Curling filament

Posted by Joost

|

Curling filament October 26, 2007 10:45AM |

Registered: 17 years ago Posts: 79 |

Hello all,

It's been a while, but I figured it was about time to pick things up again. I have "upgraded" my Darwin variant a bit (using aluminum corner brackets instead of wood, which is a major improvement as far as accuracy/stability of the cartesian bot is concerned) and now bump into another problem.

I made an extruder based on the new design (wire driven) out of wood. It does extrude for a bit but then the filament starts to curl before the thermal barrier, which basically results in no more extrusion. I was wondering if anyone else has had this problem and perhaps a solution. I do suspect it could be that half-hole in the guide part is too shallow, but maybe it also the speed?

The attached image shows the curled filament; the right part was in the PTFE thermal barrier, the material is 3mm home-rolled CAPA. You can see the curling just left of the red mark. Any suggestions?

Joost

It's been a while, but I figured it was about time to pick things up again. I have "upgraded" my Darwin variant a bit (using aluminum corner brackets instead of wood, which is a major improvement as far as accuracy/stability of the cartesian bot is concerned) and now bump into another problem.

I made an extruder based on the new design (wire driven) out of wood. It does extrude for a bit but then the filament starts to curl before the thermal barrier, which basically results in no more extrusion. I was wondering if anyone else has had this problem and perhaps a solution. I do suspect it could be that half-hole in the guide part is too shallow, but maybe it also the speed?

The attached image shows the curled filament; the right part was in the PTFE thermal barrier, the material is 3mm home-rolled CAPA. You can see the curling just left of the red mark. Any suggestions?

Joost

|

Re: Curling filament October 26, 2007 10:50AM |

Admin Registered: 17 years ago Posts: 1,915 |

In my experience when you're extruding and then it stops you've got a problem with your polymer pump spring tension. You're talking about a "wire driven" design. How about blogging what you're doing along with some pics in the builders' blog so that we can see what you're talking about.

In any case, congrats! You've at least extruded a bit, if not reliably. That's progress!

In any case, congrats! You've at least extruded a bit, if not reliably. That's progress!

|

Re: Curling filament October 26, 2007 12:19PM |

Admin Registered: 17 years ago Posts: 7,879 |

It looks like you must have a gap between the end of the pump and the start of the PTFE barrel or your channel is too shallow.

With the official design there is no way for the filament to escape in this way. The channel is slighly deeper than the radius and the other half of the pump is only a couple of milimeters away. The filimant has to either enter the barrel or jam, it can't go sideways.

[www.hydraraptor.blogspot.com]

With the official design there is no way for the filament to escape in this way. The channel is slighly deeper than the radius and the other half of the pump is only a couple of milimeters away. The filimant has to either enter the barrel or jam, it can't go sideways.

[www.hydraraptor.blogspot.com]

|

Re: Curling filament October 30, 2007 02:55PM |

Registered: 17 years ago Posts: 79 |

Well, I made some modifications. First of all, the "wire design" is basically the one that is described here: [www.reprap.org]

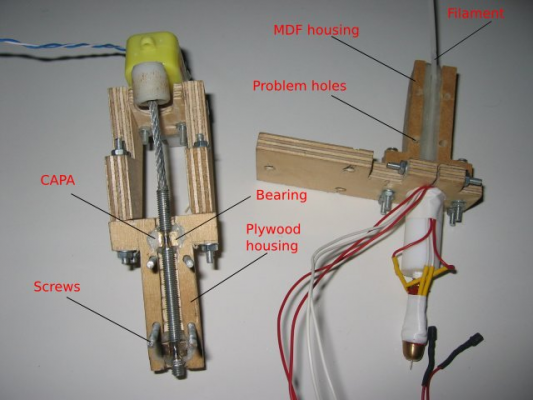

Attached an image showing both sides of the top extruder parts with some mark-up.

What I changed was the filament-guide-channel (made out of CAPA and placed in the MDF slot, used a 3mm rod to impress the shape) and I put in the half-washer bearings (used some CAPA as bearings before). This does help, but it still is not good enough.

What I found out is that movement of the two parts (probably due to misalignment of the top part where the motor is attached) during my experiments, resulted in holes-getting-bigger in the MDF and/or plywood (marked as "Problem holes", there are 4 of them). This misaligns the driving screw and thus no consistent extrusion.

I will try to fill the holes with some CAPA to make it all align better, otherwise I'll have to resort to a different material.

Joost

Attached an image showing both sides of the top extruder parts with some mark-up.

What I changed was the filament-guide-channel (made out of CAPA and placed in the MDF slot, used a 3mm rod to impress the shape) and I put in the half-washer bearings (used some CAPA as bearings before). This does help, but it still is not good enough.

What I found out is that movement of the two parts (probably due to misalignment of the top part where the motor is attached) during my experiments, resulted in holes-getting-bigger in the MDF and/or plywood (marked as "Problem holes", there are 4 of them). This misaligns the driving screw and thus no consistent extrusion.

I will try to fill the holes with some CAPA to make it all align better, otherwise I'll have to resort to a different material.

Joost

Sorry, only registered users may post in this forum.