Heated Bed ideas?

Posted by mantus

|

Heated Bed ideas? January 28, 2015 03:52AM |

Registered: 10 years ago Posts: 1,516 |

Hi,

i am upgrading my sparkcube to print on an 440x220 surface, but i am not sure what to use :/

At the moment i am printing on an 220x220x8 aluminium plate that i "impregnated" with PEI myself, heated with an silicon heater glued to the bottom.

This is a very good printing surface ... but in order to get the part of the surface it needs to cool down at least <50°C in order to pop the parts of.

at the moment i am testing woven carbon sheets, and they are also working very well, but also need to cool down to get the parts of.

So i had the idea that my ideal surface would be an 440x220x8 Aluminium block with the heaters attached to it, and a carbon sheet on top of it that is interchangeable.

So i am able to get the sheet of the the aluminium block with the parts on it, but another sheet on top of the aluminium, wait a few minutes in order to heat the sheet up, and start printing, without having to wait till the entire system cools down under 50°C and heat it up again in order to print the next parts.

But how can i attach the carbon sheet to the aluminium so that it is still changeable, but also is attached well enough so that it will not bend to prevent ABS from warping :/

Any ideas? or any ideas what else i can use as a surface, that suits my needs?

i am upgrading my sparkcube to print on an 440x220 surface, but i am not sure what to use :/

At the moment i am printing on an 220x220x8 aluminium plate that i "impregnated" with PEI myself, heated with an silicon heater glued to the bottom.

This is a very good printing surface ... but in order to get the part of the surface it needs to cool down at least <50°C in order to pop the parts of.

at the moment i am testing woven carbon sheets, and they are also working very well, but also need to cool down to get the parts of.

So i had the idea that my ideal surface would be an 440x220x8 Aluminium block with the heaters attached to it, and a carbon sheet on top of it that is interchangeable.

So i am able to get the sheet of the the aluminium block with the parts on it, but another sheet on top of the aluminium, wait a few minutes in order to heat the sheet up, and start printing, without having to wait till the entire system cools down under 50°C and heat it up again in order to print the next parts.

But how can i attach the carbon sheet to the aluminium so that it is still changeable, but also is attached well enough so that it will not bend to prevent ABS from warping :/

Any ideas? or any ideas what else i can use as a surface, that suits my needs?

|

Re: Heated Bed ideas? January 28, 2015 04:13AM |

Registered: 10 years ago Posts: 14,672 |

Many people use interchangeable glass plates on top of an aluminium heated bed. I hold mine down using picture frame clips:

I guess you could use this approach with carbon fibre sheet too, if you don't like printing on glass..

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

I guess you could use this approach with carbon fibre sheet too, if you don't like printing on glass..

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heated Bed ideas? January 28, 2015 04:33AM |

Registered: 10 years ago Posts: 1,516 |

ABS does not stick to glass without any modifications like ABS-juice, kapton tape, or PVA-juice ..

Carbon sheets would have the advantage that ABS sticks directly to it at the right temperatures, and pops of by itself when cooling down.

i already tried glueing the carbon sheet to a sheet of glas and attaching that to an aluminium plate .... but the heat take ages in order to heat up the new cold glas/carbon combination to 130°C :/

so i tried to use a thin carbon sheet directly on top of the aluminium .... the surface heats very quick after changing the carbon sheet, but the problem is that this thin sheet lifts during printing due to the fact that it is not stiff enough on its own :/

Carbon sheets would have the advantage that ABS sticks directly to it at the right temperatures, and pops of by itself when cooling down.

i already tried glueing the carbon sheet to a sheet of glas and attaching that to an aluminium plate .... but the heat take ages in order to heat up the new cold glas/carbon combination to 130°C :/

so i tried to use a thin carbon sheet directly on top of the aluminium .... the surface heats very quick after changing the carbon sheet, but the problem is that this thin sheet lifts during printing due to the fact that it is not stiff enough on its own :/

|

Re: Heated Bed ideas? January 28, 2015 06:03AM |

Registered: 10 years ago Posts: 14,672 |

Would a thicker piece of carbon sheet work?

Otherwise, I guess you could use suction to hold the thin piece down. Machine a set of narrow grooves in the top of the alu plate, stopping short of the edges. Connect each groove to the underside by drilling a small hole, and connect a suction pump to the holes. But it seems over-complicated to me.

Edited 1 time(s). Last edit at 01/28/2015 06:12AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Otherwise, I guess you could use suction to hold the thin piece down. Machine a set of narrow grooves in the top of the alu plate, stopping short of the edges. Connect each groove to the underside by drilling a small hole, and connect a suction pump to the holes. But it seems over-complicated to me.

Edited 1 time(s). Last edit at 01/28/2015 06:12AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heated Bed ideas? January 28, 2015 06:51AM |

Registered: 10 years ago Posts: 1,516 |

|

Re: Heated Bed ideas? January 29, 2015 09:15AM |

Registered: 12 years ago Posts: 88 |

|

Re: Heated Bed ideas? March 06, 2015 10:24AM |

Registered: 9 years ago Posts: 65 |

As has been mentioned, a thicker piece of carbon might work. Or try bonding the CF sheet to another piece of aluminum to stiffen it up and help the heat transfer. Glass is a very poor conductor of heat, aluminum is ~250x better.

Sorry to pull the thread a little OT but can you describe your current AL bed and how you treated it? I'm thinking on trying an aluminum bed but finding FLAT aluminum for the DIYer is a little difficult. I can make it perfectly flat myself by hand but that would take a lot of elbow grease.

Sorry to pull the thread a little OT but can you describe your current AL bed and how you treated it? I'm thinking on trying an aluminum bed but finding FLAT aluminum for the DIYer is a little difficult. I can make it perfectly flat myself by hand but that would take a lot of elbow grease.

|

Re: Heated Bed ideas? March 06, 2015 12:23PM |

Registered: 10 years ago Posts: 869 |

Quote

Ryan_M

I'm thinking on trying an aluminum bed but finding FLAT aluminum for the DIYer is a little difficult. I can make it perfectly flat myself by hand but that would take a lot of elbow grease.

If you have a Metals Supermarket near you, they sell (or at least can order) MIC6 aluminum plate. The one near me occasionally has cutoffs at a discount. I'm sure other similar type retailers can do the same. You can also find it on ebay in various sizes and shapes. The downside of MIC6 or similar cast plates is that while they are very flat, they are at least 1/4" thick so it will take considerable time to reach full temp due to their mass.

If you don't need the same flatness tolerance of MIC6 and want lighter, you can get just a piece of rolled sheet or plate that's probably "good enough" in the flatness department.

|

Re: Heated Bed ideas? March 07, 2015 11:49AM |

Registered: 11 years ago Posts: 5,780 |

You could place a couple fans along side the bed and turn them on after a print has finished using custom gcode. That should speed the cooling of the bed.

If you go with aluminum, definitely get cast tooling plate. Extruded plate is not flat enough in the size you're talking about. If your bed moves in the Y axis you'll have a high moving mass which will require a more powerful motor if you want to keep print speeds reasonably high. That means going to NEMA-23 size motor, but that will lead to vibration and noise, especially if the bed plate is stood up on springs as per usual. You can reduce vibration/noise a bit by using a DSP driver with higher microstepping and a higher voltage power supply. I've done all these and more for my 305mm x 317mm bed, including changing from belt to screw drive to eliminate artifacts created by belt stretch, and while precision and print quality are very high, the machine is noisy.

I'm considering ditching the heated bed completely and printing on PIR foam. There's no need for any electronics and it's simpler mechanically because there's no need to level the bed. It can also have a much lower moving mass because all you need is a light frame to hold the foam in place. When you print you just bury the nozzle about a mm into the foam for the first layer. You have to print on a raft every time so you never get the shiny smooth bottom surface that a metal or glass plate provides, but you never have a glossy top or side surfaces either. The foam costs about $0.50 for a square foot and can be printed on multiple times before it needs to be replaced, so the cost isn't really an issue. The cost savings from not buying a heater, dedicated power supply, flat plate, etc. can buy an awful lot of PIR foam. I have used ABS successfully from the first attempt, but have not tried other materials.

PIR foam is used as insulation material. It is fire resistant and does not decompose at printer nozzle temperatures. It is readily available at home improvement stores for $15 for a 4' x 8' x 1" thick sheet. It comes with paper and/or foil glued to one or both sides that you have to peel off before printing on it, but that's easy. You can cut it to whatever size you need in seconds with a razor knife.

The idea of printing on a sacrificial bed is not new- Stratasys has been doing it for many years. See: [haveblue.org] and [vimeo.com]. The skull in the video was printed using ABS. As you can see, it hangs on tight.

A couple photos here: [mark.rehorst.com]

and here: [mark.rehorst.com]

Note: this bearing block was printed with ABS directly on the foam without a raft. The second photo shows that the bottom surface actually picks up some of the foam when pulled off the bed.

If one were going to print on PIR foam a lot, it might be best to cut the foam piece to the approximate size of the base of the print. That way when the print is finished, if the part doesn't want to release (see the video for the grip it provides) you can use a knife or saw to release the part from the foam. Using a raft would probably eliminate the problem of too much adhesion for large prints. For my experiments I used contact cement and double sided tape to hold the foam on the glass bed of my printer. if I were designing a bed to hold the foam I might use a couple short, sharp tacks to stick into the foam to prevent it shifting while printing and/or make a perimeter of aluminum angle stock that holds it down.

Edited 4 time(s). Last edit at 03/07/2015 12:10PM by the_digital_dentist.

If you go with aluminum, definitely get cast tooling plate. Extruded plate is not flat enough in the size you're talking about. If your bed moves in the Y axis you'll have a high moving mass which will require a more powerful motor if you want to keep print speeds reasonably high. That means going to NEMA-23 size motor, but that will lead to vibration and noise, especially if the bed plate is stood up on springs as per usual. You can reduce vibration/noise a bit by using a DSP driver with higher microstepping and a higher voltage power supply. I've done all these and more for my 305mm x 317mm bed, including changing from belt to screw drive to eliminate artifacts created by belt stretch, and while precision and print quality are very high, the machine is noisy.

I'm considering ditching the heated bed completely and printing on PIR foam. There's no need for any electronics and it's simpler mechanically because there's no need to level the bed. It can also have a much lower moving mass because all you need is a light frame to hold the foam in place. When you print you just bury the nozzle about a mm into the foam for the first layer. You have to print on a raft every time so you never get the shiny smooth bottom surface that a metal or glass plate provides, but you never have a glossy top or side surfaces either. The foam costs about $0.50 for a square foot and can be printed on multiple times before it needs to be replaced, so the cost isn't really an issue. The cost savings from not buying a heater, dedicated power supply, flat plate, etc. can buy an awful lot of PIR foam. I have used ABS successfully from the first attempt, but have not tried other materials.

PIR foam is used as insulation material. It is fire resistant and does not decompose at printer nozzle temperatures. It is readily available at home improvement stores for $15 for a 4' x 8' x 1" thick sheet. It comes with paper and/or foil glued to one or both sides that you have to peel off before printing on it, but that's easy. You can cut it to whatever size you need in seconds with a razor knife.

The idea of printing on a sacrificial bed is not new- Stratasys has been doing it for many years. See: [haveblue.org] and [vimeo.com]. The skull in the video was printed using ABS. As you can see, it hangs on tight.

A couple photos here: [mark.rehorst.com]

and here: [mark.rehorst.com]

Note: this bearing block was printed with ABS directly on the foam without a raft. The second photo shows that the bottom surface actually picks up some of the foam when pulled off the bed.

If one were going to print on PIR foam a lot, it might be best to cut the foam piece to the approximate size of the base of the print. That way when the print is finished, if the part doesn't want to release (see the video for the grip it provides) you can use a knife or saw to release the part from the foam. Using a raft would probably eliminate the problem of too much adhesion for large prints. For my experiments I used contact cement and double sided tape to hold the foam on the glass bed of my printer. if I were designing a bed to hold the foam I might use a couple short, sharp tacks to stick into the foam to prevent it shifting while printing and/or make a perimeter of aluminum angle stock that holds it down.

Edited 4 time(s). Last edit at 03/07/2015 12:10PM by the_digital_dentist.

|

Re: Heated Bed ideas? March 07, 2015 12:43PM |

Registered: 10 years ago Posts: 14,672 |

Quote

the_digital_dentist

I'm considering ditching the heated bed completely and printing on PIR foam. There's no need for any electronics and it's simpler mechanically because there's no need to level the bed. It can also have a much lower moving mass because all you need is a light frame to hold the foam in place.

The other way to simplify the bed design is to use a different architecture - although I appreciate this isn't an upgrade option for an existing printer. A delta printer has a fixed bed, so keeping it level is easy. It also makes it more practical to use AC mains power for the bed, which is an advantage for large beds. Of course, electrical safety still needs to be designed in. A CoreXY printer moves the bed in the Z direction, and as Z movement can be much slower than XY movement, the mass of the bed is not such a big issue.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Heated Bed ideas? September 03, 2015 08:14PM |

Registered: 12 years ago Posts: 325 |

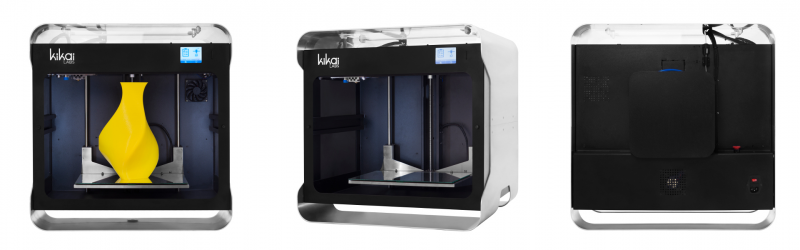

paste magnets beneath the glass, and have a metal part on the platform for it to adhere to... works great for us at Kikai Labs!

Just be careful when removing the object from the glass when it's on the table, using a spatula, since the magnets will prevent the glass from lying flat on the table.

Edited 1 time(s). Last edit at 09/03/2015 08:16PM by paucus.

Just be careful when removing the object from the glass when it's on the table, using a spatula, since the magnets will prevent the glass from lying flat on the table.

Edited 1 time(s). Last edit at 09/03/2015 08:16PM by paucus.

Sorry, only registered users may post in this forum.