Building Mendel - Extruder

Posted by khiraly

|

Building Mendel - Extruder January 16, 2010 03:03AM |

Registered: 16 years ago Posts: 204 |

Hi!

Have you anybody successfully built the extruder?

I have some basic problems with the design (I downloaded the latest from svn):

[reprap.svn.sourceforge.net]

Attaching the RP parts to the carriage, one of the M4-40 screw is not long enough.

Also the part is too thick to screw the M3-20 screws into it, so the motor cant be attached to it.

So Im wondering if it was tested and built at least once.

I will post some photos later today.

Have you anybody successfully built the extruder?

I have some basic problems with the design (I downloaded the latest from svn):

[reprap.svn.sourceforge.net]

Attaching the RP parts to the carriage, one of the M4-40 screw is not long enough.

Also the part is too thick to screw the M3-20 screws into it, so the motor cant be attached to it.

So Im wondering if it was tested and built at least once.

I will post some photos later today.

|

Re: Building Mendel - Extruder January 16, 2010 05:49AM |

Registered: 16 years ago Posts: 1,094 |

mine is fine, and made from wood- extruder block is only 16mm thick, so a M3x20 screw should leave 4mm for the motor. all the m4x40 bolts are too long in my carriage, and could do with being cut down.

mine is made according to the STLs in svn.

see photos at [wooden-mendel.blogspot.com]

mine is made according to the STLs in svn.

see photos at [wooden-mendel.blogspot.com]

|

Re: Building Mendel - Extruder January 16, 2010 07:21AM |

Registered: 15 years ago Posts: 478 |

I bought an Acrylic stamping block from a craft shop to make the extruder body it is also 16mm thick.

In my opinion this is one of the BIG problems with only having STL files of the printed parts. It is been a mammoth task to retrieve the true dimensions as different applications do give different dimensions.

The best method found so far is to use two free applications to retrieve stl file dimensions:-

"You need two to get all of the dimensions."

The 3D print screen gives the external dimensions of height width and depth.

And the E Drawings viewer to get a top,bottom or side view that I then screen grab by print screen. I then paste this into an old free version of V7 Paint shop pro ~ where I crop to the image to the outside lines then re-size in mm to one of the dimensions gathered from the 3D print program.

You can then fiddle with the picture to get an outline to print and then measure with a ruler.

Its a great pity that there not any dimensioned or scale 2D drawings of these parts to allow for the building of a Repstrap machine. I have made very simple pictures of parts I have made for my Darwin build to help others build them. I will make the similar drawings for the parts made for my Mendel build. I must say this process was easier with Mendel tho. As I was able to use a combination of Metal Mendel drawings and Wooden Mendel PDF files for making most of the parts.

[www.edrawingsviewer.com]

Edited 1 time(s). Last edit at 01/16/2010 07:23AM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

In my opinion this is one of the BIG problems with only having STL files of the printed parts. It is been a mammoth task to retrieve the true dimensions as different applications do give different dimensions.

The best method found so far is to use two free applications to retrieve stl file dimensions:-

"You need two to get all of the dimensions."

The 3D print screen gives the external dimensions of height width and depth.

And the E Drawings viewer to get a top,bottom or side view that I then screen grab by print screen. I then paste this into an old free version of V7 Paint shop pro ~ where I crop to the image to the outside lines then re-size in mm to one of the dimensions gathered from the 3D print program.

You can then fiddle with the picture to get an outline to print and then measure with a ruler.

Its a great pity that there not any dimensioned or scale 2D drawings of these parts to allow for the building of a Repstrap machine. I have made very simple pictures of parts I have made for my Darwin build to help others build them. I will make the similar drawings for the parts made for my Mendel build. I must say this process was easier with Mendel tho. As I was able to use a combination of Metal Mendel drawings and Wooden Mendel PDF files for making most of the parts.

[www.edrawingsviewer.com]

Edited 1 time(s). Last edit at 01/16/2010 07:23AM by BodgeIt.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: Building Mendel - Extruder January 16, 2010 09:05AM |

Registered: 16 years ago Posts: 204 |

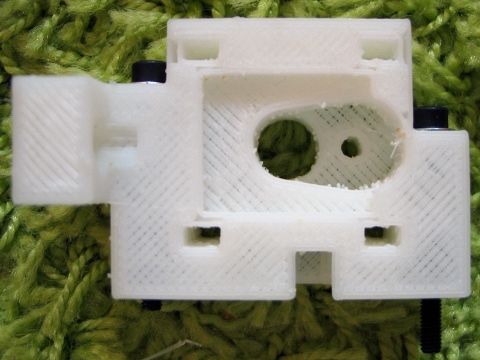

Ok, here is the problem, backed up with photos.

The M4 screw (M4x40) is too short on one side:

The four M3 screws(M3x20), which attach the stepper motor are too short, because the RP part are too thick:

The M4 screw (M4x40) is too short on one side:

The four M3 screws(M3x20), which attach the stepper motor are too short, because the RP part are too thick:

|

Re: Building Mendel - Extruder January 16, 2010 09:36AM |

Registered: 15 years ago Posts: 478 |

The print looks very nice on all the parts you have printed.

Do any of the holes or other parts look like they could be like 10% bigger / thicker as it could be a Z axis or extrusion depth / Z axis calibration problem you are getting that is causing this problem.

I would just use longer screws for now until you can identify where the Z axis printed height error is coming from.

the base looks like it has some warping though I don't think that is enough to make that a big difference in size.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

Do any of the holes or other parts look like they could be like 10% bigger / thicker as it could be a Z axis or extrusion depth / Z axis calibration problem you are getting that is causing this problem.

I would just use longer screws for now until you can identify where the Z axis printed height error is coming from.

the base looks like it has some warping though I don't think that is enough to make that a big difference in size.

Bodge It [reprap.org]

=======================================

My rep strap: [repstrapbertha.blogspot.com]

Buy the bits from B&Q pipestrap [diyrepstrap.blogspot.com]

How to Build a Darwin without any Rep Rap Parts [repstrapdarwin.blogspot.com]

Web Site [www.takeaway3dtech.com]

|

Re: Building Mendel - Extruder January 16, 2010 09:53AM |

Admin Registered: 17 years ago Posts: 7,879 |

If you look at the SVN change log it was modified 3 days ago.

The previous version is thinner. This new one must need longer screws.

[www.hydraraptor.blogspot.com]

Quote

Extruder design improved by the addition of a screw adjuster for setting the filament compression.

The previous version is thinner. This new one must need longer screws.

[www.hydraraptor.blogspot.com]

|

Re: Building Mendel - Extruder January 16, 2010 10:57AM |

Registered: 16 years ago Posts: 204 |

|

Re: Building Mendel - Extruder January 16, 2010 02:13PM |

Registered: 15 years ago Posts: 199 |

Looks like the relevant change was on December 16th:

"Revision 3396

Modified Wed Dec 16 12:19:19 2009 UTC by adrian-bowyer

Improved version of the extruder motor bracket. It's thicker, and so the pinch-bearing screw is less prone to moving through the bracket's distorting."

It sounds like a worthwhile change if the piece had a tendency to flex. Just another example where a change in one place has ripple effects. Does this require more sizes of bolt than needed before? One of the stated goals of Mendel was to minimize the number of different sizes of bolts.

Perhaps using a higher percentage of infill would have accomplished the same thing without changing fasteners.

"Revision 3396

Modified Wed Dec 16 12:19:19 2009 UTC by adrian-bowyer

Improved version of the extruder motor bracket. It's thicker, and so the pinch-bearing screw is less prone to moving through the bracket's distorting."

It sounds like a worthwhile change if the piece had a tendency to flex. Just another example where a change in one place has ripple effects. Does this require more sizes of bolt than needed before? One of the stated goals of Mendel was to minimize the number of different sizes of bolts.

Perhaps using a higher percentage of infill would have accomplished the same thing without changing fasteners.

|

Re: Building Mendel - Extruder January 16, 2010 03:25PM |

Registered: 16 years ago Posts: 204 |

> Does this require more sizes of bolt than needed before?

Yes. M3x35 and M4x45 or M4x50 are not used anywhere.

> Perhaps using a higher percentage of infill would have accomplished

> the same thing without changing fasteners.

I think fill precentage changing has more trouble then benefit. I didnt changed the infill at the whole build.

Im thinking more like sunken the head of the bolt inside the model. Kind of cylinder cut-out. It looks doable.

But for a short term fix, buying the appropriate bolts are the best.

Yes. M3x35 and M4x45 or M4x50 are not used anywhere.

> Perhaps using a higher percentage of infill would have accomplished

> the same thing without changing fasteners.

I think fill precentage changing has more trouble then benefit. I didnt changed the infill at the whole build.

Im thinking more like sunken the head of the bolt inside the model. Kind of cylinder cut-out. It looks doable.

But for a short term fix, buying the appropriate bolts are the best.

|

Re: Building Mendel - Extruder January 17, 2010 12:10AM |

Registered: 16 years ago Posts: 1,094 |

Sorry, only registered users may post in this forum.