Building Low Pressure Solenoid Valves

Posted by zzorn

|

Building Low Pressure Solenoid Valves October 27, 2007 09:12AM |

Registered: 16 years ago Posts: 34 |

I created some simple home-made solenoid valves for controlling low pressure fluid flow. They are aimed towards controlling the air muscles discussed in the artificial muscle thread ( [forums.reprap.org] ), but might be possible to apply to other fluids too.

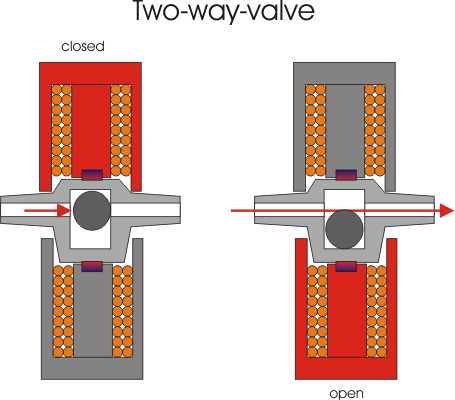

Here's a picture of a two-way solenoid valve, based on a T-junction for aquarium air tubing, and a nail with a piece of isolation tape around the center acting as a moving plug.

It seems to work fairly well, although there are some details to tune, and it is sensitive to the amount of pressure from the different connections.

Full writeup with a video on my blog, along with an idea for a pressure insensitive version: [zzorn.nfshost.com]

Apart from the coil and iron nail the parts should be easy to make with a reprap.

Here's a picture of a two-way solenoid valve, based on a T-junction for aquarium air tubing, and a nail with a piece of isolation tape around the center acting as a moving plug.

It seems to work fairly well, although there are some details to tune, and it is sensitive to the amount of pressure from the different connections.

Full writeup with a video on my blog, along with an idea for a pressure insensitive version: [zzorn.nfshost.com]

Apart from the coil and iron nail the parts should be easy to make with a reprap.

|

Re: Building Low Pressure Solenoid Valves October 27, 2007 02:18PM |

Registered: 16 years ago Posts: 82 |

Great job.

It seems to work pretty well. And I think I understand your idea for a pressure insensitive valve. Basically, the valve piston, i.e. nail, needs to move perpendicularly to the air pressure direction. Then you only have to worry about friction.

Also, for gravity independence, I'm not sure exactly how to lock it either way, but you could use a spring to hold it closed most of the time. Then you would just apply current when you wanted to hold it open to contract the muscle. I think that if you really wanted to get it to hold either way, it would probably be much more complicated, but I'm not sure.

-Samuel

It seems to work pretty well. And I think I understand your idea for a pressure insensitive valve. Basically, the valve piston, i.e. nail, needs to move perpendicularly to the air pressure direction. Then you only have to worry about friction.

Also, for gravity independence, I'm not sure exactly how to lock it either way, but you could use a spring to hold it closed most of the time. Then you would just apply current when you wanted to hold it open to contract the muscle. I think that if you really wanted to get it to hold either way, it would probably be much more complicated, but I'm not sure.

-Samuel

|

Re: Building Low Pressure Solenoid Valves October 27, 2007 02:23PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi zzorn,

... a better way for precise switching and applying short pressure-pulses of air or liquid could be a solenoid-valve with a trapped steel-sphere, which is through the solenoid moved in the way and settled on the tube to stop flow and pulled away, to give the way free ...

Viktor

... a better way for precise switching and applying short pressure-pulses of air or liquid could be a solenoid-valve with a trapped steel-sphere, which is through the solenoid moved in the way and settled on the tube to stop flow and pulled away, to give the way free ...

Viktor

|

Re: Building Low Pressure Solenoid Valves October 27, 2007 02:56PM |

Registered: 16 years ago Posts: 82 |

Viktor,

Sounds almost like an old fashioned synthetic heart valve, called the Ball and Cage. It's a one way valve. When the fluid tries flowing in one direction, it forces the ball away from the hole, where it is caught by the cage, allowing the liquid to flow through. In the other direction, the fluid forces the ball against the hole, preventing the fluid from passing.

You could instead make a T-shaped gravity independent valve, in which there are two holes the fluid could exit. Unfortunately, it wouldn't be pressure independent. The pressure would be applied to the vertical tube, and the ball would be trapped between the two exit holes. Two coils either pull the ball to one side or the other, and then turn off. The pressure of the fluid flowing through the other hole keeps the ball in place. Thus, by using the pressure, the ball can be held to either side without power, but this means that the ball is subject to the influence of pressure in the first place, so it would take more energy to make it cross the barrier.

I hope that made sense, I haven't drawn any pictures.

Any other ideas?

-Samuel

Sounds almost like an old fashioned synthetic heart valve, called the Ball and Cage. It's a one way valve. When the fluid tries flowing in one direction, it forces the ball away from the hole, where it is caught by the cage, allowing the liquid to flow through. In the other direction, the fluid forces the ball against the hole, preventing the fluid from passing.

You could instead make a T-shaped gravity independent valve, in which there are two holes the fluid could exit. Unfortunately, it wouldn't be pressure independent. The pressure would be applied to the vertical tube, and the ball would be trapped between the two exit holes. Two coils either pull the ball to one side or the other, and then turn off. The pressure of the fluid flowing through the other hole keeps the ball in place. Thus, by using the pressure, the ball can be held to either side without power, but this means that the ball is subject to the influence of pressure in the first place, so it would take more energy to make it cross the barrier.

I hope that made sense, I haven't drawn any pictures.

Any other ideas?

-Samuel

|

Re: Building Low Pressure Solenoid Valves October 27, 2007 03:30PM |

Admin Registered: 16 years ago Posts: 13,884 |

... here is an image of a valve, which can handle pressure from both dirctions - the ball in 'close'-position would be pressed on the opposite hole.

One problem could be with oszillating pressure-pulses, that the ball in 'closed' position would be oszillating between the two holes an a small amount of fluid can pass by with every pulse-periode ...

Viktor

Edited 1 time(s). Last edit at 10/27/2007 05:55PM by Viktor Dirks.

One problem could be with oszillating pressure-pulses, that the ball in 'closed' position would be oszillating between the two holes an a small amount of fluid can pass by with every pulse-periode ...

Viktor

Edited 1 time(s). Last edit at 10/27/2007 05:55PM by Viktor Dirks.

|

Re: Building Low Pressure Solenoid Valves October 27, 2007 03:58PM |

Registered: 16 years ago Posts: 82 |

Hi Viktor,

The other problem with that design is that it requires constant power to hold the ball in either position, at least as far as I can tell. It seems that the pressure of the flow may be able to hold the ball in the "open" position, but unless I'm mistaken it won't stay "closed" without constant power.

I suppose it depends on the application which is better, pressure independency, or the ability to hold the same position without applying continuous power.

-Samuel

The other problem with that design is that it requires constant power to hold the ball in either position, at least as far as I can tell. It seems that the pressure of the flow may be able to hold the ball in the "open" position, but unless I'm mistaken it won't stay "closed" without constant power.

I suppose it depends on the application which is better, pressure independency, or the ability to hold the same position without applying continuous power.

-Samuel

|

Re: Building Low Pressure Solenoid Valves October 27, 2007 04:10PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Samuel,

... if i insert two small permanent-magnets on the opposite sides, so the ball would stay without power in the last activated position - then the solenoids have to be powerfull enough, to pull the ball away from the opposite magnet, then the now nearer magnet holds the ball ...

Viktor

... if i insert two small permanent-magnets on the opposite sides, so the ball would stay without power in the last activated position - then the solenoids have to be powerfull enough, to pull the ball away from the opposite magnet, then the now nearer magnet holds the ball ...

Viktor

|

Re: Building Low Pressure Solenoid Valves October 27, 2007 04:29PM |

Registered: 16 years ago Posts: 82 |

Hi Viktor,

Sounds like my pressure-sensitive three-way valve. The pressure would hold the ball to one side, and it would be that much harder to pull the ball away to the other side when you want to switch. Of course, the pressure in the liquid could easily be much higher than the force created by your magnets. Maybe the computer would be smart enough to stop pumping just long enough to switch the pump, or switch the pump in the natural lull between pumping cycles in a piston-pump.

The only issue with mine is that I'm not sure how easy it would be to use both solenoids at once to hold the ball in the middle and block off both tubes at once. But I'm not sure that's necessary.

Also, I don't think that yours would have the problem that you mentioned of liquid sometimes flowing around the ball. I think that if you have your permanent magnet, so that the ball doesn't accidentally move out of the way when jostled, then the force of the pressure from the fluid would hold it against the opposite hole, preventing flow. So that probably isn't an issue, unless you are speaking from experience, and I'm just demonstrating my ignorance.

-Samuel

Sounds like my pressure-sensitive three-way valve. The pressure would hold the ball to one side, and it would be that much harder to pull the ball away to the other side when you want to switch. Of course, the pressure in the liquid could easily be much higher than the force created by your magnets. Maybe the computer would be smart enough to stop pumping just long enough to switch the pump, or switch the pump in the natural lull between pumping cycles in a piston-pump.

The only issue with mine is that I'm not sure how easy it would be to use both solenoids at once to hold the ball in the middle and block off both tubes at once. But I'm not sure that's necessary.

Also, I don't think that yours would have the problem that you mentioned of liquid sometimes flowing around the ball. I think that if you have your permanent magnet, so that the ball doesn't accidentally move out of the way when jostled, then the force of the pressure from the fluid would hold it against the opposite hole, preventing flow. So that probably isn't an issue, unless you are speaking from experience, and I'm just demonstrating my ignorance.

-Samuel

|

Re: Building Low Pressure Solenoid Valves October 28, 2007 03:34PM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Samuel,

... look on the image above - i changed it and inserted the holding magnets, so the solenoids acts only in short pulses, to pull the ball between the two possible end-positions ...

With oszillating pressure-pulses the ball moves in the 'closed'-position slightly between the two holes - until it's properly pressed at the opposition hole and blocks the flow, a small amount of fluid can pass by ...

As it's symmetrical, there wouldn't escape much fluid over time, but the pulses could be sensed in the end-capilaries, so i have to block the tubes better somehow ...

Viktor

Edited 1 time(s). Last edit at 10/28/2007 04:21PM by Viktor Dirks.

... look on the image above - i changed it and inserted the holding magnets, so the solenoids acts only in short pulses, to pull the ball between the two possible end-positions ...

With oszillating pressure-pulses the ball moves in the 'closed'-position slightly between the two holes - until it's properly pressed at the opposition hole and blocks the flow, a small amount of fluid can pass by ...

As it's symmetrical, there wouldn't escape much fluid over time, but the pulses could be sensed in the end-capilaries, so i have to block the tubes better somehow ...

Viktor

Edited 1 time(s). Last edit at 10/28/2007 04:21PM by Viktor Dirks.

|

Re: Building Low Pressure Solenoid Valves November 05, 2007 06:16PM |

Registered: 16 years ago Posts: 246 |

Hmm. You could get away from the permanent magnets by putting an indentation in the downstream side of the valve. When the ball is under pressure, it would tend to stay in the closed state. I don't know how you'd get rid of the lower magnet, though. Bernoulli effects would probably tend to draw the ball into the stream.

|

Re: Building Low Pressure Solenoid Valves November 06, 2007 04:34AM |

Admin Registered: 16 years ago Posts: 13,884 |

Hi Sean,

... the magnets arent so expensive (maybe 10 cents or so) so that's not the problem - with my oszillating-pressure-setup there would be the real chance, that the ball drifts away from the holes, so the magnets on both sides are essential for switching the solenoids off after changing position ...

Viktor

... the magnets arent so expensive (maybe 10 cents or so) so that's not the problem - with my oszillating-pressure-setup there would be the real chance, that the ball drifts away from the holes, so the magnets on both sides are essential for switching the solenoids off after changing position ...

Viktor

|

Re: Building Low Pressure Solenoid Valves November 07, 2007 01:41PM |

Admin Registered: 17 years ago Posts: 1,487 |

|

Re: Building Low Pressure Solenoid Valves September 26, 2009 09:10AM |

|

Re: Building Low Pressure Solenoid Valves October 07, 2009 06:42AM |

Registered: 16 years ago Posts: 900 |

Guys

Looking good, It might be worth your while having a read up on balanced valves and spool valves.

I have done a lot over the years with SCUBA diving and high pressure gasses. Valves that operate pressure independently are very important for these types of application.

A SCUBA tank go from 300 bar to 0 bar and still be required to be as easy to operate at as well at all of the pressure range.

Demand valves etc operate from 10 bar to ambient.

I appreciate you are talking about low pressure techniques here but the pressure independence techniques apply what ever the pressure applied.

Hope this helps in some way.

cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Looking good, It might be worth your while having a read up on balanced valves and spool valves.

I have done a lot over the years with SCUBA diving and high pressure gasses. Valves that operate pressure independently are very important for these types of application.

A SCUBA tank go from 300 bar to 0 bar and still be required to be as easy to operate at as well at all of the pressure range.

Demand valves etc operate from 10 bar to ambient.

I appreciate you are talking about low pressure techniques here but the pressure independence techniques apply what ever the pressure applied.

Hope this helps in some way.

cheers

aka47

Necessity hopefully becomes the absentee parent of successfully invented children.

Sorry, only registered users may post in this forum.