Power Wiring

Posted by blt3dp

|

Power Wiring December 27, 2017 05:22PM |

Registered: 10 years ago Posts: 651 |

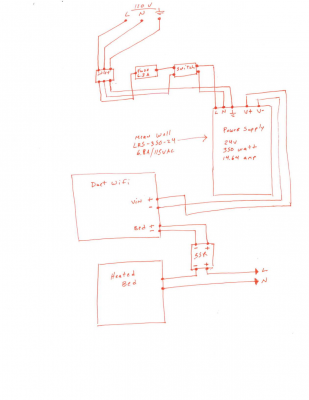

Designing a new printer and wanted to include a couple of things that weren't on my current.

I'd like to use a Mean Well power supply, an inlet, fuse, and switch.

I would like someone to take a look at the drawing below and tell me if I'd wire it correctly.

I also need help choosing a bed heater and method to power it.

I'll be heating a relatively small build plate. It's a 130mm x 130mm plate of 6mm thick Mic6. I intend to use a 100mm x 100mm silicone heater.

I guess I need help determining what power is going to heat that plate quickly enough, and power it properly.

I need help determining if I can run that heater directly from a Duet Wifi or if I'll need to connect it to mains.

The power supply I intend to use is a 350 watt supply, that can supply up to 14.64 amps @ 24v

I'll be running your average Duet WiFi, hotend, motors, and fans

I'm estimating that running the system, bed heater excluded, would take about 8 amps

Any suggestions?

Edited 2 time(s). Last edit at 12/28/2017 05:38PM by FA-MAS.

I'd like to use a Mean Well power supply, an inlet, fuse, and switch.

I would like someone to take a look at the drawing below and tell me if I'd wire it correctly.

I also need help choosing a bed heater and method to power it.

I'll be heating a relatively small build plate. It's a 130mm x 130mm plate of 6mm thick Mic6. I intend to use a 100mm x 100mm silicone heater.

I guess I need help determining what power is going to heat that plate quickly enough, and power it properly.

I need help determining if I can run that heater directly from a Duet Wifi or if I'll need to connect it to mains.

The power supply I intend to use is a 350 watt supply, that can supply up to 14.64 amps @ 24v

I'll be running your average Duet WiFi, hotend, motors, and fans

I'm estimating that running the system, bed heater excluded, would take about 8 amps

Any suggestions?

Edited 2 time(s). Last edit at 12/28/2017 05:38PM by FA-MAS.

|

Re: Power Wiring December 29, 2017 03:49AM |

Registered: 6 years ago Posts: 1,007 |

|

Re: Power Wiring December 29, 2017 09:16AM |

Registered: 11 years ago Posts: 5,780 |

I'd connect the power line ground to the printer's metal frame (if it is metal!). The bed moves, so there's always a possibility of wires getting pulled or broken and shorted, so I added an electrical fuse to that circuit.

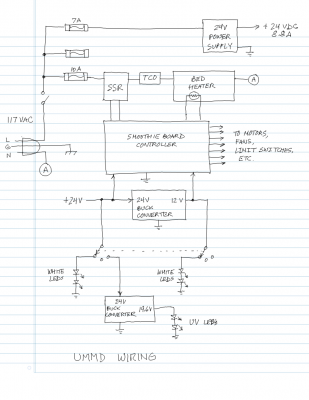

Here's how I wired UMMD, my coreXY machine:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Here's how I wired UMMD, my coreXY machine:

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Power Wiring December 29, 2017 10:47AM |

Registered: 10 years ago Posts: 651 |

Most definitely, I had planned to connect the frame to ground. The design is entirely metal, with the exception of the holders for the endstops (opitcal), the endstop flags, and the hotend carriage. The bed will only move in Z direction. I had still planned to ground it also, even though everything is metal.

That diagram clears up a couple of questions I had.

1. I had planned to connect the heated bed after the fuse and switch, either to the output terminals of the switch, or to the terminals on the power supply. It shouldn't matter right?

2. Going off of dc42's blog (where I extrapolated that drawing), it said to use a 6.3A fuse. The power supply I'm planning to use is a Mean Well LRS-350-24. The datasheet says it can draw up to 6.8 amps. If I were to use that fuse, and put it under a load higher than 6.3 amps but still under it's rated 6.8, wouldn't that fuse blow? I mean, I don't really plan on putting the power supply under that heavy of a load, but I would have thought to go with a 7A, like what Dentist's drawing shows.

3. You also answered my other question about fusing the bed heater. Here's my question, Say I originally chose a 7A fuse for everything but the bed heater like in my drawing. I then connect the bed downstream from the fuse. Lets say the bed heater is 300 Watt 120V, that would draw 2.5A. Could I then just increase the value of the fuse to a 10A fuse? Typing this out now, I'm thinking it would probably be better to fuse it separately, so if one part causes the fuse to blow, the other would be isolated.

3. Any suggestions on how I can figure out how many Watts I should choose for the heater? I'll be heating a piece of Mic6 6.35mm thick, measuring 130mm x 130mm

4. Suggestions for other parts, SSR, Thermal Cutoff Switch, etc?

Also Digital Dentist, what's that 3rd fuse there for, the one between the 7A and 10A?

That diagram clears up a couple of questions I had.

1. I had planned to connect the heated bed after the fuse and switch, either to the output terminals of the switch, or to the terminals on the power supply. It shouldn't matter right?

2. Going off of dc42's blog (where I extrapolated that drawing), it said to use a 6.3A fuse. The power supply I'm planning to use is a Mean Well LRS-350-24. The datasheet says it can draw up to 6.8 amps. If I were to use that fuse, and put it under a load higher than 6.3 amps but still under it's rated 6.8, wouldn't that fuse blow? I mean, I don't really plan on putting the power supply under that heavy of a load, but I would have thought to go with a 7A, like what Dentist's drawing shows.

3. You also answered my other question about fusing the bed heater. Here's my question, Say I originally chose a 7A fuse for everything but the bed heater like in my drawing. I then connect the bed downstream from the fuse. Lets say the bed heater is 300 Watt 120V, that would draw 2.5A. Could I then just increase the value of the fuse to a 10A fuse? Typing this out now, I'm thinking it would probably be better to fuse it separately, so if one part causes the fuse to blow, the other would be isolated.

3. Any suggestions on how I can figure out how many Watts I should choose for the heater? I'll be heating a piece of Mic6 6.35mm thick, measuring 130mm x 130mm

4. Suggestions for other parts, SSR, Thermal Cutoff Switch, etc?

Also Digital Dentist, what's that 3rd fuse there for, the one between the 7A and 10A?

|

Re: Power Wiring December 29, 2017 11:12AM |

Registered: 11 years ago Posts: 5,780 |

1) it would be better to run it to the switch terminals. Daisy chaining high current loads is generally a bad idea.

2) You want to size the fuse to allow some margin over the power supply full-load draw. I'd probably go for 8A or 10A. Meanwell supplies have their own internal fuses, usually.

3) I prefer to separate the circuits because you can fuse each appropriately. If the bed needs 3A, give it a 4A or 5A fuse.

3) 0.4-0.5W / cm^2 will heat it up quickly and allow the PID control to regulate it easily. That bed size is small and doesn't need a very high powered heater. You have 169 cm^2 so I'd look for a heater that's around 75W. With such a low powered heater you could just run it from the DC supply and save the messing around with line power. The controller board MOSFETs should easily handle switching power to that load.

4) The type of TCO I used is a single-use device like a fuse. It's operating temperature (184C) that is about 24C above the highest temperature I ever intend to operate the heater (160C). Different type TCOs vary in how you select operating temperature, so check the data sheet.

The third fuse is there for a 500W enclosure heater that I am (still...) in the process of adding. Progress has slowed to a crawl lately, partially because my work room is in the basement and it's cold down here!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

2) You want to size the fuse to allow some margin over the power supply full-load draw. I'd probably go for 8A or 10A. Meanwell supplies have their own internal fuses, usually.

3) I prefer to separate the circuits because you can fuse each appropriately. If the bed needs 3A, give it a 4A or 5A fuse.

3) 0.4-0.5W / cm^2 will heat it up quickly and allow the PID control to regulate it easily. That bed size is small and doesn't need a very high powered heater. You have 169 cm^2 so I'd look for a heater that's around 75W. With such a low powered heater you could just run it from the DC supply and save the messing around with line power. The controller board MOSFETs should easily handle switching power to that load.

4) The type of TCO I used is a single-use device like a fuse. It's operating temperature (184C) that is about 24C above the highest temperature I ever intend to operate the heater (160C). Different type TCOs vary in how you select operating temperature, so check the data sheet.

The third fuse is there for a 500W enclosure heater that I am (still...) in the process of adding. Progress has slowed to a crawl lately, partially because my work room is in the basement and it's cold down here!

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Power Wiring December 29, 2017 11:20AM |

Registered: 10 years ago Posts: 651 |

Quote

the_digital_dentist

3) 0.4-0.5W / cm^2 will heat it up quickly and allow the PID control to regulate it easily. That bed size is small and doesn't need a very high powered heater. You have 169 cm^2 so I'd look for a heater that's around 75W. With such a low powered heater you could just run it from the DC supply and save the messing around with line power. The controller board MOSFETs should easily handle switching power to that load.

This was actually what I was looking for. My math showed that I needed about a 70 Watt heater (though I did the math at 100mm x 100 mm), I'm sure it would be close to 75W if I did it at 130x130 (the actual plate size). If I went with that, it would draw roughly 3.2A on 24V. I figure that the rest of system would take roughly 6A-8A to run. That would fall far below what the power supply could handle, the Duet WiFi wouldn't have a problem with that either.

|

Re: Power Wiring December 29, 2017 05:26PM |

Registered: 10 years ago Posts: 651 |

So, checking with Mean Well if that power supply has a fuse, if it does, I needn't add one correct? If it doesn't I'll add one.

Looking to get a custom bed heater made, looking to go with 24V and 100W may be the lowest I can order. It would obviously draw more power, but also provide more heat, and would heat up the bed quicker? Shouldn't be a problem right, so long as the power supply and Duet can handle it correct?

Looking to get a custom bed heater made, looking to go with 24V and 100W may be the lowest I can order. It would obviously draw more power, but also provide more heat, and would heat up the bed quicker? Shouldn't be a problem right, so long as the power supply and Duet can handle it correct?

|

Re: Power Wiring December 29, 2017 07:24PM |

Registered: 11 years ago Posts: 5,780 |

Higher power in the heater just means the bed will heat up faster and PID will be able to regulate temperature easily. Should be fine.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Power Wiring December 30, 2017 01:05PM |

Registered: 12 years ago Posts: 2,470 |

The internal fuse will be rated for the maximum power the PSU can supply, you should add an own fuse for the heat bed that is rated for it, the internal fuse of the PSU might set in to late.Quote

FA-MAS

So, checking with Mean Well if that power supply has a fuse, if it does, I needn't add one correct? If it doesn't I'll add one.

[www.bonkers.de]

[merlin-hotend.de]

[www.hackerspace-ffm.de]

|

Re: Power Wiring November 19, 2018 01:49PM |

Registered: 10 years ago Posts: 651 |

Gonna resurrect this thread for another power question. I'm going forward with my delta which has a 12" diameter 1/4" thick piece of cast tooling plate for the bed. Maybe if someone could check my math.

By my math, area = pi*radius2

12" = 304.8mm

304.8mm / 2 = 152.4mm

152.4mm / 10 = 15.24cm

15.24cm * 15.24cm = 232.2576cm2

3.14 * 232.2576cm2 = 729.288864cm2

729.288864cm2 * 0.5W = 364.644432W needed to power

364.644432W / 120VAC = 3.0387036A power draw

I'm thinking a 274.8mm (275) diameter, 360W silicone heater should be sufficient.

Edited 13 time(s). Last edit at 11/19/2018 06:04PM by FA-MAS.

Quote

the_digital_dentist

3) 0.4-0.5W / cm^2 will heat it up quickly and allow the PID control to regulate it easily. That bed size is small and doesn't need a very high powered heater. You have 169 cm^2 so I'd look for a heater that's around 75W. With such a low powered heater you could just run it from the DC supply and save the messing around with line power. The controller board MOSFETs should easily handle switching power to that load.

By my math, area = pi*radius2

12" = 304.8mm

304.8mm / 2 = 152.4mm

152.4mm / 10 = 15.24cm

15.24cm * 15.24cm = 232.2576cm2

3.14 * 232.2576cm2 = 729.288864cm2

729.288864cm2 * 0.5W = 364.644432W needed to power

364.644432W / 120VAC = 3.0387036A power draw

I'm thinking a 274.8mm (275) diameter, 360W silicone heater should be sufficient.

Edited 13 time(s). Last edit at 11/19/2018 06:04PM by FA-MAS.

|

Re: Power Wiring November 19, 2018 05:26PM |

Registered: 10 years ago Posts: 14,672 |

That sounds about right. My delta has a 330mm diameter bed, and I use a 350W heater.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Power Wiring November 19, 2018 06:13PM |

Registered: 10 years ago Posts: 651 |

|

Re: Power Wiring November 20, 2018 03:09PM |

Registered: 10 years ago Posts: 14,672 |

Quote

FA-MAS

You can reach abs temps too?

Looking at the Crydom D2425 or D2410

Seeing as though the bed will only take 3A @ 120V, the D2410 should be enough without a heatsink shouldn't it?

At full power the bed will reach more than 190C. The heater was specified as 350W @ 230V and the mains is actually 240V here, so the real heating power should be about 380W. I use a Fotek SSR-10DA to control it. It's bolted to the aluminium base plate of my printer, which provides a small amount of heatsinking (small because the base plate isn't very thick).

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Power Wiring November 20, 2018 06:21PM |

Registered: 10 years ago Posts: 651 |

Looking at the datasheet for the Crydom D2410,

https://www.mouser.com/datasheet/2/657/series-1-240-ac-panel-mount-1370756.pdf

Am I reading the thermal derating curves right? I take it to read like this.

As it gets hotter, it will continue to be able to provide that almost 6A up to a certain temperature (40C) and then the amount of current it can handle will drop.

I'm also reading that you probably don't want them operate at more than 40C which seems to coincide with the derating curves.

If you take the load and ambient temperature and plot it on the graph, it will tell you what if any heatsink you'll need.

Say in my case, depending on the bed power I choose, I'd not exceed 4A and lets say I choose worst case ambient temperature of 50C (122F)

If I plot those on the graph, it falls below the no heatsink line.

It looks like I'd be fine without a heatsink.

Edited 1 time(s). Last edit at 11/20/2018 06:23PM by FA-MAS.

https://www.mouser.com/datasheet/2/657/series-1-240-ac-panel-mount-1370756.pdf

Am I reading the thermal derating curves right? I take it to read like this.

As it gets hotter, it will continue to be able to provide that almost 6A up to a certain temperature (40C) and then the amount of current it can handle will drop.

I'm also reading that you probably don't want them operate at more than 40C which seems to coincide with the derating curves.

If you take the load and ambient temperature and plot it on the graph, it will tell you what if any heatsink you'll need.

Say in my case, depending on the bed power I choose, I'd not exceed 4A and lets say I choose worst case ambient temperature of 50C (122F)

If I plot those on the graph, it falls below the no heatsink line.

It looks like I'd be fine without a heatsink.

Edited 1 time(s). Last edit at 11/20/2018 06:23PM by FA-MAS.

|

Re: Power Wiring November 21, 2018 02:44AM |

Registered: 10 years ago Posts: 14,672 |

That's right, no heatsink needed to carry 4A if the ventilation is sufficient to keep the ambient temperature in the vicinity of the SSR below 60C.

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

Large delta printer [miscsolutions.wordpress.com], E3D tool changer, Robotdigg SCARA printer, Crane Quad and Ormerod

Disclosure: I design Duet electronics and work on RepRapFirmware, [duet3d.com].

|

Re: Power Wiring November 30, 2018 06:15PM |

Registered: 10 years ago Posts: 651 |

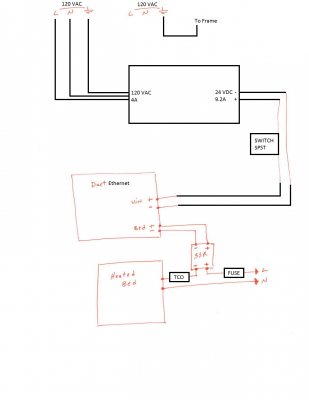

Updated my drawing, would someone double check if it's right.

Also I have the switch where it's at as I'm using a "brick style" power supply, similar to a laptop power supply and switching the DC side of it would allow me to hide the power brick under a desk or whatnot and not have to resort to hacking it up. But a switch would be nice for convenience.

Looking at the drawing, all I should need is a SPST switch right?

The heated bed would plug into the other receptacle on the outlet.

Also notice there's no switch on it, it has a thermal cutoff and a fuse, do I need a switch on it?

If I do, could I swap the switch I have in the drawing to a DPST switch and just use it to switch it at the same time as the 24 VDC?

Looking at the switches I have in mind, they're rated:

250 VAC / 10A

125 VAC / 15A

24 VDC / 15A

Those ratings are for the contacts per circuit usually? And the circuits could operate at different voltages right? As in I could have one circuit @ 24V / 15A and another @ 125V / 15A?

Also I have the switch where it's at as I'm using a "brick style" power supply, similar to a laptop power supply and switching the DC side of it would allow me to hide the power brick under a desk or whatnot and not have to resort to hacking it up. But a switch would be nice for convenience.

Looking at the drawing, all I should need is a SPST switch right?

The heated bed would plug into the other receptacle on the outlet.

Also notice there's no switch on it, it has a thermal cutoff and a fuse, do I need a switch on it?

If I do, could I swap the switch I have in the drawing to a DPST switch and just use it to switch it at the same time as the 24 VDC?

Looking at the switches I have in mind, they're rated:

250 VAC / 10A

125 VAC / 15A

24 VDC / 15A

Those ratings are for the contacts per circuit usually? And the circuits could operate at different voltages right? As in I could have one circuit @ 24V / 15A and another @ 125V / 15A?

|

Re: Power Wiring November 30, 2018 07:02PM |

Registered: 11 years ago Posts: 5,780 |

It would be a good idea to connect the negative side of the power supply to the line input ground on the frame. That will help with protecting the electronics from static discharges, etc. It's also a good idea if the bed plate is connected to the frame/power line ground. In UMMD the bed plate connects to the frame electrically via the three springs that hold the plate down onto the leveling screws. It's probably not going to get a UL certification, but I've measured the resistance between the bed and the frame and it is a couple tenths of an Ohm. If you wanted UL certification, you'd probably have to run a ground wire in the wire bundle connecting to the bed plate and physically bond the wire to the plate with a screw.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Power Wiring December 01, 2018 09:29AM |

Registered: 10 years ago Posts: 651 |

Quote

the_digital_dentist

It would be a good idea to connect the negative side of the power supply to the line input ground on the frame. That will help with protecting the electronics from static discharges, etc.

We’re talking about the negative side on the 24 VDC side of the power supply? I did plan on grounding the frame and bed using the ground connection on the inlet I plan to use on the 120 VAC for the bed. I’d probably run an extra wire for ground to the effector as well as ensure there’s a connection to the hot end heatsink.

I’d be worried that if if the bed somehow did short against the frame that it’d feed the voltage directly into the 24 VDC power supply if I connected it’s negative to the frame.

|

Re: Power Wiring December 01, 2018 09:54AM |

Registered: 11 years ago Posts: 5,780 |

Yes, the negative terminal of the 24V output should connect to ground (the printer's frame). If the bed shorts to the frame, the fuse on the bed input should open. When you ground the frame to the power line input ground wire, you set the frame at zero volts. It won't matter if the 24V output is tied to the frame if the bed shorts to the frame. The frame is still zero volts- the power supply should be OK. Put the fuse and power switch on the "line" side, not the "neutral" side of the power input.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Power Wiring December 01, 2018 11:43AM |

Registered: 7 years ago Posts: 558 |

I wouldn’t tie the 0V line to ground from your 24V power supply. Most powersupplys have circuitry internal to the power supply to handle 0V and ground and shorts. Your power supply should have the L N and Gnd connections, which should be true L N and Gnd connections with your incoming feed. Beyond that, I wouldn't bother connecting 0V to ground.

Edited 1 time(s). Last edit at 12/01/2018 12:25PM by PDBeal.

Edited 1 time(s). Last edit at 12/01/2018 12:25PM by PDBeal.

|

Re: Power Wiring December 02, 2018 02:05AM |

Registered: 6 years ago Posts: 1,007 |

Quote

PDBeal

.... Beyond that, I wouldn't bother connecting 0V to ground.

Why ?

Indeed, why as it is against all accepted rules (except a very few case but not applicable here).

Are you confusing mains neutral and 0V ?

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Power Wiring December 02, 2018 08:14AM |

Registered: 11 years ago Posts: 5,780 |

It get's very dry here in the winter, and very easy to generate static electricity by walking across a floor. I used to print using SD cards to hold the gcode (and it's still my preferred way). In an older printer I had not grounded the power supply to the printer's frame. I used to get all sorts of problems in the winter due to static discharge when I would insert the SD card after walking across the floor. After grounding the power supply output to the frame, the static discharge problems stopped. Grounding the power supply output means you're grounding the controller board to the printer's frame. When you approach the machine with a static charge you're likely to interact with the ground by touching the frame, a switch, etc., before you come into contact with any of the electronics.

On the other hand, grounding the power supply output means you have created a huge terminal on which you can accidentally short the electronics by dropping a tool or a wire (like connecting the negative terminal of the battery to the chassis in your car). But you're careful with tools and wires around live electronics anyway, right? And static discharge is a potential problem in the normal operation of the machine. So I think it's best to ground the power supply output.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

On the other hand, grounding the power supply output means you have created a huge terminal on which you can accidentally short the electronics by dropping a tool or a wire (like connecting the negative terminal of the battery to the chassis in your car). But you're careful with tools and wires around live electronics anyway, right? And static discharge is a potential problem in the normal operation of the machine. So I think it's best to ground the power supply output.

Ultra MegaMax Dominator 3D printer: [drmrehorst.blogspot.com]

|

Re: Power Wiring December 02, 2018 08:45AM |

Registered: 10 years ago Posts: 651 |

|

Re: Power Wiring December 02, 2018 10:35AM |

Registered: 6 years ago Posts: 1,007 |

Note, it is the LAW to ground all metallic frames, parts ... unless there is "double insulation" between main and equipment.

The cheap chinese power supplies are potentially hazardous and I wouldn't trust the insulation between main lines and the 0V output.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

The cheap chinese power supplies are potentially hazardous and I wouldn't trust the insulation between main lines and the 0V output.

"A comical prototype doesn't mean a dumb idea is possible" (Thunderf00t)

|

Re: Power Wiring December 02, 2018 03:34PM |

Registered: 10 years ago Posts: 651 |

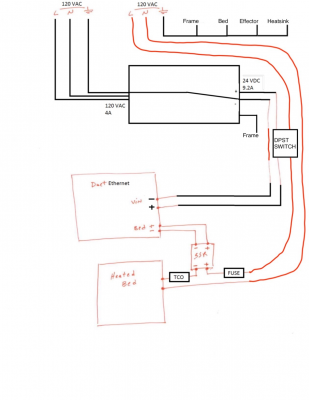

Ok, so I did a little checking with a multimeter. The power supply has a 4 pin connector on it similar to a PS2 Keyboard connector. 2 pins are supposed to be 24 VDC and 2 are supposed to be the Negative and the Outer Shield. I have confirmed that the power supply internally connects that Negative as well as that Outer Shield to the Earth Ground . Additionally, the receptacle that mates with that connector has 2 versions, one version will connect that Outer Shield to nothing as in makes no electrical connection to anything. the other version will connect that Outer Shield to whatever panel you mount it. In my case it would be metal attached to the frame.

I do think I've got it sorted out. Here's what my drawing looks like.

Edited 5 time(s). Last edit at 12/02/2018 03:40PM by FA-MAS.

I do think I've got it sorted out. Here's what my drawing looks like.

Edited 5 time(s). Last edit at 12/02/2018 03:40PM by FA-MAS.

|

Re: Power Wiring December 02, 2018 09:20PM |

Registered: 7 years ago Posts: 558 |

Quote

MKSA

Note, it is the LAW to ground all metallic frames, parts ...

In what country are you referring to with this LAW. I know of no such law that governs this in the US in an industrial aspect. There are requirements from NEC and OSHA for some of these requirements when you request or obtain UL certification, but there are no hard governing laws that I’ve ever come across that carry that requirement. And I believe most commercial applications must be UL certified to be “sold” in the US.

Sorry, only registered users may post in this forum.