Types of linear guides and mounting options

Posted by Dalius98

|

Types of linear guides and mounting options November 05, 2015 06:07PM |

Registered: 8 years ago Posts: 67 |

Hello. Following my recent topic, I've decided to stay with my initial intentions of building a coreXY type machine with a 300x300 or 400x400mm bed size.

Now I'm trying to decide on a linear guide system... I've been told that any kind will be more than adequate, but since I'll probably end up buying them new, I might as well get something a bit more suited for this operation...

So far I was under the impression that linear blocks with four rows of steel balls are better than the ones with just two (medium load vs miniature type), but I've found this spec sheet of misumi's guide precision, and I'm not sure I'm interpreting this right. Basically, miniature rails are more consistent in their with/height (does that even matter) and are available in "precision" grade, while medium load type has a lower friction coef (needs less force to move?) and is a tiny bit more accurate in a standart accuracy grade, right?

The pricing of all these rails adds even more confusion... A standart medium load carriage + 500mm of its rail is ~47€, while a standart size miniature carriage + rail is ~51€... adding a second carriage adds about 6-8€, and getting a longer block is just +2€ in some cases...

Buut, that's only if Misumi actually sells to private customers. I've tried registering but it asked for a company name, so I'm not too sure they do... If not, I'm kinda limited on my choices, so far I was able to find a German reseller (not sure if I'm allowed to advertise or something, so here's a photo the "selection") of some guides (doesn't seem like Misumi or Hiwin part numbers though). Could you recommend someone withing Europe with reasonable shipping costs?

On to the next topic - what is a better way to mount the guides to the body of a printer? I've seen most of the pictured mounting options incorporated into some designs, but I wasn't able to find any reason why one or another way was used... (keep in mind this is a CoreXY build). Also, how are we supposed to mount the hotend to a single rail on X axis? Mounting it in the middle of two smooth rods seemed very obvious, now - not so much. Also, is a piece of aluminium extrusion to support the X guide rail a good idea? (seen this on some designs too).

By the way if this is of any help - I'll probably end up building the printer out of 40x40mm (and 40x80) aluminium extrusions, just because these are readily available at a local scrapyard for incredibly cheap (per kg) prices. I'm not too concerned about the weight of the whole assembly and it might just add enough stiffness I already have some Nema23 stepper motors i'll be using (though they are 5200g/cm (~72oz/in) torque, 1.5A, just like your usual nema17), and ordered some GT2 belts and pulleys, some radial bearings and other bits and pieces not too dependent on my following decisions.

I already have some Nema23 stepper motors i'll be using (though they are 5200g/cm (~72oz/in) torque, 1.5A, just like your usual nema17), and ordered some GT2 belts and pulleys, some radial bearings and other bits and pieces not too dependent on my following decisions.

I'll probably end up creating another topic concerning the whole build process and to ask some more questions, but it would be nice to get some fresh tips while I still have your attention: preferred hotend? I'm considering going dual with something like Chimera, but any tips are welcome. preferred bowden type extruder? Any good youtube channels about 3D printing?

Big thanks in advance. (I just hope that people actually visit this "Mechanics" part of a forum)

Edited 3 time(s). Last edit at 11/06/2015 04:29AM by Dalius98.

Now I'm trying to decide on a linear guide system... I've been told that any kind will be more than adequate, but since I'll probably end up buying them new, I might as well get something a bit more suited for this operation...

So far I was under the impression that linear blocks with four rows of steel balls are better than the ones with just two (medium load vs miniature type), but I've found this spec sheet of misumi's guide precision, and I'm not sure I'm interpreting this right. Basically, miniature rails are more consistent in their with/height (does that even matter) and are available in "precision" grade, while medium load type has a lower friction coef (needs less force to move?) and is a tiny bit more accurate in a standart accuracy grade, right?

The pricing of all these rails adds even more confusion... A standart medium load carriage + 500mm of its rail is ~47€, while a standart size miniature carriage + rail is ~51€... adding a second carriage adds about 6-8€, and getting a longer block is just +2€ in some cases...

Buut, that's only if Misumi actually sells to private customers. I've tried registering but it asked for a company name, so I'm not too sure they do... If not, I'm kinda limited on my choices, so far I was able to find a German reseller (not sure if I'm allowed to advertise or something, so here's a photo the "selection") of some guides (doesn't seem like Misumi or Hiwin part numbers though). Could you recommend someone withing Europe with reasonable shipping costs?

On to the next topic - what is a better way to mount the guides to the body of a printer? I've seen most of the pictured mounting options incorporated into some designs, but I wasn't able to find any reason why one or another way was used... (keep in mind this is a CoreXY build). Also, how are we supposed to mount the hotend to a single rail on X axis? Mounting it in the middle of two smooth rods seemed very obvious, now - not so much. Also, is a piece of aluminium extrusion to support the X guide rail a good idea? (seen this on some designs too).

By the way if this is of any help - I'll probably end up building the printer out of 40x40mm (and 40x80) aluminium extrusions, just because these are readily available at a local scrapyard for incredibly cheap (per kg) prices. I'm not too concerned about the weight of the whole assembly and it might just add enough stiffness

I already have some Nema23 stepper motors i'll be using (though they are 5200g/cm (~72oz/in) torque, 1.5A, just like your usual nema17), and ordered some GT2 belts and pulleys, some radial bearings and other bits and pieces not too dependent on my following decisions.

I already have some Nema23 stepper motors i'll be using (though they are 5200g/cm (~72oz/in) torque, 1.5A, just like your usual nema17), and ordered some GT2 belts and pulleys, some radial bearings and other bits and pieces not too dependent on my following decisions.I'll probably end up creating another topic concerning the whole build process and to ask some more questions, but it would be nice to get some fresh tips while I still have your attention: preferred hotend? I'm considering going dual with something like Chimera, but any tips are welcome. preferred bowden type extruder? Any good youtube channels about 3D printing?

Big thanks in advance. (I just hope that people actually visit this "Mechanics" part of a forum)

Edited 3 time(s). Last edit at 11/06/2015 04:29AM by Dalius98.

|

Re: Types of liner guides and mounting options November 05, 2015 08:03PM |

Registered: 11 years ago Posts: 5,780 |

First of all, kudos for using your local scrap yard to get the aluminum for the frame. More people would have much better printers if they just did the same.

Build a rectangular frame and it will be solid as a rock and easy to enclose. It is best if you can design it so the motors will be outside the build chamber, and of course, put the electronics outside the build chamber so you can run it at 50C or so and print ABS with wild abandon.

You can use small linear guides because the load presented by a 3D printer mechanism/motion is close to no load at all.

Mounting the extruder carriage is very easy- an L bracket screwed to the bearing block will do the job. The bearing block, and so the extruder, will not wobble at all.

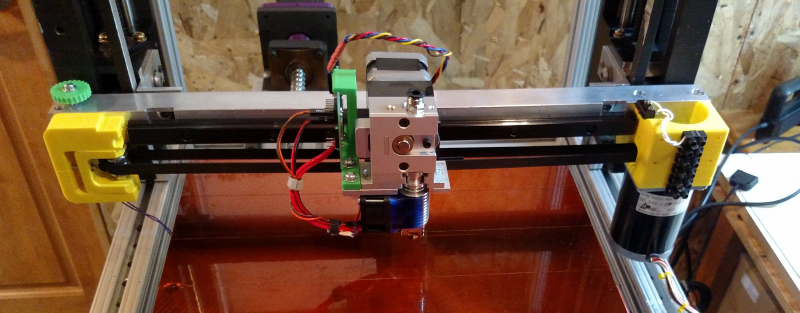

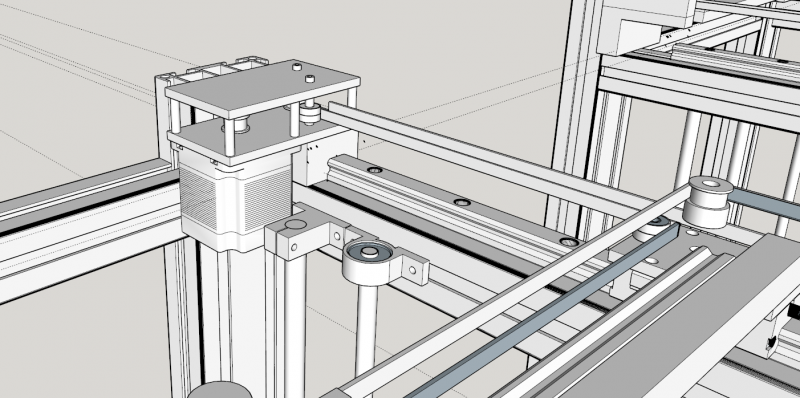

This is the X axis in my machine:

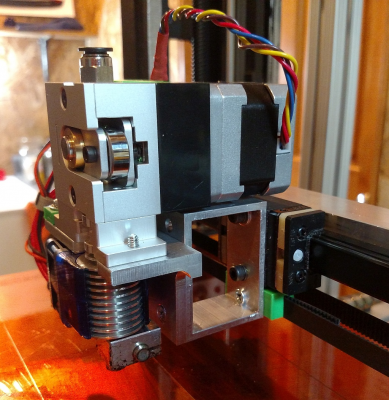

Here is the extruder carriage- the belt clamp is green (https://www.youmagine.com/designs/gt2-belt-clamps), and you can see the whole thing screws to the bearing block with just two screws:

You can see more details of the machine by following the link in my sig, below. It isn't coreXY but it might give you some ideas anyway.

The 15 mm linear guide is screwed to a 1" square aluminum tube, though I suspect the sag in the guide without the tube would not be large enough to matter. The tube provides a convenient place to mount the motor and the belt tensioner. The extruder carriage in my machine consists of a spacer made of aluminum tubing and an L bracket- I needed the spacer because of the mechanical configuration- it should not be needed in every printer design. The extruder and hot-end are held on by two screws that make it very easy to remove and reinstall them.

I used preloaded linear guides (because that's what was available) which provide extraordinary precision in their motion, but adds to the friction. The ordinary type should be more than precise enough for a 3D printer and won't require so much work from the motor to push them around.

Edited 1 time(s). Last edit at 11/05/2015 08:05PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Build a rectangular frame and it will be solid as a rock and easy to enclose. It is best if you can design it so the motors will be outside the build chamber, and of course, put the electronics outside the build chamber so you can run it at 50C or so and print ABS with wild abandon.

You can use small linear guides because the load presented by a 3D printer mechanism/motion is close to no load at all.

Mounting the extruder carriage is very easy- an L bracket screwed to the bearing block will do the job. The bearing block, and so the extruder, will not wobble at all.

This is the X axis in my machine:

Here is the extruder carriage- the belt clamp is green (https://www.youmagine.com/designs/gt2-belt-clamps), and you can see the whole thing screws to the bearing block with just two screws:

You can see more details of the machine by following the link in my sig, below. It isn't coreXY but it might give you some ideas anyway.

The 15 mm linear guide is screwed to a 1" square aluminum tube, though I suspect the sag in the guide without the tube would not be large enough to matter. The tube provides a convenient place to mount the motor and the belt tensioner. The extruder carriage in my machine consists of a spacer made of aluminum tubing and an L bracket- I needed the spacer because of the mechanical configuration- it should not be needed in every printer design. The extruder and hot-end are held on by two screws that make it very easy to remove and reinstall them.

I used preloaded linear guides (because that's what was available) which provide extraordinary precision in their motion, but adds to the friction. The ordinary type should be more than precise enough for a 3D printer and won't require so much work from the motor to push them around.

Edited 1 time(s). Last edit at 11/05/2015 08:05PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Types of linear guides and mounting options November 06, 2015 04:27AM |

Registered: 8 years ago Posts: 67 |

Yeah... I've read through your instructable at least three times now

I guess you really need that piece of aluminum tube to hold the guide, since you have to carry the whole extruder, but if I'll use bowden, I should be fine with just the guide then.

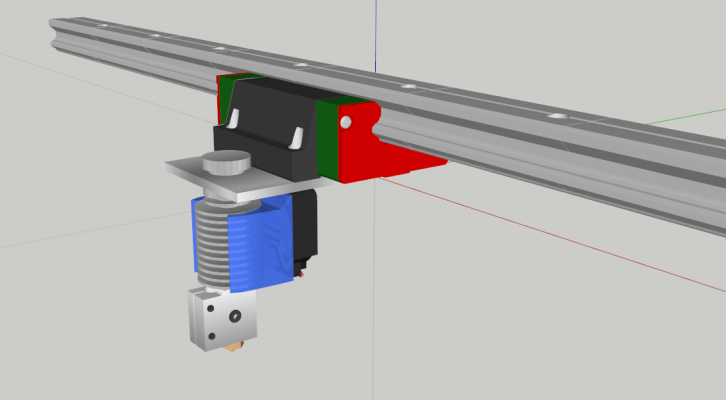

Another question - I've always thought this way of mounting the hotend would be the most simple

does this introduce any kind of forces I'm not aware of, or is it perfectly fine too? Might have to rethink the way to mount the belts though...

I guess you really need that piece of aluminum tube to hold the guide, since you have to carry the whole extruder, but if I'll use bowden, I should be fine with just the guide then.

Another question - I've always thought this way of mounting the hotend would be the most simple

does this introduce any kind of forces I'm not aware of, or is it perfectly fine too? Might have to rethink the way to mount the belts though...

|

Re: Types of linear guides and mounting options November 06, 2015 07:06AM |

Registered: 9 years ago Posts: 233 |

That way of mounting the hot end is pretty much how I mount mine in my CoreXY constuct. Here is how I clamped the belts:

Edited 1 time(s). Last edit at 11/06/2015 07:08AM by patrickrio.

Edited 1 time(s). Last edit at 11/06/2015 07:08AM by patrickrio.

|

Re: Types of linear guides and mounting options November 06, 2015 07:28AM |

Registered: 11 years ago Posts: 5,780 |

If you study one of the linear guide tech sheets, a bearing block and rail combo is rated for different loads depending on the orientation of the block and the direction of the applied load. That's all nice, but since 3D printers are effectively no load, it won't matter at all how you orient the rail, bearing block, or load. A simple flat piece coming off the bearing block should work fine.

The rail will sag with only end support, so it might sag a little less if you orient it so that the longest cross sectional dimension is vertical, but again, unless you're using a really long rail, it probably won't sag enough to matter. You can always measure the sag by supporting the rail from the ends on a granite surface plate (if you have access to one) and mounting a dial gauge on the bearing block. A bigger cross section rail will sag less than a smaller one. Belt tension will contribute to the rail's sag or even lateral deviation from straightness.

In any case, I doubt an end-supported linear guide will suffer nearly as much flex as the typical 8mm round rails. If you have any doubts, do what I did and use 1" square x 1/8" thick tubing which is pretty cheap. I drilled and tapped for 6-32 holes so the linear guide just screws down easy-peasy. If you want to get really anal about it, you can mill the surface of the tubing to make sure it is really flat before you mount the linear guide on it, but I haven't found any problems in my machine/prints using the tubing without milling. In my machine, the belt tension is pulling against the aluminum tubing so it doesn't pull on the Z axis rails/screws. If you use an end-supported linear guide for the X axis in a coreXY, you'll need to watch how the belt tension pulls on the Y axis rails.

If you mount the hot end on an L bracket with the rail rotated 90 degrees, the rail can be along side the hot-end reducing the vertical dimension of the assembly, which might provide a couple more cm of vertical print capacity.

Edited 1 time(s). Last edit at 11/06/2015 07:30AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The rail will sag with only end support, so it might sag a little less if you orient it so that the longest cross sectional dimension is vertical, but again, unless you're using a really long rail, it probably won't sag enough to matter. You can always measure the sag by supporting the rail from the ends on a granite surface plate (if you have access to one) and mounting a dial gauge on the bearing block. A bigger cross section rail will sag less than a smaller one. Belt tension will contribute to the rail's sag or even lateral deviation from straightness.

In any case, I doubt an end-supported linear guide will suffer nearly as much flex as the typical 8mm round rails. If you have any doubts, do what I did and use 1" square x 1/8" thick tubing which is pretty cheap. I drilled and tapped for 6-32 holes so the linear guide just screws down easy-peasy. If you want to get really anal about it, you can mill the surface of the tubing to make sure it is really flat before you mount the linear guide on it, but I haven't found any problems in my machine/prints using the tubing without milling. In my machine, the belt tension is pulling against the aluminum tubing so it doesn't pull on the Z axis rails/screws. If you use an end-supported linear guide for the X axis in a coreXY, you'll need to watch how the belt tension pulls on the Y axis rails.

If you mount the hot end on an L bracket with the rail rotated 90 degrees, the rail can be along side the hot-end reducing the vertical dimension of the assembly, which might provide a couple more cm of vertical print capacity.

Edited 1 time(s). Last edit at 11/06/2015 07:30AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Types of linear guides and mounting options November 08, 2015 09:05AM |

Registered: 9 years ago Posts: 233 |

|

Re: Types of linear guides and mounting options November 19, 2015 03:27PM |

Registered: 8 years ago Posts: 67 |

Alright guys, a quick update:

I'm going for 300x300mm bed, anything larger seems too hard to keep flat, or get a heater for.. though 300x300mm 220V heaters aren't that common either.. I might end up making one myself... we'll see how that works out...

anyway, I've ordered everything I need, except for power supply, linear guides, lead screws and some bearings/holders for them.

Still haven't decided on what guides to use... Honestly, cheap chinese guides look pretty tempting (would save me ~100€) but if I'll end up buying another set of guides just because I'm being cheap... well, that's no good...

Another thing, miniature rails vs medium ones... I'm wondering if any of these carriages tend to "pop off" from the rails? If anything, medium rails will just cause more moving mass... might go for miniature...

As for the lead screws, I've got a pretty good idea on what I'm going to use... Three 10X2 trapezoidal screws driven with a belt, with bearing supports on both ends. Will try to get my friend to machine the ends to 8mm on his lathe...

And I have a question regarding a power supply. I'm going for 24V. already have the fans, heater cartridges, etc... I'm just not too sure I'm calculating the stepper power requirements right... They are rated for 4.7V 1.5A and have a 3.1Ohm per phase.

I Should take the power from the 4.7V and 1.5A (which would be ~7W) right? or should I take the 1.5A no matter what voltage I'm using?

Anyway, considering I'm going to use a 220V heatbed (or a separate PSU for it), the heater cartriges are ~40W, the ~6 fans would be ~20W total... a dual extruder setup would be close to 150W or something. I guess going with a 10A PSU would be a safe bet?

Sorry if this seems trivial or stupid to you, I'm doing my best

I'm going for 300x300mm bed, anything larger seems too hard to keep flat, or get a heater for.. though 300x300mm 220V heaters aren't that common either.. I might end up making one myself... we'll see how that works out...

anyway, I've ordered everything I need, except for power supply, linear guides, lead screws and some bearings/holders for them.

Still haven't decided on what guides to use... Honestly, cheap chinese guides look pretty tempting (would save me ~100€) but if I'll end up buying another set of guides just because I'm being cheap... well, that's no good...

Another thing, miniature rails vs medium ones... I'm wondering if any of these carriages tend to "pop off" from the rails? If anything, medium rails will just cause more moving mass... might go for miniature...

As for the lead screws, I've got a pretty good idea on what I'm going to use... Three 10X2 trapezoidal screws driven with a belt, with bearing supports on both ends. Will try to get my friend to machine the ends to 8mm on his lathe...

And I have a question regarding a power supply. I'm going for 24V. already have the fans, heater cartridges, etc... I'm just not too sure I'm calculating the stepper power requirements right... They are rated for 4.7V 1.5A and have a 3.1Ohm per phase.

I Should take the power from the 4.7V and 1.5A (which would be ~7W) right? or should I take the 1.5A no matter what voltage I'm using?

Anyway, considering I'm going to use a 220V heatbed (or a separate PSU for it), the heater cartriges are ~40W, the ~6 fans would be ~20W total... a dual extruder setup would be close to 150W or something. I guess going with a 10A PSU would be a safe bet?

Sorry if this seems trivial or stupid to you, I'm doing my best

|

Re: Types of linear guides and mounting options November 19, 2015 05:32PM |

Registered: 11 years ago Posts: 5,780 |

I look at used linear guides via ebay before buying low-end Chinese guides. I think you find similar pricing but you can get higher quality.

Of course, I'm assuming that low priced Chinese linear guides are not as good as some of the Japanese (NSK, IKO, etc.), German (Bosch, Rexroth, etc.), or even Taiwanese (HiWin) guides, and I may be wrong.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Of course, I'm assuming that low priced Chinese linear guides are not as good as some of the Japanese (NSK, IKO, etc.), German (Bosch, Rexroth, etc.), or even Taiwanese (HiWin) guides, and I may be wrong.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Types of linear guides and mounting options November 19, 2015 05:59PM |

Registered: 10 years ago Posts: 14,672 |

The 4.7W + a bit for driver losses is correct for the static power consumed by each motor. It will be a little higher when the motors are moving quickly, but against that you won't be driving them at full current anyway. A 24V 10A psu will be more than enough. You could get away with a 180W or 200W psu. Also some hot ends such as E3D use only a 25W heater, not 40W.

There is a company advertising on Aliexpress that will make a custom silicone heate to your voltage, power and size specifications at a very good price. It's called Shenzen Ali Brother Technology or something like that. They made me a 300mm diameter 230V 350W heater for my delta printer.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

There is a company advertising on Aliexpress that will make a custom silicone heate to your voltage, power and size specifications at a very good price. It's called Shenzen Ali Brother Technology or something like that. They made me a 300mm diameter 230V 350W heater for my delta printer.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Types of linear guides and mounting options November 19, 2015 06:21PM |

Registered: 8 years ago Posts: 67 |

Quote

the_digital_dentist

I look at used linear guides via ebay before buying low-end Chinese guides. I think you find similar pricing but you can get higher quality.

Of course, I'm assuming that low priced Chinese linear guides are not as good as some of the Japanese (NSK, IKO, etc.), German (Bosch, Rexroth, etc.), or even Taiwanese (HiWin) guides, and I may be wrong.

Well, the main reason I'm considering the cheapest Chinese guides, is because they are close to 22€ each for 400mm lengths, which allows me to avoid paying any import taxes (21% of the price+shipping). (this is also the reason why custom made silicone heaters are out of the question)

The other option is to source parts from within EU (so no more taxes), but this quite limits my choices as most of the guides I've found are either too expensive or not sold to individuals... (this also limits the ebay results)

Of course if I'm unable to find something adequate in EU, I can pay the taxes... it's just that I'd rather spend that money on better components...

I guess that mostly depends on the heater block size, right? is 40W more of a fire hazard? harder to control? any reason why I couldn't swap a 25W heater cartridge to 40W (or vice versa)?Quote

dc42

Also some hot ends such as E3D use only a 25W heater, not 40W.

Would you say 350W is enough for a bed this size? I've seen people recommending ~700W for bigger beds... How long does it take to heat up?Quote

dc42

There is a company advertising on Aliexpress that will make a custom silicone heater to your voltage, power and size specifications at a very good price. It's called Shenzen Ali Brother Technology or something like that. They made me a 300mm diameter 230V 350W heater for my delta printer.

|

Re: Types of linear guides and mounting options November 19, 2015 06:35PM |

Registered: 11 years ago Posts: 5,780 |

My bed is 317 x 305 x 6.35 mm cast tooling plate, has a 450W heater, and heats up to 105C for printing ABS in about 5 minutes.

It is generally better to have an over powered heater than an under powered heater, especially if you're using PID temperature control. If the heater is under powered and you're trying to push the temperature to the limits of the heater's capability, the PID control doesn't work very well. With an under powered heater the power will be on continuously and the bed will eventually creep up to the set temperature while you grow older. With an over powered heater and PID control, the temperature will rise very quickly to the set temperature and may overshoot a little but will quickly settle to the set temperature and will stay there.

The same is true for the hot-end. A higher powered heater will quickly reach print temperature and will be well regulated by the PID controller. A higher powered heater allows you to use different materials that require higher melt temperatures, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

It is generally better to have an over powered heater than an under powered heater, especially if you're using PID temperature control. If the heater is under powered and you're trying to push the temperature to the limits of the heater's capability, the PID control doesn't work very well. With an under powered heater the power will be on continuously and the bed will eventually creep up to the set temperature while you grow older. With an over powered heater and PID control, the temperature will rise very quickly to the set temperature and may overshoot a little but will quickly settle to the set temperature and will stay there.

The same is true for the hot-end. A higher powered heater will quickly reach print temperature and will be well regulated by the PID controller. A higher powered heater allows you to use different materials that require higher melt temperatures, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Types of linear guides and mounting options November 21, 2015 03:23PM |

Registered: 9 years ago Posts: 722 |

Hi guys,

Dalius98, have a look on Ebay.de with the keyword "linearführung".

I bought INA, Rexroth, Igus, linear guides at pretty reasonable prices.

Sometimes there's used expensive ones discounted.

They're still pretty good for hobbyist.

Even if german post is always a bit expensive, it's inside EU and you should not pay duty.

++JM

Dalius98, have a look on Ebay.de with the keyword "linearführung".

I bought INA, Rexroth, Igus, linear guides at pretty reasonable prices.

Sometimes there's used expensive ones discounted.

They're still pretty good for hobbyist.

Even if german post is always a bit expensive, it's inside EU and you should not pay duty.

++JM

|

Re: Types of linear guides and mounting options November 21, 2015 06:13PM |

Registered: 8 years ago Posts: 67 |

Quote

J-Max

Hi guys,

Dalius98, have a look on Ebay.de with the keyword "linearführung".

I bought INA, Rexroth, Igus, linear guides at pretty reasonable prices.

Sometimes there's used expensive ones discounted.

They're still pretty good for hobbyist.

Even if german post is always a bit expensive, it's inside EU and you should not pay duty.

++JM

Thanks for the tip. This actually doubled my selection of vendors

Found some IKO LWL15 rails and guides, total for 3 400mm rails + 3 carriages would end up at ~209€...

Then there's Dold Mechatronic with some of their guides, which look better on spec sheets, total would end up at 156€.

And the last option I might consider is CNC-discount with some no-name guides, totaling at about 155€ for 4 rails + 4 carriages (only sold in sets of two)...

Now comes the hardest part... IKO seems to be a known Japanese brand, but the rails I've found are used and I would have to buy one carriage separate (included in the 209€ estimate)...

Dold on the other hand might not be a well known brand (at least I've never heard of it), but the "spec sheet pdf" they provide, as well as their website, seems professional to me.The guides have higher load ratings (not that it matters in this scenario, but I'm thinking it might improve stability?). And I would end up buying lead screws from them anyway, so that would save me on some shipping too

Then there's cnc-discount, but I have a feeling these might not be that different from Chinese rails...

So, if anyone has ANY information (or experience, good or bad) regarding the aforementioned brands/sellers, it would be greatly appreciated.

EDIT: oh, and I should be able to get SKF set locally for about 200€... have anyone heard of SKF?

Edited 1 time(s). Last edit at 11/22/2015 08:39AM by Dalius98.

|

Re: Types of linear guides and mounting options November 22, 2015 11:02AM |

Registered: 9 years ago Posts: 722 |

|

Re: Types of linear guides and mounting options November 23, 2015 02:21PM |

Registered: 8 years ago Posts: 67 |

Quote

J-Max

Hi,

SKF is a trustable brand

++JM

Thanks for the reassurance. My machinist friend said the same, so SKF it is! Ordered LLTHC15A carriages and LLTHR15 rails... 420mm was a standart length so I went with it, quick calculation tells me I should be able to get at least 370x300mm build area, depending on the way I choose to mount them... well... guess that's fine too... I can always cut them to size later if it turns out to be a problem. (though, I feel a nice aluminium build plate would take most of the bed leveling problems away, and a 15mm shouldn't sag enough to matter...)

Anyway, the rails arrive in 2-3 days and since most of the stuff is still on the way from China - I might give a review of the rails or something, shame I have nothing to compare them to

Last thing to do - decide on the Z height and order the leadscrews + smooth rods (12mm).

Thanks for the help so far

|

Re: Types of linear guides and mounting options November 23, 2015 02:59PM |

Registered: 11 years ago Posts: 5,780 |

If you do end up cutting the linear guides, you'll need to use a cut off wheel on a grinder. I wasn't able to do more than make a dent with a chop saw. Linear guides seem to be hardened all the way through.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Types of linear guides and mounting options November 23, 2015 03:19PM |

Registered: 9 years ago Posts: 722 |

|

Re: Types of linear guides and mounting options December 02, 2015 04:18PM |

Registered: 8 years ago Posts: 67 |

another update, since I need some tips

I did not have time to get any real work done, just spent a few hours struggling with SketchUp... This being the last month of the semester, I have a lot of assignments and not much free time, hopefully I will be able to move on to assembly after the exams...

Anyway, the linear rails arrived a week ago, they look pretty nice... but I didn't even put the carriages on them yet...

So, moving on to the questions:

How big of a gap I need between the belts when running them on two levels? (like this) I guess they shouldn't sag under proper tension, but I've seen some complaints about the belts rubbing on each other, so I'm not too sure about that... But having a bigger gap means more force exerted on the X carriage which might wear the bearings a little bit faster... I'm just trying to find a balance between the two... And no, I'm not yet considering crossed belts as a valid solution... no reason why though.

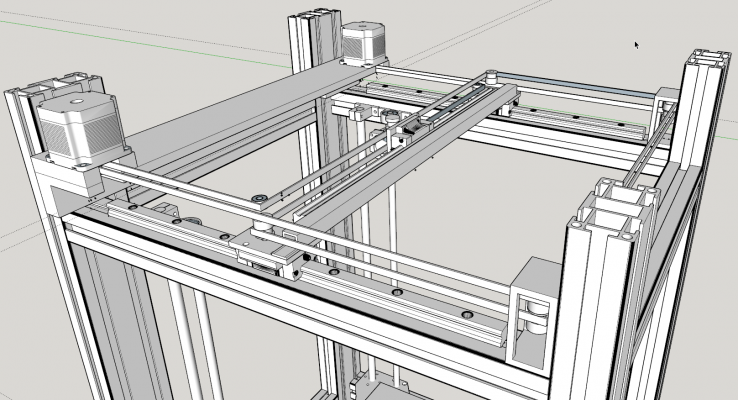

Another design "issue" I'm not too happy about is motor mounting. Here's the first model I made

,

and here's the second version

.

While trying to figure out the location of the idler mounting holes on the Y carriages, I realized it's not that easy to keep them perfectly parallel directly off the motor. But mounting the motor on a corner bracket like in the second design, gives me a predictable belt path and known positions of the mounting holes. First time I saw this "corner bracket" solution I though of it as some gimmick - 4 more idlers, and no space savings... Now I get it... Anyway, the motor mounting still seems a bit (a lot, actually) awkward, but I fail to see another solution that would give me the same amount of build area...

I'm not too happy about the square tube holding the X rail in place, but it would let me use full length of the rail, and with two screws on each side the whole assembly shouldn't get skewed and whatnot...

Now, I've been told to mount the idlers on the Y carriages in such way, to apply force across the length of the X rail, rather than to the sides of Y, to prevent unwanted forces and preserve the bearings, or something... I fail to see how that works. If the X rail is mounted firmly on to the Y carriages, how does the belt tension effect them differently? Could someone explain it to me or direct to some information?

if anyone's interested in the current state of my "design", here's the SketchUp file for it, it's not made to be perfect, and I just didn't bother with some things yet, since not all the parts are finalized... And the Z height is quite big, I wasn't aiming for anything and it just ended up like this. I think I'll go for a build volume of 350x350x350 in the final version...

Now the real question is - should I get a proper topic in the CoreXY forum instead of filling this up with unrelated things?

I did not have time to get any real work done, just spent a few hours struggling with SketchUp... This being the last month of the semester, I have a lot of assignments and not much free time, hopefully I will be able to move on to assembly after the exams...

Anyway, the linear rails arrived a week ago, they look pretty nice... but I didn't even put the carriages on them yet...

So, moving on to the questions:

How big of a gap I need between the belts when running them on two levels? (like this) I guess they shouldn't sag under proper tension, but I've seen some complaints about the belts rubbing on each other, so I'm not too sure about that... But having a bigger gap means more force exerted on the X carriage which might wear the bearings a little bit faster... I'm just trying to find a balance between the two... And no, I'm not yet considering crossed belts as a valid solution... no reason why though.

Another design "issue" I'm not too happy about is motor mounting. Here's the first model I made

,

and here's the second version

.

While trying to figure out the location of the idler mounting holes on the Y carriages, I realized it's not that easy to keep them perfectly parallel directly off the motor. But mounting the motor on a corner bracket like in the second design, gives me a predictable belt path and known positions of the mounting holes. First time I saw this "corner bracket" solution I though of it as some gimmick - 4 more idlers, and no space savings... Now I get it... Anyway, the motor mounting still seems a bit (a lot, actually) awkward, but I fail to see another solution that would give me the same amount of build area...

I'm not too happy about the square tube holding the X rail in place, but it would let me use full length of the rail, and with two screws on each side the whole assembly shouldn't get skewed and whatnot...

Now, I've been told to mount the idlers on the Y carriages in such way, to apply force across the length of the X rail, rather than to the sides of Y, to prevent unwanted forces and preserve the bearings, or something... I fail to see how that works. If the X rail is mounted firmly on to the Y carriages, how does the belt tension effect them differently? Could someone explain it to me or direct to some information?

if anyone's interested in the current state of my "design", here's the SketchUp file for it, it's not made to be perfect, and I just didn't bother with some things yet, since not all the parts are finalized... And the Z height is quite big, I wasn't aiming for anything and it just ended up like this. I think I'll go for a build volume of 350x350x350 in the final version...

Now the real question is - should I get a proper topic in the CoreXY forum instead of filling this up with unrelated things?

|

Re: Types of linear guides and mounting options December 08, 2015 04:56PM |

Registered: 9 years ago Posts: 722 |

Hi,

Maybe a new topic about your CoreXY design process is better.

On my CoreXY I just left a 1mm gap between the two pulleys tooth height.

On your seccond design you don't need the upper plates to cover the motor side.

Don't forget about the endstops in your design.

A system to setup parallel guides is very usefull with linear rails.

It can be just screws push/pullinging on the sides of the rail @ both ends.

You want to get linear guides as parallel as possible.

When the rails are set properly you can unmount the setup system to use rails at full lenght.

++JM

Maybe a new topic about your CoreXY design process is better.

On my CoreXY I just left a 1mm gap between the two pulleys tooth height.

On your seccond design you don't need the upper plates to cover the motor side.

Don't forget about the endstops in your design.

A system to setup parallel guides is very usefull with linear rails.

It can be just screws push/pullinging on the sides of the rail @ both ends.

You want to get linear guides as parallel as possible.

When the rails are set properly you can unmount the setup system to use rails at full lenght.

++JM

Sorry, only registered users may post in this forum.