Flexible hosepipe style air-ducts... using Masking tape!

Posted by lkcl

|

Flexible hosepipe style air-ducts... using Masking tape! September 01, 2017 08:17AM |

Registered: 8 years ago Posts: 776 |

[youtu.be]

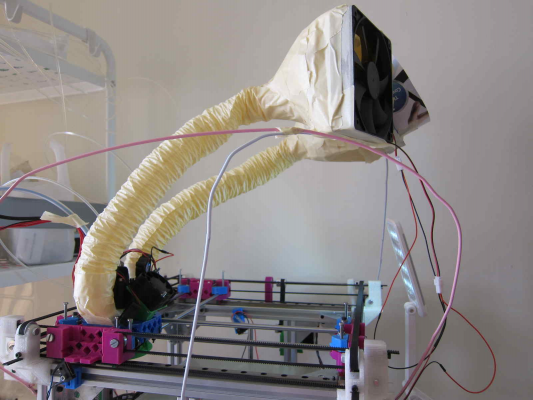

i thought people might find this funny, to know that there is someone seriously considering using 1.5in wide masking tape to create an air duct (flexible hosepipe) for a 3D printer cooling system. i can't exactly recall where it was but i've seen someone use PVC tubing for air ducting before now, but they used a very low inner diameter tube (something like 8mm or less) and they have to use absolutely enormous pressure to get the kind of airflow they needed.

so i then thought, ok, well how about that black off-the-shelf flexible hosepipe, the stuff that we normally use as cable-ducting when it has a split down the middle? hmm, that's still quite a bit heavier. okay, so how about polythene sheet, cut up and made into a tube? hmmm, that would likely collapse. i could tape a wire all the way round it, just like those reinforced flexible tubes, but it's a lot of hassle...

how about just using Masking Tape or Duct Tape! it's really strong, really sticky. buuut, you need to make it "flex" and the simplest way to do that would be to "crumple" it. hmmm, duct tape doesn't really crumple, but Masking Tape does!

and i'm absolutely amazed. a 600mm length at around 30mm diameter is actually the same sort of weight as the 50mm fan i'm planning to connect it to!

also the nice thing about moving the fans off the carriage is that you can make them HUGE without adversely impacting the weight of the carriage...

i thought people might find this funny, to know that there is someone seriously considering using 1.5in wide masking tape to create an air duct (flexible hosepipe) for a 3D printer cooling system. i can't exactly recall where it was but i've seen someone use PVC tubing for air ducting before now, but they used a very low inner diameter tube (something like 8mm or less) and they have to use absolutely enormous pressure to get the kind of airflow they needed.

so i then thought, ok, well how about that black off-the-shelf flexible hosepipe, the stuff that we normally use as cable-ducting when it has a split down the middle? hmm, that's still quite a bit heavier. okay, so how about polythene sheet, cut up and made into a tube? hmmm, that would likely collapse. i could tape a wire all the way round it, just like those reinforced flexible tubes, but it's a lot of hassle...

how about just using Masking Tape or Duct Tape! it's really strong, really sticky. buuut, you need to make it "flex" and the simplest way to do that would be to "crumple" it. hmmm, duct tape doesn't really crumple, but Masking Tape does!

and i'm absolutely amazed. a 600mm length at around 30mm diameter is actually the same sort of weight as the 50mm fan i'm planning to connect it to!

also the nice thing about moving the fans off the carriage is that you can make them HUGE without adversely impacting the weight of the carriage...

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 01, 2017 05:37PM |

Registered: 9 years ago Posts: 978 |

Ummm... how do you stop the masking tape tube from collapsing and sticking together into a ribbon? Do you do two layers, with the sticky sides facing each other?

Since you're concerned about weight, I assume that one end will connect to (I guess) the hot-end, and move around. I'd be worried that the tube would crease, fatigue, and eventually tear. No big deal to repair, but you maybe lose a print and get a hot-end jam along the way.

Since you're concerned about weight, I assume that one end will connect to (I guess) the hot-end, and move around. I'd be worried that the tube would crease, fatigue, and eventually tear. No big deal to repair, but you maybe lose a print and get a hot-end jam along the way.

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 01, 2017 08:19PM |

Registered: 8 years ago Posts: 776 |

Quote

frankvdh

Ummm... how do you stop the masking tape tube from collapsing and sticking together into a ribbon? Do you do two layers, with the sticky sides facing each other?

effectively yes. there's two questions here. the first about how i made it, and the second on crinkling it to make it not collapse.

i stretched out the first piece, about 70cm long, then cut a 2nd piece and overlaid it (same way, sticky side up) overlapping only about 3mm tricky to do, but doable. then i put another piece *face* down on top, 50% over one and 50% over the other. had to be really careful because i got it wrong one time, tried lifting it (unsticking) and... DAMN it was tough as hell. Masking tape isn't just paper (wood fibres) it seems to also be coated with something or perhaps might have cotton fibres in it or somethiing, but the glue is hellishly strong if you get two sticky sides together.

anyway fourth piece was again 3mm overlap sticky side up, 5th was face down this time *again* 50% overlap with pieces 2 and 5 but also this time 3mm overlap with piece... 3 (which is also "down"). last one (6th) i put at the *front* edge, face down, but lifting piece 1 up off the floor slightly to do it, then curled the whole thing into a tube and CAREFULLY stuck piece 6 down so that it overlapped by 3mm again, WITHOUT touching piece 5's sticky-side-up face AT ALL.

then, finally, i stuck down piece 5's last 45-or-so-percent to make a sealed, no-sticky-bits-at-all-anywhere tube.

making sure it can't collapse... actually means you need to collapse it, ironically, but collapse as in "concertina" so that the crinkles have a "memory" effect of where to go. basically i put three fingers into the end of the tube and started pushing them down concertina-style so that the tube overlapped itself as many times as i could manage without hurting my fingers. i managed about 35 cm before it got too much, then opened it up, turned it round and did the other end.

i then did that 3 or 4 times because the more times you do it, the more "crinkles" you get. the smaller the crinkles, mechanically the more flexible it gets and the *less* chance it will collapse at any one point. the important thing however is *NOT* to straighten it out (don't pull it taut) the moment you do that the memory of the crinkles and the whole concertina shape is gone, and it could collapse flat.

Quote

Since you're concerned about weight, I assume that one end will connect to (I guess) the hot-end, and move around. I'd be worried that the tube would crease, fatigue, and eventually tear. No big deal to repair, but you maybe lose a print and get a hot-end jam along the way.

one end yeah will be on the carriage where the fan currently is: i'll make a housing for it. i'll see how it gets on, basically, but this is *masking* tape, not sellotape, cardboard or paper. like duct tape, it's backed with some sort of PVC (waterproof) plastic that ensures that it won't just... tear. remember, it's also doubled-up.

also, i actually have two of them, one on each of the *two* fans that go on this "space-age" cooling duct. it's designed like a pair of trousers

so in theeeorryyyy.... if one _did_ ever fail (and i wasn't keeping an eye on it to drop a piece of tape over the hole) it shouuild still keep going, at least with 50% airflow.

so in theeeorryyyy.... if one _did_ ever fail (and i wasn't keeping an eye on it to drop a piece of tape over the hole) it shouuild still keep going, at least with 50% airflow.oh. also, it's for the part-cooling not the hotend. i'm leaving that one on the carriage, definitely. no, this is so i can put Monster Fans statically - not on the carriage - and get really good part cooling. i want to see what happens if i use a couple of 120mm fans. just for a laugh i plan to make a funnel to turn the 30mm diameter into 120mm.... out of duct tape and more masking tape. if you're on to a good thing, why stop the party, ehn?

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 02, 2017 03:30AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 02, 2017 05:25AM |

Registered: 8 years ago Posts: 776 |

Quote

o_lampe

Why not use shrinktube and shrink it on top of the off_the_shelf flexible hosepipe. Then remove the inner hosepipe and voilá: crinkled rubber hosepipe.

Removing the inner hosepipe should be easy when it's slotted lengthwise.

can you get 30mm OD shrinktube? or 40mm? [edit: i didn't find any - i looked around. it was one of the first things i googled

]

]Edited 1 time(s). Last edit at 09/02/2017 07:24AM by lkcl.

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 03, 2017 03:00AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 03, 2017 06:07AM |

Registered: 8 years ago Posts: 776 |

Quote

o_lampe

You can get shrinktube in any size, but it's not rubber. Food industry uses shrinking foil ( and tubes ). Its more flexible too.

ahhh awesome. ok so the idea you propose is: use one of those flexible pipes that has a cut down the middle in effect as a "mould form". i like that idea a lot. i wonder if it'll be lighter or as flexible / resilient as masking tape. reason i ask is, whenever i've heat-shrunk that tube stuff, it seemed to go a little bit less... flexible. seemed a bit more stiff. that would have me slightly concerned. can always experiment and see though

l.

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 04, 2017 01:59AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 04, 2017 07:41AM |

Registered: 11 years ago Posts: 5,780 |

It's a nice idea, but if you have to run air though a flexible hose, something that doesn't crush easily might be a good idea. Try a CPAP hose. Light and flexible and won't get crushed if you look at it wrong. No need to be concerned about adhesive letting go. The ends have soft rubber fittings that can easily mate to 3D printed fan mounts, nozzles, etc.

[www.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[www.ebay.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 06, 2017 04:52AM |

Registered: 10 years ago Posts: 150 |

Use a cheap corrugated tube from an aquarium cleaner :

It works very well with a 60x15mm blower. You need to print an adapter. I use this sort of tube since 2 years on my Zatsit delta prototype:

www.zatsit.fr

It works very well with a 60x15mm blower. You need to print an adapter. I use this sort of tube since 2 years on my Zatsit delta prototype:

www.zatsit.fr

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 07, 2017 08:23AM |

Registered: 8 years ago Posts: 776 |

Quote

M_Xeno

Use a cheap corrugated tube from an aquarium cleaner :

It works very well with a 60x15mm blower. You need to print an adapter. I use this sort of tube since 2 years on my Zatsit delta prototype:

www.zatsit.fr

awesome, i like it. that tube would be extremely light, wouldn't it.

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 07, 2017 12:40PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 07, 2017 06:58PM |

Registered: 8 years ago Posts: 776 |

Quote

MKSA

Masking tape has the big advantage to capture any insect avoiding it to clog heatsink fins etc....

it really doesn't: with the two layers being back-to-back 100% with a 3-5% overlap there's not a single place where sticky side is showing, and, the two sides being 100% together i literally couldn't separate them if i tried

Quote

Not to mention the fun to make it. Cling film and scotch tape, hard to beat to test your nervous system.

it was actually a lot of fun to make

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 11, 2017 01:09AM |

Registered: 8 years ago Posts: 776 |

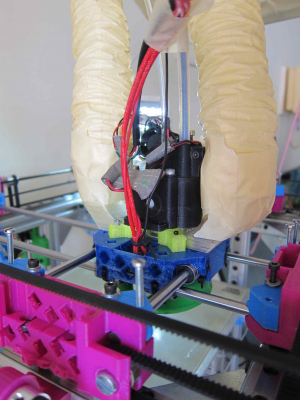

it's alive, alive i tell you! so... it works, but the 120mm computer fans are absolute rubbish. i naively believed that bigger would mean more air-flow. instead, i remembered Mythbusters, and on close examination of the fan cowling found a whopping THREE millimetre gap between the edge of the blades and the inner ring of the cowling. you can see i tried putting a ring on it (save on 3D printing as a first experiment) and it failed completely.

fans are rubbish!! so i looked around and found this: [www.desiquintans.com]

and indeed, fans are... rubbish.

soOoo... i will be getting *four* 50x50mm blowers, throwing those 120mm fans in the trash, and putting two per tube.

the holders are two wire coathangers btw. yes really. why waste money on expensive aluminium extrusion and 3D printing more bits of plastic when you can just raid your clothes line....

fans are rubbish!! so i looked around and found this: [www.desiquintans.com]

and indeed, fans are... rubbish.

soOoo... i will be getting *four* 50x50mm blowers, throwing those 120mm fans in the trash, and putting two per tube.

the holders are two wire coathangers btw. yes really. why waste money on expensive aluminium extrusion and 3D printing more bits of plastic when you can just raid your clothes line....

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 11, 2017 06:24AM |

Registered: 11 years ago Posts: 5,780 |

Either it's a work of art, or it will scare the crap out of children, or both. Oh yeah, that's the other thing. Axial fans can't blow air through a tube. You need a radial fan, aka a blower.

Edited 1 time(s). Last edit at 09/11/2017 06:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Edited 1 time(s). Last edit at 09/11/2017 06:25AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 11, 2017 11:36AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 11, 2017 11:41AM |

Registered: 8 years ago Posts: 776 |

Quote

MKSA

Always look at the big picture. Done. OK, now, what is the purpose again ? Usually it is one 30mm fan for the hot end, one blower fan for the part. SO ?

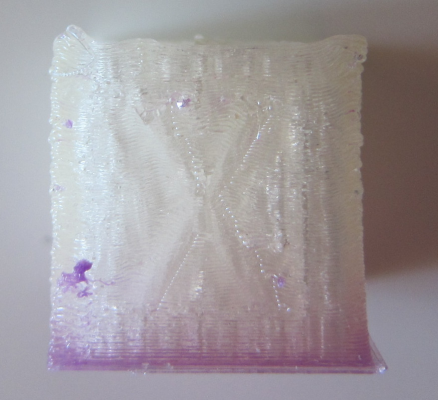

one blower is nowhere near enough to deal with 250 to 300mm / sec or above print speeds. i'm getting perfect prints at 50mm/sec even with 50 to 55 degree overhangs. but with a square 20x20x20mm test cube running at 300mm / sec the edges curl up by at least 2 or 3 layers (0.4 to 0.6mm).

i need a *lot* of airflow, basically. one blower is nowhere near enough.

l.

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 11, 2017 01:09PM |

Registered: 6 years ago Posts: 1,007 |

Quote

lkcl

Quote

MKSA

Always look at the big picture. Done. OK, now, what is the purpose again ? Usually it is one 30mm fan for the hot end, one blower fan for the part. SO ?

one blower is nowhere near enough to deal with 250 to 300mm / sec or above print speeds. i'm getting perfect prints at 50mm/sec even with 50 to 55 degree overhangs. but with a square 20x20x20mm test cube running at 300mm / sec the edges curl up by at least 2 or 3 layers (0.4 to 0.6mm).

i need a *lot* of airflow, basically. one blower is nowhere near enough.

l.

Where can we see it printing at these speeds ? 0 to 300 mm/s on a 20mm long race track, gee ! (in fact more than 2

)

)Edited 2 time(s). Last edit at 09/11/2017 01:11PM by MKSA.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 11, 2017 03:44PM |

Registered: 11 years ago Posts: 5,780 |

If you need a LOT of air flow, find a used CPAP machine at a garage sale, Craig's list, or get one from one of your uncles or cousins. The blower from one of those can be used to sweep up leaves in your yard this fall. It will move air through a tube, no problem.

[vimeo.com]

I'm working on a PWM speed controlled driver using a MCP8063, and once I get a couple boards made will be testing it out on my printer. Don't be alarmed by the noise the fan makes on the video- that was running it at a ridiculous speed. In normal operation those fans are very quiet even when moving a lot more air than you'll get from typical fans/blowers used to cool prints.

Edited 1 time(s). Last edit at 09/12/2017 01:30AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

[vimeo.com]

I'm working on a PWM speed controlled driver using a MCP8063, and once I get a couple boards made will be testing it out on my printer. Don't be alarmed by the noise the fan makes on the video- that was running it at a ridiculous speed. In normal operation those fans are very quiet even when moving a lot more air than you'll get from typical fans/blowers used to cool prints.

Edited 1 time(s). Last edit at 09/12/2017 01:30AM by the_digital_dentist.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 11, 2017 08:39PM |

Registered: 8 years ago Posts: 776 |

Quote

MKSA

Where can we see it printing at these speeds ? 0 to 300 mm/s on a 20mm long race track, gee ! (in fact more than 2)

[youtu.be]

it's pretty fricking funny. i had to to hold it so it didn't shake the table: certain frequencies ended up with resonant harmonics and i was a bit concerned

amazingly the straight edges came out perfectly fine. no stringing, no breaking - bear in mind i'd ramped that down to 200mm/sec (for edges). the acceleration figures (3500mm/s^2) are also deceptive due to the fact that they apply *before* the pulley takes effect, which adds a 2:1 velocity ratio. i can never quite work out if that means the acceleration is effectively quadrupled or if it's just doubled. it's probably effectively quadrupled.

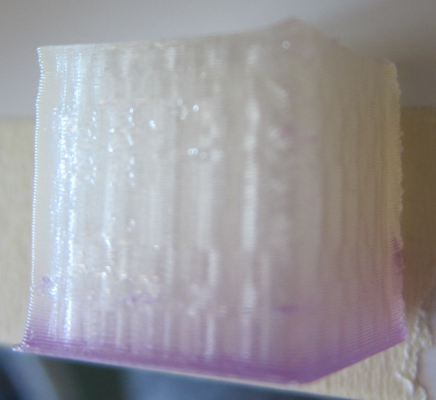

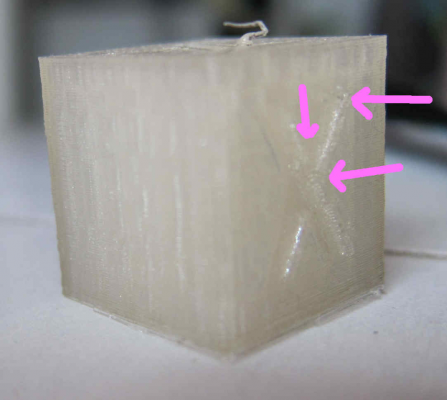

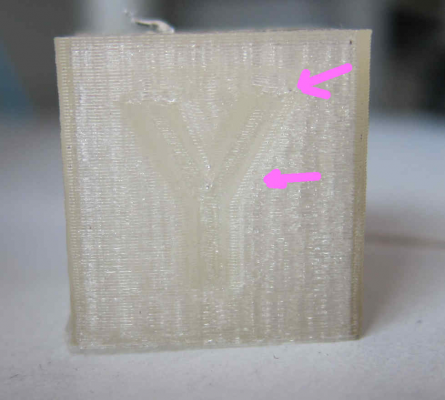

i'm deliberately using transparent PLA so i can see inside the object and inspect it, does make photos a bit challenging though, sorry. there's no strand-breaks @ 200mm/s on the outer edge. corner-lifting on the best corner is still around 0.1mm, worst-case is around *three* layers especially on the Y and X indentation letters on the test cube

until the blowers arrive, i think the next experiment, just to see what happens, would need to be to create some larger objects or at least multiply up some small ones. give the layers time to cool down somewhat (without a huge amount of cooling).

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 11, 2017 09:01PM |

Registered: 8 years ago Posts: 776 |

Quote

the_digital_dentist

Either it's a work of art, or it will scare the crap out of children, or both.

haha yeah. modern art makes me nervous and i'm 47

Quote

Oh yeah, that's the other thing. Axial fans can't blow air through a tube. You need a radial fan, aka a blower.

well i know that _now_! nnngggggh just another thing in a long line of things that need to be known when doing 3d printing nggggggh

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 12, 2017 02:20AM |

Registered: 6 years ago Posts: 1,007 |

Looks like you have far more problems than just the part cooling fan !

And definitely the speed is NOT 300mm/s. It may look like it but that is because of the noise and the shaking , typical of these playful crappy chinese bearings that must grind the rods !

, typical of these playful crappy chinese bearings that must grind the rods !

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

And definitely the speed is NOT 300mm/s. It may look like it but that is because of the noise and the shaking

, typical of these playful crappy chinese bearings that must grind the rods !

, typical of these playful crappy chinese bearings that must grind the rods !"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 12, 2017 03:08AM |

Registered: 8 years ago Posts: 776 |

Quote

MKSA

Looks like you have far more problems than just the part cooling fan !

And definitely the speed is NOT 300mm/s. It may look like it but that is because of the noise and the shaking, typical of these playful crappy chinese bearings that must grind the rods !

it definitely is - i've been doing 150, 180 and 200mm/sec speeds for some years now, i know what they sound like: this is shaking the table enough to make me nervous about taking my hand off the frame.

the "glank, glank" sound you're hearing which sounds like rod-to-bearing grinding isn't: it's an extremely fast change of direction with the X and Y min-jerk values set so high (1000 mm / min) that RepRapFirmware is throwing the carriage really, really hard around corners. When it's set to even 600 mm / min that noise completely disappears, but ironically and paradoxically you start to get corner-bulging. i don't yet know why: i haven't even established a good hypothesis on that one.

the only reason i can even consider trying this at all is because of the doubled-up (pulley) belts unique to this design. the twin belt sections provide double the amount of protection from hard acceleration.

anyway. next i'll try a long piece, see if the strands break up at all.

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 12, 2017 05:01AM |

Registered: 6 years ago Posts: 1,007 |

How do you measure the speed to be so sure ? Is it average, peak etc ??? PLA is the easiest to print.

What about PETG ? I bet at this speed and with all these fans, the required T° and filament output won't be achieved.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

What about PETG ? I bet at this speed and with all these fans, the required T° and filament output won't be achieved.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 12, 2017 05:38AM |

Registered: 8 years ago Posts: 776 |

Quote

MKSA

How do you measure the speed to be so sure ? Is it average, peak etc ??? PLA is the easiest to print.

What about PETG ? I bet at this speed and with all these fans, the required T° and filament output won't be achieved.

yeah PETG i would expect to stutter and break up at these kinds of speeds: i've only had a little bit of experience with PETG so far and i'm not hugely fond of it (structurally) despite the higher temperatures it can stand. i usually run PETG at no more than about... 120mm / sec infill and 80mm / sec on the edges.

how do i measure the speed? last time i measured it i ran a piece 160mm long (which i happened to have around) at 200mm/sec and timed it: it came out to just under 1 second end-to-end so that was fine.

i trust the firmware, basically MKSA. if it's told to run at 50mm / sec it runs at 50mm / sec. if it's told to run at 150mm / sec it runs at 150mm / sec. the only thing to bear in mind is that the acceleration graph can cut you off: you think you're reaching 300mm/sec within 30mm but the acceleration only allows the speed to reach half of that.

i wish i could find that online javascript acceleration calculator i saw a few months back. anyway. testing time

[edit] ok so i think i understand what you're saying, you're saying that the fans would cut the temperature so that the extruder wouldn't reach PETG temperatures? i'm running a 40W 24v heater, so in theory it should be fine. have to wait a week to get the blowers from Shenzhen Markets over here in TW, we'll find out. just doing tests now, i think there's something up with RepRapFirmware.

Edited 1 time(s). Last edit at 09/12/2017 07:01AM by lkcl.

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 12, 2017 03:00PM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Flexible hosepipe style air-ducts... using Masking tape! September 12, 2017 11:06PM |

Registered: 8 years ago Posts: 776 |

Quote

MKSA

OK and how does these test cubes look at 60mm/s, 120mm/s and 180mm/s ?

well now that i disccovered that i have had debug logging enabled for over 2 years on the duet 0.8.5 without realising it... *smack*... should look really good. 60 should be fine anyway. using skeinforge (it's quirky but i had a bit of a run-in with cura over some awkward slicing and rebelled....) 230 C temperature on clear PLA (it's quite stringy, runs out the nozzle) 0.4mm nozzle 0.2mm layer height. acceleration is now set to 8,000 mm/sec^2 and max jerk mm/min to 1000 mm/min. i like using clear PLA for these tests as it shows the internal structure.

also, kist so you know, i fixed a bug (actually some commented out code *then* a bug) in skeinforge where people had stopped using fillet (corner-rounding) because of the bugs. i've been able to set corner-rounding to 0.65mm and i don't get the horrible corner-bulging as a result.

just tracking the print whilst it's going... the top V-part (overhang) of the X and the Y have a loop that's sticking up in the air by about 0.2 mm.... ok now about 0.5mm... so it's obviously molten still. gahh these 120mm fans are utterly useless. ok the top of the X and the Y are completed - took a few layers for that over-height to calm down and straighten out... this is at 60mm/s btw...

right, so arrows show where the (useless) cooling isn't helping. plus this is really high temperature for PLA.

again, lack of cooling artefacts

here it's just skeinforge

on the left, that's an entry/exit point for the outer perimeter, and the "blob" is because i haven't yet set manual commands for retract on stop.

on the left, that's an entry/exit point for the outer perimeter, and the "blob" is because i haven't yet set manual commands for retract on stop.overall though this is supposed to be a *ringing* test and despite the insane accelerations and jerk speeds there's absolutely no sign of ringing whatsoever.

anyway if it's ok i'll wait until i have proper cooling in place before doing faster.

Sorry, only registered users may post in this forum.