skip. Too few threads and you may not get enough grip on the filament. It turns out that the 3mm or so of threads in a standard 6-32 nut is enough to grip but not too much to prevent the motor from being able to turn, so I'm guessing it is serendipitously close to optimal as is. Since you need only a few mm of threads, there's nothing wrong with using tubing and a nut, however, drilling out a solid shaft and tapping the last few mm would reduce the parts count and assure good alignment of the center of the nut with the axis of the shaft, so it may be worthwhile to do it that way.

I think using aluminum might be best because you can make a custom tap - maybe 25.4 tpi, using drill stock on a lathe, then quench in oil to harden it, then tap the hole. It might take a special lathe setup to do left hand threads.

I think you'd want it open so the filament can move freely without binding. Maybe using a 3.2-3.5mm hole would be sufficient for 3mm filament. I don't think it matters much.

The thread profile is what counts most. I think you want something that grips without cutting deeply into the filament. Since you're not tapping a blind hole, I don't think it would be necessary to use a bottom tap. The hole size you start with is more important than the type of tap. Some off-the-shelf 6-32 nuts will simply slip over 3mm filament while others will grip it, depending upon the size of hole that was tapped.

Quote

cozmicray

If one were to use a solid shaft (Brass, Al, Steel)

with a hole drilled in it,

What length of threads should be tapped into the shaft.

Are the 3 or four threads of a nut optimum?

I have no idea what is optimum. I started with off-the-shelf stuff to see if it would work at all. If you get too many threads the drag will become too high and the motor may stall/skip. Too few threads and you may not get enough grip on the filament. It turns out that the 3mm or so of threads in a standard 6-32 nut is enough to grip but not too much to prevent the motor from being able to turn, so I'm guessing it is serendipitously close to optimal as is. Since you need only a few mm of threads, there's nothing wrong with using tubing and a nut, however, drilling out a solid shaft and tapping the last few mm would reduce the parts count and assure good alignment of the center of the nut with the axis of the shaft, so it may be worthwhile to do it that way.

I think using aluminum might be best because you can make a custom tap - maybe 25.4 tpi, using drill stock on a lathe, then quench in oil to harden it, then tap the hole. It might take a special lathe setup to do left hand threads.

Quote

cozmicray

Would you open the drilled diameter above threaded section, ow much?

I think you'd want it open so the filament can move freely without binding. Maybe using a 3.2-3.5mm hole would be sufficient for 3mm filament. I don't think it matters much.

Quote

cozmicray

Bottom tap or standard tap?

The thread profile is what counts most. I think you want something that grips without cutting deeply into the filament. Since you're not tapping a blind hole, I don't think it would be necessary to use a bottom tap. The hole size you start with is more important than the type of tap. Some off-the-shelf 6-32 nuts will simply slip over 3mm filament while others will grip it, depending upon the size of hole that was tapped.

|

Re: SnakeBite Extruder April 05, 2014 11:19PM |

Registered: 11 years ago Posts: 5,780 |

I did some thinking about what might be causing the loop blebs. I think it is occurring during retracts- i.e. the retraction isn't working as it should. I have clipped a spring clamp onto the filament entering the extruder to check rotation of the filament. What I have noticed is that the filament twists back and forth a few degrees as the machine prints, primarily due to misalignment of the nuts with the axis of the tubes. When a retraction occurs, the motor spins 1,26 revs to move the filament back 1mm, however, the clamp I placed on the filament shows that the filament coming into the extruder is rotating about 1/2 a turn. That means the retraction is not going the full 1mm and I suspect that the hot-end is "drooling" a little, exactly what retraction is supposed to prevent. I will try using the smaller version of the extruder with the better-aligned nuts and see if the situation improves. It will take a couple days to get it all set up and ready.

Stay tuned!

Stay tuned!

|

Re: SnakeBite Extruder April 12, 2014 12:09PM |

Registered: 11 years ago Posts: 5,780 |

Status update:

further development is delayed by a nasty cold and even nastier income tax season. Those of you not living in the US should count yourselves lucky that you don't have the sort of crap we have to go through every year- there is no greater waste of time, effort, money, and most importantly, human intellect, than the US income tax preparation industry.

further development is delayed by a nasty cold and even nastier income tax season. Those of you not living in the US should count yourselves lucky that you don't have the sort of crap we have to go through every year- there is no greater waste of time, effort, money, and most importantly, human intellect, than the US income tax preparation industry.

|

Re: SnakeBite Extruder April 21, 2014 02:36AM |

Registered: 11 years ago Posts: 51 |

Awesome idea DD. A while back I asked the best lathe machinist I know if he could cut a multi start thread in the size needed for 3mm filament and he was skeptical. I also looked for one that could be bought off the shelf. They don't seem to exist unfortunately. Seems like regular 6-32's seem to work great for the extrusion but is the retract fast enough? I bet multi lead nuts could be printed in stainless by shapeways if you even thought there might be an advantage. For that matter, the whole tube with the gears/nuts could be printed as one piece. Hope you're feeling better (and got a huge tax return  )

)

)

)

|

Re: SnakeBite Extruder May 18, 2014 08:46AM |

Registered: 11 years ago Posts: 5,780 |

I think the retraction will be fast enough, but right now the problem is that uneven torque on the filament, caused by one nut hanging on tighter than the other, is causing the filament to rotate with the lower nut when the thing tries to retract. That prevents the molten filament from being sucked back into the nozzle and causes blebs in the surface of the print where the retracts are supposed to happen.

I recently ran a test using the extruder with the 30 tooth drive gear on the motor and 20 tooth gears on the nuts. It was a no-go. The motor doesn't seem to have the necessary torque to turn even a single nut on the filament with that gear set-up. I'm going back to the 30/30 gear arrangement to try to get retraction working better. A machinist friend made some nuts on a lathe with good alignment with the axis of the bearings which should eliminate some of the problems with my original set-up. I'll cut a new set of tubes and mount those nuts and see how it goes.

I have produced some very high quality single-walled spiral vase prints using the SnakeBiter. If I can get retraction to work right it will be a great extruder.

Edited 1 time(s). Last edit at 05/18/2014 08:51AM by the_digital_dentist.

I recently ran a test using the extruder with the 30 tooth drive gear on the motor and 20 tooth gears on the nuts. It was a no-go. The motor doesn't seem to have the necessary torque to turn even a single nut on the filament with that gear set-up. I'm going back to the 30/30 gear arrangement to try to get retraction working better. A machinist friend made some nuts on a lathe with good alignment with the axis of the bearings which should eliminate some of the problems with my original set-up. I'll cut a new set of tubes and mount those nuts and see how it goes.

I have produced some very high quality single-walled spiral vase prints using the SnakeBiter. If I can get retraction to work right it will be a great extruder.

Edited 1 time(s). Last edit at 05/18/2014 08:51AM by the_digital_dentist.

|

Re: SnakeBite Extruder May 18, 2014 07:16PM |

Registered: 11 years ago Posts: 51 |

|

Re: SnakeBite Extruder May 18, 2014 09:17PM |

Registered: 10 years ago Posts: 1,381 |

|

Re: SnakeBite Extruder May 19, 2014 11:37PM |

Registered: 11 years ago Posts: 5,780 |

I started out thinking of a design that used a single nut, then realized it would try to twist the filament, so then I thought about how to stop filament rotation (square filament?). I considered pizza cutter type wheels to dig into the filament and stop rotation, then came up with the idea of using a second nut turning in the opposite direction, then realized I'd need left hand threads, then, as they say on Seinfeld, "yatta yatta yatta" I ended up with the Snakebiter.

That brings up the question why are we using round filament instead of square filament? With square filament you can grip it much more firmly on two sides and have a larger grip area, even with the usual pinch wheel type direct drive arrangement.

If you're controlling the twist of the filament with the discs you can use a single nut to drive the filament.

That brings up the question why are we using round filament instead of square filament? With square filament you can grip it much more firmly on two sides and have a larger grip area, even with the usual pinch wheel type direct drive arrangement.

If you're controlling the twist of the filament with the discs you can use a single nut to drive the filament.

|

Re: SnakeBite Extruder May 20, 2014 03:28PM |

Registered: 10 years ago Posts: 979 |

I think there are a few drawbacks to square filament. The obvious is that it is much easier to make round filament. Additionally, all filament drives would have to have twist prevention (guides). Finally, the extruders would probably have to be redesigned and wouldn't be as easy to make. (I think the backflow would be increased which would cause more friction.)

Bottomline: It would be fun to test to figure out what the reality of it would be.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

Bottomline: It would be fun to test to figure out what the reality of it would be.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

Sorry, only registered users may post in this forum.