Passive GT3 pulleys

Posted by fma

|

Passive GT3 pulleys April 03, 2017 05:22AM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 04, 2017 05:43PM |

Registered: 11 years ago Posts: 335 |

You can get them from Misumi, although they run roughly $30 a pop. [us.misumi-ec.com]

Note that despite confusion over nomenclature, GT2 and GT3 are distinct belt tooth profiles and both come in 2, 3, and 5mm pitches. The pulley tooth profile is identical for both GT2 and GT3 belts of the same pitch.

For example part number 2MGT is a GT3 tooth profile with 2mm pitch, and would be functionally identical to GT2 belts (abeilt with a higher power rating).

[www.gates.com]

[www.torquetrans.com]

Edited 1 time(s). Last edit at 04/04/2017 05:44PM by 691175002.

Note that despite confusion over nomenclature, GT2 and GT3 are distinct belt tooth profiles and both come in 2, 3, and 5mm pitches. The pulley tooth profile is identical for both GT2 and GT3 belts of the same pitch.

For example part number 2MGT is a GT3 tooth profile with 2mm pitch, and would be functionally identical to GT2 belts (abeilt with a higher power rating).

[www.gates.com]

[www.torquetrans.com]

Edited 1 time(s). Last edit at 04/04/2017 05:44PM by 691175002.

|

Re: Passive GT3 pulleys April 05, 2017 12:39AM |

Registered: 12 years ago Posts: 300 |

Didn't know that both existed in different pitches! Thanks for the info.

About power, I plan to re-build a CoreXY from an old Stratasys mechanic, using Nema23. They used GT3 (3mm pitch) belt, but their design carries the X motor with the extruder, which mean that both X/Y axes are heavy.

Do you think I can use GT2 belt, with the CoreXY design, which is much lighter?

Frédéric

About power, I plan to re-build a CoreXY from an old Stratasys mechanic, using Nema23. They used GT3 (3mm pitch) belt, but their design carries the X motor with the extruder, which mean that both X/Y axes are heavy.

Do you think I can use GT2 belt, with the CoreXY design, which is much lighter?

Frédéric

|

Re: Passive GT3 pulleys April 05, 2017 11:16AM |

Registered: 11 years ago Posts: 335 |

I did some baseline math and a 2mm pitch x 9mm wide belt is rated to apply roughly 2Kg of force, so if you plan to achieve 2m/s^2 of acceleration the moving weight of the printer should be less than 1Kg. 3mm pitch belts are roughly 4 times as strong for a given pitch diameter.

Many hobby 3d printers use very small belts at high accelerations but end up deforming the frame and producing ringing artifacts instead of skipping belt teeth. In practice the motors and frame provide enough compliance to reduce shock loads to the belt. It is also likely that overloading the belt will simply reduce its expected lifespan and not cause catastrophic failure even if your carriage is much heaver than recommended.

I suspect that 2mm pitch is sufficient for virtually every printer, especially if you are using quality belts.

I last checked a couple years ago but at that time a 100' roll of name-brand Gates GT3-MGN3 belt was roughly $400 and very hard to source.

Many hobby 3d printers use very small belts at high accelerations but end up deforming the frame and producing ringing artifacts instead of skipping belt teeth. In practice the motors and frame provide enough compliance to reduce shock loads to the belt. It is also likely that overloading the belt will simply reduce its expected lifespan and not cause catastrophic failure even if your carriage is much heaver than recommended.

I suspect that 2mm pitch is sufficient for virtually every printer, especially if you are using quality belts.

I last checked a couple years ago but at that time a 100' roll of name-brand Gates GT3-MGN3 belt was roughly $400 and very hard to source.

|

Re: Passive GT3 pulleys April 05, 2017 11:45AM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 06, 2017 07:01AM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 06, 2017 10:28AM |

Registered: 11 years ago Posts: 335 |

Quote

fma

BTW, do you confirm it is mandatory to have teeth on the passive pulley, for a 3GT (3mm pitch) belt?

Toothed idlers will be recommended in the documentation, but in practice many low cost designs use bearings instead. I expect smooth idlers reduce belt life because they apply uneven pressure to the teeth.

Belts must be under very high tension to achieve maximum performance in positioning applications (10-30Kg). If you are working in that range toothed idlers might be necessary to maintain reasonable belt life. Most 3d printers run much less tension, say 0.5-2Kg, so you can pretty much do whatever and receive adequate performance and life.

If the original Stratasys design had an H-Bot belt path I would recommend sticking with it instead of converting to CoreXY. CoreXY will compensate for a weak frame but has fewer benefits if the printer is sufficiently rigid from the start.

|

Re: Passive GT3 pulleys April 06, 2017 11:09AM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 06, 2017 11:55AM |

Registered: 11 years ago Posts: 5,780 |

SDP/SI recommends that if you are using smooth pulleys in contact with belt teeth, for 2mm pitch belt, the pulley diameter should be equivalent to a 40 tooth gear. I don't know if that recommendation is based on positioning accuracy, operating noise, or belt life. A 40 tooth gear has approximately 80mm circumference or about 25 mm diameter. F608zz skate wheel bearings are very common, dirt cheap, and 22 mm in diameter and stacking them leaves 11mm width for the belt between the flanges, perfect for 9 or 10mm wide belt, and the same width as the drive pulleys for 9 or 10mm belt. I used F608zz bearings in my coreXY printer for the XY stage and see no print artifacts that occur at regular intervals anywhere close to the belt pitch.

I use the same pulleys in the Z axis with HTD-3M 3mm pitch belt and see no issues there either and I have printed as thin as 36 um layer thickness and as thick as 300 um.

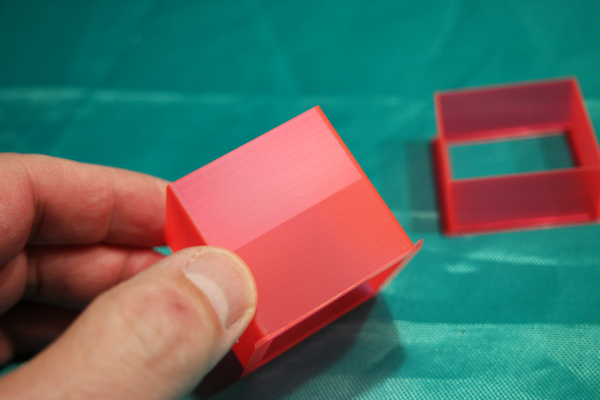

Here's a single walled test print at 270 um (bottom half) and 180 um (top half) (IRIC). Click on the picture to see it at full resolution. Do you see any problems there?

Edited 2 time(s). Last edit at 04/06/2017 12:04PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I use the same pulleys in the Z axis with HTD-3M 3mm pitch belt and see no issues there either and I have printed as thin as 36 um layer thickness and as thick as 300 um.

Here's a single walled test print at 270 um (bottom half) and 180 um (top half) (IRIC). Click on the picture to see it at full resolution. Do you see any problems there?

Edited 2 time(s). Last edit at 04/06/2017 12:04PM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Passive GT3 pulleys April 06, 2017 12:37PM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 06, 2017 12:49PM |

Registered: 12 years ago Posts: 2,470 |

To the best of my knowledge HTD and GT belts have a shape that lets them run smoothly over simple idlers. T belts on the other hand will show artifacts.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Passive GT3 pulleys April 06, 2017 12:53PM |

Registered: 11 years ago Posts: 5,780 |

Quote

fma

Looks good to me! If I can get such nice print, I'm happy

What would be the minimum diameter, for a 3mm pitch belt? Where did you find this info?

SDP/SI has an engineering manual on belt drive systems. Its buried in there somewhere... [sdp-si.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Passive GT3 pulleys April 06, 2017 01:23PM |

Registered: 12 years ago Posts: 300 |

"Idlers, either of the inside or outside type, are not recommended and should not be used except for power takeoff or functional use. When an idler is necessary, it should be on the slack side of the belt. Inside idlers must be grooved, unless their diameters are greater than an equivalent 40-groove pulley. Flat idlers must not be crowned (use edge flanges). Idler diameters must exceed the smallest diameter drive pulley. Idler arc of contact should be held to a minimum."

So, the 40-groove pulley equivalent is to be used for any pitch.

Mmm, this will give me too large pulleys... And Misumi idlers are a little bit expensive! One solution is to buy a normal pulley, and re-drill it to add bearings.

Frédéric

So, the 40-groove pulley equivalent is to be used for any pitch.

Mmm, this will give me too large pulleys... And Misumi idlers are a little bit expensive! One solution is to buy a normal pulley, and re-drill it to add bearings.

Frédéric

|

Re: Passive GT3 pulleys April 06, 2017 03:20PM |

Registered: 11 years ago Posts: 335 |

Adding bearings to existing pulleys isn't really an option, it is very hard to do concentric work on a timing pulley even if you have a lathe. Runout in your pulleys or idlers will introduce periodic error to the motion which is far worse than whatever artifacts smooth idlers may produce.

From a geometry perspective using a smooth idler won't produce any positional artifacts but will introduce some vibration when teeth first hit the idler. This will not be a problem as positioning applications don't run at constant speed so you can't hit a resonant frequency.

The engineering guidelines are very conservative and guarentee specific belt lifetimes in power transfer applications. You can take quite a few liberties for our applications.

Here is an example of how timing belts can be abused in practice: [www.youtube.com]

A Kuka retails for 5-6 figures and they've broken almost every rule of timing belt design.

From a geometry perspective using a smooth idler won't produce any positional artifacts but will introduce some vibration when teeth first hit the idler. This will not be a problem as positioning applications don't run at constant speed so you can't hit a resonant frequency.

The engineering guidelines are very conservative and guarentee specific belt lifetimes in power transfer applications. You can take quite a few liberties for our applications.

Here is an example of how timing belts can be abused in practice: [www.youtube.com]

A Kuka retails for 5-6 figures and they've broken almost every rule of timing belt design.

|

Re: Passive GT3 pulleys April 06, 2017 06:02PM |

Registered: 11 years ago Posts: 1,049 |

Note :

Kuka robot belts NOT black belts with core

Probably a polypropylene belt designed for twists and tight turns.

Not abused --- Designed by Timing belt engineer!

Kuka robot belts NOT black belts with core

Probably a polypropylene belt designed for twists and tight turns.

Not abused --- Designed by Timing belt engineer!

Quote

691175002

Here is an example of how timing belts can be abused in practice: [www.youtube.com]

A Kuka retails for 5-6 figures and they've broken almost every rule of timing belt design.

|

Re: Passive GT3 pulleys April 07, 2017 02:25AM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 07, 2017 02:34AM |

Registered: 12 years ago Posts: 2,470 |

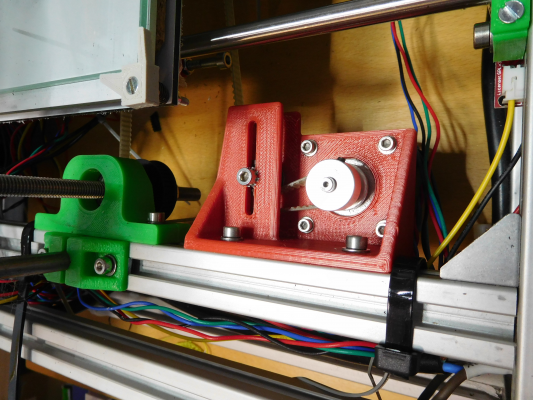

That will work nicely, i use it myself on the Z Belt

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Passive GT3 pulleys April 07, 2017 02:41AM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 07, 2017 02:53AM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 07, 2017 08:06AM |

Registered: 11 years ago Posts: 5,780 |

The PU belts usually (always?) have steel core which will stretch less than the neoprene belts with a glass core. However, the steel core makes them a lot stiffer so it takes more motor torque to bend them around the pulleys. I tried Steel core PU belts in my XY stage and after a brief test decided to go back to the glass core neoprene belt. I suspect that all the flexing in the XY stage would limit the life of the steel core belts in that application. Also, since belt position is critical in XY stages, you have to take the thickness of the belt into account when positioning pulleys. The two belts really aren't interchangeable because the PU belts are thicker. I think bending a steel core belt around a 16 tooth pulley would take a lot of effort, and the small radius might limit the life of the belt.

I did use steel core PU in the Z axis- I wanted minimum stretch, I have lots of torque available, the belt only bends around two pulleys, and it doesn't move fast or a lot.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I did use steel core PU in the Z axis- I wanted minimum stretch, I have lots of torque available, the belt only bends around two pulleys, and it doesn't move fast or a lot.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Passive GT3 pulleys April 07, 2017 08:16AM |

Registered: 12 years ago Posts: 300 |

|

Re: Passive GT3 pulleys April 07, 2017 08:31AM |

Registered: 11 years ago Posts: 5,780 |

I'm sure they use quality belts- there are different core materials available- I think kevlar is pretty common. AFAIK, the PU belts are always whitish in color, but there could be other colors.

I have a Stratasys XY stage and the belts that drive the X and Y axes are black- they appear to be neoprene with a nylon (?) facing on the tooth side. Probably not steel core.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

I have a Stratasys XY stage and the belts that drive the X and Y axes are black- they appear to be neoprene with a nylon (?) facing on the tooth side. Probably not steel core.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Sorry, only registered users may post in this forum.