Air Hockey Implementation of CoreXY

Posted by benjamin_le

|

Air Hockey Implementation of CoreXY March 24, 2017 02:46PM |

Registered: 7 years ago Posts: 8 |

Hello Forum!

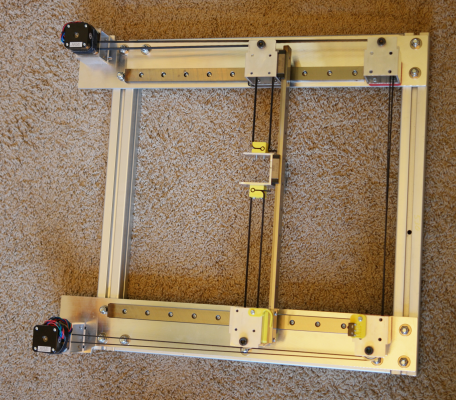

I am new to the 3D printing scene and am learning a lot. For my senior design project, I am making the track movement portion of an air hockey robot utilizing the CoreXY design (http://corexy.com/reference.png).

I am struggling, however, with my unfamiliarity with the equipment and parts necessary for my purposes which is to move a carriage on a 48"x48" 2D plane.

My questions, for now, are the following:

- Can I use 9mm wide GT2 timing belts and avoid having to buy belts that are 15mm wide? staying under budget is tough...

- Are there any helpful tips or common problems you've faced when working with CoreXY?

Here is what I have so far, I used fishing line and eye bolts for my proof of concept: [drive.google.com]

Thank you!

I am new to the 3D printing scene and am learning a lot. For my senior design project, I am making the track movement portion of an air hockey robot utilizing the CoreXY design (http://corexy.com/reference.png).

I am struggling, however, with my unfamiliarity with the equipment and parts necessary for my purposes which is to move a carriage on a 48"x48" 2D plane.

My questions, for now, are the following:

- Can I use 9mm wide GT2 timing belts and avoid having to buy belts that are 15mm wide? staying under budget is tough...

- Are there any helpful tips or common problems you've faced when working with CoreXY?

Here is what I have so far, I used fishing line and eye bolts for my proof of concept: [drive.google.com]

Thank you!

|

Re: Air Hockey Implementation of CoreXY March 24, 2017 03:17PM |

Registered: 7 years ago Posts: 8 |

Also! I am using 1/2" rods for the y axis and 3/8" rods the x axis. Considering the load (small 3D printed carriages, the x-axis rods, and an air hockey mallet that will be hitting a puck), will I have to go up in diameter for structural stability? I'd rather stick with what I have if possible.

|

Re: Air Hockey Implementation of CoreXY March 25, 2017 07:54AM |

Registered: 11 years ago Posts: 5,780 |

9 mm belts can take a lot of abuse. How much moving mass will there be in the extruder carriage? How fast does it all need to move?

In the CoreXY mechanism, the belts are divided into segments by the motor, pulleys and the extruder carriage. The fine point that a lot of people seem to miss when implementing a CoreXY mechanism is that the belt segments that vary in length with position of the extruder carriage and the Y axis must be kept parallel to their respective guide rails. All four belt segments that attach to the extruder carriage must be kept parallel to their respective guide rails, and the four segments that pass over the pulleys at the end of the X axis must be parallel to the Y axis guide rails.

Example:

Edited 1 time(s). Last edit at 03/25/2017 07:57AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

In the CoreXY mechanism, the belts are divided into segments by the motor, pulleys and the extruder carriage. The fine point that a lot of people seem to miss when implementing a CoreXY mechanism is that the belt segments that vary in length with position of the extruder carriage and the Y axis must be kept parallel to their respective guide rails. All four belt segments that attach to the extruder carriage must be kept parallel to their respective guide rails, and the four segments that pass over the pulleys at the end of the X axis must be parallel to the Y axis guide rails.

Example:

Edited 1 time(s). Last edit at 03/25/2017 07:57AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Air Hockey Implementation of CoreXY March 25, 2017 04:51PM |

Registered: 7 years ago Posts: 8 |

The extruder carriage will hold an air hockey mallet (~5oz), though perhaps not the full weight as the mallet can slide along the near frictionless table. The belt will have to support that weight and also the force of the incoming puck.

Doing a speed test of the air hockey club president's top speed, we recorded the puck to be traveling at ~21 mph. With a worst case scenario of the robot being completely out of position and having to return a top speed puck, we hope to be able to achieve 20 mph.

I'm aware that might seem unrealistic, but I don't want to rule out that goal without it being proven unfeasible (As I said, I'm very new to this haha).

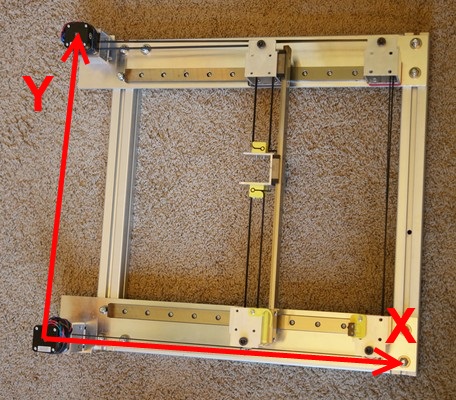

Thanks for the insight to keeping those various segments parallel, that'll be very helpful for me. Is this your axis convention by the way?

Edited 1 time(s). Last edit at 03/25/2017 04:58PM by benjamin_le.

Doing a speed test of the air hockey club president's top speed, we recorded the puck to be traveling at ~21 mph. With a worst case scenario of the robot being completely out of position and having to return a top speed puck, we hope to be able to achieve 20 mph.

I'm aware that might seem unrealistic, but I don't want to rule out that goal without it being proven unfeasible (As I said, I'm very new to this haha).

Thanks for the insight to keeping those various segments parallel, that'll be very helpful for me. Is this your axis convention by the way?

Edited 1 time(s). Last edit at 03/25/2017 04:58PM by benjamin_le.

|

Re: Air Hockey Implementation of CoreXY March 25, 2017 08:10PM |

Registered: 11 years ago Posts: 5,780 |

The (0,0) position is at the corner of the top motor in the picture. The extruder carriage moves on the X axis.

Calculate the speed in mm/sec. That will give you some idea of what the motors and the controller are going to have to do.

Edited 1 time(s). Last edit at 03/25/2017 08:20PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Calculate the speed in mm/sec. That will give you some idea of what the motors and the controller are going to have to do.

Edited 1 time(s). Last edit at 03/25/2017 08:20PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Air Hockey Implementation of CoreXY March 25, 2017 11:26PM |

Registered: 11 years ago Posts: 1,049 |

Looks like defense mechanism only,

unless some type of pusher on paddle?

May just need one axis across table?

See:

[www.theverge.com]

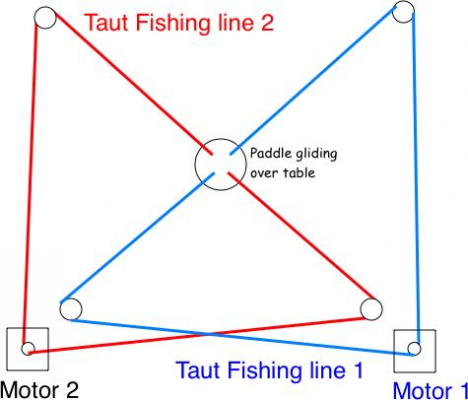

Perhaps taut line system (system skycam would use)

you have to work out kinematics, math and code --- but that is the fun!

What sensor to track puck?

Perhaps:

pixyCMUcam

[charmedlabs.com]

unless some type of pusher on paddle?

May just need one axis across table?

See:

[www.theverge.com]

Perhaps taut line system (system skycam would use)

you have to work out kinematics, math and code --- but that is the fun!

What sensor to track puck?

Perhaps:

pixyCMUcam

[charmedlabs.com]

|

Re: Air Hockey Implementation of CoreXY March 26, 2017 04:29PM |

Registered: 7 years ago Posts: 8 |

No sir, we are making an algorithm to move the robot to an intercept on the puck's projected path that gives it the best chance to score or avoid being scored on. We think that the holding torque of the motors and the grip of the belt can support the force of impact. What do you mean specifically when you say a pusher?

We may consider the taut line system if it proves more beneficial to us. At the moment, we are using a university provided thorlabs scientific camera, but we may opt for a practical alternative that so we don't risk damaging precious equipment haha.

We may consider the taut line system if it proves more beneficial to us. At the moment, we are using a university provided thorlabs scientific camera, but we may opt for a practical alternative that so we don't risk damaging precious equipment haha.

|

Re: Air Hockey Implementation of CoreXY March 27, 2017 02:43PM |

Registered: 11 years ago Posts: 1,049 |

benjamin_le "What do you mean specifically when you say a pusher?"

ie pinball flipper?

I think you must add energy to puck, to slap it, add energy, to score.

If you are just intercepting puck

and paddle is not perfect reflector

--- you will only have a slower return

FWIW --- I don't think you are going to move the core XY system fast enough to accomplish your mission!

Pretty neat project for high school senior project!

ie pinball flipper?

I think you must add energy to puck, to slap it, add energy, to score.

If you are just intercepting puck

and paddle is not perfect reflector

--- you will only have a slower return

FWIW --- I don't think you are going to move the core XY system fast enough to accomplish your mission!

Pretty neat project for high school senior project!

|

Re: Air Hockey Implementation of CoreXY March 27, 2017 03:33PM |

Registered: 7 years ago Posts: 8 |

|

Re: Air Hockey Implementation of CoreXY March 29, 2017 09:26PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Air Hockey Implementation of CoreXY March 29, 2017 09:37PM |

Registered: 7 years ago Posts: 8 |

That likely isn't feasible with how thick the underside of the table we are using is.

A goal of ours is to implement our robot on top of an existing table without damaging the table in anyway. The air hockey table at our university's game room has existing screws that are screwed in from the top all along the border of the playing field. But, sorry, that's getting ahead of myself! It's likely a second semester objective (we are in our first of 2).

A goal of ours is to implement our robot on top of an existing table without damaging the table in anyway. The air hockey table at our university's game room has existing screws that are screwed in from the top all along the border of the playing field. But, sorry, that's getting ahead of myself! It's likely a second semester objective (we are in our first of 2).

|

Re: Air Hockey Implementation of CoreXY March 30, 2017 01:16PM |

Registered: 11 years ago Posts: 1,049 |

|

Re: Air Hockey Implementation of CoreXY March 30, 2017 02:00PM |

Registered: 9 years ago Posts: 135 |

Rather than putting the mechanism under the entire table, you could probably put it inside the air chamber, then the only material the magnetic field has to cross is the thin porous top surface. You would have to disassemble the whole table, but there are ways to implement it where you don't have to drill even a single hole.

|

Re: Air Hockey Implementation of CoreXY October 07, 2017 06:24PM |

Registered: 7 years ago Posts: 8 |

Hi Forum!

It's been a long time since i've last posted but i thought i'd share our progress!

Right now, our neural network air hockey robot (NNAHR) is trying to achieve high-torque, high-speed movement (our end goal is for it to move up to 5 mph).

For motor control, we are using two NEMA-23 Stepper Motors (Bipolar, 3Nm, 4.2A), two DRV 8825 Stepper Motor Drivers, and controlling thru a Raspberry Pi.

The track system is currently a 48" width by 40" length implementation of the CoreXY design. It uses 1/2" y-rods, 3/8" x-rods, 3D printed y-carriages, 3D printed 80t GT2 pulleys, and two open end 9mm GT2 timing belts.

Here are some videos of us testing out the max-reliable rpm speeds our robot can handle: [drive.google.com]

We've found that currently, the robot can move at 600 rpm without skipping steps though we are almost capable of up to 800 rpm.

It's been a long time since i've last posted but i thought i'd share our progress!

Right now, our neural network air hockey robot (NNAHR) is trying to achieve high-torque, high-speed movement (our end goal is for it to move up to 5 mph).

For motor control, we are using two NEMA-23 Stepper Motors (Bipolar, 3Nm, 4.2A), two DRV 8825 Stepper Motor Drivers, and controlling thru a Raspberry Pi.

The track system is currently a 48" width by 40" length implementation of the CoreXY design. It uses 1/2" y-rods, 3/8" x-rods, 3D printed y-carriages, 3D printed 80t GT2 pulleys, and two open end 9mm GT2 timing belts.

Here are some videos of us testing out the max-reliable rpm speeds our robot can handle: [drive.google.com]

We've found that currently, the robot can move at 600 rpm without skipping steps though we are almost capable of up to 800 rpm.

|

Re: Air Hockey Implementation of CoreXY October 08, 2017 02:30AM |

Registered: 8 years ago Posts: 5,232 |

Quote

two NEMA-23 Stepper Motors (Bipolar, 3Nm, 4.2A), two DRV 8825 Stepper Motor Drivers,

Congrats!

But TBH, the drv8825 is a bad choice for these 4.2A steppers. You should look for external stepper drivers with more oomph and a higher driver voltage.

Max stepper rpm is a question of voltage, max achieveable torque is related to current.

If you have to stick to plugin drivers, take a look at RAPS128 drivers. They are the best you can get in pololu compatible pinout. ( I'm sure there are international resellers, too. )

Edited 1 time(s). Last edit at 10/08/2017 02:34AM by o_lampe.

|

Re: Air Hockey Implementation of CoreXY March 21, 2019 10:45AM |

Registered: 5 years ago Posts: 1 |

Using 1/2" rods for the y axis and 3/8" rods the x axis is fine and no need to go up diameter from my viewpoint. Also, check top 4 air hockey table at https://airhockeytablereviews.com/best-pool-table-air-hockey-combo

|

Re: Air Hockey Implementation of CoreXY March 21, 2019 10:53PM |

Registered: 7 years ago Posts: 8 |

|

Re: Air Hockey Implementation of CoreXY March 27, 2019 11:52AM |

Registered: 7 years ago Posts: 619 |

Quote

benjamin_le

[youtu.be]

Sorry for the lack of reply. Here was our finished product! Mechanically sound but lacking in intelligence. We did the most we could with our timetable using a deterministic algorithm (not my expertise).

That is a very credible first attempt!

Good job,

DLC

Kits: Folgertech Kossel 2020 upgraded E3Dv6, Anet A8 upgraded E3Dv6, Tevo Tarantula enhanced parts and dual-head, TronXY X5SA Pro(E3DHemera).

Scratch: Large bed Cartesian, exchangeable heads, Linear slide Delta, Maker-Beam XL Micro Delta, 220x220CoreXY.

Sorry, only registered users may post in this forum.