Replace timing belts with FireLine

Posted by j0achim

|

Replace timing belts with FireLine March 24, 2018 07:30AM |

Registered: 6 years ago Posts: 16 |

Hi,

I am very curious with the approach to replace traditional timing belts with FireLine (FireLine have no stretch), there is video on this approach but extremely little actual information about the subject.

FireLine has no stretch what so ever, and high tensile strength, the 0,32mm cord I have has a 24kg breaking strength, which I believe is more than enough for the purpose in 3D printing.

By looking at the video from the source information, he uses quite large pulley "gear" wheels attached to the motor (which also btw looks like Nema 23 that provides more torque, maybe 0,9deg/step?) considering I am working with 1,8deg/step Nema 17 motors the size in the video would be very inefficient.

Source video.

So I got into some math figuring out a optimal size for the pulley as its not actually a "gear", my Nema 17 with 1,8 deg step angle being ran with 1/16 micro stepping one full revolution is 3200 steps (360/1,8=200*16=3200) Now lets say we want to have movement being able to divide into whole numbers at a resolution of 0,01mm.

3200*0,01 = 32 (circumference of pulley)

32/3,14 = 10,19 (diameter of pulley)

1/0,01 = 100 (steps per mm)

Perfect this diameter also provide decent torque compared to traditional GT2 pulley wheels having 80steps per mm (resulting in 12,73mm diameter or 40mm circumference gear) increasing potentional torque by 25%! (10,19*1,25=12,73)

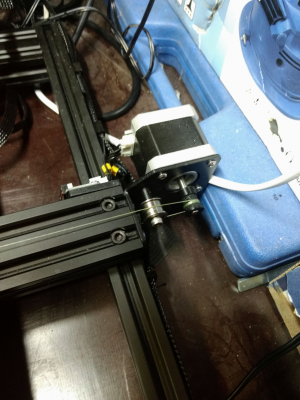

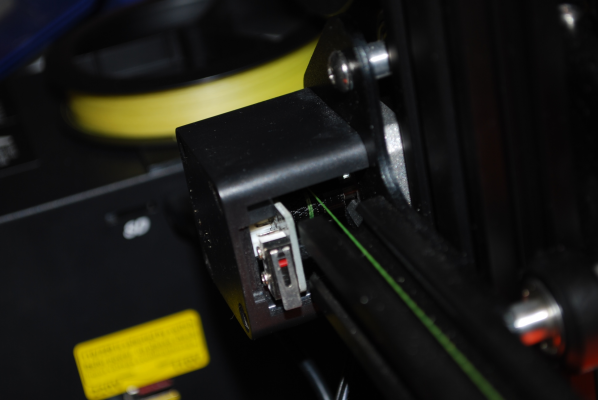

Initially I designed a stepper wheel, without any fastening on the pulley for the cord I believed that twinning the cord around the pulley 3-4 times would provide enough friction without slippage, however after some attempts I quickly realize that this is not the case due to the material of the pulley and the coating on the FireLine itself.

I would love to hear suggestions on this!

Thanks for reading.

Edited 1 time(s). Last edit at 03/24/2018 07:35AM by j0achim.

I am very curious with the approach to replace traditional timing belts with FireLine (FireLine have no stretch), there is video on this approach but extremely little actual information about the subject.

FireLine has no stretch what so ever, and high tensile strength, the 0,32mm cord I have has a 24kg breaking strength, which I believe is more than enough for the purpose in 3D printing.

By looking at the video from the source information, he uses quite large pulley "gear" wheels attached to the motor (which also btw looks like Nema 23 that provides more torque, maybe 0,9deg/step?) considering I am working with 1,8deg/step Nema 17 motors the size in the video would be very inefficient.

Source video.

So I got into some math figuring out a optimal size for the pulley as its not actually a "gear", my Nema 17 with 1,8 deg step angle being ran with 1/16 micro stepping one full revolution is 3200 steps (360/1,8=200*16=3200) Now lets say we want to have movement being able to divide into whole numbers at a resolution of 0,01mm.

3200*0,01 = 32 (circumference of pulley)

32/3,14 = 10,19 (diameter of pulley)

1/0,01 = 100 (steps per mm)

Perfect this diameter also provide decent torque compared to traditional GT2 pulley wheels having 80steps per mm (resulting in 12,73mm diameter or 40mm circumference gear) increasing potentional torque by 25%! (10,19*1,25=12,73)

Initially I designed a stepper wheel, without any fastening on the pulley for the cord I believed that twinning the cord around the pulley 3-4 times would provide enough friction without slippage, however after some attempts I quickly realize that this is not the case due to the material of the pulley and the coating on the FireLine itself.

I would love to hear suggestions on this!

Thanks for reading.

Edited 1 time(s). Last edit at 03/24/2018 07:35AM by j0achim.

|

Re: Replace timing belts with FireLine March 24, 2018 04:02PM |

Registered: 7 years ago Posts: 507 |

You could try anchoring the line to the pulley, that would get rid of any slip. The flip side is you'd need have enough string spooled onto your pulley for your entire range of travel and t would walk a little. If it's a material issue, you can get non coated spetra lines. Most I believe come with a PTFE coating because it's good for letting out a lot of line real fast. You can also sand the pulley a little or coat it with some rubber to help with friction on that end.

|

Re: Replace timing belts with FireLine March 24, 2018 04:14PM |

Registered: 6 years ago Posts: 16 |

More tension did the trick!

Testing so far looks very promising, I am able to go from 20 to 30 jerk as well nearly all signs of ringing are gone!

Edited 1 time(s). Last edit at 03/24/2018 04:16PM by j0achim.

Testing so far looks very promising, I am able to go from 20 to 30 jerk as well nearly all signs of ringing are gone!

Edited 1 time(s). Last edit at 03/24/2018 04:16PM by j0achim.

|

Re: Replace timing belts with FireLine March 25, 2018 04:20AM |

Registered: 8 years ago Posts: 5,232 |

I'm wondering if the crisscross pattern on the pulley made it worse to get enough friction?

BTW: There is no material without stretch, especially when it's braided. ( hard to see on your pic, but definitely the case in the video)

We had a discussion about spectra line vs. belt lately...

IMHO it is more important to have a round number for mm/fullstep, which in your case is 0.16mm. But that's more relevant on Z-axis for layer height optimization.

BTW: There is no material without stretch, especially when it's braided. ( hard to see on your pic, but definitely the case in the video)

We had a discussion about spectra line vs. belt lately...

IMHO it is more important to have a round number for mm/fullstep, which in your case is 0.16mm. But that's more relevant on Z-axis for layer height optimization.

|

Re: Replace timing belts with FireLine March 25, 2018 05:52AM |

Registered: 6 years ago Posts: 16 |

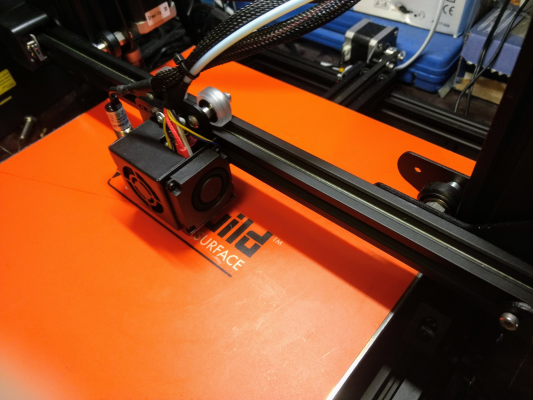

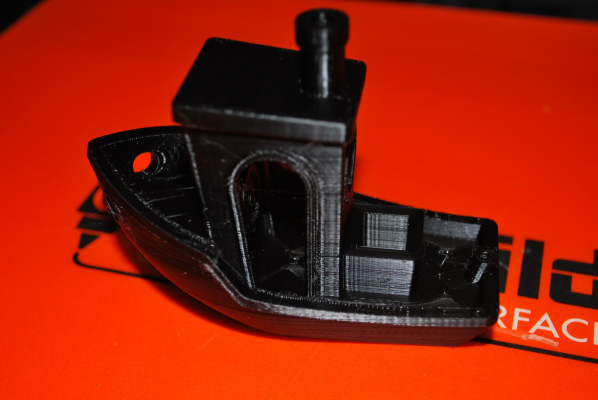

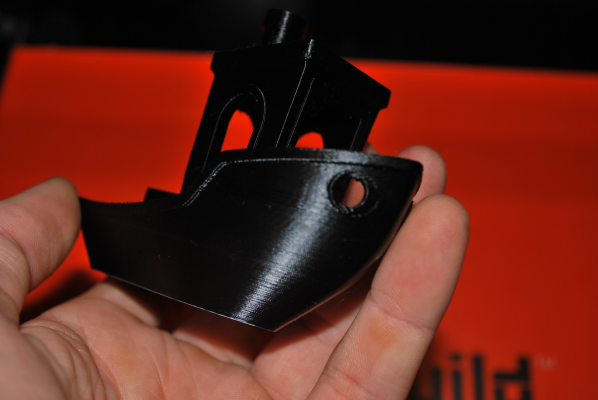

High speed benchy printed @ 150% scale. (acceleration, jerk far above stock configuration)

0,1 layer height, inner/outer walls and top/bottom 45mm/s, infill and travel 100mm/s, jerk 30, acceleration 1000, two wall shells, 0,8mm top/bottom, 0,4 nozzle

Unfortunately there are a few issues with both Z and Y axis.

Z having some binding issues due to the bent sheet metal is far from true and quite flimsy (can bend almost all sheet metal parts on this printer by hand)

Y axis still show some signs of ringing, the aluminium bed I used to replace the stock glass bed is nearly twice as heavy, I will check the VREF voltage as well as try with a smaller pulley.

You are right braided material will stretch, I'll do some testing to figure out exactly how much stretch this material has, I'll map out the different stretch points at different tension levels.

Edited 3 time(s). Last edit at 03/25/2018 06:03AM by j0achim.

0,1 layer height, inner/outer walls and top/bottom 45mm/s, infill and travel 100mm/s, jerk 30, acceleration 1000, two wall shells, 0,8mm top/bottom, 0,4 nozzle

Unfortunately there are a few issues with both Z and Y axis.

Z having some binding issues due to the bent sheet metal is far from true and quite flimsy (can bend almost all sheet metal parts on this printer by hand)

Y axis still show some signs of ringing, the aluminium bed I used to replace the stock glass bed is nearly twice as heavy, I will check the VREF voltage as well as try with a smaller pulley.

Quote

o_lampe

BTW: There is no material without stretch, especially when it's braided. ( hard to see on your pic, but definitely the case in the video)

We had a discussion about spectra line vs. belt lately...

You are right braided material will stretch, I'll do some testing to figure out exactly how much stretch this material has, I'll map out the different stretch points at different tension levels.

Edited 3 time(s). Last edit at 03/25/2018 06:03AM by j0achim.

|

Re: Replace timing belts with FireLine March 25, 2018 04:14PM |

Registered: 6 years ago Posts: 16 |

For future reference if anyone are interested, also included some footage of high speed printing @ thing:2839482

|

Re: Replace timing belts with FireLine April 05, 2018 01:47AM |

Registered: 9 years ago Posts: 6 |

j0achim!

Great work! I think it could have some promising potential.

What changes have you made that have given noticeable improvements?

I would think tension guides and more wraps would make it better, but eventually you have to worry about friction & wear against itself. I was thinking that with increased windings, some linear slide guides could help avoid some of the friction/wear against itself. For example, a linear guide/divider placed before the pulley, could help prevent wear against itself. There would be some wear due to travel against the pulley itself. It would be the difference between the first contact point as it first touches the pulley, and the point as it exits the pulley. I imagine it would be some sort of distance that is calculated based on material diameter - something along the lines of (# or wraps) * (line diameter) = friction distance. Am I explaining this well? I feel like I am beating a simple idea to death.....

Crazy idea - would ABS juice, gluestick, hairspray, etc. applied to the surface of the pulley have any positive effect? Let me know what you think.

Kudos on trying a cool idea, and sharing it with the rest of the class! Good luck!

B.

Great work! I think it could have some promising potential.

What changes have you made that have given noticeable improvements?

I would think tension guides and more wraps would make it better, but eventually you have to worry about friction & wear against itself. I was thinking that with increased windings, some linear slide guides could help avoid some of the friction/wear against itself. For example, a linear guide/divider placed before the pulley, could help prevent wear against itself. There would be some wear due to travel against the pulley itself. It would be the difference between the first contact point as it first touches the pulley, and the point as it exits the pulley. I imagine it would be some sort of distance that is calculated based on material diameter - something along the lines of (# or wraps) * (line diameter) = friction distance. Am I explaining this well? I feel like I am beating a simple idea to death.....

Crazy idea - would ABS juice, gluestick, hairspray, etc. applied to the surface of the pulley have any positive effect? Let me know what you think.

Kudos on trying a cool idea, and sharing it with the rest of the class! Good luck!

B.

|

Re: Replace timing belts with FireLine April 08, 2018 06:13PM |

Registered: 6 years ago Posts: 16 |

After a huge amount of testing and a few hundred hours of printing I found that a single full revolution wind was actually enough to prevent slipping, more windings increase wear on the strings almost exponentially.

Though there are a few pros and cons with this concept.

Pros:

Extremely cheap compared let's say genuine Gates belts, and not easy to actually source either unless you buy at least 50 feet.

Lots of torque to spare that let's you get a lot more speed and acceleration.

A lot less jerk, this is really where you see most of time saved on prints.

Very DIY friendly (to some extent, more about this in cons)

Very little string wearing when done correctly, it is critical that idler pulleys are both smooth and 1 part, mine are 2 part, the groove in the middle eats the string, sleeve for pulley helps a lot but true 1 part smooth pulley is the way to go.

Cons:

Pulleys must be made of a rigid material that will not deform due to static tension, PLA is known for this as very little heat makes it malleable. I do intentd to go through annealing and see if this makes PLA as a viable material. My guess is PC-ABS, Nylon or PC is best suited material for this use, not particularly DIY as most of the cheap printers can't work with these materials, except maybe PC-ABS.

Aligning the string can be a true pain in the ass, it takes some time and practice to properly align the string so that when axies are at min and max string aligns respectively on the pulley. Some fiddling and forcing required during this process. (though when string is properly seated you don't need to babysit it)

Though there are a few pros and cons with this concept.

Pros:

Extremely cheap compared let's say genuine Gates belts, and not easy to actually source either unless you buy at least 50 feet.

Lots of torque to spare that let's you get a lot more speed and acceleration.

A lot less jerk, this is really where you see most of time saved on prints.

Very DIY friendly (to some extent, more about this in cons)

Very little string wearing when done correctly, it is critical that idler pulleys are both smooth and 1 part, mine are 2 part, the groove in the middle eats the string, sleeve for pulley helps a lot but true 1 part smooth pulley is the way to go.

Cons:

Pulleys must be made of a rigid material that will not deform due to static tension, PLA is known for this as very little heat makes it malleable. I do intentd to go through annealing and see if this makes PLA as a viable material. My guess is PC-ABS, Nylon or PC is best suited material for this use, not particularly DIY as most of the cheap printers can't work with these materials, except maybe PC-ABS.

Aligning the string can be a true pain in the ass, it takes some time and practice to properly align the string so that when axies are at min and max string aligns respectively on the pulley. Some fiddling and forcing required during this process. (though when string is properly seated you don't need to babysit it)

|

Re: Replace timing belts with FireLine April 09, 2018 12:04AM |

Registered: 7 years ago Posts: 507 |

You mention rigidity being important, in that case I'd scrap Nylon from the list. It's known for being ductile, not rigid. Similarly ABS is less rigid than PLA. If you're looking for a rigid material go for PET-G, or if you can print PC go for that. I'll be doing some testing on this as well soon, on some machines where slipping is more likely (higher load), I'll be sure to share my results.

Interesting to hear about the more windings increasing wear and not helping much with reducing slip. Do you know for sure it's the fact there are more windings causing the extra wear and not just the seam in the 2 part pulley? Really curious to know more about this since I'll be using this sort of system in a higher load situation where slipping is more of an issue.

Edited 1 time(s). Last edit at 04/09/2018 12:07AM by Trakyan.

Interesting to hear about the more windings increasing wear and not helping much with reducing slip. Do you know for sure it's the fact there are more windings causing the extra wear and not just the seam in the 2 part pulley? Really curious to know more about this since I'll be using this sort of system in a higher load situation where slipping is more of an issue.

Edited 1 time(s). Last edit at 04/09/2018 12:07AM by Trakyan.

|

Re: Replace timing belts with FireLine April 09, 2018 02:19AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Replace timing belts with FireLine April 09, 2018 04:45AM |

Registered: 6 years ago Posts: 16 |

Quote

Trakyan

Interesting to hear about the more windings increasing wear and not helping much with reducing slip. Do you know for sure it's the fact there are more windings causing the extra wear and not just the seam in the 2 part pulley? Really curious to know more about this since I'll be using this sort of system in a higher load situation where slipping is more of an issue.

At most 2 windings I find works, my X axis had two windings and over the timespan of about 200 hours of printing the string had no signs of wearing at all, that being said my X axis did not require a idler pulley on the motor side. Y axis I tried multiple options, my findings are that 6mm idler pulley is tight but works, I'd suggest 9mm smooth idler pulley as the wire will need to travel as freely as possible, on opposite side of motor I would like to try using a curved pulley that keeps the string in center.

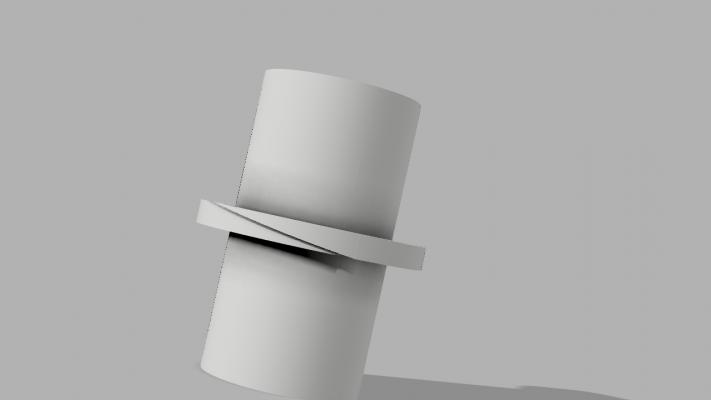

Calculating the width of the motor pulley:

CW (cord width): 0,32mm

PD (pulley diameter): 7,2mm

BS (bed size): 300mm

T (travel): 1 revolution 7,2*3,14=22,92+0,32 = 23,24mm actual travel

RN (revolutions needed): to travel full distance 300/23,24=12,9

WT (wind travel): 1 winding = 0,32*2=0,64

PW (pulley width): with 1 wind to travel 300mm 12,9*0,64=8,25mm

XYs (steps per mm): X or Y steps required for 1 mm 1/(23,24/3200)=138,8

Math with your own parameters.

T=(PD*PI)+CW

RN=BS/T

WT=CW*(YOUR_AMOUNT_OF_WINDS+1)

PW=RN*WT

XYs=1/(T/3200)

Idler pulley on motor side needs either being wider or match closely the width of the motor pulley.

Edited 6 time(s). Last edit at 04/09/2018 04:58AM by j0achim.

|

Re: Replace timing belts with FireLine April 09, 2018 04:51AM |

Registered: 6 years ago Posts: 16 |

|

Re: Replace timing belts with FireLine April 10, 2018 02:07AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Replace timing belts with FireLine April 10, 2018 02:07PM |

Registered: 6 years ago Posts: 16 |

Quote

o_lampe

Please finish this statement:

Restricting the cord-travel along the pulleys would end in _________.

Not sure if I got that question correctly, is it left and right steering of center on pulley you are looking for? If so that's PW / 2

I know many have used spectra line in the past, I cannot vouch for it as I personally have no experience with it, but from what I can tell they claim it has very low stretch properties, so it'll perform equally or better than FireLine is my assumption.

Edited 1 time(s). Last edit at 04/10/2018 02:08PM by j0achim.

|

Re: Replace timing belts with FireLine April 11, 2018 07:44AM |

Registered: 8 years ago Posts: 5,232 |

IMHO, the scary thing about fishing line printers is the insane amount of tension required to prevent slipping.

So I thought of a different approach which doesn't require excessive tension. ( I'm sure it's been done before )

We could clamp the fishing line to the pulley, so it can't slip. Now we have to wind up the right amount of line to the pulley required to do the whole travel.

With a bit of tinkering, we could share that amount of turns equally between drive pulley and idler.

Let's say, the drive and idler both have a diameter of 10mm = 31.4mm per turn and we want 300mm travel. That's 5 turns on each side. Not too much I'd say.

Edited 2 time(s). Last edit at 04/11/2018 07:48AM by o_lampe.

So I thought of a different approach which doesn't require excessive tension. ( I'm sure it's been done before )

We could clamp the fishing line to the pulley, so it can't slip. Now we have to wind up the right amount of line to the pulley required to do the whole travel.

With a bit of tinkering, we could share that amount of turns equally between drive pulley and idler.

Let's say, the drive and idler both have a diameter of 10mm = 31.4mm per turn and we want 300mm travel. That's 5 turns on each side. Not too much I'd say.

Edited 2 time(s). Last edit at 04/11/2018 07:48AM by o_lampe.

|

Re: Replace timing belts with FireLine April 11, 2018 12:39PM |

Registered: 6 years ago Posts: 16 |

I tried that, problem is that the string want to steer towards center and eventually it will cross itself, now I have yet to snap a string but it wears out the string quickly.

The amount of tension is not that high, string I use will snap at 25kg and I have yet to snap one, I recon I have about 10kg worth of static tension.

Lets say you have belts sitting at 8kg using belts, now with the smaller pulley you can increase the static tension by 75% (8*1,75=14kg) and still the sideways force would equal that of belts because the smaller radius of the string pulley.

I know using kg is incorrect for this use case but lets face it dealing with force in newtons is just complicating things more than we need to.

Edited 2 time(s). Last edit at 04/11/2018 12:45PM by j0achim.

The amount of tension is not that high, string I use will snap at 25kg and I have yet to snap one, I recon I have about 10kg worth of static tension.

Lets say you have belts sitting at 8kg using belts, now with the smaller pulley you can increase the static tension by 75% (8*1,75=14kg) and still the sideways force would equal that of belts because the smaller radius of the string pulley.

I know using kg is incorrect for this use case but lets face it dealing with force in newtons is just complicating things more than we need to.

Edited 2 time(s). Last edit at 04/11/2018 12:45PM by j0achim.

|

Re: Replace timing belts with FireLine April 11, 2018 06:42PM |

Registered: 7 years ago Posts: 507 |

Quote

o_lampe

IMHO, the scary thing about fishing line printers is the insane amount of tension required to prevent slipping.

So I thought of a different approach which doesn't require excessive tension. ( I'm sure it's been done before )

We could clamp the fishing line to the pulley, so it can't slip. Now we have to wind up the right amount of line to the pulley required to do the whole travel.

With a bit of tinkering, we could share that amount of turns equally between drive pulley and idler.

Let's say, the drive and idler both have a diameter of 10mm = 31.4mm per turn and we want 300mm travel. That's 5 turns on each side. Not too much I'd say.

The issue with this is you can't actually split the windings between the drive pulley and idler, you need to store all the windings you'll need on your drive pulley. Besides, anchoring the line to the idler doesn't actually prevent slipping, the idler is basically there to let the cable "slip" over the bolt its wrapped around. You'll also need large diameter pulleys for this otherwise the large number of windings will result in the string "walking" back and forth along the drive pulley which causes triangulation error. I would be all for anchoring the line to the pulley, and using a large diameter pulley, but the size of the pulley quickly gets out of hand. Not so much for the loss of resolution, you can quickly and easily get back to the resolution of a regular sized pulley in a single stage gear reduction, but more because it gets hard to find a place to put the 70mm diameter pulley. Last note about pulleys with the string anchored onto them, they actually don't suffer from the rubbing issues with the string moving axially along the pulley as has been described in this thread.

15T GT2 belts would be equivalent to around a 9.5 mm diameter drive pulley for cables. For a typically sized machine that needs 200 mm of travel, you'd need around 7 windings on the drive pulley. That's not too bad I guess, considering most fishing line is less than 1 mm thick. You can keep the triangulation error minimal by ensuring the limits of travel are reasonably far away from any pulleys (drive or idler). Unfortunately this doesn't scale so nicely. For a 1000 mm travel distance (like I'm building on one of my machines), it would result in a lot of windings.

If you're interested in cable driven systems for reasons other than cost, have a look at synchromesh cable. It's a shame it's only imperial. I feel like there's some simple way to make a DIY version of this stuff but it eludes me.

|

Re: Replace timing belts with FireLine April 12, 2018 02:30AM |

Registered: 8 years ago Posts: 5,232 |

I made a test setup yesterday and I was able to split the windings between the idler and driver. But you are right, both have to be big enough to store all windings (in my case 5 turns left of center OR 5t right of center), which is a problem for longer Delta towers. But there is for sure an usecase in the future, I'll pick up this idea again.

|

Re: Replace timing belts with FireLine April 12, 2018 05:39AM |

Registered: 7 years ago Posts: 507 |

|

Re: Replace timing belts with FireLine April 14, 2018 08:56AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Replace timing belts with FireLine April 14, 2018 11:05AM |

Registered: 6 years ago Posts: 16 |

Quote

o_lampe

Just uploaded a short video to demonstrate the shared windings and such.

The setup isn't perfect. The idler bracket should be fixed. I thought it would help aligning and centering.

I absolutely love the idea of having the fastening screw in the center and using that to anchor the string.

One could also potentially go with a guide in the center, in places where you don't have the ability to have a wide pulley.

btw I annealed a few PLA pulleys they are sure more sturdy than the non-annealed PLA pulleys, though only time will tell if they can withstand heat from the motor axle without deforming.

Edited 1 time(s). Last edit at 04/14/2018 11:06AM by j0achim.

|

Re: Replace timing belts with FireLine April 14, 2018 11:51AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Replace timing belts with FireLine April 14, 2018 05:29PM |

Registered: 7 years ago Posts: 507 |

|

Re: Replace timing belts with FireLine May 03, 2018 04:11AM |

Registered: 8 years ago Posts: 28 |

|

Re: Replace timing belts with FireLine May 03, 2018 06:24AM |

Registered: 7 years ago Posts: 507 |

A quick google says it's PE, not kevlar. Most high strength fishing lines are braided polyethene (PE). They have fairly low stretch after they settle in initially. If memory serves PE as a material can outperform Kevlar (that's the trademark, can't remember the actual material name) but I can't quite remember in what metric.

|

Re: Replace timing belts with FireLine May 04, 2018 02:49AM |

Registered: 8 years ago Posts: 5,232 |

|

Re: Replace timing belts with FireLine May 04, 2018 04:49PM |

Registered: 10 years ago Posts: 150 |

|

Re: Replace timing belts with FireLine May 05, 2018 03:07AM |

Registered: 8 years ago Posts: 5,232 |

I read a bit in Wikipedia about Kevlar and Dyneema. They are in fact different.

Dyneema has a very low friction coefficient almost like PTFE, which makes it less useable in our application, where no slip is required.

OTOH Kevlar is used for bullet proof vests, car tyres and other high impact scenarios. The tensile strength is 5 times better than steel.

Dyneema has a very low friction coefficient almost like PTFE, which makes it less useable in our application, where no slip is required.

OTOH Kevlar is used for bullet proof vests, car tyres and other high impact scenarios. The tensile strength is 5 times better than steel.

|

Re: Replace timing belts with FireLine May 05, 2018 04:04AM |

Registered: 7 years ago Posts: 507 |

PE is the general name for the polymer. The HD infront of it (or UHMW if you really want to get technical for dyneema and the likes) just relates to how the PE chains are structured.

[www.newscientist.com]

This article and some others (just google PE vs kevlar) mention PE being "stronger" than kevlar, though that's a bit vague. If it's referring to UTS, then that's not too helpful for our application, but if it's saying it's less elastic, then that is definitely useful for us.

But yes, PE as a whole is a fairly slick and slippery substance, as anyone who has ever tried to glue it can testify. Not so good for us, but a rubbery coating on the pulley should overcome this I recon, or a fixed anchor. That being said, I've seen and heard of a lot of people using PE lines instead of belts and slipping generally isn't an issue. PU spray could be used to create a rubbery coating, or use heat shrink around the pulley. The latter will change the radius, but you'll likely need to calibrate steps/mm anyway with a string and pulley. Don't know how long the heat shrink would last, either, all things to test.

[www.newscientist.com]

This article and some others (just google PE vs kevlar) mention PE being "stronger" than kevlar, though that's a bit vague. If it's referring to UTS, then that's not too helpful for our application, but if it's saying it's less elastic, then that is definitely useful for us.

But yes, PE as a whole is a fairly slick and slippery substance, as anyone who has ever tried to glue it can testify. Not so good for us, but a rubbery coating on the pulley should overcome this I recon, or a fixed anchor. That being said, I've seen and heard of a lot of people using PE lines instead of belts and slipping generally isn't an issue. PU spray could be used to create a rubbery coating, or use heat shrink around the pulley. The latter will change the radius, but you'll likely need to calibrate steps/mm anyway with a string and pulley. Don't know how long the heat shrink would last, either, all things to test.

|

Re: Replace timing belts with FireLine May 17, 2018 10:25AM |

Registered: 5 years ago Posts: 155 |

For the problem winding the fireline and fixing I thought, you could use a relative long aluminium tube, fix the line and then move it in z direction depending on the position needed to make sure the line is not crossing. If the line is moving independent x or y axis, like in dualwire-gantry, you should be able to link the positions directly to the stepper.

I would rotate the tube a little bit to support winding with not crossing.

I would rotate the tube a little bit to support winding with not crossing.

Sorry, only registered users may post in this forum.