Removing gears from steppers

Posted by ksmith5135

|

Removing gears from steppers May 14, 2010 12:18PM |

Registered: 14 years ago Posts: 43 |

I bought 4 Nema17 steppers from ebay. they work fine but they already have gears attached and I don't know how to remove them. There is no set screw and I haven't been able to pry them off with gentle pressure so I am at a loss. There seems to be a metal insert in the centre of the plastic gear, perhaps it is force fit onto the shaft?

These are single shaft motors so I can't clamp the rear shaft in a vice to apply greater pressure. I am afraid of damaging the motor bearings if I pry too hard on the gears with the motor body in the vice.

Any suggestions on removing them?

Kevin

Always use the right tool for the job, and the right tool for every job is a hammer.

Note - the above is not true but some days it feels like it's true.

[kevins3dprinter.blogspot.com]

These are single shaft motors so I can't clamp the rear shaft in a vice to apply greater pressure. I am afraid of damaging the motor bearings if I pry too hard on the gears with the motor body in the vice.

Any suggestions on removing them?

Kevin

Always use the right tool for the job, and the right tool for every job is a hammer.

Note - the above is not true but some days it feels like it's true.

[kevins3dprinter.blogspot.com]

|

Re: Removing gears from steppers May 14, 2010 12:51PM |

Registered: 15 years ago Posts: 132 |

You need a device called a "Wheel Puller." I had a machinist friend take the gear off when he knurled my motor.

Larger versions are sold by auto parts dealers. For a Nema-17 the puller is fairly small.

Usually there are 3 adjustable clamp arms which grip the underside of the wheel or gear to remove. In the center is a screw that contacts with the shaft. By tightening the screw the arms close in and the shorter distance causes the press fit part to slide off.

Sometimes it helps to freeze the shaft and the gear, this causes the metal to contract. I seem to recall though that the freezing work better when press fitting.

Only a few thousandths are needed to press fit. Such joins require great precision.

-julie

Larger versions are sold by auto parts dealers. For a Nema-17 the puller is fairly small.

Usually there are 3 adjustable clamp arms which grip the underside of the wheel or gear to remove. In the center is a screw that contacts with the shaft. By tightening the screw the arms close in and the shorter distance causes the press fit part to slide off.

Sometimes it helps to freeze the shaft and the gear, this causes the metal to contract. I seem to recall though that the freezing work better when press fitting.

Only a few thousandths are needed to press fit. Such joins require great precision.

-julie

|

Re: Removing gears from steppers May 14, 2010 12:53PM |

Registered: 14 years ago Posts: 8 |

|

Re: Removing gears from steppers May 14, 2010 01:34PM |

Registered: 14 years ago Posts: 43 |

Thanks for the replies. I will check with my machinist resources for a gear puller. I have used them when working on cars but I didn't realize that they made them this small.

I considered heating up the gears but I wasn't certain what heating the shaft would do to the motor. also, the gears are plastic with a metal insert so it would be a smelly and messy job to burn off the gear and then heat the insert.

Kevin

Always use the right tool for the job, and the right tool for every job is a hammer.

Note - the above is not true but some days it feels like it's true.

[kevins3dprinter.blogspot.com]

I considered heating up the gears but I wasn't certain what heating the shaft would do to the motor. also, the gears are plastic with a metal insert so it would be a smelly and messy job to burn off the gear and then heat the insert.

Kevin

Always use the right tool for the job, and the right tool for every job is a hammer.

Note - the above is not true but some days it feels like it's true.

[kevins3dprinter.blogspot.com]

|

Re: Removing gears from steppers May 14, 2010 04:42PM |

Registered: 15 years ago Posts: 180 |

You can also make your own mini gear puller using a flat steel bar, a tap, and a screw or bolt, a hammer, and a file.

Start with a piece of 1/8 inch thick steel, 1 inch wide, and 3 or more inches long (3 inches will let you pull a 1 inch diameter gear). Bend the steel bar into a box that is 1 inch long and 1/2 high, with the plate ends touching in the center of one of the 1 inch long sides. File the gap between the plates until it is the width of your shaft. Drill and tap the other 1 inch long side so that the hole is on center over the gap. Insert your screw into the tapped hole.

Now all you have to do is slide the gear yanker over the shaft and gear, tighten the screw down onto the shaft, keep tightening it until the gear comes off.

Heat treating the little puller is optional. You can add a nut to the top and bottom of screw is your tapped hole pulls out.

Thanks goes to Gordon McComb for the idea many years ago.

Start with a piece of 1/8 inch thick steel, 1 inch wide, and 3 or more inches long (3 inches will let you pull a 1 inch diameter gear). Bend the steel bar into a box that is 1 inch long and 1/2 high, with the plate ends touching in the center of one of the 1 inch long sides. File the gap between the plates until it is the width of your shaft. Drill and tap the other 1 inch long side so that the hole is on center over the gap. Insert your screw into the tapped hole.

Now all you have to do is slide the gear yanker over the shaft and gear, tighten the screw down onto the shaft, keep tightening it until the gear comes off.

Heat treating the little puller is optional. You can add a nut to the top and bottom of screw is your tapped hole pulls out.

Thanks goes to Gordon McComb for the idea many years ago.

|

Re: Removing gears from steppers May 22, 2010 09:52PM |

Registered: 14 years ago Posts: 149 |

I'd try putting it in a vise, with the gear on top of the jaws and the vise NOT clamped tight to the shaft. You want close, but not touching the shaft. You want the edge of the vise on the metal insert, not on the plastic.

Now take a punch and hammer and tap downward on the stepper shaft. You should be able to get it off and save both parts for re-use

Now take a punch and hammer and tap downward on the stepper shaft. You should be able to get it off and save both parts for re-use

|

Re: Removing gears from steppers October 12, 2010 06:43PM |

I think I purchased my nema-17 steppers from the same seller on ebay. Great price, 4 motors for $22 and they are great quality motors. The gears on mine were all metal though. I didn't have a bearing puller small enough to pull the gears off, so what I had used was a nut-splitter. It worked like a charm and didn't damage the shaft.

|

Re: Removing gears from steppers November 22, 2011 01:05AM |

I've bought the same motors like ksmith5135 did from ebay. Mine are metal, they seem. After some thought from reading criswilson10's post, i've come to the conclusion that i can do the same thing nearly with just a small piece of metal and two small bolts threaded onto a 1 inch by 1 inch piece of about 1/8 inch thick plate (even angle iron). After measuring and tapping the two holes, make so as the heads will nearly touch when screwed on. (the space between them being the thickness of your motor shaft). Now screw them on leaving only enough room to slide the metal on top of the gear and the bolt heads are under the gear, with shaft between them. Then drill, tap, and then screw a smaller bolt with the same diameter or bit smaller diameter as the shaft in between the other two holes. This makes a small puller using the two heads (screwed in upside down on the bottom of plate) of the bottom two small bolts and the shaft size bolt going straight down the middle pushing the pulley off with all force being applied to only upper part of shaft and the gear (or pulley).

Will post an update after i try this, don't see any reason it would not work. Only i may, depending on pressure needed to remove the gear, may have to flip on the old stick welder and zap the two screws keeping them from stripping threads and pulling through. I guess it depends on what size bolts you use and how tightly there are tapped.

Should save in good shape both shaft and gear or pulley.

Will post an update after i try this, don't see any reason it would not work. Only i may, depending on pressure needed to remove the gear, may have to flip on the old stick welder and zap the two screws keeping them from stripping threads and pulling through. I guess it depends on what size bolts you use and how tightly there are tapped.

Should save in good shape both shaft and gear or pulley.

|

Re: Removing gears from steppers November 22, 2011 12:12PM |

Registered: 15 years ago Posts: 180 |

Looks like someone finally put up an instructable on how to make the cheap mini gear puller.

[www.instructables.com]

[www.instructables.com]

|

Re: Removing gears from steppers January 23, 2012 02:39PM |

Registered: 13 years ago Posts: 61 |

|

Re: Removing gears from steppers April 07, 2012 01:17AM |

|

Machdiamond

Re: Removing gears from steppers May 01, 2012 12:41PM |

pica Wrote:

-------------------------------------------------------

> I'd try putting it in a vise, with the gear on top

> of the jaws and the vise NOT clamped tight to the

> shaft. You want close, but not touching the shaft.

> You want the edge of the vise on the metal insert,

> not on the plastic.

>

> Now take a punch and hammer and tap downward on

> the stepper shaft. You should be able to get it

> off and save both parts for re-use

DO NOT DO THIS! Any impact vibrations that travel to the stepper will render it junk. You know how I found out? By following the advice in this post. I ruined three expensive stepper motors to the tune of $175 with shipping. I only hit the center of each shaft with a punch and not even very hard. None of the motors would turn smoothly after doing this. The reason why, as I later found out, is that the rotor has a bunch of stacked plates that have to be precisely lined up. The vibrations cause them to move out of position. For the same reason that dropping a stepper motor is a bad idea. You can't take them apart to fix, because once you take a stepper apart, it loses a large amount of magnetism, and will have low torque. Special thanks to the person who posted the hammer trick, it cost me a bunch of money. Hopefully this reply will save someone from the same fate.

-------------------------------------------------------

> I'd try putting it in a vise, with the gear on top

> of the jaws and the vise NOT clamped tight to the

> shaft. You want close, but not touching the shaft.

> You want the edge of the vise on the metal insert,

> not on the plastic.

>

> Now take a punch and hammer and tap downward on

> the stepper shaft. You should be able to get it

> off and save both parts for re-use

DO NOT DO THIS! Any impact vibrations that travel to the stepper will render it junk. You know how I found out? By following the advice in this post. I ruined three expensive stepper motors to the tune of $175 with shipping. I only hit the center of each shaft with a punch and not even very hard. None of the motors would turn smoothly after doing this. The reason why, as I later found out, is that the rotor has a bunch of stacked plates that have to be precisely lined up. The vibrations cause them to move out of position. For the same reason that dropping a stepper motor is a bad idea. You can't take them apart to fix, because once you take a stepper apart, it loses a large amount of magnetism, and will have low torque. Special thanks to the person who posted the hammer trick, it cost me a bunch of money. Hopefully this reply will save someone from the same fate.

|

Re: Removing gears from steppers May 01, 2012 01:17PM |

Admin Registered: 17 years ago Posts: 7,879 |

I have taken steppers apart and put them back together with no great loss of torque, if any. I have received motors in the post where the rotor was touching the stator. I fixed one by dismantling and re-assembling and I fixed a second one just be loosening the screws and realigning.

Dr Adrian Bowyer asked a stepper motor manufacturer if it was a problem and they said not, so it may be a common myth like the one about micro stepping reducing torque.

[www.hydraraptor.blogspot.com]

Dr Adrian Bowyer asked a stepper motor manufacturer if it was a problem and they said not, so it may be a common myth like the one about micro stepping reducing torque.

[www.hydraraptor.blogspot.com]

|

Re: Removing gears from steppers May 01, 2012 02:35PM |

Registered: 13 years ago Posts: 2,947 |

I remove pulley by crushing them with vise grips really hard until they break and fall off. I got the idea because I know someone that uses a nut splitter to remove them. You can also just use the vise to crush them.

Note: This only works if the pulleys are cast.

Note: This only works if the pulleys are cast.

| FFF Settings Calculator | Gcode post processors | Geometric Object Deposition Tool Blog |

| Tantillus.org | Mini Printable Lathe | How NOT to install a Pololu driver |

|

Re: Removing gears from steppers May 02, 2012 02:44AM |

Admin Registered: 15 years ago Posts: 1,470 |

I have disassembled and reassembled steppers before with no ill-effects. They are not exactly precision mechanisms.

|

Help improve the RepRap wiki!

Just click "Edit" in the top-right corner of the page and start typing. Anyone can edit the wiki! |

|

Re: Removing gears from steppers May 03, 2012 12:57PM |

Registered: 13 years ago Posts: 43 |

NewPerfection Wrote:

-------------------------------------------------------

> I have disassembled and reassembled steppers

> before with no ill-effects. They are not exactly

> precision mechanisms.

There were ill effects, you just didn't realize. Steppers are essentially ruining by opening them up. You will never be able to get it back to factory condition after doing that. Maybe you aren't pushing the motors and didn't need the full capabilities of the motors, but reset assured that they were damaged to a certain degree by that.

-------------------------------------------------------

> I have disassembled and reassembled steppers

> before with no ill-effects. They are not exactly

> precision mechanisms.

There were ill effects, you just didn't realize. Steppers are essentially ruining by opening them up. You will never be able to get it back to factory condition after doing that. Maybe you aren't pushing the motors and didn't need the full capabilities of the motors, but reset assured that they were damaged to a certain degree by that.

|

Re: Removing gears from steppers May 03, 2012 05:30PM |

Admin Registered: 17 years ago Posts: 7,879 |

If this was true why would a motor manufacture say it was not a problem?

[www.hydraraptor.blogspot.com]

[www.hydraraptor.blogspot.com]

|

Re: Removing gears from steppers May 04, 2012 03:01AM |

Admin Registered: 16 years ago Posts: 13,886 |

... i think, this depends on the motor design - some hybrid motors with high torque are sensitive to sharp changes in magnetic field gradient, what's the case when pulling the end of the rotor along the stator with unsymmetric feeding.

Here you need a setup, that secure the symmetric assembly/disassembly of the rotor.

Others aren't sensible, so you won't detect any changes when reassembling them ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

Here you need a setup, that secure the symmetric assembly/disassembly of the rotor.

Others aren't sensible, so you won't detect any changes when reassembling them ...

Viktor

--------

Aufruf zum Projekt "Müll-freie Meere" - [reprap.org] -- Deutsche Facebook-Gruppe - [www.facebook.com]

Call for the project "garbage-free seas" - [reprap.org]

|

Re: Removing gears from steppers May 04, 2012 05:29PM |

Registered: 12 years ago Posts: 142 |

|

Re: Removing gears from steppers May 07, 2012 07:02PM |

Registered: 12 years ago Posts: 72 |

|

Re: Removing gears from steppers May 10, 2012 01:52AM |

Registered: 12 years ago Posts: 17 |

I've disassembled a bunch of steppers that weren't turning smoothly and reassembled them and they work great now.

I was surprised that some of them used standard 625ZZ bearings. A little bit of oil on them and they're good as new.

It's nice to know that when the bearings need to be replaced, they are cheap and easy to find.

Also, 625ZZ bearings can take moderate axial loads, so there's no need to use a thrust bearing when using them with a screw drive.

I was surprised that some of them used standard 625ZZ bearings. A little bit of oil on them and they're good as new.

It's nice to know that when the bearings need to be replaced, they are cheap and easy to find.

Also, 625ZZ bearings can take moderate axial loads, so there's no need to use a thrust bearing when using them with a screw drive.

|

Re: Removing gears from steppers May 25, 2012 07:55PM |

yngndrw Wrote:

-------------------------------------------------------

> Machdiamond:

>

> If the motors are broken anyway, you have nothing

> to lose by taking them apart and attempting a fix.

> Good luck with them, hopefully they will run find

> afterwards.

I did take them apart, that's how I found out how fragile they are regarding impact. I put them back together, but they only have about half the torque. Anyone who says that taking them apart does not make them weaker is wrong. The loss of torque is real and measurable. Those who do not have measuring equipment and are using these motors in light applications would most likely not notice, but if you are using them where you need all of the torque you paid for, they will come up short. See this thread:

[www.cnczone.com]

-------------------------------------------------------

> Machdiamond:

>

> If the motors are broken anyway, you have nothing

> to lose by taking them apart and attempting a fix.

> Good luck with them, hopefully they will run find

> afterwards.

I did take them apart, that's how I found out how fragile they are regarding impact. I put them back together, but they only have about half the torque. Anyone who says that taking them apart does not make them weaker is wrong. The loss of torque is real and measurable. Those who do not have measuring equipment and are using these motors in light applications would most likely not notice, but if you are using them where you need all of the torque you paid for, they will come up short. See this thread:

[www.cnczone.com]

|

Re: Removing gears from steppers April 02, 2016 12:18AM |

Registered: 8 years ago Posts: 1 |

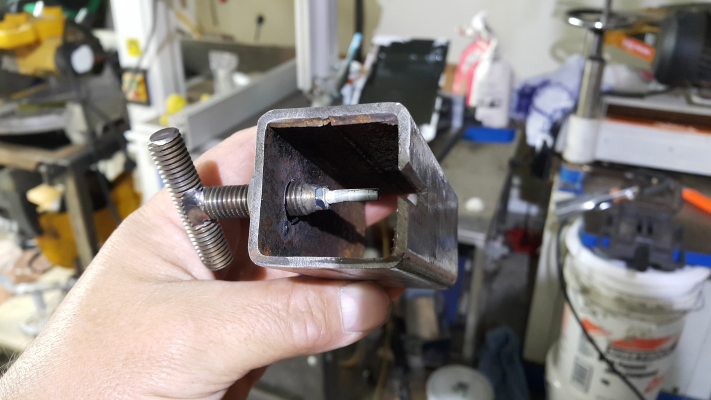

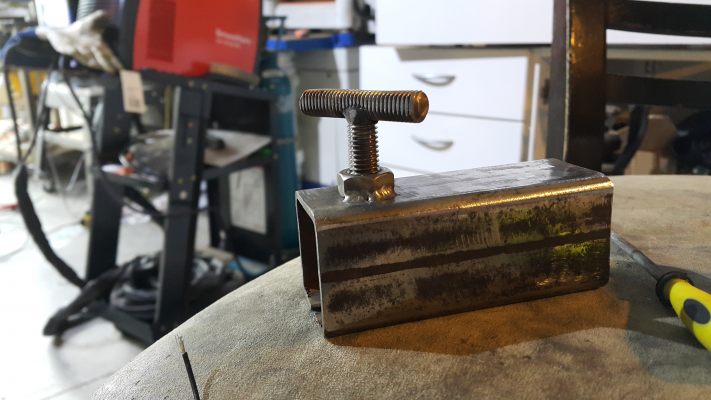

I'd just like to thank everyone for the help I found on this thread and show my example of solving the problem of removing these gears.

I had a couple of failures along the way including using too small a thread on the through bolt and grinding the push rod too thin due to not having a lathe. I ended up welding on a clean 4mm shaft on after the ground end failed. You definitely want to use a larger thread, I went with 10mm but 8mm would probably do.

Sorry If the images don't work.

I had a couple of failures along the way including using too small a thread on the through bolt and grinding the push rod too thin due to not having a lathe. I ended up welding on a clean 4mm shaft on after the ground end failed. You definitely want to use a larger thread, I went with 10mm but 8mm would probably do.

Sorry If the images don't work.

|

Anonymous User

Re: Removing gears from steppers April 02, 2016 05:27AM |

Sorry, only registered users may post in this forum.