Extruder revolver

Posted by Tiberius

|

Extruder revolver April 20, 2010 12:20PM |

I'm currently thinking about building a 3d printer. So I was checking on the available kits and noticed that several projects offer electronics that support multiple extruders. Somewhere in the RepMan wiki I read that the usable print area will be significantly reduced when 2 or 3 extruders are mounted.

I'm looking for a machine that can do something like A4 size print area so this really made me think.

I immediately though about a toolhead that can carry 2 or 3 extruders (or other tools) which can be changed by the firmware.

You could either use some kind of revolving mechanism to move the unused head out of the way (like this Dual Drill thing from TV ads) or even think of something like a docking mechanism and "parking position" for the unused head where it can be detached from the carthesian robot.

Has anyone tried something like that yet? Any thoughts?

I'm looking for a machine that can do something like A4 size print area so this really made me think.

I immediately though about a toolhead that can carry 2 or 3 extruders (or other tools) which can be changed by the firmware.

You could either use some kind of revolving mechanism to move the unused head out of the way (like this Dual Drill thing from TV ads) or even think of something like a docking mechanism and "parking position" for the unused head where it can be detached from the carthesian robot.

Has anyone tried something like that yet? Any thoughts?

|

Re: Extruder revolver April 20, 2010 01:36PM |

Registered: 14 years ago Posts: 278 |

Originally, Mendel included using docking heads as a desired goal. See [blog.reprap.org], for example, with a video demonstrating a proposed docking mechanism.

|

Re: Extruder revolver April 20, 2010 02:57PM |

Registered: 14 years ago Posts: 117 |

|

Re: Extruder revolver April 20, 2010 03:07PM |

Admin Registered: 17 years ago Posts: 1,791 |

That looks promising. So I guess the project was abandoned for sake of simplicity?

More likely we'll wake up one morning and a random developer, such as yourself, will have figured it out.

How would you do it?

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

More likely we'll wake up one morning and a random developer, such as yourself, will have figured it out.

How would you do it?

-Sebastien, RepRap.org library gnome.

Remember, you're all RepRap developers (once you've joined the super-secret developer mailing list), and the wiki, RepRap.org, [reprap.org] is for everyone and everything!

|

Re: Extruder revolver April 20, 2010 03:18PM |

Admin Registered: 17 years ago Posts: 7,879 |

I think the original plan was docking extruders that park on the rails at the top of the machine, but more recently it seems to have moved to side by side nozzles feed by Bowden cables, driven from stationary drive mechanisms mounted on the top rails.

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Extruder revolver April 20, 2010 03:18PM |

Registered: 14 years ago Posts: 278 |

Postponed, rather than abandoned. Other improvements made on Mendel probably pushed an earlier, simpler release (Smaller size, fewer vitamin parts, higher stability, etc.) I believe there is still the idea of adding dockable heads or other multi-head printing to the mendel frame.

Several designs and branches also have thoughts or stated goals for multi-head printing; for example Hydra MMM; or my own pet project, RepolaRap, which could acquire multi-head printing by adding additional Z + Extruder arms radially around the lower platforms.

Several designs and branches also have thoughts or stated goals for multi-head printing; for example Hydra MMM; or my own pet project, RepolaRap, which could acquire multi-head printing by adding additional Z + Extruder arms radially around the lower platforms.

|

Re: Extruder revolver April 20, 2010 03:40PM |

Registered: 14 years ago Posts: 117 |

SebastienBailard Wrote:

-------------------------------------------------------

>

> How would you do it?

Well I'm not a mechanical engineer and have never seen an extruder in real life but from what I see the really bulky part of the extruder is the stepper. The hot end is mostly vertical.

Since most extruder designs are geared my take on it would be to mount multiple hot ends on one extruder platform and use some kind of selectable gear setup to drive only the one you want to use.

I don't really see the need for two identical extruder heads. I'm an IT tech. We think doing the same thing twice is boring. Thats what scripts are for

-------------------------------------------------------

>

> How would you do it?

Well I'm not a mechanical engineer and have never seen an extruder in real life but from what I see the really bulky part of the extruder is the stepper. The hot end is mostly vertical.

Since most extruder designs are geared my take on it would be to mount multiple hot ends on one extruder platform and use some kind of selectable gear setup to drive only the one you want to use.

I don't really see the need for two identical extruder heads. I'm an IT tech. We think doing the same thing twice is boring. Thats what scripts are for

|

Re: Extruder revolver April 20, 2010 05:52PM |

Registered: 14 years ago Posts: 278 |

Tiberius Wrote:

----

> I don't really see the need for two identical

> extruder heads. I'm an IT tech. We think doing the

> same thing twice is boring. Thats what scripts are

> for

Unless you're talking about printing in different plastics or colors, the extruders may very well be very different from each other. Some may not use a stepper or heater at all -- they might use an air compressor and pressure, for example, to extrude dough and frosting...

----

> I don't really see the need for two identical

> extruder heads. I'm an IT tech. We think doing the

> same thing twice is boring. Thats what scripts are

> for

Unless you're talking about printing in different plastics or colors, the extruders may very well be very different from each other. Some may not use a stepper or heater at all -- they might use an air compressor and pressure, for example, to extrude dough and frosting...

|

Re: Extruder revolver April 20, 2010 06:19PM |

Registered: 14 years ago Posts: 149 |

|

Re: Extruder revolver April 20, 2010 07:02PM |

Registered: 14 years ago Posts: 117 |

BeagleFury Wrote:

-------------------------------------------------------

> Some may not use

> a stepper or heater at all -- they might use an

> air compressor and pressure, for example, to

> extrude dough and frosting...

I was thinking about thermoplastics only at this point since this is what I was reading about at BFB. I found no detailed description on what they plan but the little info suggests they'd be mounting 2 or 3 identical thermoplastic extruders on their robot.

Like I already wrote I don't have any experiences with those machines but this was just staring in my face when I was reading up.

-------------------------------------------------------

> Some may not use

> a stepper or heater at all -- they might use an

> air compressor and pressure, for example, to

> extrude dough and frosting...

I was thinking about thermoplastics only at this point since this is what I was reading about at BFB. I found no detailed description on what they plan but the little info suggests they'd be mounting 2 or 3 identical thermoplastic extruders on their robot.

Like I already wrote I don't have any experiences with those machines but this was just staring in my face when I was reading up.

|

Re: Extruder revolver April 30, 2010 02:34PM |

Registered: 14 years ago Posts: 387 |

|

Re: Extruder revolver April 30, 2010 03:35PM |

Registered: 14 years ago Posts: 278 |

jbayless Wrote:

-------------------------------------------------------

> I'd love to have double thermoplastic extruders so

> that one could be super-fine, for printing precise

> boundaries, and the other could be super-wide, for

> doing fast infill.

>

There may be other solutions to printing in bulkier larger filament while still getting print detail beyond the current capabilities of the extruder. E.G, 0.1mm detail using 1mm extruded filament.

Think about analogies in clay -- if your robotic device could lay down 1cm diameter coils of clay, and had access to extra tool heads to shape that coil afterwords, could software be written to shape the rough forms created by the coils, layer by layer? How much greater detail could it actually achieve? Imagine it used a tool along the lines of a dentist's pick?

Now, from that, imagine shrinking the tools (if necessary), heating them, and applying those same techniques to thermoplastic. This is one of the ideas I'd like to play with at some time in the future. There certainly may be problems, such as how to prevent the thermoplastic from sticking to the tools, etc, but it seems with some trial and error, some solution could be utilized, and even work from the same mechanical device as the extruder... (I.E, one toolhead for both high detail as well as fast infill)

-------------------------------------------------------

> I'd love to have double thermoplastic extruders so

> that one could be super-fine, for printing precise

> boundaries, and the other could be super-wide, for

> doing fast infill.

>

There may be other solutions to printing in bulkier larger filament while still getting print detail beyond the current capabilities of the extruder. E.G, 0.1mm detail using 1mm extruded filament.

Think about analogies in clay -- if your robotic device could lay down 1cm diameter coils of clay, and had access to extra tool heads to shape that coil afterwords, could software be written to shape the rough forms created by the coils, layer by layer? How much greater detail could it actually achieve? Imagine it used a tool along the lines of a dentist's pick?

Now, from that, imagine shrinking the tools (if necessary), heating them, and applying those same techniques to thermoplastic. This is one of the ideas I'd like to play with at some time in the future. There certainly may be problems, such as how to prevent the thermoplastic from sticking to the tools, etc, but it seems with some trial and error, some solution could be utilized, and even work from the same mechanical device as the extruder... (I.E, one toolhead for both high detail as well as fast infill)

|

Re: Extruder revolver May 16, 2010 01:21AM |

Registered: 14 years ago Posts: 54 |

Here is a Bowden Tool-Change idea I had... when i wrote this i was really looking to post it here... but i couldn't find this thread when I was posting my idea.... go fig.... sorry.... MB

here's the link...

Bowden Tool Change Idea

here's the link...

Bowden Tool Change Idea

|

Re: Extruder revolver February 11, 2011 02:11PM |

Registered: 13 years ago Posts: 49 |

jbayless Wrote:

-------------------------------------------------------

> I'd love to have double thermoplastic extruders so

> that one could be super-fine, for printing precise

> boundaries, and the other could be super-wide, for

> doing fast infill.

[this is an old thread.. I'm having fun digging through the archives]

How about combining some ideas.

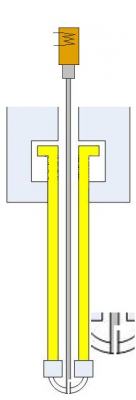

Over on the Anti-ooze nozzle thread, peteredworthy proposed a spring-loaded pin to plug the nozzle. If you modified the pin in his idea to not completely plug the nozzel hole, but leave an effectively smaller hole, and drove the pin with a solenoid so you can control when it is completely open/partially closed off, you might be able to get what you want without the need for a whole second extruder.

Here's a hacked up copy of peteredworthy's picture illustrating what I'm talking about:

I've drawn the pin with a central hole, but just machining a flat on one side of it would work too, although extrusion wouldn't be concentric at the two different nozzel sizes.

Truth be told, this isn't even my idea -- the diesel injectors on my car are designed this way.

-------------------------------------------------------

> I'd love to have double thermoplastic extruders so

> that one could be super-fine, for printing precise

> boundaries, and the other could be super-wide, for

> doing fast infill.

[this is an old thread.. I'm having fun digging through the archives]

How about combining some ideas.

Over on the Anti-ooze nozzle thread, peteredworthy proposed a spring-loaded pin to plug the nozzle. If you modified the pin in his idea to not completely plug the nozzel hole, but leave an effectively smaller hole, and drove the pin with a solenoid so you can control when it is completely open/partially closed off, you might be able to get what you want without the need for a whole second extruder.

Here's a hacked up copy of peteredworthy's picture illustrating what I'm talking about:

I've drawn the pin with a central hole, but just machining a flat on one side of it would work too, although extrusion wouldn't be concentric at the two different nozzel sizes.

Truth be told, this isn't even my idea -- the diesel injectors on my car are designed this way.

Sorry, only registered users may post in this forum.