Driving Two Leadscrews With One Stepper Using a Belt

Posted by Garry Bartsch

|

Driving Two Leadscrews With One Stepper Using a Belt October 25, 2016 11:13PM |

Registered: 10 years ago Posts: 363 |

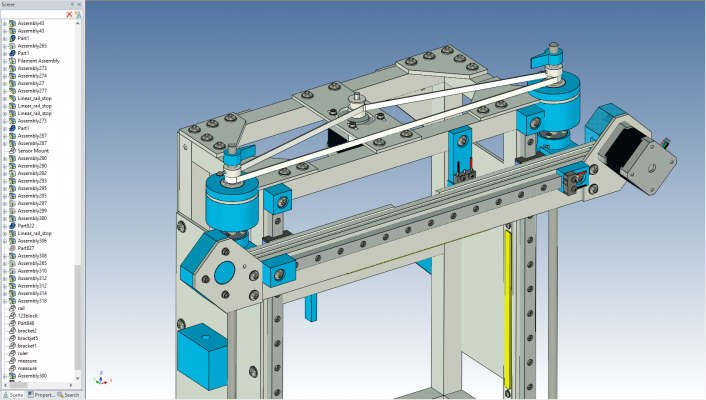

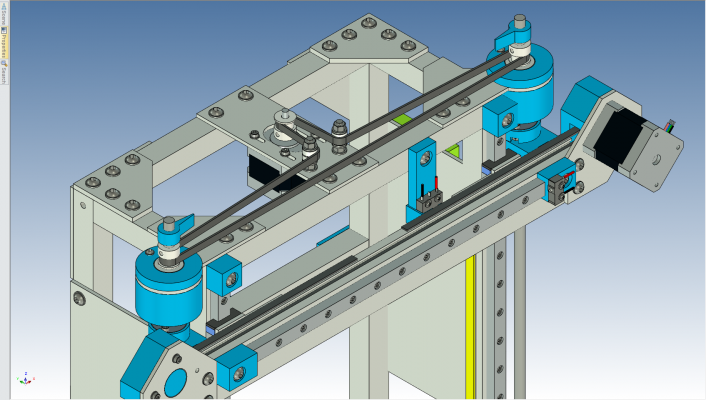

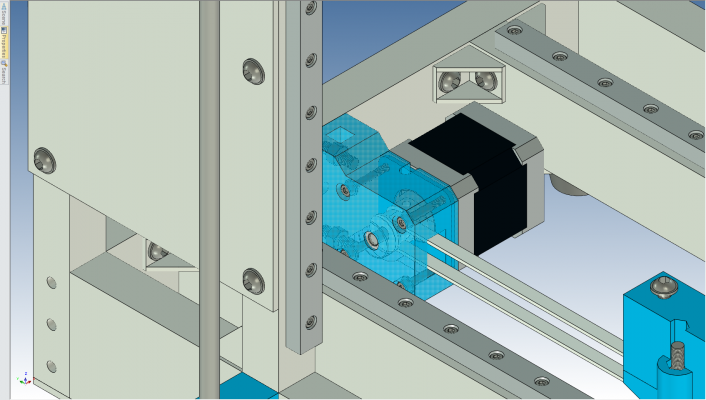

This design has the two leadscrews driven by one stepper to eliminate the problems that can occur with driving two z leadscrews each with their own steppers. The leadscrews hang from the top of the printer. Inside the cylindrical housing is a thrust bearing supporting the leadscrew. Radial bearings position the leadscrew left and right [but see point 3 below]. The bottom end of the leadscrews sits in a protector bracket but is free moving.

I have some concerns:

1) Can the single stepper support the x cross member when it's powered off? Or will the weight of the assembly pull down enough to turn the stepper? (The leadscrew is Tr8*8)

2) Could there be enough play between the belt teeth and the GT2 pulley so that z movements will not be precise enough?

3) Will it be difficult to position the leadscrew centered axially over the leadscrew nut? My concern is the leadscrew isn’t a tight fit inside the two radial bearings (one inside the lower cylindrical housing and one in the upper hosuing) and there might be the tiniest bit of slop. When the belt is tensioned the leadscrew will be pulled tight against the inside of the bearing. The leadscrew nut mounted to the x cross member can move left and right to adjust it's position under the center of the leadscrew along x, BUT it cannot move front and back (y) at all because the leadscrew nut housing is a fixed size. When the belt is tensioned in the way I have drawn it here there will be some rearward pull (y) on the leadscrew. This could pull the leadscrew out of axial alignment with the leadscrew?

Two idler pulleys could be added to the belt path so it would only pull directly to the center of the machine, thus eliminating that problem but I'm wondering if that is even needed?

I'd appreciate comments if this is a good arrangement or should I consider another? Thank you.

[Sorry the belt isn’t drawn properly around the stepper pulley.]

New browser from the creator of Opera: [vivaldi.com]

I have some concerns:

1) Can the single stepper support the x cross member when it's powered off? Or will the weight of the assembly pull down enough to turn the stepper? (The leadscrew is Tr8*8)

2) Could there be enough play between the belt teeth and the GT2 pulley so that z movements will not be precise enough?

3) Will it be difficult to position the leadscrew centered axially over the leadscrew nut? My concern is the leadscrew isn’t a tight fit inside the two radial bearings (one inside the lower cylindrical housing and one in the upper hosuing) and there might be the tiniest bit of slop. When the belt is tensioned the leadscrew will be pulled tight against the inside of the bearing. The leadscrew nut mounted to the x cross member can move left and right to adjust it's position under the center of the leadscrew along x, BUT it cannot move front and back (y) at all because the leadscrew nut housing is a fixed size. When the belt is tensioned in the way I have drawn it here there will be some rearward pull (y) on the leadscrew. This could pull the leadscrew out of axial alignment with the leadscrew?

Two idler pulleys could be added to the belt path so it would only pull directly to the center of the machine, thus eliminating that problem but I'm wondering if that is even needed?

I'd appreciate comments if this is a good arrangement or should I consider another? Thank you.

[Sorry the belt isn’t drawn properly around the stepper pulley.]

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 26, 2016 12:15AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Garry Bartsch

This design has the two leadscrews driven by one stepper to eliminate the problems that can occur with driving two z leadscrews each with their own steppers. The leadscrews hang from the top of the printer. Inside the cylindrical housing is a thrust bearing supporting the leadscrew. Radial bearings position the leadscrew left and right [but see point 3 below]. The bottom end of the leadscrews sits in a protector bracket but is free moving.

I have some concerns:

1) Can the single stepper support the x cross member when it's powered off? Or will the weight of the assembly pull down enough to turn the stepper? (The leadscrew is Tr8*8)

It is unlikely that the weight of the X axis will turn the motor, allowing the X axis to drop, but if you used larger pulleys on the screws than on the motor you'd get increased resolution (not that you need it) and the X axis would be less likely to drop.

Compared to what, two motors driving two screws that get out of sync every time you look at them? It will work fine.Quote

Garry Bartsch

2) Could there be enough play between the belt teeth and the GT2 pulley so that z movements will not be precise enough?

Quote

Garry Bartsch

3) Will it be difficult to position the leadscrew centered axially over the leadscrew nut? My concern is the leadscrew isn’t a tight fit inside the two radial bearings (one inside the lower cylindrical housing and one in the upper hosuing) and there might be the tiniest bit of slop. When the belt is tensioned the leadscrew will be pulled tight against the inside of the bearing. The leadscrew nut mounted to the x cross member can move left and right to adjust it's position under the center of the leadscrew along x, BUT it cannot move front and back (y) at all because the leadscrew nut housing is a fixed size. When the belt is tensioned in the way I have drawn it here there will be some rearward pull (y) on the leadscrew. This could pull the leadscrew out of axial alignment with the leadscrew?

Two idler pulleys could be added to the belt path so it would only pull directly to the center of the machine, thus eliminating that problem but I'm wondering if that is even needed?

I'd appreciate comments if this is a good arrangement or should I consider another? Thank you

The bearings should fit tightly. If they don't, get the right size bearings or turn the screws down to fit properly. If there are bearings anchored to the frame rear-ward forces due to belt tension shouldn't matter any more that the forces pulling toward the motor. You definitely don't have enough teeth on the motor bearing engaging the belt. You'll need a couple pulleys to wrap more belt around the motor pulley. I read on one of the belt manufacturer's web sites that belts should engage 6 teeth or 90 degrees, whichever is greater.

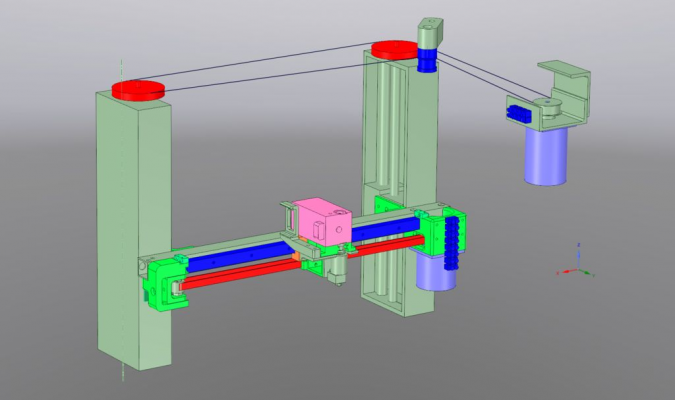

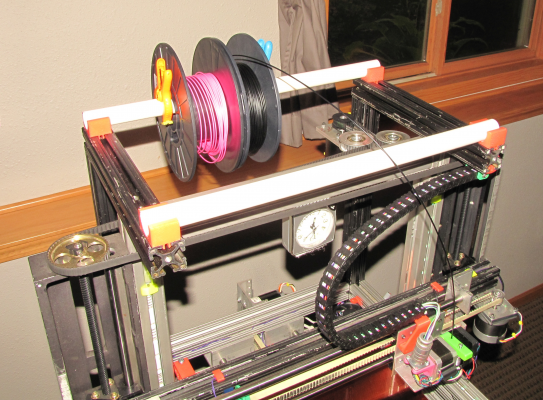

Here's the way I arranged things in my printer:

Once you have the mechanism put together, you will discover that besides keeping the X axis in permanent alignment, it will be MUCH easier to work on the extruder or X axis with the single motor. You won't have to turn on the printer and computer, then step through multiple menus to jog the Z axis. All you have to do is pull the belt whether the power is on or off. Leveling and zeroing the bed becomes fast and trivially easy. You will wonder, as I do, why anyone messes around with dual motor arrangements.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 26, 2016 12:08PM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 26, 2016 03:23PM |

Registered: 10 years ago Posts: 363 |

Thank you Mark. Your article on SoM was one of the chief influences in my decision to design this machine this way. I will add two pulleys to force more teeth in contact with the stepper pulley as you recommend. I know it's difficult to quantify, but can you say roughly how much tension do you have on the belt? Is the belt tight enough so you can't defect it much by pushing on it?

New browser from the creator of Opera: [vivaldi.com]

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 26, 2016 08:18PM |

Registered: 11 years ago Posts: 5,780 |

No, not nearly that tight. If you make the belts too tight they wear faster. In the Z axis, it probably won't wear much at all, anyway, but you don't want the tension causing unnecessary loading on the motor, either.

The belt should be just tight enough...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

The belt should be just tight enough...

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 26, 2016 08:19PM |

Registered: 11 years ago Posts: 5,780 |

Quote

o_lampe

Quote

DD

You will wonder, as I do, why anyone messes around with dual motor arrangements

Maybe because you'd need a rigid printer frame to cope with the belt tension. Something I wouldn't dare to try with my cheap acrylic framed Prusa I3...

I wonder about acrylic frames, too.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 26, 2016 08:54PM |

Registered: 10 years ago Posts: 363 |

Quote

the_digital_dentist

No, not nearly that tight. If you make the belts too tight they wear faster. In the Z axis, it probably won't wear much at all, anyway, but you don't want the tension causing unnecessary loading on the motor, either.

The belt should be just tight enough...

I like it ... just tight enough.

On the advice of a friend I have supported the ends of the y and x stepper shafts. This way the y and x belts can be fairly tight without putting stress on the stepper bearing or the shaft. But I'll be careful not to over tighten them because of the wear issue.

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 26, 2016 10:44PM |

Registered: 10 years ago Posts: 363 |

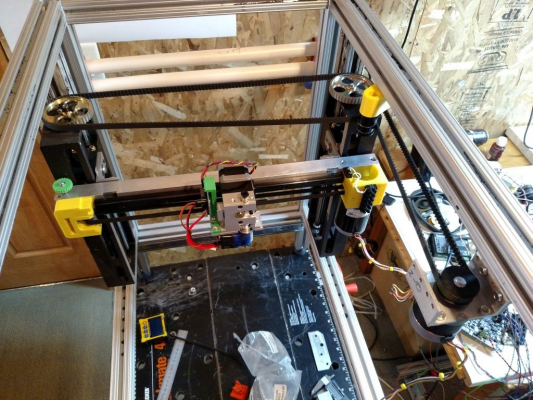

This is how I had thought to route the belt so it would pull inwards only. Plus it would give the belt contact with the stepper pulley as Mark advised.

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 27, 2016 12:36AM |

Registered: 11 years ago Posts: 5,780 |

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 07:45AM |

Registered: 9 years ago Posts: 1,873 |

Looks good. What size motor are you using for Z? I have a nema17 on two TR8*8 screws and I spent some time recently tracking down issues I was having with it. I didn't have enough belt-pulley engagement, so I was getting very occasional jumped teeth resulting in loss of sync between the two screws. When I started fixing that I discovered I was also extremely marginal on motor torque. The missed steps are difficult to detect, causing layers of different thickness to extrude different widths - visually it looks like a form of Z wobble. I solved both problems by using 40 tooth pulleys on the screws. The larger diameter increases the amount of belt engagement and the mechanical advantage puts the motor back into it's comfort zone. The extra resolution on the Z is a nice bonus, since an 8mm lead is a little on the coarse side.

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 08:19AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Garry Bartsch

[attachment 85429 beltpath.png]

This is how I had thought to route the belt so it would pull inwards only. Plus it would give the belt contact with the stepper pulley as Mark advised.

That's almost exactly how I did it in my first printer and it worked perfectly. I put the motor off to one side so I could feed filament from the central part of the frame.

You can see the pulleys and just a little of the motor to the right of the filament spools. I used 42 tooth pulleys on the screws and a 20 tooth pulley on the motor. The screws were (and still are) 4 starts, 1/2" lead.

No Z artifacts at all in spite of dire warnings about using imperial screws:

I used a NEMA-23 motor (I don't recall the torque spec) because I had one handy. My X axis was very heavy and I doubt a NEMA-17 motor would have been able to lift it.

Edited 1 time(s). Last edit at 10/30/2016 08:23AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 04:12PM |

Registered: 10 years ago Posts: 363 |

Quote

JamesK

Looks good. What size motor are you using for Z?

This machine is in the design stage so I haven't settled on a stepper but I'm wondering if I should be considering a NEMA-23? Can NEMA-23 run off the same driver as a NEMA-17? But if I did as you with larger pulleys on the screws then the smaller stepper would be fine? I'm just learning as I go and relying heavily on experience like yours and others. Your belts are 6mm GT2? (Please see my question to Mark about belts.)

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 04:14PM |

Registered: 10 years ago Posts: 363 |

Quote

the_digital_dentist

Great pictures. I can see nicely how you did many things. I WANT layer alignment like you. That is just killer.

Your machine has a heavy belt for Z. Can I expect not to have trouble using 6mm GT2? Or is a heavy belt required?

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 04:53PM |

Registered: 9 years ago Posts: 1,873 |

Quote

But if I did as you with larger pulleys on the screws then the smaller stepper would be fine? I'm just learning as I go and relying heavily on experience like yours and others. Your belts are 6mm GT2?

Yes, if you use larger pulleys on the screws and a smaller one on the motor you get a gearing advantage that reduces the load on the motor. So with a 20T pulley on the motor and 40T on the screws I get a 2:1 reduction that lets the nema17 cope much better than it did before. I have a relatively heavy X axis with a dual direct extruder setup, so my guess is that a nema17 will cope for your design too. The other place you can get some mechanical advantage is to use a smaller lead on the screw. I've been thinking of getting some T12 with 2mm lead.

Yes again to 6mm GT2 belt. I think it's adequate for the job, but the relatively shallow profile does seem more prone to jumping a tooth than the chunkier belts I've seen. I don't think you will have any problems with the belt path you now have, and given that your frame looks plenty rigid enough to carry adequate belt tension.

We'd all like to have layer registration like DD's! Mine can't match that, I think because of the overly flexible (whippy!) 8mm smooth rods in it. The next build will hopefully be a lot more rigid using linear guides.

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 05:46PM |

Registered: 10 years ago Posts: 363 |

Quote

JamesK

Yes again to 6mm GT2 belt. I think it's adequate for the job, but the relatively shallow profile does seem more prone to jumping a tooth than the chunkier belts I've seen. I don't think you will have any problems with the belt path you now have, and given that your frame looks plenty rigid enough to carry adequate belt tension.

My x and y steppers have the ends supported so those belts can be snugged right up (I guess tighter is better for consistent nozzle positioning) and they should not slip because of their almost full wrap on the pulley. I could do something similar for the z arrangement but likely won't because of DD's advice before about belt wear. However, I do have a friend who run his belts really tight and he said he isn’t wearing them out. Maybe there are different grades of belts?

Quote

JamesK

We'd all like to have layer registration like DD's! Mine can't match that, I think because of the overly flexible (whippy!) 8mm smooth rods in it. The next build will hopefully be a lot more rigid using linear guides.

That's my goal. If I don't achieve it I won't be happy. With linear guides on z there is no play so as long as the layers are a consistent height, and x and y move the same distance repeatedly, the edges should be perfect. My first printer was a commercial UP! Plus using linear rails and surface finish was gorgeous so I knew I wanted to make one with linear rails.

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 05:55PM |

Registered: 9 years ago Posts: 1,873 |

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 06:57PM |

Registered: 11 years ago Posts: 5,780 |

I used a 5mm pitch XL belt because I had the 42 tooth pulleys for the screws and the 20 tooth pulley for the motor. In my machine, the X axis weighed about 4-5 kg. I would not have felt comfortable with 6 mm GT2 belt. Maybe 9 or 10 mm would be OK.

I drove NEMA-23 motors with a RAMPS board for a long time. As long as you keep the current within the driver's capabilities you can drive any size motor. The NEMA-23 motors I used were not especially high torque for that size motor and were rated at 2A. I used a small one that delivered about 100 oz-in holding torque which can be done with a NEMA-17 motor, and a couple 130-150 oz-in motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I drove NEMA-23 motors with a RAMPS board for a long time. As long as you keep the current within the driver's capabilities you can drive any size motor. The NEMA-23 motors I used were not especially high torque for that size motor and were rated at 2A. I used a small one that delivered about 100 oz-in holding torque which can be done with a NEMA-17 motor, and a couple 130-150 oz-in motors.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 06:59PM |

Registered: 10 years ago Posts: 363 |

Quote

JamesK

Quote

My x and y steppers have the ends supported

Out of interest, how did you arrange that? The shaft on my motors isn't long enough to pass through the pulley and into a bearing.

Indeed the shafts are barely long enough. For y I printed a block that holds a bearing. The stepper shaft doesn't protrude through the bearing enough shaft is in the bearing to support it. Both ends of x are similarly supported in a block (the idler end has a toothed pulley with two bearings).

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 07:16PM |

Registered: 11 years ago Posts: 5,780 |

I think the main problem with over tightening belts is that it can cause the motor or other pulleys to tilt if they aren't mounted very solidly (one of the problems with non metallic printer frames) resulting in the belt teeth engaging the pulley's teeth at an angle. That will wear the belt quickly.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 07:26PM |

Registered: 10 years ago Posts: 363 |

Quote

the_digital_dentist

I think the main problem with over tightening belts is that it can cause the motor or other pulleys to tilt if they aren't mounted very solidly (one of the problems with non metallic printer frames) resulting in the belt teeth engaging the pulley's teeth at an angle. That will wear the belt quickly.

My friend who supports the end of the stepper shaft broke a shaft because the belt was too tight. Sounds crazy and he was surprised. But now that he supports them he doesn't have trouble with wear likely for the reason you mention: the shaft isn’t tilted at all.

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 30, 2016 09:43PM |

Registered: 10 years ago Posts: 363 |

Quote

the_digital_dentist

I used a 5mm pitch XL belt because I had the 42 tooth pulleys for the screws and the 20 tooth pulley for the motor. In my machine, the X axis weighed about 4-5 kg. I would not have felt comfortable with 6 mm GT2 belt. Maybe 9 or 10 mm would be OK.

My x axis weighs very close to 1.5 kg. so I'm guessing finding a NEMA-17 that can lift this will be easy even if I use a 20 tooth pulley on the z screws and the motor. But a 40 tooth on the screws would be really safe.

Quote

the_digital_dentist

I drove NEMA-23 motors with a RAMPS board for a long time. As long as you keep the current within the driver's capabilities you can drive any size motor. The NEMA-23 motors I used were not especially high torque for that size motor and were rated at 2A. I used a small one that delivered about 100 oz-in holding torque which can be done with a NEMA-17 motor, and a couple 130-150 oz-in motors.

I'm remembering (maybe): amps are pulled not pushed? Drawing too much current from the driver will fry it? From the above it sounds like I can use a NEMA-17 anyway without overworking it.

Edited 1 time(s). Last edit at 10/30/2016 09:44PM by Garry Bartsch.

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 31, 2016 10:37AM |

Registered: 11 years ago Posts: 5,780 |

Quote

Garry Bartsch

I'm remembering (maybe): amps are pulled not pushed? Drawing too much current from the driver will fry it? From the above it sounds like I can use a NEMA-17 anyway without overworking it.

The drivers act as current sources and will modulate the waveform sent to the motor to achieve the rms current you have set the chip to deliver. The driver chips are not 100% efficient, so setting current too high will cook them. If they are properly heat sunk (soldered to a large ground plane in a PCB ), they can deliver more current than if they are not properly heat sunk (plug-in modules). Gluing a tiny heat sink to the top of a plastic chip is not proper heat sinking. The data sheet for the driver chip has a maximum operating current rating based on proper heat sinking. You can't operate at that maximum current if you don't get rid of the heat.

Edited 1 time(s). Last edit at 10/31/2016 06:10PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt October 31, 2016 12:31PM |

Registered: 10 years ago Posts: 363 |

Quote

the_digital_dentist

If they are properly heat sunk (soldered to a large ground plane in a PC, they can deliver more current than it they are not properly heat sunk (plug-in modules).

Great explanation. I have a feeling I will need to review the electronic section of your SoM Instructable. It seems maybe you are hinting there is more information about this there.

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt November 07, 2016 12:31PM |

Registered: 7 years ago Posts: 29 |

|

Re: Driving Two Leadscrews With One Stepper Using a Belt November 07, 2016 12:36PM |

Registered: 10 years ago Posts: 363 |

Quote

dthomas6184

How did you go about picking your belt length? i'm looking to implement a similar 2 screw 1 motor setup myself to drive my bed instead of a cantilever bed setup.

I haven't gotten to that point yet so it's a bridge I'll have to work on crossing eventually.

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt November 07, 2016 04:08PM |

Registered: 8 years ago Posts: 601 |

|

Re: Driving Two Leadscrews With One Stepper Using a Belt November 07, 2016 05:45PM |

Registered: 11 years ago Posts: 5,780 |

Draw the thing in CAD, measure the lengths of the straight belt segments, add to that the lengths wrapped around the pulleys. That will get you into the ball-park. Then make the motor or pulleys adjustable to adjust tension. Make sure you pick a belt that's a little longer than you need- you can always take up slack, but there isn't much you can do if the belt is too short.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt November 07, 2016 06:10PM |

Registered: 10 years ago Posts: 363 |

Quote

Origamib

I have a similar system rigged up to mine. The stepper can easily be moved left and right to make it tighter, as well as the two central pulleys. This means the belt can be any length (within reason) and then just move the stepper to take up the slack.

Cool setup. How's the print quality from this machine? Do you have any pictures of the entire machine?

New browser from the creator of Opera: [vivaldi.com]

|

Re: Driving Two Leadscrews With One Stepper Using a Belt November 07, 2016 06:13PM |

Registered: 10 years ago Posts: 363 |

Quote

the_digital_dentist

Draw the thing in CAD, measure the lengths of the straight belt segments, add to that the lengths wrapped around the pulleys. That will get you into the ball-park. Then make the motor or pulleys adjustable to adjust tension. Make sure you pick a belt that's a little longer than you need- you can always take up slack, but there isn't much you can do if the belt is too short.

That's what I had thought to do as well. Old school would be to wrap string around the pulleys and measure? That might be easy and quite accurate? Drawing/calculating should be bang on too I suppose.

New browser from the creator of Opera: [vivaldi.com]

Sorry, only registered users may post in this forum.