Tool change like HP pen plotter

Posted by Dale Dunn

|

Tool change like HP pen plotter April 20, 2014 09:48PM |

Registered: 13 years ago Posts: 485 |

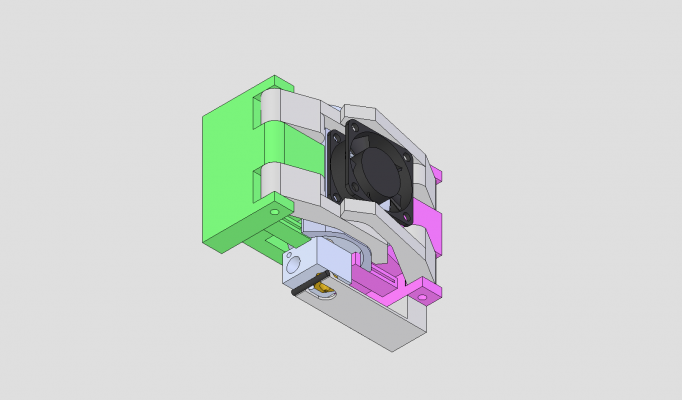

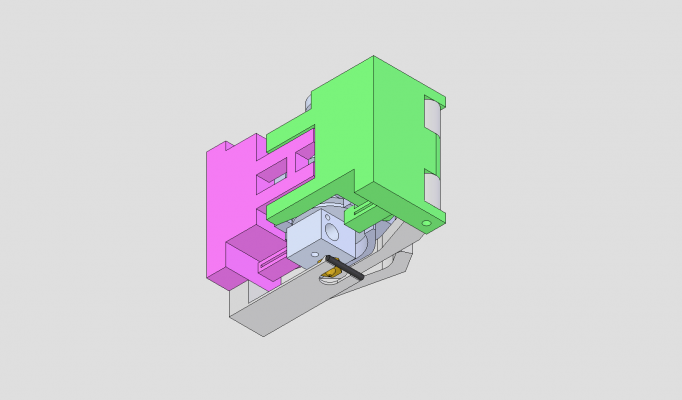

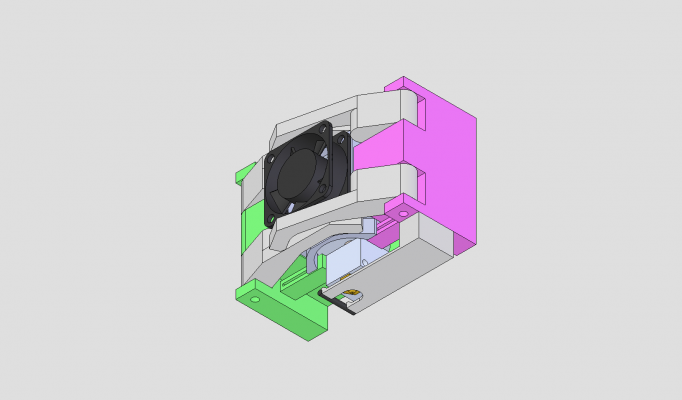

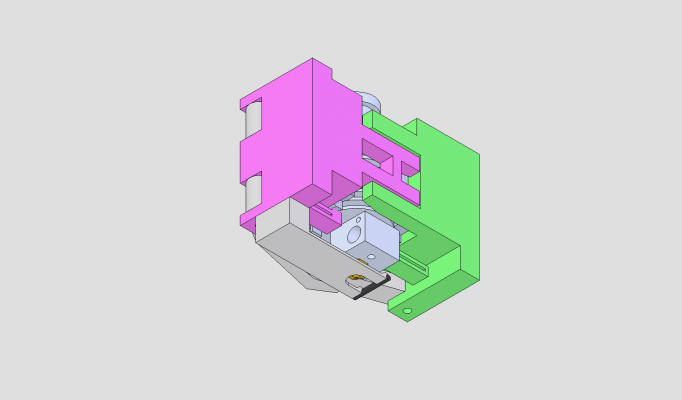

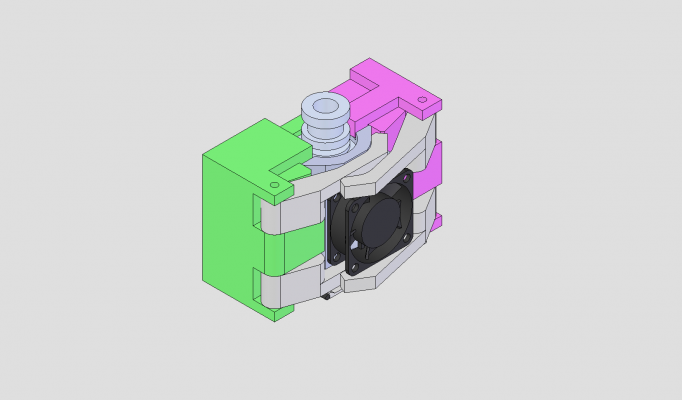

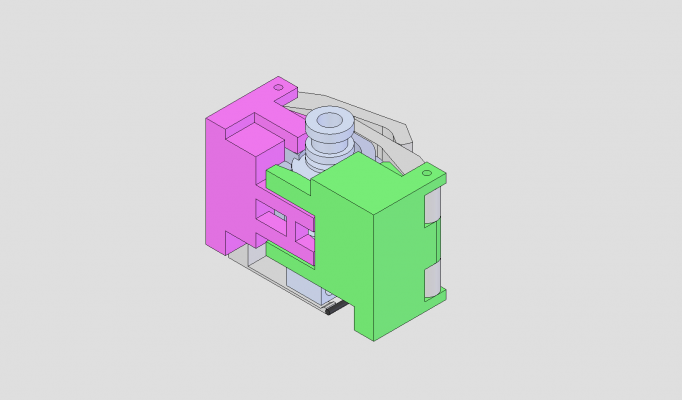

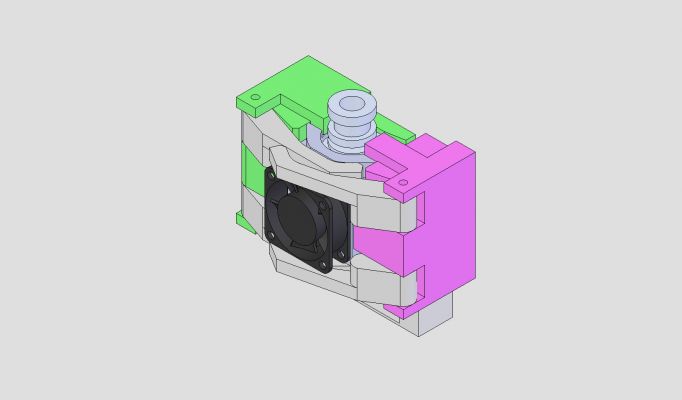

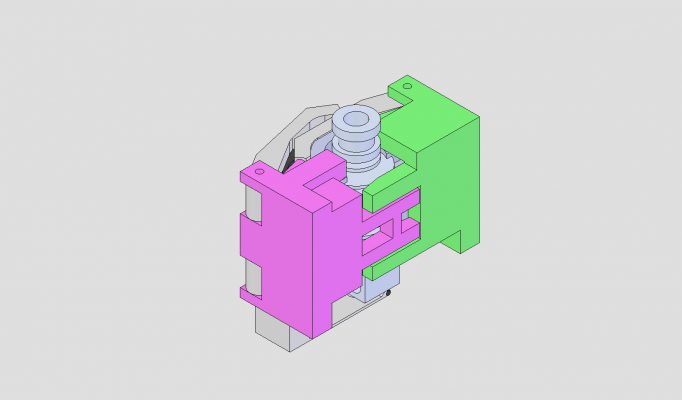

Here's a design study of a tool changer based on the old HP pen plotters. They didn't seem to need an extra motion control of any kind to pick or stow a pen on the carousel. I had never had an opportunity to dismantle one to see how they work, so a bit of Googling led me to the HP online museum where a user's manual showed me enough of the mechanism to figure it out. The gist of it is this: Spring-loaded fingers on either the carriage or the carousel grip the tool. During a transfer, the carriage is forced against the carousel, and the empty side fingers force the other fingers off of the tool, gripping it in turn. Every time the carriage and carousel come together, the tool is transferred from one side to the other.

I adapted that concept to an E3D V5 Bowden hot-end. The hot end is gripped on a modified fan shroud, instead of by the groovemount. In my models, the green side is the carriage, and the purple side is the station in the tool magazine (if the wiper wasn’t a dead giveaway). Clearly a lot of detail is missing, such as screws, and springs in the obvious places. I only put enough effort into the design to see if it pans out.

The tool-changer’s advantage is the lowest possible moving mass for multiple tools. Lower mass allows higher acceleration, which tends to allow higher quality or speed. The tool changer also allows the opportunity to design for large numbers of tools, including things that aren’t extruders. Things like digitizing probes, swivel-knives, pens, and maybe small machining spindles.

The primary disadvantage is complexity. A printer with a single travelling beam (H-bot, CoreXY, etc.) can give up about 55 mm of travel on one side of the machine to mount a row of tool stations. So no other controls need to be added than are necessary for the tools themselves. Anything else will need to be able to move a magazine of tool stations into position for the carriage to pick tools from.

Whether it's worth the trouble is not an easy question to answer. The carriage-side parts are about half the mass of a 2nd E3D V5. The Kraken appears to be amazingly mass-efficient for 4 extruders. I think it will still add significantly more moving mass than this tool-changing carriage, but I don’t have good enough numbers for the Kraken’s mass to be sure the tool-changer complexity is worthwhile. It does seem obvious that the simplicity of the Kraken makes it an obvious choice as the development platform for multi-extruder printers.

I think something like this will become necessary in the pursuit of utmost speed, but for now, I think I’ll need to be content with mounting a 2nd V5.

See the attached 3D pdf if you want to look closer.

Edited 1 time(s). Last edit at 04/20/2014 09:52PM by Dale Dunn.

I adapted that concept to an E3D V5 Bowden hot-end. The hot end is gripped on a modified fan shroud, instead of by the groovemount. In my models, the green side is the carriage, and the purple side is the station in the tool magazine (if the wiper wasn’t a dead giveaway). Clearly a lot of detail is missing, such as screws, and springs in the obvious places. I only put enough effort into the design to see if it pans out.

The tool-changer’s advantage is the lowest possible moving mass for multiple tools. Lower mass allows higher acceleration, which tends to allow higher quality or speed. The tool changer also allows the opportunity to design for large numbers of tools, including things that aren’t extruders. Things like digitizing probes, swivel-knives, pens, and maybe small machining spindles.

The primary disadvantage is complexity. A printer with a single travelling beam (H-bot, CoreXY, etc.) can give up about 55 mm of travel on one side of the machine to mount a row of tool stations. So no other controls need to be added than are necessary for the tools themselves. Anything else will need to be able to move a magazine of tool stations into position for the carriage to pick tools from.

Whether it's worth the trouble is not an easy question to answer. The carriage-side parts are about half the mass of a 2nd E3D V5. The Kraken appears to be amazingly mass-efficient for 4 extruders. I think it will still add significantly more moving mass than this tool-changing carriage, but I don’t have good enough numbers for the Kraken’s mass to be sure the tool-changer complexity is worthwhile. It does seem obvious that the simplicity of the Kraken makes it an obvious choice as the development platform for multi-extruder printers.

I think something like this will become necessary in the pursuit of utmost speed, but for now, I think I’ll need to be content with mounting a 2nd V5.

See the attached 3D pdf if you want to look closer.

Edited 1 time(s). Last edit at 04/20/2014 09:52PM by Dale Dunn.

Attachments:

open | download - 140314.05 Tool Station2.JPG (200.5 KB)

open | download - 140314.05 Tool Station1.JPG (208.2 KB)

open | download - 140314.05 Tool Station3.JPG (198.1 KB)

open | download - 140314.05 Tool Station4.JPG (196 KB)

open | download - 140314.05 Tool Station5.JPG (207.1 KB)

open | download - 140314.05 Tool Station6.JPG (196.1 KB)

open | download - 140314.05 Tool Station7.JPG (205 KB)

open | download - 140314.05 Tool Station8.JPG (194.1 KB)

open | download - Tool Station.pdf (388.2 KB)

open | download - 140314.05 Tool Station2.JPG (200.5 KB)

open | download - 140314.05 Tool Station1.JPG (208.2 KB)

open | download - 140314.05 Tool Station3.JPG (198.1 KB)

open | download - 140314.05 Tool Station4.JPG (196 KB)

open | download - 140314.05 Tool Station5.JPG (207.1 KB)

open | download - 140314.05 Tool Station6.JPG (196.1 KB)

open | download - 140314.05 Tool Station7.JPG (205 KB)

open | download - 140314.05 Tool Station8.JPG (194.1 KB)

open | download - Tool Station.pdf (388.2 KB)

|

Re: Tool change like HP pen plotter April 21, 2014 07:00AM |

Registered: 13 years ago Posts: 7,616 |

Now that electronics support half a dozen extruders you come around with such a genius idea :-) Excellent!

Of course there are a few additional problems to solve: getting the electrical connection for the heater, connecting the filament to the hobbed transport bolt and dealing with the filament sticking out of each hotend.

Of course there are a few additional problems to solve: getting the electrical connection for the heater, connecting the filament to the hobbed transport bolt and dealing with the filament sticking out of each hotend.

| Generation 7 Electronics | Teacup Firmware | RepRap DIY |

|

Re: Tool change like HP pen plotter April 21, 2014 06:27PM |

Registered: 13 years ago Posts: 485 |

Thanks for the kind assessment. But after some discussion of the pros and cons for different machine types on my G+ post (where I also linked to model files), I'm now leaning toward a magnetic kinematic coupling for the printer design I'm working on now. It's encouraging to hear that support for half a dozen tools is coming to the electronics. That half of the design work is outside my skill set.

Dealing with all the loose ends you mention was going to be taken care of (in my mind) by having complete bowden extruder systems for each tool. Hot end, cold end, power, controller, everything. Disconnecting all that would leave the extruders too cold to use when picked up. I think the extruders should be at operating temperature when they're needed, then given a short prime just before use. You can see a wiper in my design for cleaning up the ooze.

Dealing with all the loose ends you mention was going to be taken care of (in my mind) by having complete bowden extruder systems for each tool. Hot end, cold end, power, controller, everything. Disconnecting all that would leave the extruders too cold to use when picked up. I think the extruders should be at operating temperature when they're needed, then given a short prime just before use. You can see a wiper in my design for cleaning up the ooze.

|

Re: Tool change like HP pen plotter April 29, 2014 11:40AM |

Registered: 12 years ago Posts: 325 |

|

Re: Tool change like HP pen plotter May 03, 2014 06:10PM |

Registered: 13 years ago Posts: 485 |

Sorry, only registered users may post in this forum.