Whats wrong with this hotend

Posted by SQLException

|

Whats wrong with this hotend July 24, 2015 01:57PM |

Registered: 8 years ago Posts: 114 |

After a couple weeks not using my i3 Hephestos the filament gets stuck inside the Extruder. First I though it's the Pulley of the stepper so I replaced it, but filament is still blocked when trying to feed it in. This is my Extruder: [imgur.com]

The filament feeds about 3-4 cm, then it stops. When I pull it out again it looks like this: [imgur.com] At this point I can push the filament in, but only for the said 3-4 cm, then it blocks completly.

So I dissambled it to see whats wrong.Theres no lump of old filament or anything. I was able to pull that white piece of plastic out, the lid (cold end) and the piece of plastic look pretty normal to me. I can clearly see through it, nothing clogged. [imgur.com]

[imgur.com]

[imgur.com]

I don't see any dents or cracks inside, as I don't know what a working hotend looks like, but I guess this is what it should look like. Trying with PLA at 210, 220 and 240°, it's always the same. About to order a new Hotend from bq but f, this can't be it. Printer less then 5 objects with it.

Any ideas?

edit: right after writing this posting, maybe its because the lid needs more cooling? It looks like the upper end of the filament is melting faster then the real end, so it gets stuck ABOVE the piece of pastic.

edit2: nope, it gets stuck pretty much the same.

Edited 3 time(s). Last edit at 07/24/2015 03:44PM by SQLException.

The filament feeds about 3-4 cm, then it stops. When I pull it out again it looks like this: [imgur.com] At this point I can push the filament in, but only for the said 3-4 cm, then it blocks completly.

So I dissambled it to see whats wrong.Theres no lump of old filament or anything. I was able to pull that white piece of plastic out, the lid (cold end) and the piece of plastic look pretty normal to me. I can clearly see through it, nothing clogged. [imgur.com]

[imgur.com]

[imgur.com]

I don't see any dents or cracks inside, as I don't know what a working hotend looks like, but I guess this is what it should look like. Trying with PLA at 210, 220 and 240°, it's always the same. About to order a new Hotend from bq but f, this can't be it. Printer less then 5 objects with it.

Any ideas?

edit: right after writing this posting, maybe its because the lid needs more cooling? It looks like the upper end of the filament is melting faster then the real end, so it gets stuck ABOVE the piece of pastic.

edit2: nope, it gets stuck pretty much the same.

Edited 3 time(s). Last edit at 07/24/2015 03:44PM by SQLException.

|

Re: Whats wrong with this hotend July 24, 2015 02:27PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Whats wrong with this hotend July 24, 2015 02:34PM |

Registered: 8 years ago Posts: 114 |

The piece of plastic inside the Extruder is cone-shaped at the entrance. Also, when I push in filament (the hard way) it does extrude a bit. This should ensure the filament found "its way".

Tried ABS now at 220 - 250. No luck.

[youtu.be]

You can see at 00:11 and 00:18 theres only extrusion if I push it in hard. I'm out of ideas.

Edited 1 time(s). Last edit at 07/24/2015 02:53PM by SQLException.

Tried ABS now at 220 - 250. No luck.

[youtu.be]

You can see at 00:11 and 00:18 theres only extrusion if I push it in hard. I'm out of ideas.

Edited 1 time(s). Last edit at 07/24/2015 02:53PM by SQLException.

|

Re: Whats wrong with this hotend July 24, 2015 08:51PM |

Registered: 9 years ago Posts: 606 |

If you take the nozzle off, but leave everything else in place, does the filament move freely through the head? It almost sounds like either the throat is undersize, or the filament is oversize . . . Any change you have a 1.75 mm nozzle on a 3mm feed? You don't say what diameter filament you are using . . .

- Tim

- Tim

|

Re: Whats wrong with this hotend July 25, 2015 02:38AM |

Registered: 10 years ago Posts: 814 |

|

Re: Whats wrong with this hotend July 25, 2015 02:47AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Whats wrong with this hotend July 25, 2015 06:32AM |

Registered: 8 years ago Posts: 114 |

The 2 or 3 things I printed yet were not at 250°.

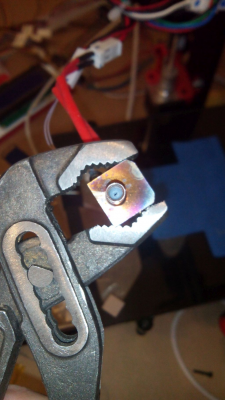

Not sure if I can take the nozzle off. [i.imgur.com]

Although its dirty and the picture shows you can take it off, I don't see how. I tried it when the end was clean, but it looks like the extruder and nozzle are one piece (or I'm just wrong)? [i.imgur.com]

Removed heating cartridge and thermistor right now, I might give the oven a try to get rid of old PLA (if theres any). Also checking the DIY stores if I can get 4x2mm teflon tubes there, although mine looks normal to me.

Olaf, looks like aceton does nothing to PLA.

Yes, I do have to pull it out hard to get it out. When its cold again, filament goes out better. So yeah it sounds like something is wrong with this stupid PTFE liner.

Edited 2 time(s). Last edit at 07/25/2015 07:05AM by SQLException.

Not sure if I can take the nozzle off. [i.imgur.com]

Although its dirty and the picture shows you can take it off, I don't see how. I tried it when the end was clean, but it looks like the extruder and nozzle are one piece (or I'm just wrong)? [i.imgur.com]

Removed heating cartridge and thermistor right now, I might give the oven a try to get rid of old PLA (if theres any). Also checking the DIY stores if I can get 4x2mm teflon tubes there, although mine looks normal to me.

Olaf, looks like aceton does nothing to PLA.

Yes, I do have to pull it out hard to get it out. When its cold again, filament goes out better. So yeah it sounds like something is wrong with this stupid PTFE liner.

Edited 2 time(s). Last edit at 07/25/2015 07:05AM by SQLException.

|

Re: Whats wrong with this hotend July 25, 2015 12:12PM |

Registered: 9 years ago Posts: 606 |

That exploded view isn't your extruder, not even close . . . The lack of a heat break is unusual . . . not exactly sure how this is supposed to work . . with the heater basically clamped into the sink, and no heat break, how do you maintain a cold section on this thing exactly? And is there a fan directly on that heatsink? If not, the problem, at least to me, is pretty apparent . . .

- Tim

Edited 2 time(s). Last edit at 07/25/2015 04:26PM by tadawson.

- Tim

Edited 2 time(s). Last edit at 07/25/2015 04:26PM by tadawson.

|

Re: Whats wrong with this hotend July 25, 2015 02:26PM |

Registered: 8 years ago Posts: 114 |

True, this isn't my extruder. I didn't look closely at the extruder until now in that picture. But the rest of it (heatsink, fan, mountings) is my unit. Weird because bq also sells single nozzles as spare parts, when they don't even offer the right extruder for it oO. (or at least the extruders in their printers differ from the spare parts they sell)

However, here it is now for reals: www.3dee.at/produkt/bq-dde-hotend/

You can see it's basicly 1 unit, the nozzle is embedded in the... Idk what it's called.

But the description says it has a mk7 nozzle.

Will order 1m of 4x2mm PTFE tube next week, this has to work then.

Edited 1 time(s). Last edit at 07/25/2015 02:29PM by SQLException.

However, here it is now for reals: www.3dee.at/produkt/bq-dde-hotend/

You can see it's basicly 1 unit, the nozzle is embedded in the... Idk what it's called.

But the description says it has a mk7 nozzle.

Will order 1m of 4x2mm PTFE tube next week, this has to work then.

Edited 1 time(s). Last edit at 07/25/2015 02:29PM by SQLException.

|

Re: Whats wrong with this hotend July 25, 2015 04:51PM |

Registered: 10 years ago Posts: 814 |

|

Re: Whats wrong with this hotend July 25, 2015 05:29PM |

Registered: 8 years ago Posts: 114 |

|

Re: Whats wrong with this hotend July 28, 2015 12:30PM |

Registered: 8 years ago Posts: 114 |

Cleaned the inside + new Inliner = same old shit.

New bearings for 90 bucks, new printing bed (another ~90) to have this thing ready, just to end up with a crap hotend. Ordered a new hotend now, not from bq though. This "single unit" wannabe hotend is really frustrating because you can't fully disassemble it (this might be likely for a "all metal hotend" - but this is none of those because it still has an inliner).

Edited 5 time(s). Last edit at 07/28/2015 04:43PM by SQLException.

New bearings for 90 bucks, new printing bed (another ~90) to have this thing ready, just to end up with a crap hotend. Ordered a new hotend now, not from bq though. This "single unit" wannabe hotend is really frustrating because you can't fully disassemble it (this might be likely for a "all metal hotend" - but this is none of those because it still has an inliner).

Edited 5 time(s). Last edit at 07/28/2015 04:43PM by SQLException.

|

Re: Whats wrong with this hotend July 28, 2015 04:32PM |

Registered: 8 years ago Posts: 114 |

Checked the temperature at the heating block/nozzle with this. It's 145 - 150° max, when I try to heat it up to 250°. The thermistor right next to the heating cartridge reads 250° though.

I don't think the heating cartridge is faulty, if I pull it out it instantly hits 200+. However, I still just replaced it...

Can it be the (original) thermistor in the heating block is horribly wrong (reading 90-100° more then the temperature actually is?). The thermistor is the last thing I didn't replace yet.

I don't think the heating cartridge is faulty, if I pull it out it instantly hits 200+. However, I still just replaced it...

Can it be the (original) thermistor in the heating block is horribly wrong (reading 90-100° more then the temperature actually is?). The thermistor is the last thing I didn't replace yet.

|

Re: Whats wrong with this hotend July 29, 2015 02:48AM |

Registered: 8 years ago Posts: 5,232 |

Wrong temperature reading would explain a lot!

What is the resistance of the thermistor at room temperature? ( unplugged )

What is the setting in the firmware?

Is it the right pullup resistor on the controller board? ( 10k instead of 4.7K would explain the 100% off temp)

What temperature do you read ( LCD or PC ) at room temp? Is it also way off compared to the heated bed temp?

-Olaf

Edited 2 time(s). Last edit at 07/29/2015 02:51AM by o_lampe.

What is the resistance of the thermistor at room temperature? ( unplugged )

What is the setting in the firmware?

Is it the right pullup resistor on the controller board? ( 10k instead of 4.7K would explain the 100% off temp)

What temperature do you read ( LCD or PC ) at room temp? Is it also way off compared to the heated bed temp?

-Olaf

Edited 2 time(s). Last edit at 07/29/2015 02:51AM by o_lampe.

|

Re: Whats wrong with this hotend July 29, 2015 04:06AM |

Registered: 10 years ago Posts: 14,672 |

Quote

SQLException

Checked the temperature at the heating block/nozzle with this. It's 145 - 150° max, when I try to heat it up to 250°. The thermistor right next to the heating cartridge reads 250° though.

You can't read the temperature of the hot and with an IR thermometer because (a) the IR thermometer sees over a much larger area than the hot end, and (b) the hot end is usual shiny, causing it to radiate less than an IR thermometer assumes.

One way of checking hot end temperature is to feed a thermocouple into the hot end. Many multimeters include a thermocouple attachment.

Do you have a hot end fan wired directly to 12V, blowing air over the heatsink all the time?

Edited 1 time(s). Last edit at 07/29/2015 04:09AM by dc42.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Whats wrong with this hotend July 29, 2015 07:25AM |

Registered: 8 years ago Posts: 114 |

I don't have a fan permanently blowing on the hotend-heatsink. But there is a fan attached to the extruder, and the extruder also has a heatsink. Somewhere in a earlier post should be a picture of the hotend. But I tried both with all of those fans on, or no fans. Same results.

There's another (axial) fan blowing on the nozzle, but with stock settings not at the first 5 layers.

With all my (wrong) IR-temperatue reading aside, it still might a heating Issue. I just had the hotend fully disassembled (except for the nozzle, as mentioned above you can't replace or remove it), then I inserted an extra long Inliner (~10cm). So it's basicly just the hotend + the long Inliner. Tried to push in filament, and it's basicly blocking instantly even when I set the temp to 250° (the heating block thermistor/LCD will correctly read 250). This must be because of low temperature at the nozzle.

When I stick the end of the filament right on the heating block (from outside...), it takes a short moment (maybe 1-3 seconds) until the end melts. Shouldn't it instantly melt?

I have a spare 100k thermistor here now from my heating bed (although not mounted in/with a M3, so it wil be a hassle to get it mounted on the heating block).

But before I do so, I will try to get the original firmware for my Hephestos. It all started when I wanted to upgrade my printing area to a new size and added a heatbed, resulting in a new Marlin-Firmware. Good point. Will look into this and also the other hints given. When I first installed my heat bed, with the new firmware I indeed had to modify some thermistor-related values (can't remember exactly what).

Edited 5 time(s). Last edit at 07/29/2015 07:31AM by SQLException.

There's another (axial) fan blowing on the nozzle, but with stock settings not at the first 5 layers.

With all my (wrong) IR-temperatue reading aside, it still might a heating Issue. I just had the hotend fully disassembled (except for the nozzle, as mentioned above you can't replace or remove it), then I inserted an extra long Inliner (~10cm). So it's basicly just the hotend + the long Inliner. Tried to push in filament, and it's basicly blocking instantly even when I set the temp to 250° (the heating block thermistor/LCD will correctly read 250). This must be because of low temperature at the nozzle.

When I stick the end of the filament right on the heating block (from outside...), it takes a short moment (maybe 1-3 seconds) until the end melts. Shouldn't it instantly melt?

I have a spare 100k thermistor here now from my heating bed (although not mounted in/with a M3, so it wil be a hassle to get it mounted on the heating block).

But before I do so, I will try to get the original firmware for my Hephestos. It all started when I wanted to upgrade my printing area to a new size and added a heatbed, resulting in a new Marlin-Firmware. Good point. Will look into this and also the other hints given. When I first installed my heat bed, with the new firmware I indeed had to modify some thermistor-related values (can't remember exactly what).

Edited 5 time(s). Last edit at 07/29/2015 07:31AM by SQLException.

|

Re: Whats wrong with this hotend July 30, 2015 03:24PM |

Registered: 8 years ago Posts: 114 |

So the bq website says the inliner is 4x2mm. I measured the old one 3.97mm, and my new one 4.04mm. A bit too large I guess, it's squeezed when inserted. No way loading filament here:

Multimeter at "200k" right? So at 23° the thermistor is at 99k. Another (new) thermistor from my heatbed is at about 95k+.

At "20k ohm", measured any endstop (red) and the red wire of the thermistor, the display shows 4.48 (4.48k like you said in the PM?).

New china Ramps + Hotend should be here in about 2 weeks, guess theres no other way out.

Edited 5 time(s). Last edit at 07/30/2015 03:30PM by SQLException.

Multimeter at "200k" right? So at 23° the thermistor is at 99k. Another (new) thermistor from my heatbed is at about 95k+.

At "20k ohm", measured any endstop (red) and the red wire of the thermistor, the display shows 4.48 (4.48k like you said in the PM?).

New china Ramps + Hotend should be here in about 2 weeks, guess theres no other way out.

Edited 5 time(s). Last edit at 07/30/2015 03:30PM by SQLException.

|

Re: Whats wrong with this hotend August 01, 2015 12:53PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Whats wrong with this hotend August 03, 2015 12:20PM |

Registered: 11 years ago Posts: 364 |

|

Re: Whats wrong with this hotend August 03, 2015 12:23PM |

Registered: 8 years ago Posts: 114 |

|

Re: Whats wrong with this hotend August 03, 2015 01:22PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Whats wrong with this hotend August 03, 2015 03:36PM |

Registered: 8 years ago Posts: 114 |

Sorry, only registered users may post in this forum.