|

Modified CoreXY May 14, 2014 04:19PM |

Registered: 10 years ago Posts: 790 |

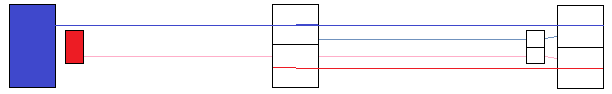

So in designing my printer to be built I was not pleased by the complexities of the CoreXY examples I saw everywhere. Not hard to design complex, but requiring more parts and spacing things correctly. Somehow my brain pooped out an idea, and I wanted to check with you guys on any reasons this wouldn't work or wouldn't work as well.

I've simplified things by stacking the pulleys on the same point, obviously with the right hardware to allow them to rotate seperate from each other.

In this way there are less points to have to take into consideration, allowing a more compact design and less parts.

Or have I missed something?

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

I've simplified things by stacking the pulleys on the same point, obviously with the right hardware to allow them to rotate seperate from each other.

In this way there are less points to have to take into consideration, allowing a more compact design and less parts.

Or have I missed something?

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Modified CoreXY May 14, 2014 06:01PM |

Registered: 10 years ago Posts: 115 |

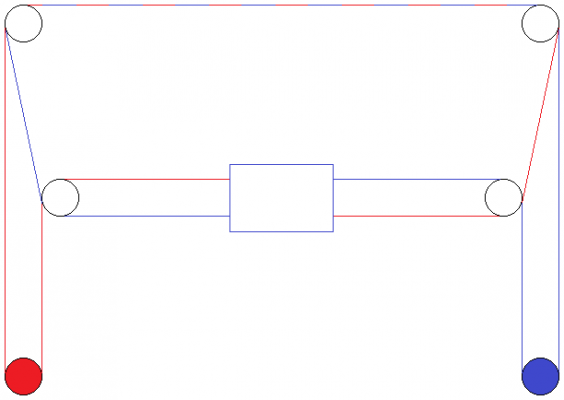

In the 2nd image the rightleft-blue and leftright-red belts need to be perpendicular to the X axis. That can be fixed by just moving the top two pulleys closer together.

Edit: sorry about the typo. I really should avoid posting late at night

Edited 1 time(s). Last edit at 05/15/2014 02:49AM by samp20.

Edit: sorry about the typo. I really should avoid posting late at night

Edited 1 time(s). Last edit at 05/15/2014 02:49AM by samp20.

|

Re: Modified CoreXY May 14, 2014 06:55PM |

Registered: 10 years ago Posts: 790 |

|

Re: Modified CoreXY May 14, 2014 08:10PM |

Registered: 10 years ago Posts: 1,381 |

In the 2nd image the left-blue and right-red belts need to be perpendicular to the X axis.

I believe you'll get a cosine error when the belts are not orthogonal.

Cosine error results from an angular misalignment between the motion of a positioning table, and the accuracy determining element (leadscrew, encoder, or laser interferometer beam path).

[www.dovermotion.com];

[...] error starts to become noticeable when this cause is as much as 10° off the ideal 90°.

[en.wikipedia.org])

[www.cncexpo.com]

[blog.cnccookbook.com]

Edited 1 time(s). Last edit at 05/14/2014 08:10PM by A2.

|

Re: Modified CoreXY May 14, 2014 10:06PM |

Registered: 10 years ago Posts: 790 |

Ahhh, yeah. I didn't play the full physics in my head [I don't do paper, I just visualize, so I'm prone to mistakes]

Thanks.

So yeah, shift the top inward, not mid outward, else rubbing belts. Anything else to keep in mind?

Is there solid evidence as to whether line/string or reinforced belt is better?

Thanks.

So yeah, shift the top inward, not mid outward, else rubbing belts. Anything else to keep in mind?

Is there solid evidence as to whether line/string or reinforced belt is better?

|

Re: Modified CoreXY May 15, 2014 04:26AM |

Registered: 10 years ago Posts: 115 |

Sorry about the earlier mistake, and thanks for fixing it A2.

For belts vs string, I think belts would have the advantage in your case. With line/string you will need to wrap it a few times around the motor pulley to minimise slipping. This will mean that your string will not be inline with at least one of the other pulleys. Also as the motor turns the string will move up and down the motor pulley, again, causing vertical misalignment. This isn't a problem with belts.

I've attached a sketch to illustrate:

For belts vs string, I think belts would have the advantage in your case. With line/string you will need to wrap it a few times around the motor pulley to minimise slipping. This will mean that your string will not be inline with at least one of the other pulleys. Also as the motor turns the string will move up and down the motor pulley, again, causing vertical misalignment. This isn't a problem with belts.

I've attached a sketch to illustrate:

|

Re: Modified CoreXY May 15, 2014 08:26AM |

Registered: 10 years ago Posts: 790 |

|

Re: Modified CoreXY May 15, 2014 09:17AM |

Registered: 10 years ago Posts: 790 |

So I think I just found what is possibly a better modified CoreXY. Observations?

At the same time, looking at their printer, I think I also found the best $1000 printer. Observations?

Because I'm now thinking that when I'm done with my build, rather than rebuilding my Solidoodle from the ground up [with no original components besides the extruder motor] I'm just going to trash it and get me one of those FABtotums.

With full stepping, it's got a 15 micron Z-axis.

Edited 1 time(s). Last edit at 05/15/2014 09:18AM by MrDoctorDIV.

At the same time, looking at their printer, I think I also found the best $1000 printer. Observations?

Because I'm now thinking that when I'm done with my build, rather than rebuilding my Solidoodle from the ground up [with no original components besides the extruder motor] I'm just going to trash it and get me one of those FABtotums.

With full stepping, it's got a 15 micron Z-axis.

Edited 1 time(s). Last edit at 05/15/2014 09:18AM by MrDoctorDIV.

|

Re: Modified CoreXY May 15, 2014 11:22AM |

Registered: 10 years ago Posts: 553 |

Quote

MrDoctorDIV

So I think I just found what is possibly a better modified CoreXY. Observations?

At the same time, looking at their printer, I think I also found the best $1000 printer. Observations?

Because I'm now thinking that when I'm done with my build, rather than rebuilding my Solidoodle from the ground up [with no original components besides the extruder motor] I'm just going to trash it and get me one of those FABtotums.

With full stepping, it's got a 15 micron Z-axis.

Interesting. It claims it can do light aluminum, whatever that means...

greghoge.com

HUGE 3D PRINTER PARTS SALE!!!

|

Re: Modified CoreXY May 15, 2014 11:26AM |

Registered: 10 years ago Posts: 790 |

In the FAQ it says you won't be able to cut 1cm thick aluminum. So thin aluminum sheets is all I see in that regard.

Keep in mind, only $1000, 3D printing, milling, and scanning all in one. I wouldn't expect it to be able to do any better.

Edited 1 time(s). Last edit at 05/15/2014 11:27AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Keep in mind, only $1000, 3D printing, milling, and scanning all in one. I wouldn't expect it to be able to do any better.

Edited 1 time(s). Last edit at 05/15/2014 11:27AM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Modified CoreXY May 15, 2014 01:52PM |

Registered: 10 years ago Posts: 115 |

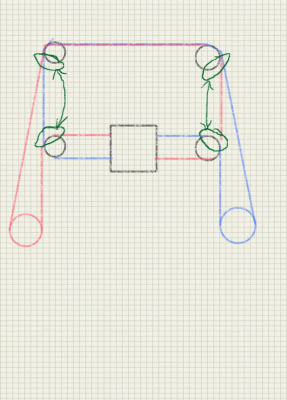

I was about to say yours was better since it is a simpler design on the X-ends. I drew up the fixed version (a bit scruffy as it was done on my phone) and noticed another problem unfortunately:

I've highlighted 4 areas in green where the belts can collide. I think that's why the design you linked uses separate pulleys for the X-ends instead of stacking them.

|

Re: Modified CoreXY May 15, 2014 02:08PM |

Registered: 10 years ago Posts: 790 |

How can they collide if they're on two different levels..?

Edit: I think I know what you're saying, not the differnt levels, but the toothed sides facing eachother and getting close.

yeah, from that point, their design is better.

Edited 1 time(s). Last edit at 05/15/2014 02:20PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

Edit: I think I know what you're saying, not the differnt levels, but the toothed sides facing eachother and getting close.

yeah, from that point, their design is better.

Edited 1 time(s). Last edit at 05/15/2014 02:20PM by MrDoctorDIV.

Realizer- One who realizes dreams by making them a reality either by possibility or by completion. Also creating or renewing hopes of dreams.

"keep in mind, even the best printer can not print with the best filament if the user is the problem." -Ohmarinus

|

Re: Modified CoreXY May 15, 2014 02:57PM |

Registered: 10 years ago Posts: 115 |

The red can collide with itself on the left, and the blue with itself on the right. Only when the carriage moves to the top in the image.

All that being said it may be a non issue if your belts are thin enough (e.g. GT2) since the rest of the frame, linear rails etc would be the limiting factor. You would have to model it to scale to see if it's a problem or not.

Edit:

Edited 1 time(s). Last edit at 05/15/2014 03:00PM by samp20.

All that being said it may be a non issue if your belts are thin enough (e.g. GT2) since the rest of the frame, linear rails etc would be the limiting factor. You would have to model it to scale to see if it's a problem or not.

Edit:

Yes, that's correct, although don't rule your design out right away. It might be only a little distance you sacrifice, since at the bottom they don't collide.Quote

MrDoctorDIV

Edit: I think I know what you're saying, not the differnt levels, but the toothed sides facing eachother and getting close.

yeah, from that point, their design is better.

Edited 1 time(s). Last edit at 05/15/2014 03:00PM by samp20.

|

Re: Modified CoreXY May 15, 2014 05:56PM |

Registered: 11 years ago Posts: 979 |

I would like to point out that this arrangement is good for belts as mentioned above. However, you can have a string drive with very little triangulation error. If you look at my CoreXZ design in my signature below, you will see that the two strings that leave each spool travel about 400mm until you get to a static pulley. The string walks less than +/- 5mm across the spool. By my math triangulation_error=(400mm^2+5mm^2)-400mm^2=30micrometers. That is hardly anything to be concerned about. However with your design the distance from the spool to a pulley changes and can get quite small. This would result in huge triangulation errors. If you allow the spool and a pulley to get 50mm from each other you could end up with 250micrometer error.

I like the layout. It looks very clean.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

I like the layout. It looks very clean.

ConceptFORGE

Wally, GUS Simpson, LISA Simpson, THOR Simpson, Sextupteron, CoreXZ

Sorry, only registered users may post in this forum.